Long fiber filler reinforced resin pellet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

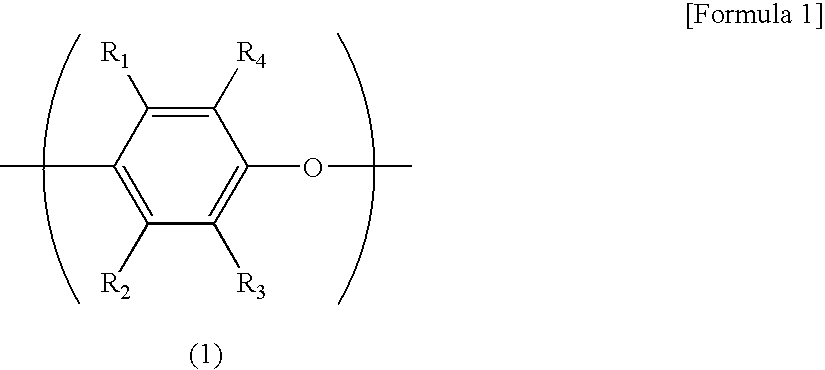

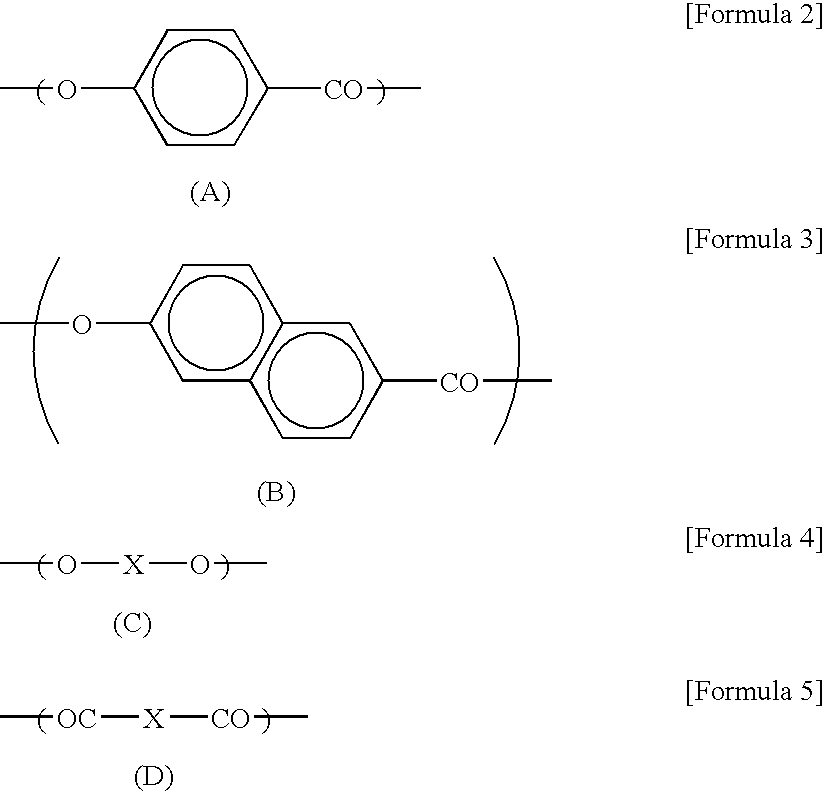

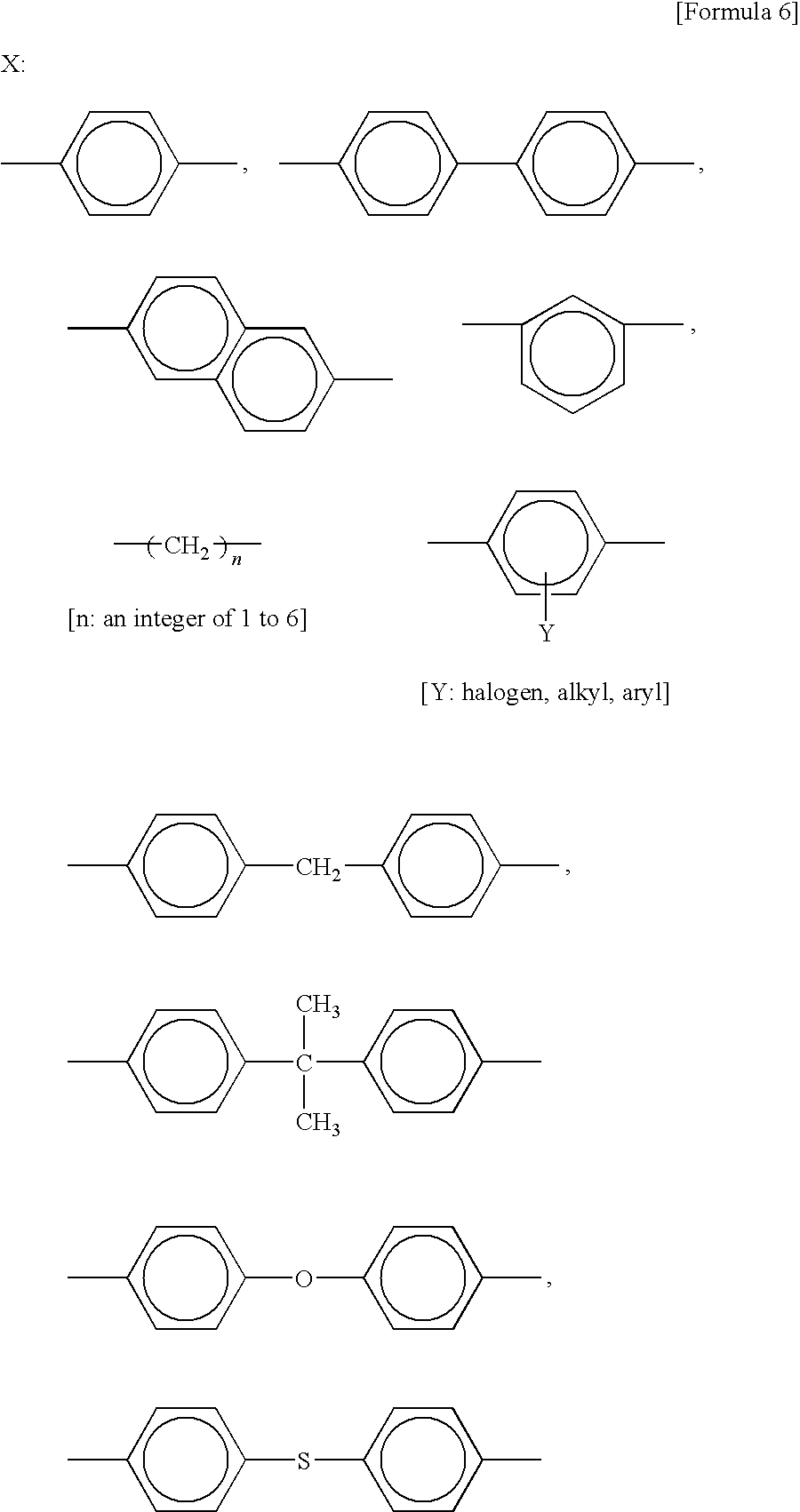

Method used

Image

Examples

preparation example 1

Production of LCP

[0456]In a 2-L polymerization reactor with a stirrer and a evaporation line p-hydroxybenzoic acid, 2-hydroxy-6-naphthoic acid, hydroquinone, 2,6-naphthalenedicarboxylic acid and acetic anhydride were charged and subjected to a polycondensation eliminating acetic acid according to the following procedures. The reactor charged with raw materials was heated from 40° C. to 190° C. over 3 hours under a nitrogen gas atmosphere, kept at 190° C. for 1 hour, further heated up to 325° C. over 2 hours, and left for reaction for 10 min. Next the reactor was vacuumed to 20 mmHg at 325° C. for 20 min, and left for reaction additionally for 5 min to complete polycondensation. As the result of polymerization, substantially theoretical amount of acetic acid was distilled off to obtain the liquid crystal polyester having the theoretical structural formula as represented by the following formula.

[0457]The melting point by DSC was 319° C. The melt viscosity measured using a capillary r...

preparation example 2

Production of Aromatic Polyamide

Polyamide 9T

[0458]According to the method described in an example of Japanese Patent Laid-Open No. 2000-103847, terephthalic acid as a dicarboxylic acid component, 1,9-nonamethylenediamine and 2-methyl-1,8-octamethylenediamine as diamine components, octylamine or benzoic acid as a terminal capping agent, sodium hypophosphite monohydrate as a polymerization catalyst, and distilled water were charged into an autoclave, which was closed hermetically (water content in the reaction system: 25% by mass). After replaced thoroughly with nitrogen, the autoclave was heated up over 2 hours to the internal temperature of 260° C. with stirring, and left reacting under the same condition. The internal pressure was 46 atm.

[0459]Next, keeping the internal temperature of the reactor at 260° C. and the water content at 25% by mass, the reaction product was discharged through a nozzle (6 mm diameter) at the bottom of the reactor over 3 min under a nitrogen atmosphere in...

example 1 to example 5

Examples and Comparative Examples

[0501]The maximum cylinder temperature of an extruder in a production facility of a long fiber reinforced resin, which was a co-rotating twin screw extruder (ZSK25: Coperion) provided with an feeding port at an upstream zone and a dipping bath with resin impregnating rolls (Kobe Steel, Ltd.) installed at the front end of the co-rotating twin screw extruder, was set at 320° C., and PS / PPE1 was fed through the extruder feeding port, and molten at a screw rotation speed of 300 rpm and filled in the dipping bath with resin impregnating rolls. Meanwhile, 2 long-fiber glass fiber rovings with filament diameter of 17 μm (ER2400T-448N by Nippon Electric Glass Co., Ltd.) were introduced from a roving supply stand to the dipping bath with resin impregnating rolls, where the molten resin in the dipping bath was impregnated into the long-fiber glass fiber rovings, which were then continuously drawn out through a nozzle (diameter 2.8 mm) of the dipping bath at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com