Method for preparing montmorillonite in situ intercalation type nanoscale zero-valent iron

A nano-zero-valent iron and in-situ intercalation technology, applied in the interdisciplinary field of environmental science and material science, can solve problems such as easy agglomeration, poor fluidity, and ineffective oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

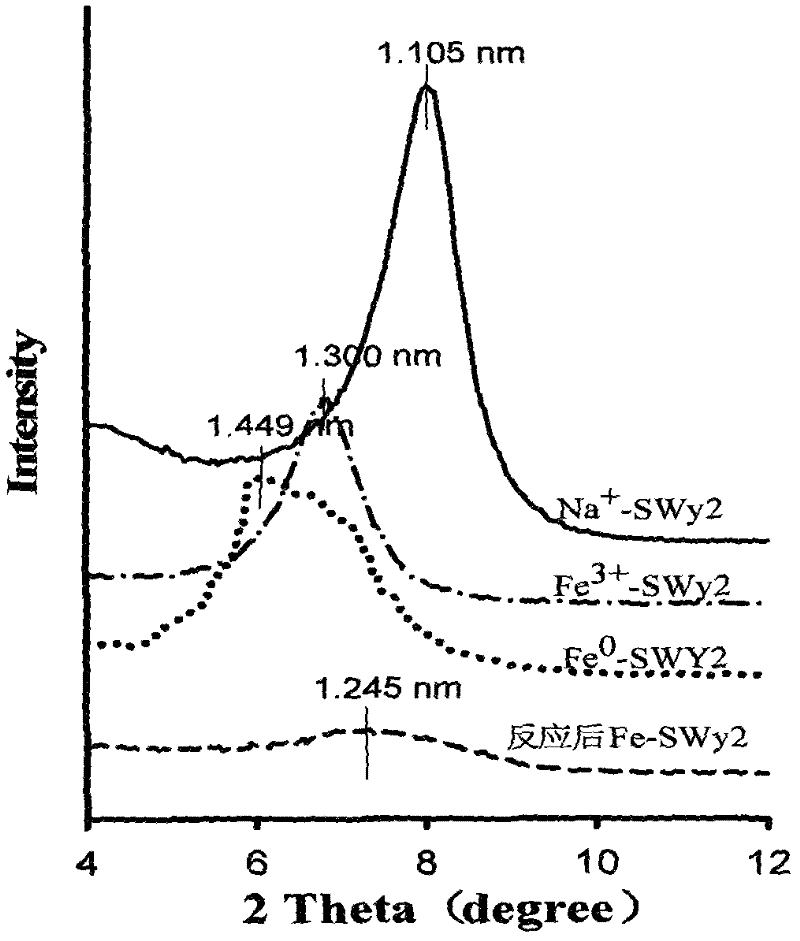

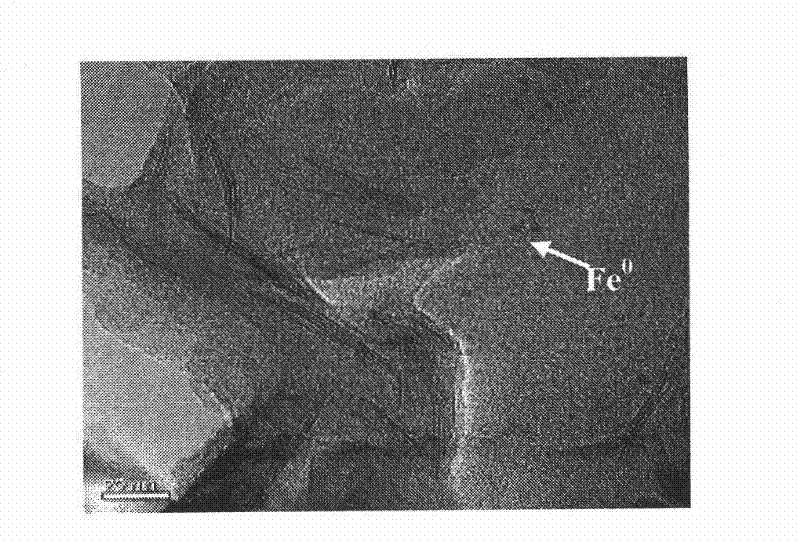

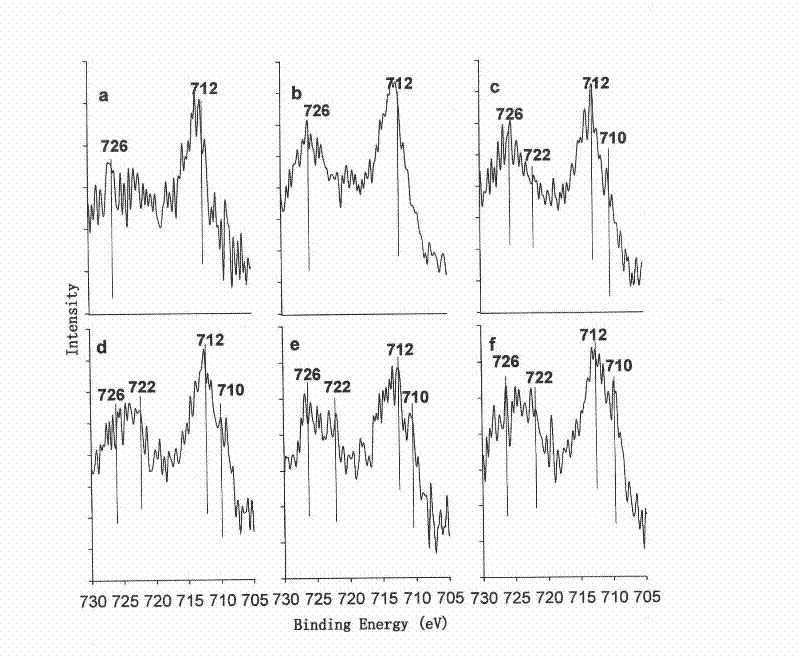

[0029] Utilizing montmorillonite clay as the template prepared by nanometer zero-valent iron, the interlayer Fe 3+The liquid phase reduction is zero-valent, and the highly active and high-stability montmorillonite-loaded (sub)nano zero-valent iron composite material is prepared. The specific operation is carried out according to the following steps:

[0030] a, pretreatment of montmorillonite: before composite material preparation, montmorillonite is carried out mineral purification, with 5g montmorillonite clay (the cation exchange capacity of montmorillonite clay is 82cmol kg -1 ) into 100ml of deionized water, stirred magnetically for 24 hours, then transferred to a 250ml polyethylene centrifuge bottle, centrifuged at 600rmp at a low speed for 6min to remove non-clay minerals, and siphoned the upper suspension into another polyethylene centrifuge bottle , to obtain particles smaller than 2μm clay particle size, add 100ml water to the precipitated particles larger than 2μm, ...

Embodiment 2

[0041] a, pretreatment of montmorillonite: before composite material preparation, montmorillonite is carried out mineral purification, with 5g montmorillonite clay (the cation exchange capacity of montmorillonite clay is 82cmol kg -1 ) into 100ml of deionized water, stirred magnetically for 24 hours and then moved into a 250ml polyethylene centrifuge bottle. The clay suspension was centrifuged at 58-60g at a low speed of 600rmp for 6 minutes to remove non-clay minerals, and the upper suspension was siphoned in In another polyethylene centrifuge bottle, get particles smaller than 2μm colloid size, add 100ml water to the precipitated particles larger than 2μm, use a vortex mixer to mix and then centrifuge at low speed to extract particles smaller than 2μm remaining in the precipitate, and suspend in the upper layer The liquid is siphoned into the centrifuge bottle of the previous suspension, and the particles larger than 2 μm are freeze-dried, stored or discarded directly, and th...

Embodiment 3

[0046] a, pretreatment of montmorillonite: before composite material preparation, montmorillonite is carried out mineral purification, with 5g montmorillonite clay (the cation exchange capacity of montmorillonite clay is 82cmol kg -1) into 100ml of deionized water, stirred magnetically for 24 hours and then moved into a 250ml polyethylene centrifuge bottle. The clay suspension was centrifuged at 58-60g at a low speed of 600rmp for 6 minutes to remove non-clay minerals, and the upper suspension was siphoned in In another polyethylene centrifuge bottle, get particles smaller than 2μm colloid size, add 100ml water to the precipitated particles larger than 2μm, use a vortex mixer to mix and then centrifuge at low speed to extract particles smaller than 2μm remaining in the precipitate, and suspend in the upper layer The liquid is siphoned into the centrifuge bottle of the previous suspension, and the particles larger than 2 μm are freeze-dried, stored or discarded directly, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com