Flotation method of rhodochrosite

A technology for rhodochrosite and tailings is applied in the field of efficient and comprehensive utilization of resources, which can solve the problems of weak research, low beneficiation index, and low manganese ore grade, and achieve the effects of improving beneficiation index, low consumption of chemicals, and efficient flotation separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples are intended to further illustrate the present invention, but not to limit the present invention. The g / t mentioned in this application refers to the mass of the agent added per ton of raw ore. Said percentages are all mass percentages.

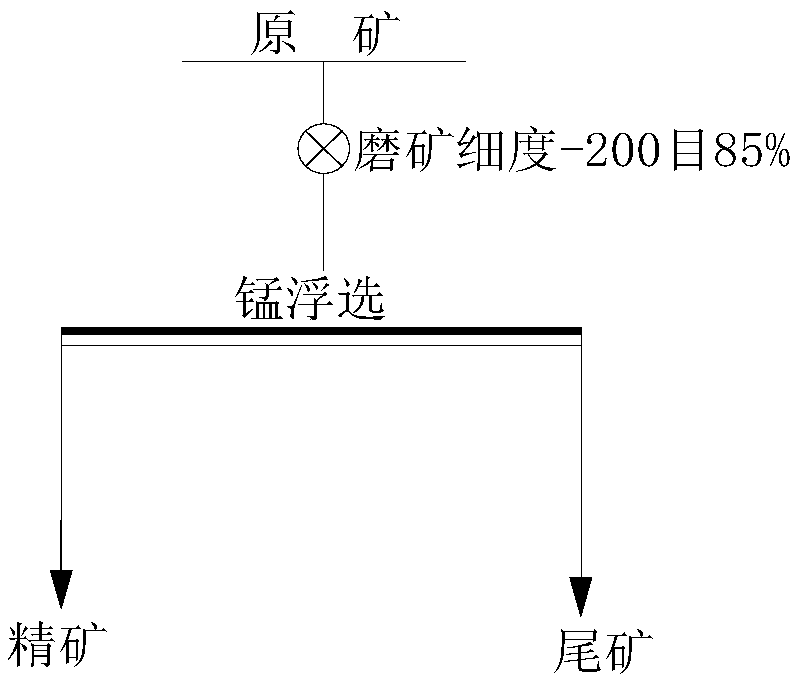

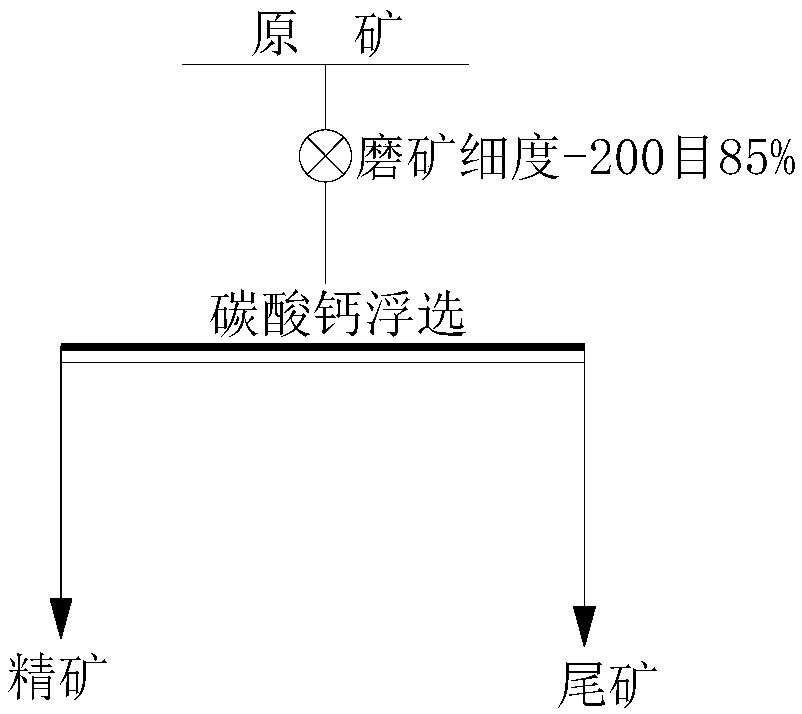

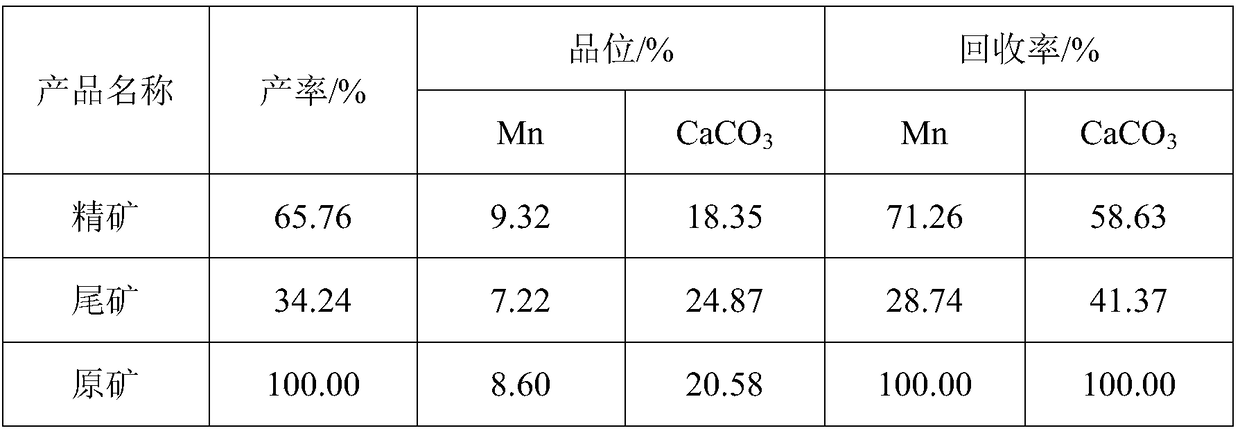

[0033] Using the technique of the present invention, a flotation test was carried out on a certain place of high calcium carbonate type manganese ore. The traditional method is that the grinding fineness is -200 mesh 85%, soda ash is used as the pH regulator, water glass and acidified water glass are used as inhibitors, and fatty acids are used as collectors to flotation manganese; the mineral processing method provided by the invention is ore grinding The fineness is -200 mesh 85%. Manganese sulfate, sodium hexametaphosphate, and carboxymethyl cellulose are used as combined inhibitors for pre-decalcification, and fatty acids are used as collectors. Compared with the traditional manganese beneficiation method, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com