High-plasticity and high-strength hexabasic refractory high-entropy alloy and verification method thereof

A technology of high-entropy alloys and verification methods, applied in the field of metal materials, can solve the problems of poor plasticity of high-entropy alloys, difficulty in predicting the properties of refractory high-entropy alloys in advance, and lack of clear design guidance, etc., to shorten the production process Time, good room temperature compression plasticity and strength, and the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A verification method for a high-plasticity and high-strength six-element refractory high-entropy alloy described in this embodiment, the method is as follows:

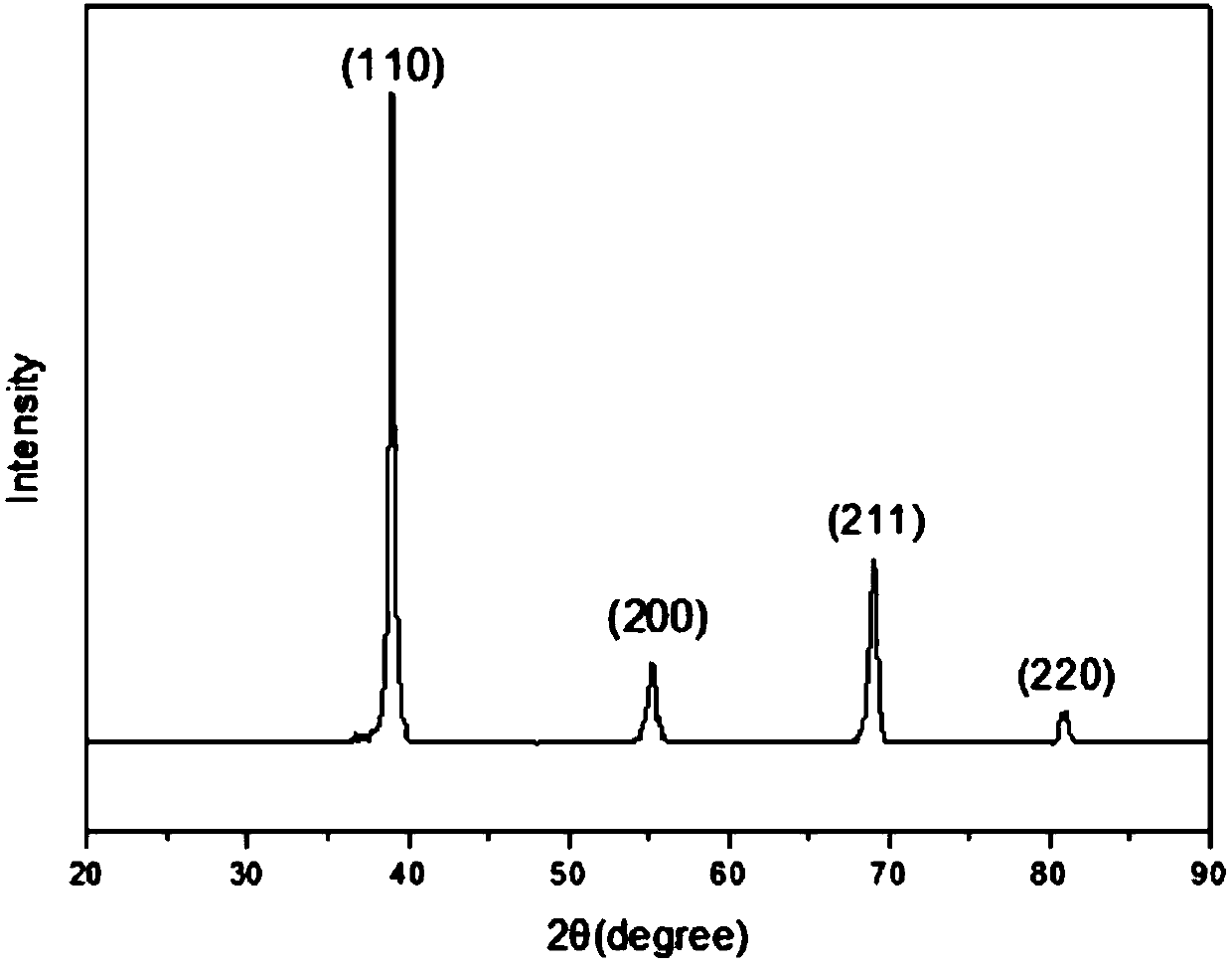

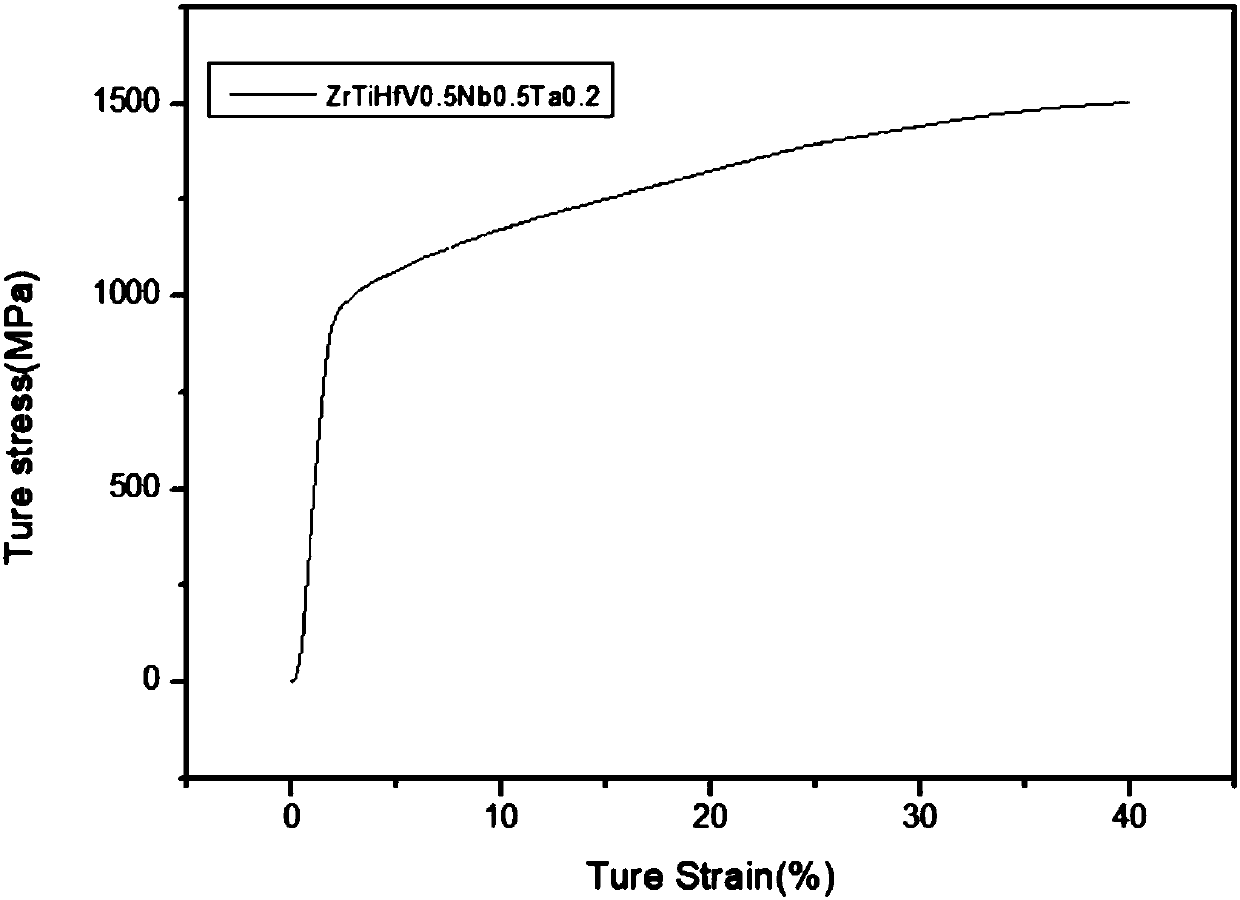

[0045] A six-element refractory high-entropy alloy with high plasticity and high strength, the component is Zr a Ti b f c V d Nb e x f , where a, b, c, d, e and f are respectively the molar proportions corresponding to each element, taking a=1, b=1, c=1, d=0.5, e=0.5, f=0.2, X is Ta, that is, the high-entropy alloy is ZrTiHfV 0.5 Nb 0.5 Ta 0.2 ;

[0046] The purity of Zr, Ti, Hf, V, Nb and Ta is 99.7wt%.

[0047] (1) ZrTiHfV 0.5 Nb 0.5 Ta 0.2 The atomic size difference parameter δ

[0048]

[0049] where C i is the mole percentage of the i-th component, r i is the atomic radius of the i-th component, N is the total number of alloy components; Zr atomic radius is 0.159nm; Ti atomic radius is 0.146nm; Hf atomic radius is 0.158nm; V atomic radius is 0.132nm; Nb atomic radius is 0.143nm nm; Ta at...

Embodiment 2

[0061] A design method of a high-plasticity high-strength six-element refractory high-entropy alloy described in this embodiment, the method is as follows:

[0062] A six-element refractory high-entropy alloy with high plasticity and high strength, the component is Zr a Ti b f c V d Nb e x f , where a, b, c, d, e and f are respectively the molar proportions corresponding to each element, a=1, b=1, c=1, d=0.5, e=0.5, f=0.5, X is Ta, that is, the high-entropy alloy is ZrTiHfV 0.5 Nb 0.5 Ta 0.5 ;

[0063] The purity of Zr, Ti, Hf, V, Nb and Ta is 99.7wt%.

[0064] (1) ZrTiHfV 0.5 Nb 0.5 Ta 0.5 Atomic size difference parameter δ

[0065]

[0066] where C i is the mole percentage of the i-th component, r i is the atomic radius of the i-th component, N is the total number of alloy components; Zr atomic radius is 0.159nm; Ti atomic radius is 0.146nm; Hf atomic radius is 0.158nm; V atomic radius is 0.132nm; Nb atomic radius is 0.143nm nm; Ta atomic radius is 0.147nm...

Embodiment 3

[0078] A design method of a high-plasticity high-strength six-element refractory high-entropy alloy described in this embodiment, the method is as follows:

[0079] A six-element refractory high-entropy alloy with high plasticity and high strength, the component is Zr a Ti b f c V d Nb e x f , where a, b, c, d, e and f are respectively the molar proportions corresponding to each element, taking a=1, b=1, c=1, d=0.5, e=0.5, f=0.2, X is Mo, that is, the high-entropy alloy is ZrTiHfV 0.5 Nb 0.5 Mo 0.2 ;

[0080] The purity of Zr, Ti, Hf, V, Nb and Mo is 99.7wt%.

[0081] (1) ZrTiHfV 0.5 Nb 0.5 Mo 0.2 The atomic size difference parameter δ

[0082]

[0083] where C i is the mole percentage of the i-th component, r i is the atomic radius of the i-th component, N is the total number of alloy components; Zr atomic radius is 0.159nm; Ti atomic radius is 0.146nm; Hf atomic radius is 0.158nm; V atomic radius is 0.132nm; Nb atomic radius is 0.143nm nm; Mo atomic radius...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com