Phodochrosite leaching technology

A technology of ore and rhodochrosite, applied in the field of leaching process of rhodochrosite ore processing, can solve the problems of high input cost of electricity, manpower and equipment, large equipment investment and high cost, achieve high manganese recovery rate and reduce production cost , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

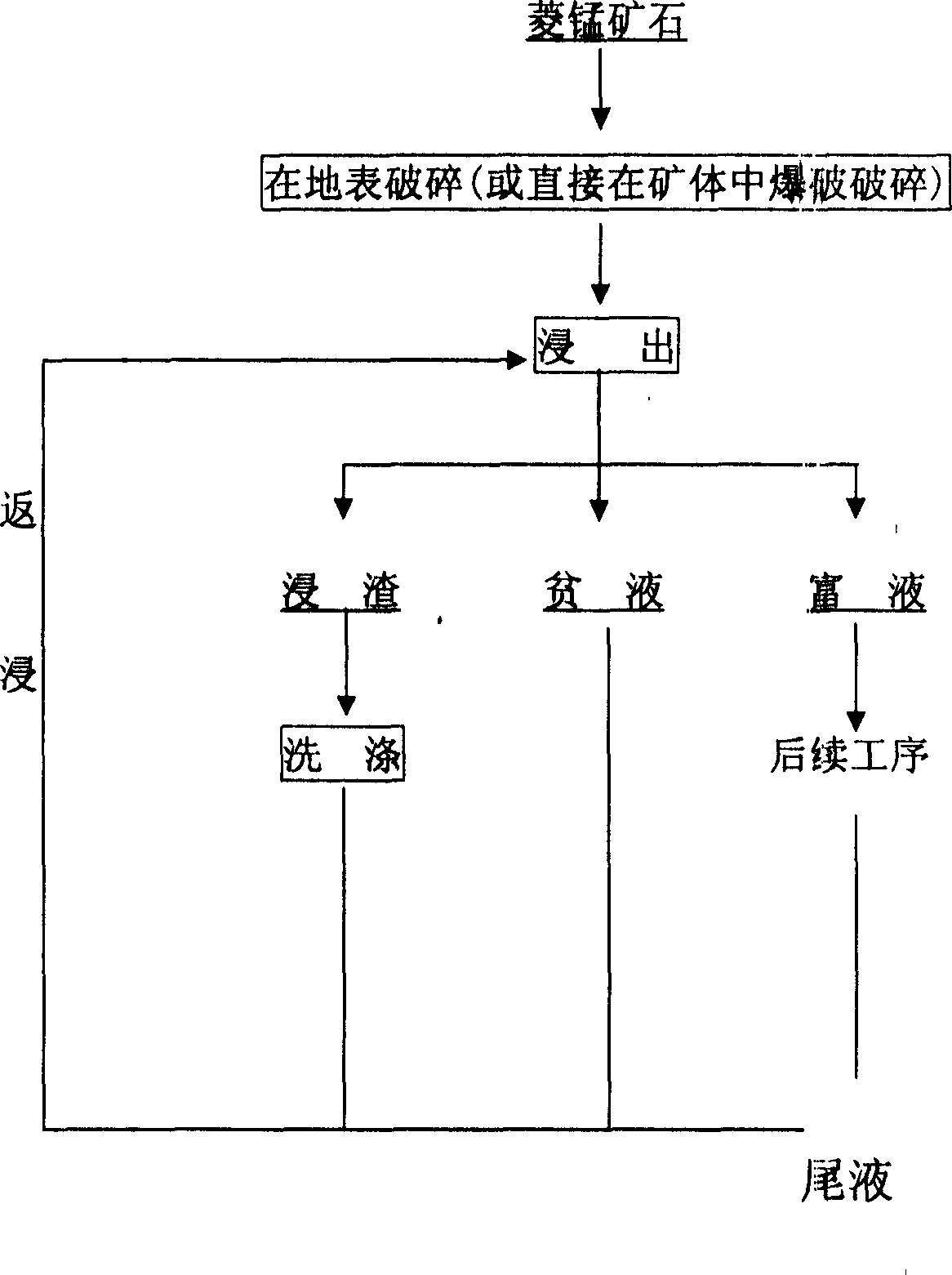

[0021] Embodiment 1: Rhodochrosite ore leaching process in surface heap leaching field:

[0022] ① Use a jaw crusher to crush the ore to a full-grain size of -20mm to -40mm;

[0023] ② Build a heap on the ore stockpiling site; the size of the heap is 10,000 square meters, and the annual processing capacity is 120,000 tons;

[0024] ③Spray with 15% (weight percent) sulfuric acid solution, and the spray intensity is 28L / h.m 2 , spray 25 large;

[0025] ④ The collected leaching solution is the manganese-rich solution for subsequent processing;

[0026] ⑤ The poor liquid returns to the secondary leaching, and the processing tail liquid enters the leaching system after being supplemented with acid to realize a closed loop;

[0027] ⑥The leaching slag is sprayed and washed with water with 10% slag content, and the washing liquid enters the leaching water circulation system to supplement the water loss of the system.

Embodiment 2

[0028] Embodiment 2: Rhodochrosite ore leaching process in surface heap leaching field:

[0029] ① The jaw crusher crushes the ore to a full-grain size of -20mm ~ -40mm;

[0030] ② Build piles on the ore dump site;

[0031] ③Spray with 25% sulfuric acid solution by volume, and the spray intensity is 18L / h.m 2 , spray for 20 days;

[0032] ④ The collected leaching solution is the manganese-rich solution for subsequent processing;

[0033] ⑤ The poor liquid returns to the secondary leaching, and the processing tail liquid enters the leaching system after being supplemented with acid;

[0034] ⑥The leaching slag is sprayed and washed with water with 8% slag content, and the washing liquid enters the leaching water circulation system to supplement the water loss of the system.

Embodiment 3

[0035] Embodiment 3: underground stope leaching process in situ:

[0036] ① Medium and deep holes are arranged in the ore body, and the ore body is crushed by extrusion blasting to a full-grain size of about -100mm;

[0037] ②The stope has been treated with anti-seepage

[0038] ③ Spray the surface of the collapsed ore with a 20% volume percent sulfuric acid solution, with a spray intensity of 28L / h.m2, and spray for one month;

[0039] ④ The leachate collected in the lower part of the stope is the manganese-rich solution for subsequent processing;

[0040] ⑤ The poor liquid returns to the secondary leaching, and the processing tail liquid enters the leaching system after being supplemented with acid;

[0041] ⑥The leaching slag is sprayed and washed with water with 10% slag content, and the washing liquid enters the leaching water circulation system to supplement the water loss of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com