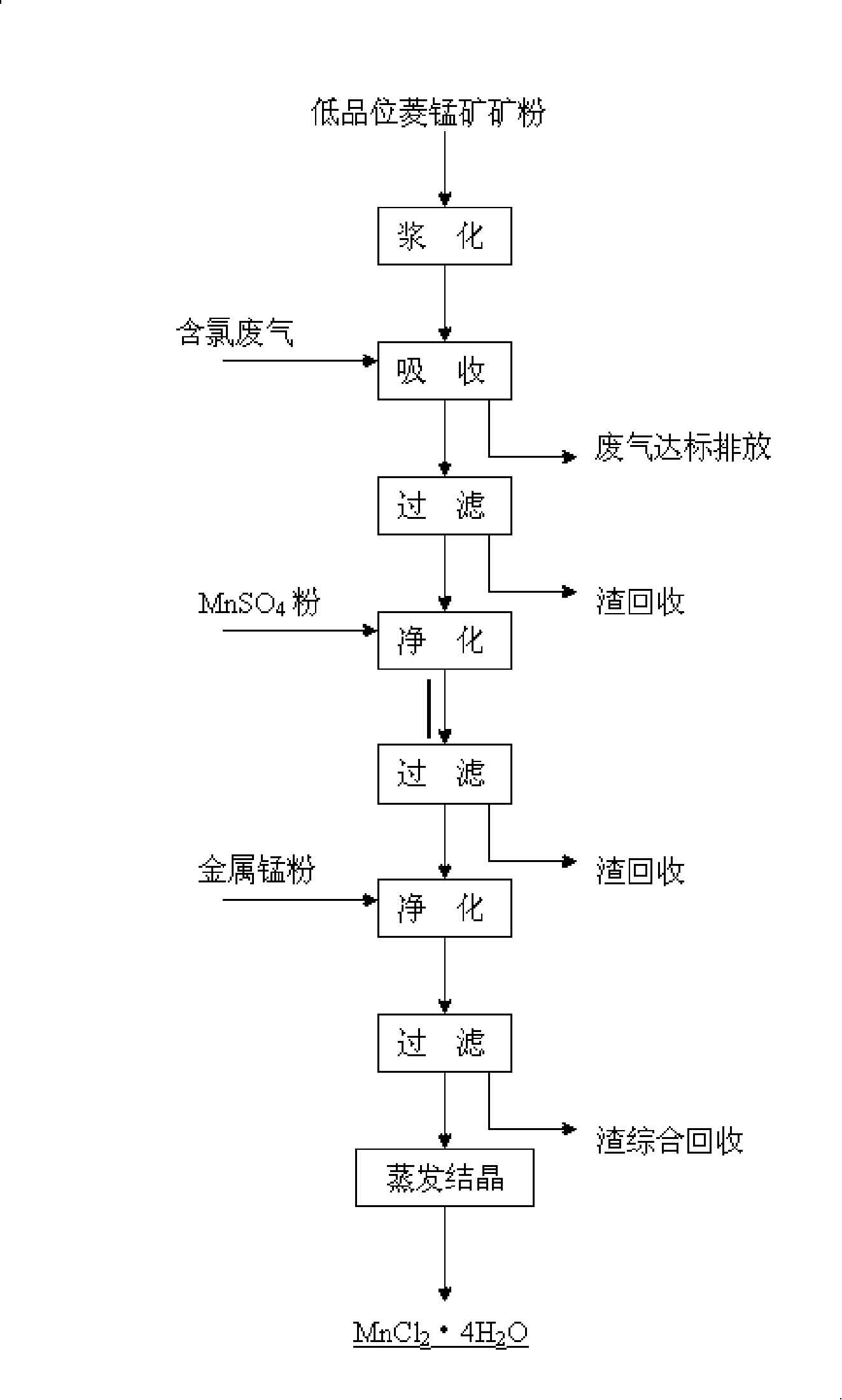

Technique for manufacturing tetrahydrate manganese chloride low ore grade rhodochrosite absorption of chlorine containing waste gas

A technology of manganese chloride tetrahydrate and rhodochrosite, applied in the direction of manganese halide, etc., can solve the problem of chlorine-containing waste gas pollution and effective utilization of low-grade rhodochrosite, and achieve the effect of improving the absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

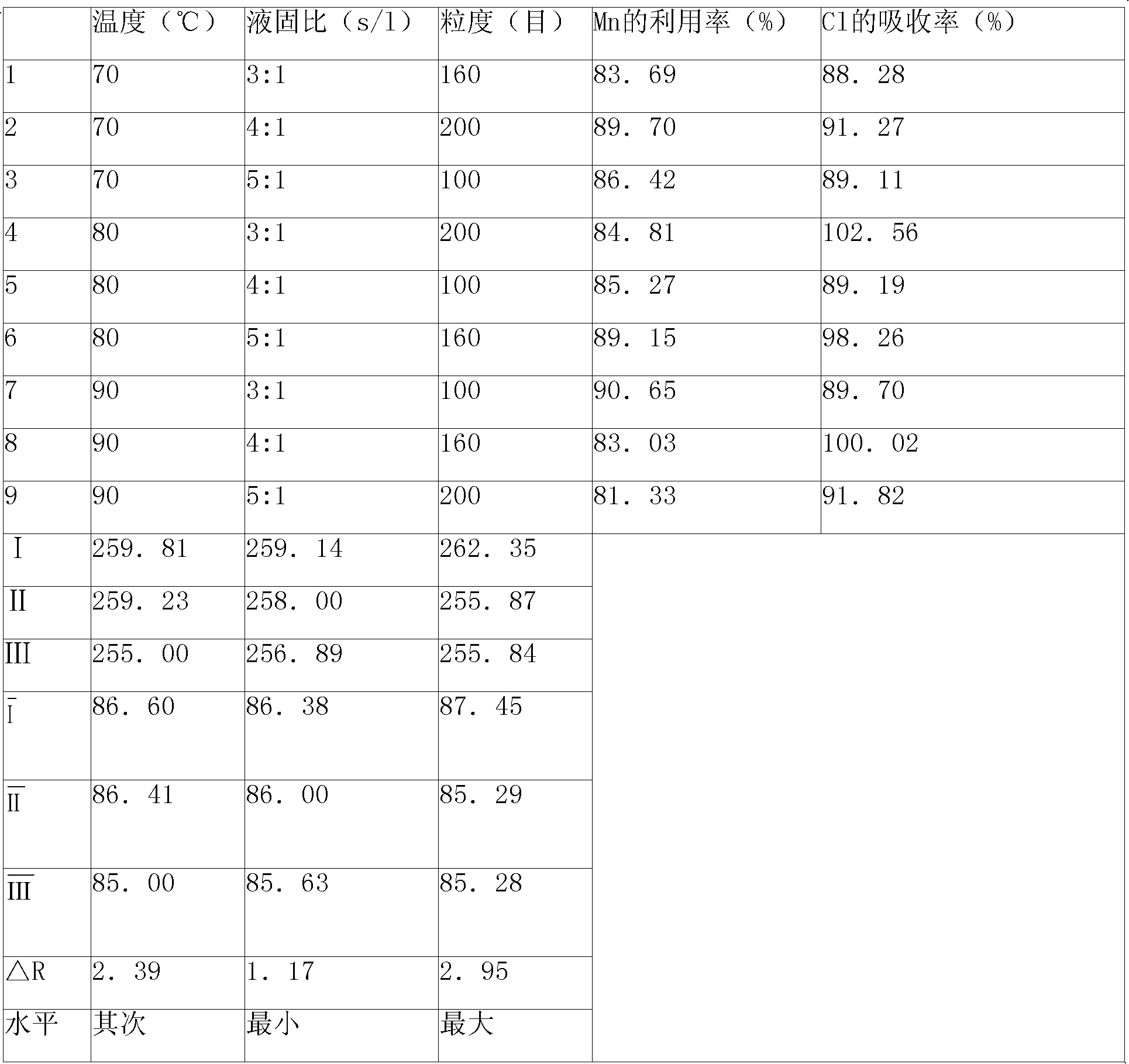

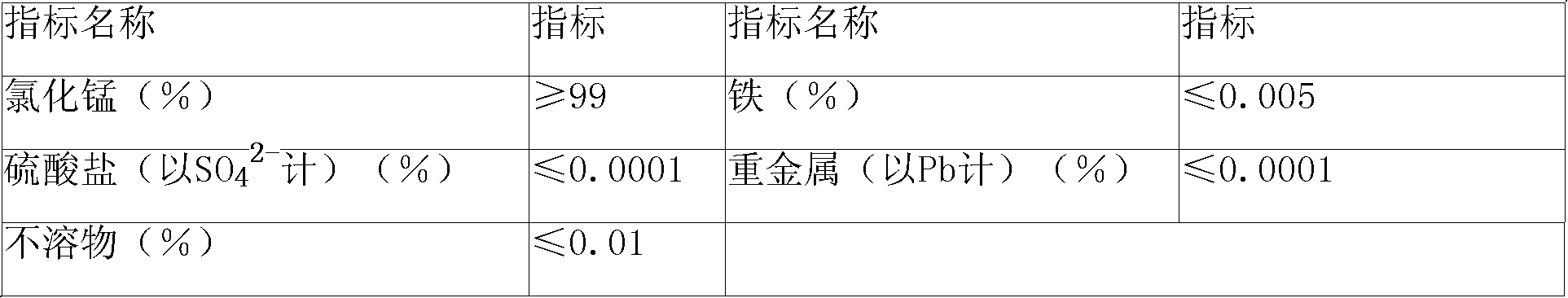

Embodiment 1

[0099] Embodiment 1: Get 320 grams of low-grade rhodochrosite (containing 17.25% manganese, passing through 80 meshes) and 1.6 liters of water to be mixed with ore slurry, and absorb chlorine-containing waste gas for 2 hours at 90° C., and obtain MnCl after cooling 2 4H 2 1.45 liters of O solution; after the reaction, adjust the pH value to 3 to remove iron, then filter, add an appropriate amount of manganese sulfate powder (according to the concentration of calcium and magnesium ions to determine the addition amount) in the filtrate, stir and purify for half an hour, and let it stand for 4-6 hours , generate a white precipitate, filter, and the filter cake is the by-product CaSO 4 and MgSO 4 ; Add metal manganese powder to the filtrate and stir and purify at 60-80°C for half an hour to form heavy metal precipitates, filter to remove impurities; then add BaCl quantitatively to the filtered solution 2 , stand still, filter, remove excess SO 4 2- ; Finally, the filtrate afte...

Embodiment 2

[0100] Embodiment 2: Get 320 grams of low-grade rhodochrosite (containing 22.35% manganese, pass 160 mesh) and 1.0 liters of water to be mixed with ore slurry, and absorb chlorine-containing waste gas circulation for 2 hours at 85 ° C, and obtain MnCl after cooling 2 4H 2 1.08 liters of O solution; after the reaction, adjust the pH value to 3 to remove iron, then filter, add an appropriate amount of manganese sulfate powder (according to the concentration of calcium and magnesium ions to determine the amount added) to the filtrate, stir and purify for half an hour, and let it stand for 4-6 hours , generate a white precipitate, filter, and the filter cake is the by-product CaSO 4 and MgSO 4 ; Add metal manganese powder to the filtrate and stir and purify at 60-80°C for half an hour to form heavy metal precipitates, filter to remove impurities; then add BaCl quantitatively to the filtered solution 2 , stand still, filter, remove excess SO 4 2- ; Finally, the filtrate after p...

Embodiment 3

[0101] Embodiment 3: Get 320 grams of low-grade rhodochrosite (22.35% manganese, pass 100 mesh) and 2.2 liters of water to be mixed with ore slurry, and absorb chlorine-containing waste gas circulation for 3 hours at 65 ° C, and obtain MnCl after cooling 2 4H 2 O solution 2.11 liters; after the reaction, adjust the pH value to 3 to remove iron, then filter, add an appropriate amount of manganese sulfate powder to the filtrate and stir and purify for half an hour, let it stand for 4-6 hours, a white precipitate is formed, filter, and the filter cake is a by-product CaSO 4 and MgSO 4 ; Add metal manganese powder to the filtrate and stir and purify at 60-80°C for half an hour to form heavy metal precipitates, filter to remove impurities; then add BaCl quantitatively to the filtered solution 2 , stand still, filter, remove excess SO 4 2- ; Finally, the filtrate after purification and removal of impurities is heated, evaporated and crystallized to obtain solid MnCl 2 4H 2 O p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com