Organic and inorganic hybridization nanometer super-hydrophobic fiber membrane and preparing method thereof

A super-hydrophobic, fibrous membrane technology, used in textiles, papermaking, non-woven fabrics, etc., can solve the problems of human body and ecological environment hazards, high price, etc., achieve high specific surface area, improve tensile properties, and good fiber-forming properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

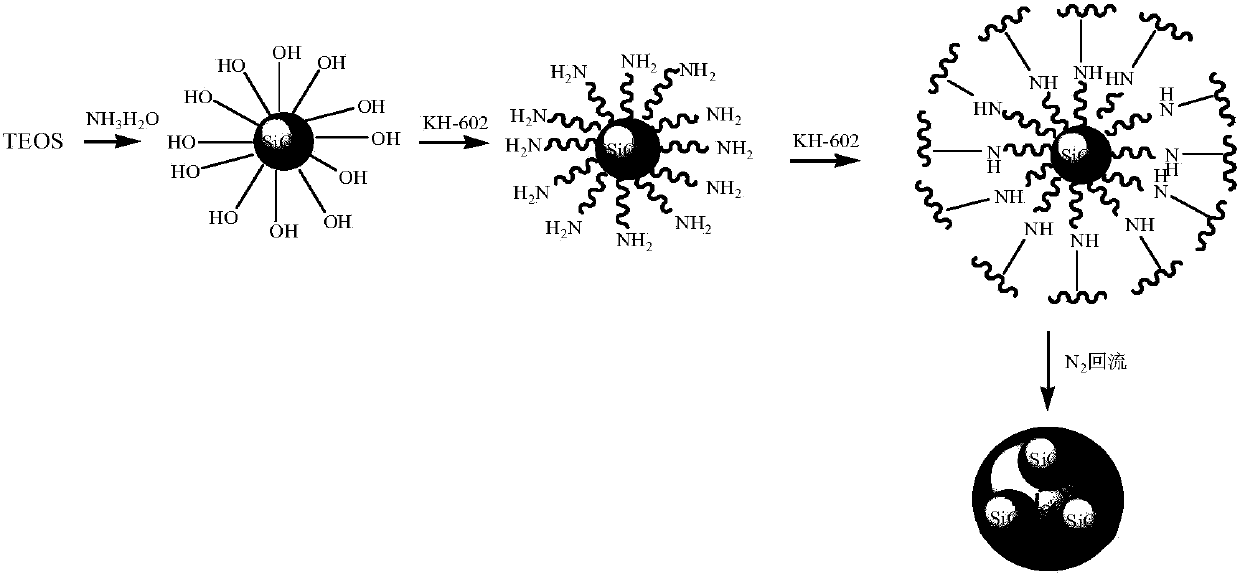

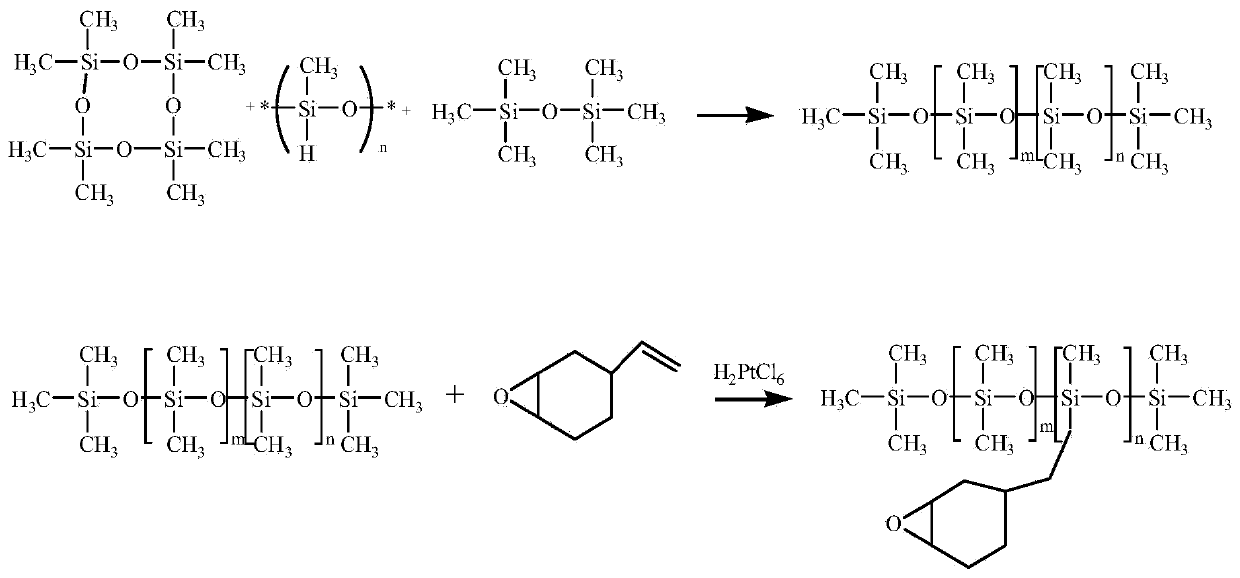

[0037] (1) Preparation of spinning solution

[0038] Preparation of PS spinning solution: at room temperature, add polystyrene (PS) to N,N dimethylformamide (DMF) / tetrahydrofuran (THF) = 3:1 solvent, completely dissolve and magnetically stir for 4 hours to obtain 30wt .% concentration of polystyrene spinning solution, then add 10wt.% SiO modified with epoxy-modified silicone oil 2 Composite nanoparticles, continue magnetic stirring until the silica nanoparticles can be completely and uniformly dispersed in the spinning solution of PS and solvent.

[0039]Preparation of PAN spinning solution: Add polyacrylonitrile (PAN) into N,N dimethylformamide (DMF) at room temperature, and stir magnetically for 3.5 hours after completely dissolving to obtain a polystyrene spinning solution with a concentration of 12wt.%. Silk liquid, then add 5wt.% epoxy modified silicone oil modified SiO 2 Composite nanoparticles, continue magnetic stirring until the silica nanoparticles can be completel...

Embodiment 2

[0043] (1) Preparation of spinning solution

[0044] Preparation of PS spinning solution: at room temperature, add polystyrene (PS) to N,N dimethylformamide (DMF) / tetrahydrofuran (THF) = 3:1 solvent, completely dissolve and magnetically stir for 4 hours to obtain 30wt .% concentration of polystyrene spinning solution, then add 15wt.% SiO modified by epoxy-modified silicone oil 2 Composite nanoparticles, continue magnetic stirring until the silica nanoparticles can be completely and uniformly dispersed in the spinning solution of PS and solvent.

[0045] Preparation of PAN spinning solution: Add polyacrylonitrile (PAN) to N,N dimethylformamide (DMF) at room temperature, and magnetically stir for 3 hours after completely dissolving to obtain 10wt.% concentration of polystyrene spinning solution, and then add 5wt.% epoxy modified silicone oil modified SiO 2 Composite nanoparticles, continue magnetic stirring until the silica nanoparticles can be completely and uniformly dispers...

Embodiment 3

[0049] (1) Preparation of spinning solution

[0050] Preparation of PS spinning solution: at room temperature, add polystyrene (PS) to N,N dimethylformamide (DMF) / tetrahydrofuran (THF) = 3:1 solvent, completely dissolve and magnetically stir for 4 hours to obtain 30wt .% concentration of polystyrene spinning solution, then add 10wt.% SiO modified with epoxy-modified silicone oil 2 Composite nanoparticles, continue magnetic stirring until the silica nanoparticles can be completely and uniformly dispersed in the spinning solution of PS and solvent.

[0051] Preparation of PAN spinning solution: at room temperature, polyacrylonitrile (PAN) was added to N,N dimethylformamide (DMF), completely dissolved and then magnetically stirred for 3 hours to obtain a polystyrene spinning solution with a concentration of 12wt.%. solution, and then add 8wt.% epoxy modified silicone oil modified SiO 2 Composite nanoparticles, continue magnetic stirring until the silica nanoparticles can be com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com