Desulfurizing method for high-sulfur rhodochrosite

A technology of sulfur rhodochrosite and rhodochrosite, which is applied in the field of desulfurization treatment of high sulfur rhodochrosite, can solve the problems of furnace grate formation, difficulty, excessive energy consumption, etc., and achieve the effect of increasing manganese content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

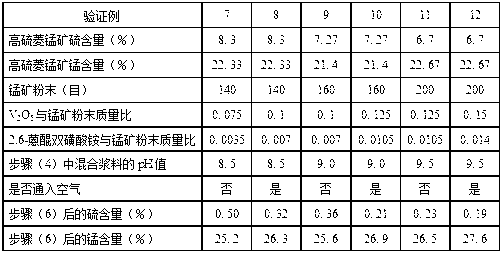

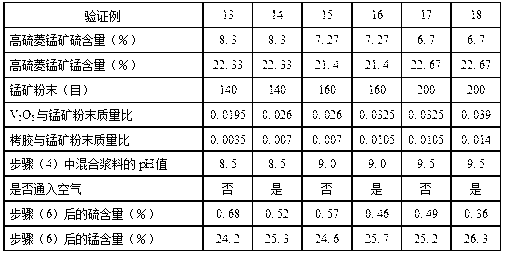

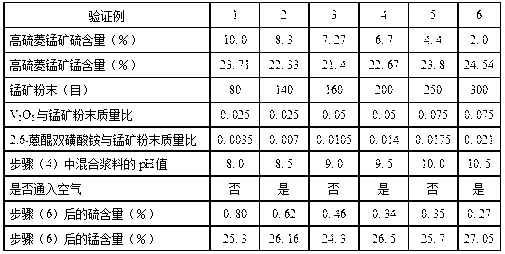

Examples

Embodiment Construction

[0015] A method of oxidizing low-valence sulfur in manganese ore to high-valence. The method has the following steps:

[0016] (1) Grinding and sieving high-sulfur rhodochrosite to obtain high-sulfur rhodochrosite powder with a particle size of 0.05-0.18mm (about 80-300 mesh of Taylor standard sieve);

[0017] (2) At room temperature, add water to the reaction vessel containing the high-sulfur rhodochrosite powder, and stir evenly to obtain a mixed slurry; wherein, the mass ratio of the high-sulfur rhodochrosite powder to water is equal to 1;

[0018] (3) Add vanadium pentoxide (V 2 o 5 ) and 2.6-ammonium anthraquinone bissulfonate (C 14 h 14 o 8 N 2 S 2 ), or vanadium pentoxide and tannins (tannin C 76 h 52 o 46 Qualified products with a mass percentage greater than 65%), and fully mixed;

[0019] Among them, the mass ratio of vanadium pentoxide to high-sulfur rhodochrosite powder is 0.0065-0.15, and the mass ratio of 2.6-ammonium anthraquinone bissulfonate or tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com