Porous carbon loaded titanium dioxide composite manufactured by utilizing ionic liquid/polyaniline and method and application thereof

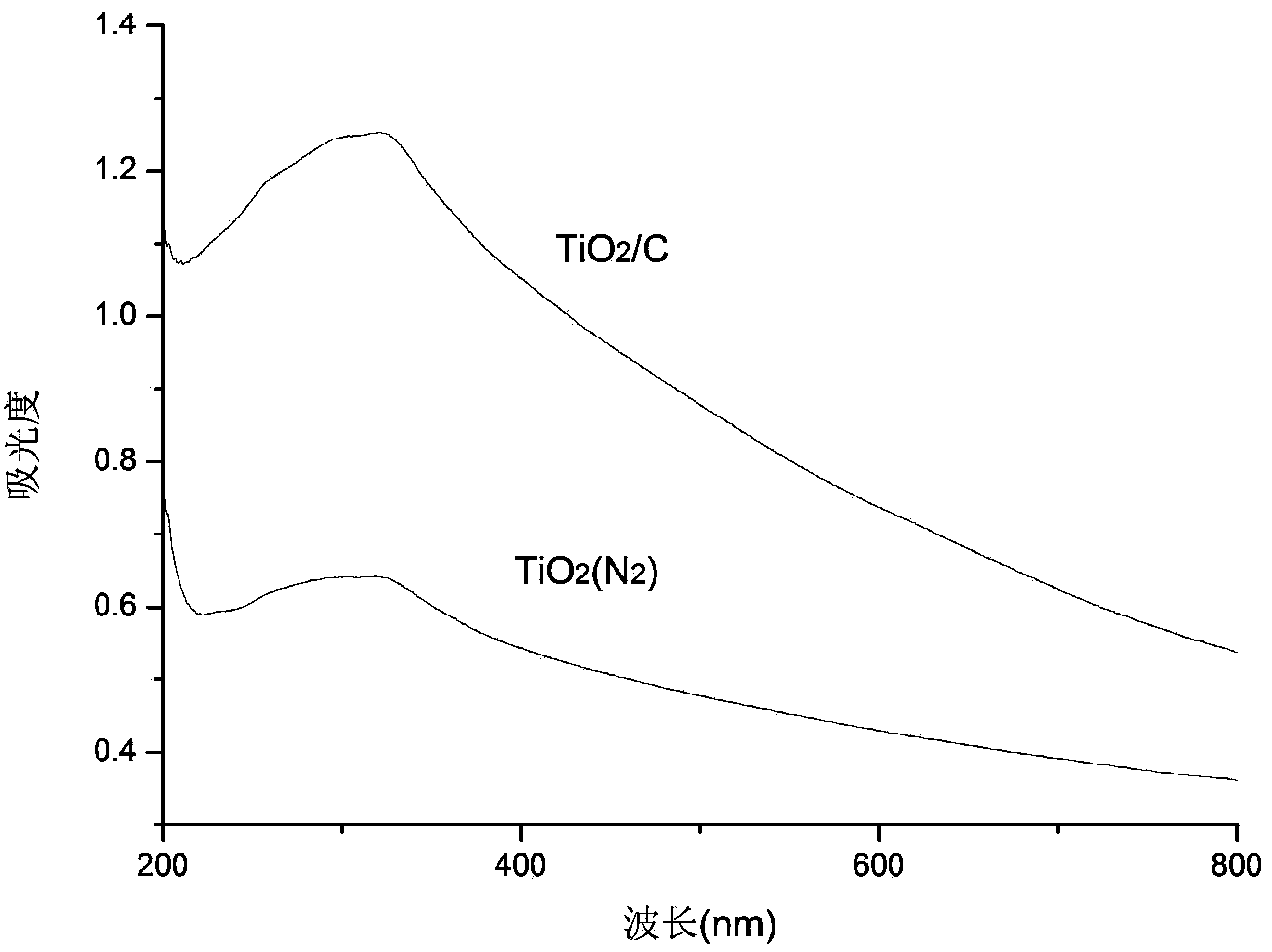

A technology of titanium dioxide and composite materials, applied in separation methods, chemical instruments and methods, catalysts for physical/chemical processes, etc., to achieve the effects of large light absorption capacity, small particle size, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The preparation method of the porous carbon-loaded titanium dioxide composite material that ionic liquid polyaniline participates in preparation comprises the following steps:

[0023] (1) Titanium dioxide sol was prepared by sol-gel method. After the sol was stirred for 15 minutes, 1.5wt% ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate and 0.1wt% aniline were added to the sol. , stirred for 15 minutes, and mixed evenly;

[0024] (2) Take ammonium persulfate accounting for 0.2wt% of the sol, prepare a hydrochloric acid solution with a concentration of 0.2wt%, and add it dropwise to the above sol mixture to initiate aniline polymerization. Continue to stir for 2h after the dropwise addition;

[0025] (3) Leave the sol to age for 3 days and then dry it in an oven at 60°C;

[0026] (4) After milling, the obtained composite was calcined at 800° C. for 1 h in a nitrogen atmosphere to carbonize the polyaniline to obtain a porous carbon-supported tit...

Embodiment 2

[0028] Embodiment 2: the preparation method of the porous carbon supported titanium dioxide composite material that ionic liquid polyaniline participates in preparation, comprises the following steps:

[0029] (1) Titanium dioxide sol was prepared by sol-gel method. After the sol was stirred for 20 minutes, 3.0wt% ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate and 0.6wt% aniline were added to the sol. , stirred for 20 minutes, and mixed evenly;

[0030] (2) Take ammonium persulfate accounting for 0.8wt% of the sol, prepare a hydrochloric acid solution with a concentration of 0.4wt%, and add it dropwise to the above sol mixture to initiate aniline polymerization. Continue to stir for 2h after the dropwise addition;

[0031] (3) Leave the sol to age for 3 days and then dry it in an oven at 60°C;

[0032] (4) After grinding, the obtained composite was calcined in a nitrogen atmosphere at 700°C for 1 h to carbonize the polyaniline to form a porous carbon-supported ti...

Embodiment 3

[0036] Embodiment 3: the preparation method of the porous carbon supported titanium dioxide composite material that ionic liquid polyaniline participates in preparation, comprises the following steps:

[0037] (1) Prepare titanium dioxide sol by sol-gel method. After stirring the sol for 20 minutes, add 3.0wt% ionic liquid 1-ethylpyridine tetrafluoroborate and 0.2wt% aniline to it, stir for 20 minutes, and mix uniform;

[0038] (2) Take ammonium persulfate accounting for 0.3wt% of the sol, prepare a hydrochloric acid solution with a concentration of 0.6wt%, and add it dropwise to the above sol mixture to initiate aniline polymerization. Continue to stir for 2h after the dropwise addition;

[0039] (3) Leave the sol to age for 3 days and then dry it in an oven at 80°C;

[0040] (4) After milling, the obtained composite was calcined in a nitrogen atmosphere at 600°C for 1 h to carbonize the polyaniline to obtain a porous carbon-supported titanium dioxide composite material.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com