Method for preparing high-purity manganese sulfate from poor rhodochrosite

A technology of rhodochrosite and manganese sulfate, applied in the direction of manganese sulfate and the like, can solve the problems of low purity of manganese sulfate, difficult separation, and few utilization technologies, and achieves the effects of high utilization efficiency, low production cost and simple separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

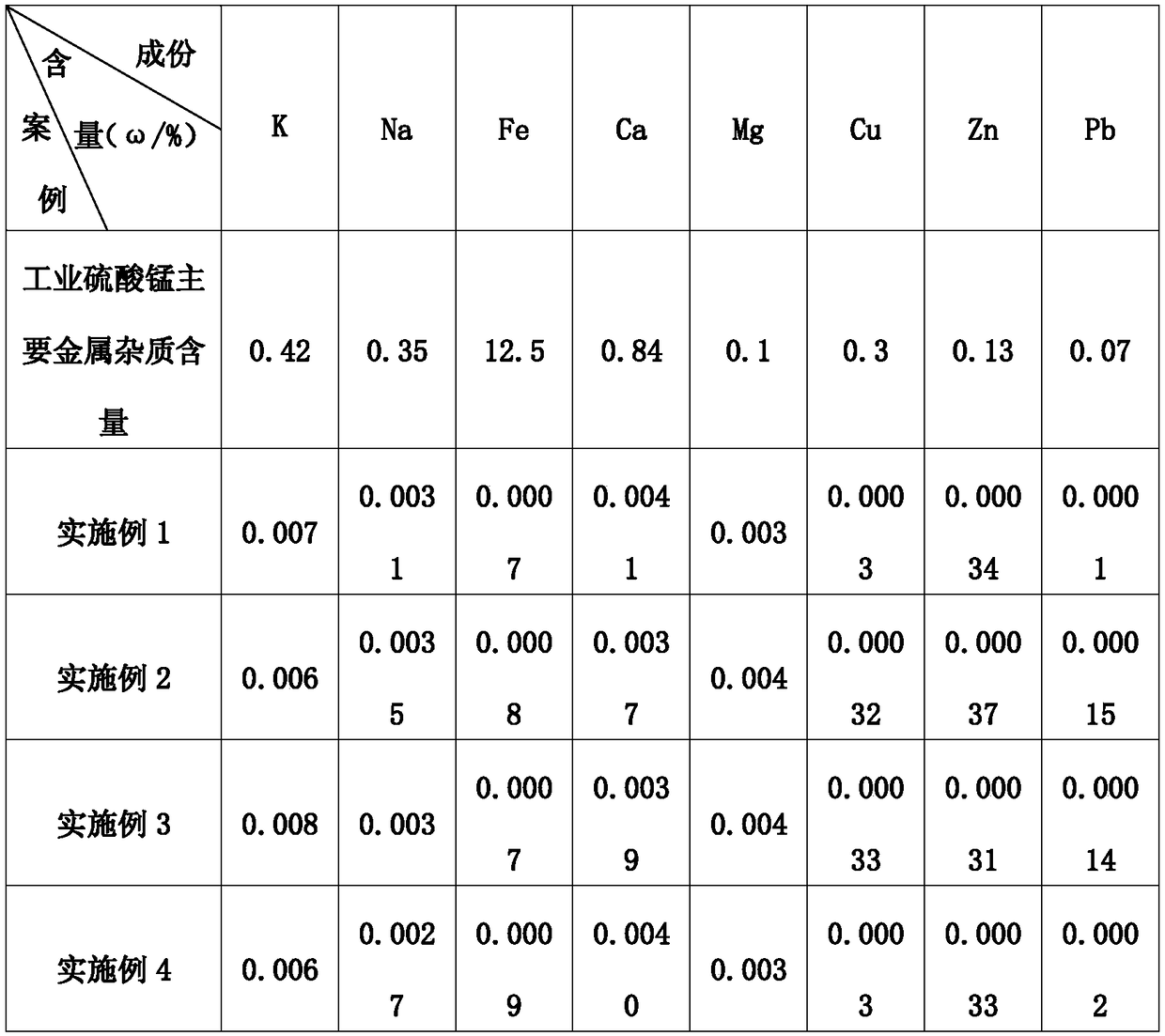

[0051] Example 1. A method for preparing high-purity manganese sulfate from poor rhodochrosite comprises the steps:

[0052] (a) Crushing the manganese-poor mineral material into 400 meshes to obtain product A;

[0053] (b) Send product A into a magnetic separator for magnetic separation to obtain product B;

[0054] (c) putting B product into concentration is to soak in the sulfuric acid solution of 40%, and manganese sulfate concentration is 300g / L in the soaking liquid, gets C product;

[0055] (d) Press filter C product, get the filtrate, get D product;

[0056] (e) According to product D, Fe 2 (SO 4 ) 3 and KMnO 4 The dosage ratio is, add 7g of Fe to 1L of D product 2 (SO 4 ) 3 and 1.5g KMnO 4 ; Add Fe to product D 2 (SO 4 ) 3 and KMnO 4 , while using Mn(OH) 2 powder or 40% H 2 SO 4 To adjust the pH of the solution to 2-4, stir at 80°C for 1h, then let stand for 2h and then filter;

[0057] (f) Take product E, using Mn(OH) 2 powder or 40% H 2 SO 4 To ...

Embodiment 2

[0061] Example 2. A method for preparing high-purity manganese sulfate from poor rhodochrosite comprises the steps:

[0062] (a) Crushing the manganese-poor mineral material into 500 meshes to obtain product A;

[0063] (b) Send product A into a magnetic separator for magnetic separation to obtain product B;

[0064] (c) B product is put into concentration and is soaked in the sulfuric acid solution of 50%, and manganese sulfate concentration is 400g / L in the soaking liquid, gets C product;

[0065] (d) Press filter C product, get the filtrate, get D product;

[0066] (e) According to product D, Fe 2 (SO 4 ) 3 and KMnO 4 The dosage ratio is, add 20g of Fe to 1L of D product 2 (SO 4 ) 3 and 3gKMnO 4 ; Add Fe to product D 2 (SO 4 ) 3 and KMnO 4 , while using Mn(OH) 2 powder or 50% H 2 SO 4 To adjust the pH of the solution to 2-4, stir at 85°C for 1.5h, and then filter after standing for 2.5h;

[0067] (f) Take product E, using Mn(OH) 2 powder or 50% H 2 SO 4...

Embodiment 3

[0071] Example 3. A method for preparing high-purity manganese sulfate from poor rhodochrosite comprises the steps:

[0072] (a) Crushing the manganese-poor mineral material into 500 meshes to obtain product A;

[0073] (b) Send product A into a magnetic separator for magnetic separation to obtain product B;

[0074] (c) B product is put into concentration and is soaked in the sulfuric acid solution of 50%, and manganese sulfate concentration is 500g / L in the soaking liquid, gets C product;

[0075] (d) Press filter C product, get the filtrate, get D product;

[0076] (e) According to product D, Fe 2 (SO 4 ) 3 and KMnO 4 The dosage ratio is, add 30g of Fe to 1L of D product 2 (SO 4 ) 3 and 4gKMnO 4 ; Add Fe to product D 2 (SO 4 ) 3 and KMnO 4 , while using Mn(OH) 2 powder or 50% H 2 SO 4 To adjust the pH of the solution to 2-4, stir at 85°C for 2h, then let stand for 3h and then filter;

[0077] (f) Take product E, using Mn(OH) 2 powder or 50% H 2 SO4 To ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com