Ore selecting method of anthrophyllite and its friction concentrator

A beneficiation method and technology of a beneficiation machine, which are applied in the direction of solid separation, etc., can solve the problems of reduced utilization value and economic value, too fine mica cannot be recovered, and mica crystal is destroyed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

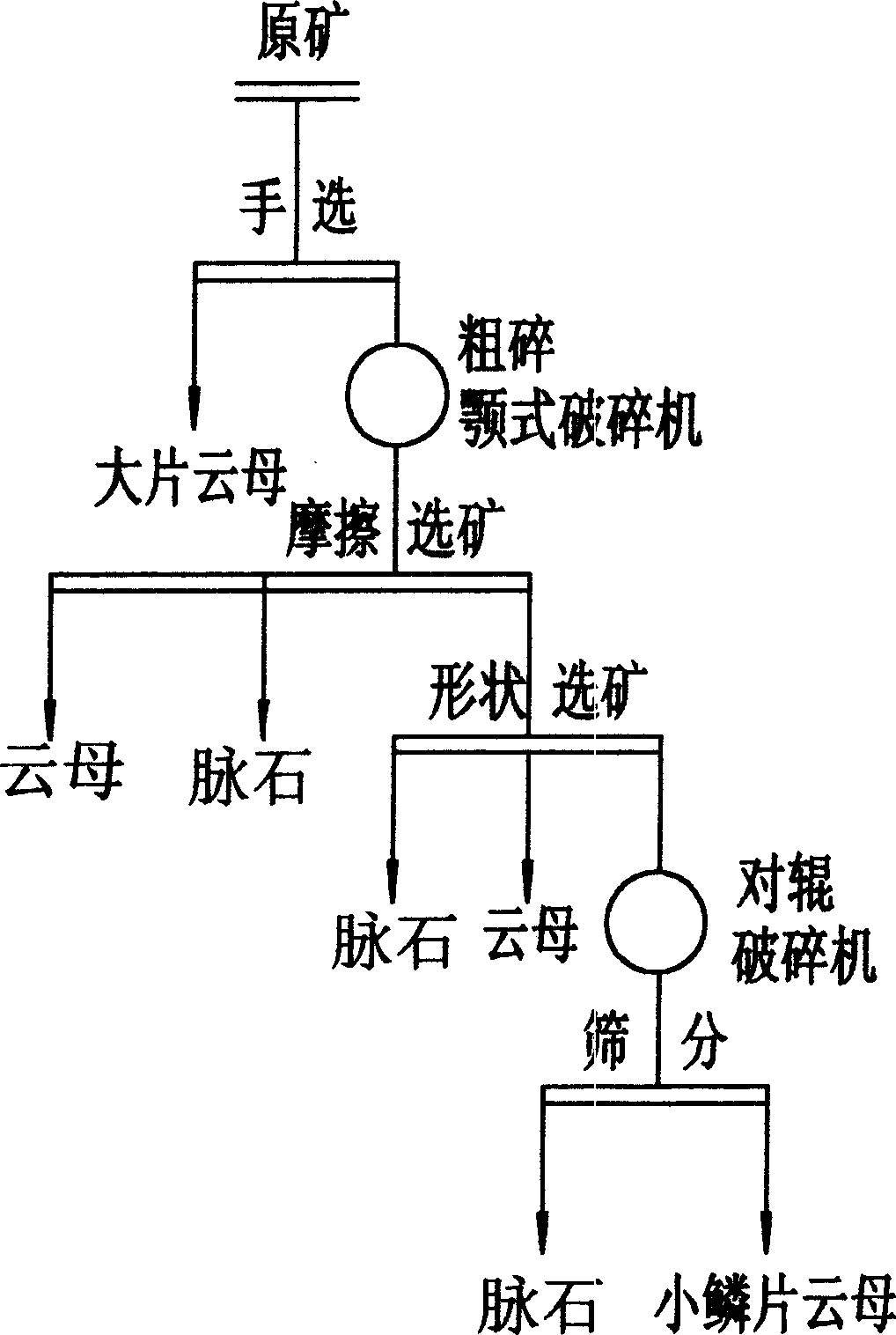

[0020] A kind of beneficiation method of mica, it comprises the steps:

[0021] 1). The raw ore is hand-selected, and after a large piece of mica is selected, the raw ore enters the PE400×600 jaw crusher for coarse crushing, and the width of the ore discharge port is 70mm. After the coarse crushing, the raw ore enters the friction beneficiation bin;

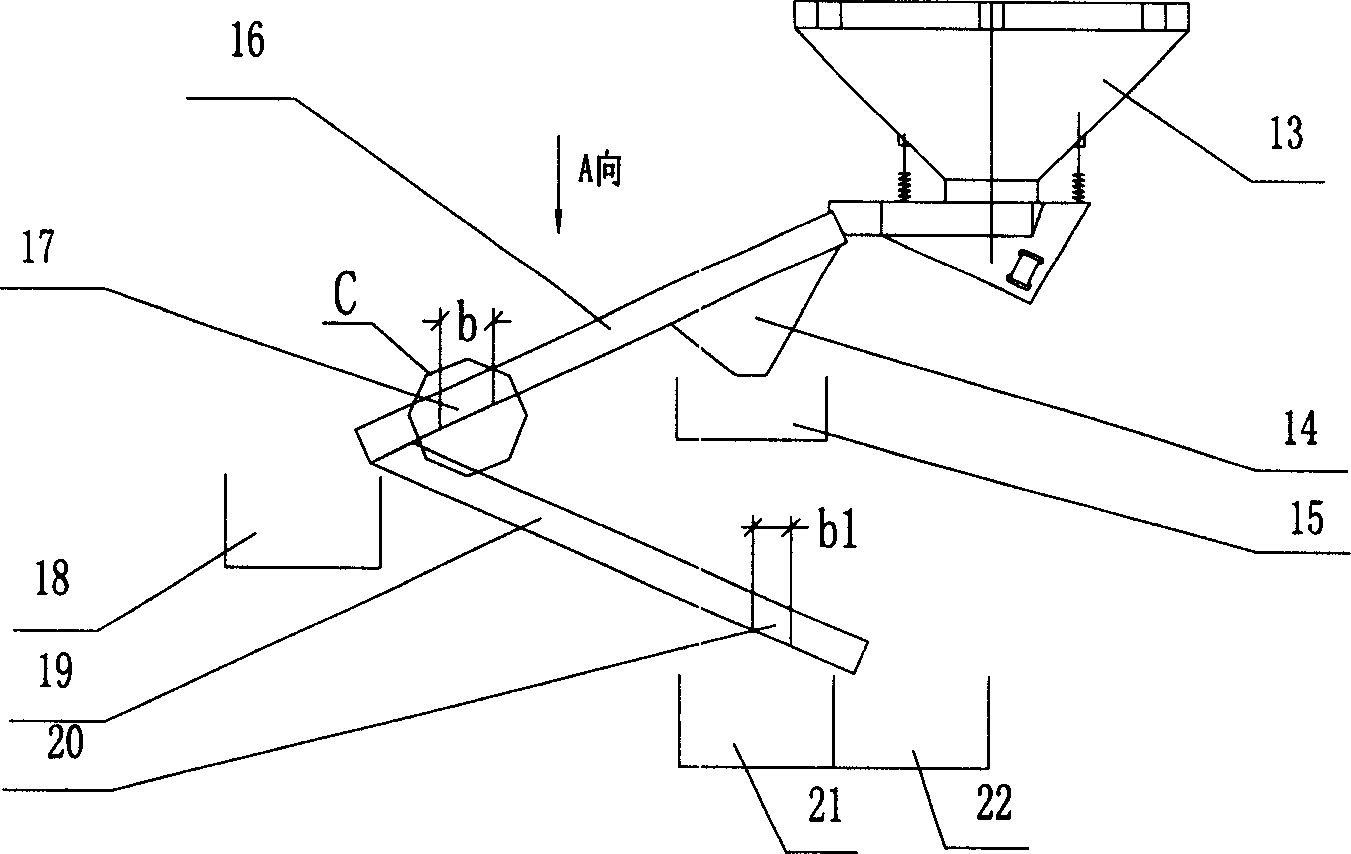

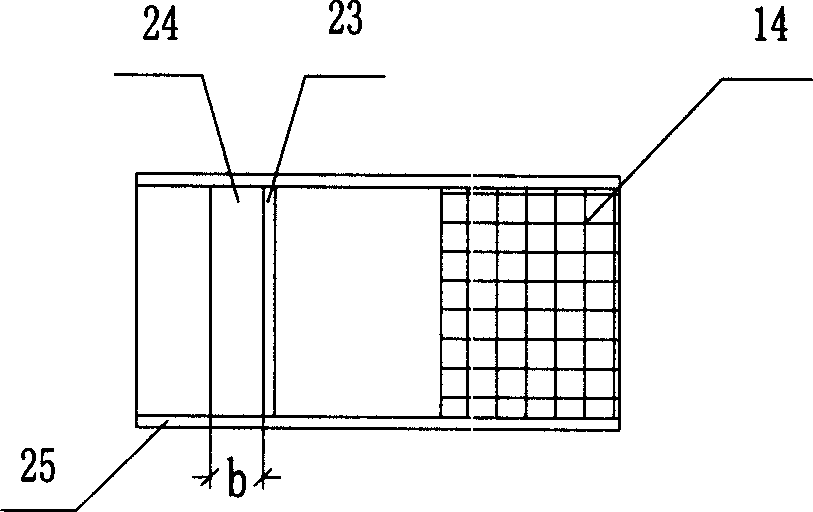

[0022] 2). Friction beneficiation: The raw ore after coarse crushing is fed into the friction concentrator by GZ-10 electric vibration feeder. The ore first passes through the inclined screen at the front end of the friction concentrator. The size of the screen hole is 25mm×25mm, and the small Granular mica and gangue are screened out and enter the raw ore recovery silo smaller than 20mm; after the ore passes through the inclined screen at the front end of the friction concentrator, the ore larger than 20mm continues to slide down the inclined plate, and when it reaches the weir plate of the friction concentrator, the rapidly roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com