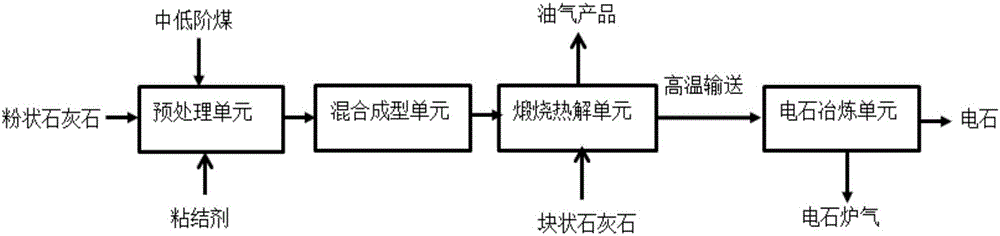

Method and system for producing calcium carbide by utilizing limestone

A limestone and calcium carbide technology, applied in the petroleum industry, special dry distillation, carbide, etc., can solve the problems of high energy consumption, low efficiency, high pollution, etc., reduce the cost of equipment and calcination energy consumption, and solve the problem of coking of radiant tubes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

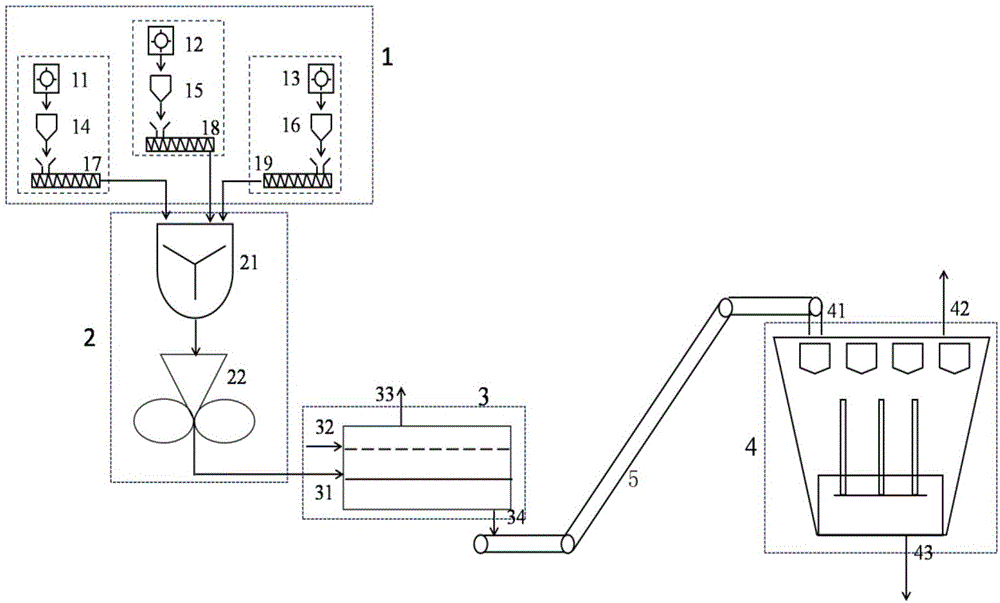

Embodiment 1

[0060] Through the crushing device, the medium and low-rank coal, powdered limestone and binder are crushed to a particle size of <50 mesh; according to the proportion (binder: powdered limestone: coal powder = 0.06:0.70:1) They are fed into the powerful mixer through the screw feeder and then put into the ball pressing machine for molding; the obtained balls are sent into the lower material plate of the double-layer non-heat carrier regenerative rotary bed, and the lump quicklime is sent into the rotary bed at the same time. The upper material plate of the bed (mass ratio of massive quicklime to initial pulverized coal is 1.1:1); the heating temperatures of the upper and lower radiant tubes are 950°C and 800°C, respectively. The massive limestone and pellets are calcined and pyrolyzed into high-temperature massive quicklime and high-temperature active pellets respectively, and high value-added oil and gas products are obtained. The oil and gas products produced by pyrolysis a...

Embodiment 2

[0062] Through the crushing device, the medium and low-rank coal, powdered limestone and binder are crushed to a particle size of <50 mesh; according to the proportion (binder: powdered limestone: coal powder = 0.23:1.1:1) They are fed into the powerful mixer through the screw feeder and then put into the ball pressing machine for molding; the obtained balls are sent into the lower material plate of the double-layer non-heat carrier regenerative rotary bed, and the lump quicklime is sent into the rotating bed at the same time. The upper material plate of the bed (mass ratio of massive quicklime to initial pulverized coal is 0.7:1); the heating temperatures of the upper and lower radiant tubes are 900°C and 750°C, respectively. The massive limestone and pellets are calcined and pyrolyzed into high-temperature massive quicklime and high-temperature active pellets respectively, and high value-added oil and gas products are obtained. The oil and gas products produced by pyrolysis ...

Embodiment 3

[0064] Through the crushing device, the medium and low-rank coal, powdered limestone and binder are crushed to a particle size of <50 mesh; according to the proportion (binder: powdered limestone: coal powder = 0.21:0.9:1) They are fed into the powerful mixer through the screw feeder and then put into the ball pressing machine for molding; the obtained balls are sent into the lower material plate of the double-layer non-heat carrier regenerative rotary bed, and the lump quicklime is sent into the rotary bed at the same time. The upper material plate of the bed (mass ratio of block quicklime to initial pulverized coal is 0.9:1); the heating temperatures of the upper layer radiant tube and the lower layer radiant tube are 1000°C and 900°C respectively. The massive limestone and pellets are calcined and pyrolyzed into high-temperature massive quicklime and high-temperature active pellets respectively, and high value-added oil and gas products are obtained. The oil and gas product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com