Phosphorous removal method for manganous sulfate produced from high-phosphorus rhodochrosite

A manganese sulfate solution, ferrous sulfate technology, applied in manganese sulfate and other directions, can solve the problems of environmental pollution, high energy consumption, only applicable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

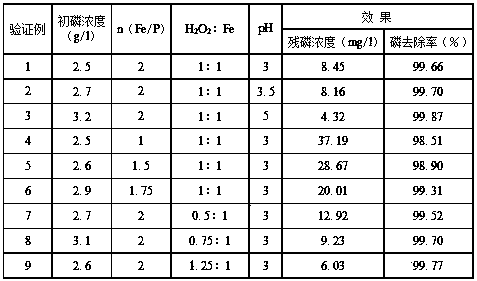

[0011] The dephosphorization method of manganese sulfate solution made from high-phosphorus rhodochrosite is characterized in that the method has the following steps:

[0012] (1) At room temperature, put the manganese sulfate solution made of high-phosphorus rhodochrosite into the stirring tank, and then add ferrous sulfate (FeSO 4 ·7H 2 O), hydrogen peroxide (H 2 o 2 ) solution to form a mixed solution; then carry out the oxidation reaction under stirring (the stirring time to ensure sufficient oxidation is usually only 3 to 5 minutes);

[0013] Wherein, the phosphorus concentration of manganese sulfate solution is between 2.5~3.2g / l, and the mol ratio=1.0~2: 1 of phosphorus in iron ion and manganese sulfate solution in ferrous sulfate, the mol ratio of iron ion in hydrogen peroxide and ferrous sulfate= 0.5~1.25:1;

[0014] (2) Add concentrated ammonia water to the mixed solution obtained in step (1) to adjust the pH value to 3-5, and then fully stir at room temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com