Aluminum alloy matrix composite material, preparation method and application

A composite material and aluminum alloy-based technology, which is applied in the field of aluminum alloy materials, can solve problems such as easy oxidation of copper coating, insufficient bonding force, and inability to meet the requirements of high-current conductive parts, and achieve considerable economic benefits and low oxidation rate. , significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

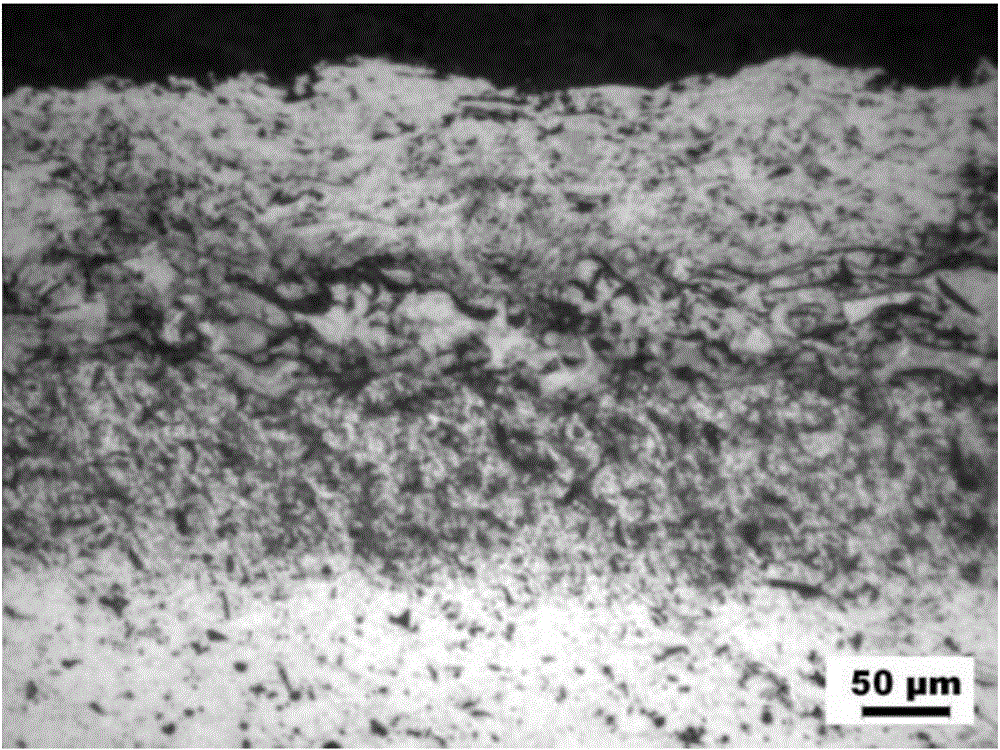

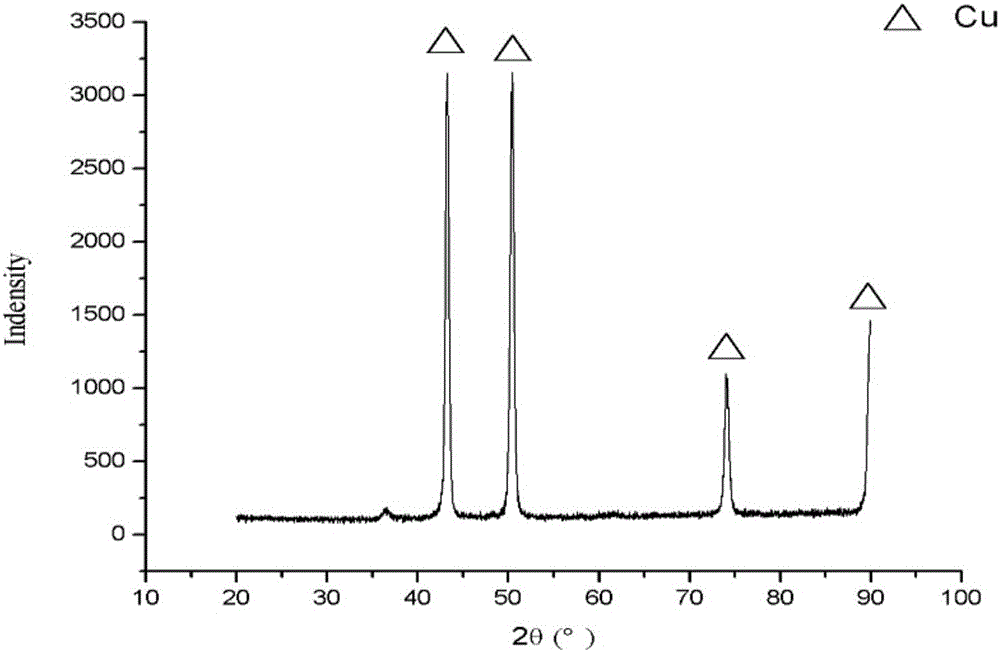

[0035] The aluminum alloy-based composite material in this embodiment includes an aluminum alloy matrix, and the surface of the aluminum alloy matrix is sequentially attached with a bonding layer and a functional layer from the inside to the outside, and the bonding layer is made of aluminum-coated nickel composite powder The aluminum-nickel alloy layer, the functional layer is a copper coating. Wherein, the bonding layer is made by plasma spraying aluminum-coated nickel composite powder on the surface of the aluminum alloy substrate; the functional layer is made by plasma spraying pure copper powder on the bonding layer of the aluminum alloy substrate. The thickness of the adhesive layer was 50 μm, and the thickness of the functional layer was 50 μm.

[0036] The preparation method of the aluminum alloy matrix composite material of this embodiment includes the following steps:

[0037] 1) After the surface of the aluminum alloy substrate is purified by chemical degreasing,...

Embodiment 2

[0044] The aluminum alloy-based composite material in this embodiment includes an aluminum alloy matrix, and the surface of the aluminum alloy matrix is sequentially attached with a bonding layer and a functional layer from the inside to the outside, and the bonding layer is made of aluminum-coated nickel composite powder The aluminum-nickel alloy layer, the functional layer is a copper coating. Wherein, the bonding layer is made by plasma spraying aluminum-coated nickel composite powder on the surface of the aluminum alloy substrate; the functional layer is made by plasma spraying pure copper powder on the bonding layer of the aluminum alloy substrate. The thickness of the adhesive layer was 50 μm, and the thickness of the functional layer was 100 μm.

[0045] The preparation method of the aluminum alloy matrix composite material of this embodiment includes the following steps:

[0046] 1) After the surface of the aluminum alloy substrate is purified by chemical degreasing...

Embodiment 3

[0051] The aluminum alloy-based composite material in this embodiment includes an aluminum alloy matrix, and the surface of the aluminum alloy matrix is sequentially attached with a bonding layer and a functional layer from the inside to the outside, and the bonding layer is made of aluminum-coated nickel composite powder The aluminum-nickel alloy layer, the functional layer is a copper coating. Wherein, the bonding layer is made by plasma spraying aluminum-coated nickel composite powder on the surface of the aluminum alloy substrate; the functional layer is made by plasma spraying pure copper powder on the bonding layer of the aluminum alloy substrate. The adhesive layer had a thickness of 100 μm, and the functional layer had a thickness of 150 μm.

[0052] The preparation method of the aluminum alloy matrix composite material of this embodiment includes the following steps:

[0053] 1) After the surface of the aluminum alloy substrate is purified by chemical degreasing, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com