Composite separator membrane, preparation method thereof, and application thereof in lithium ion batteries

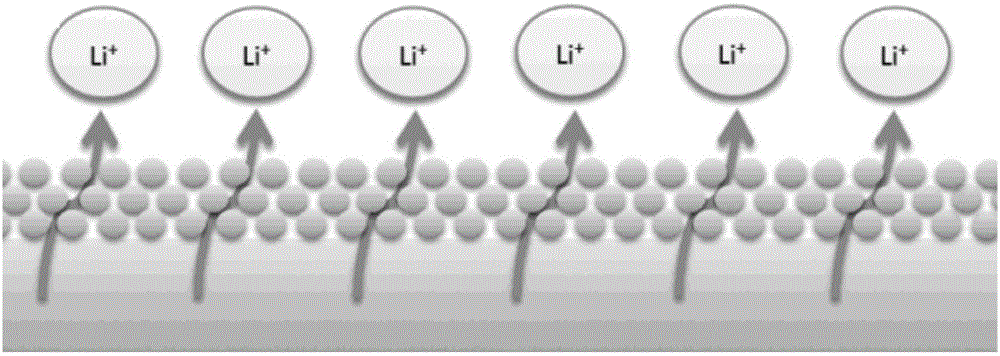

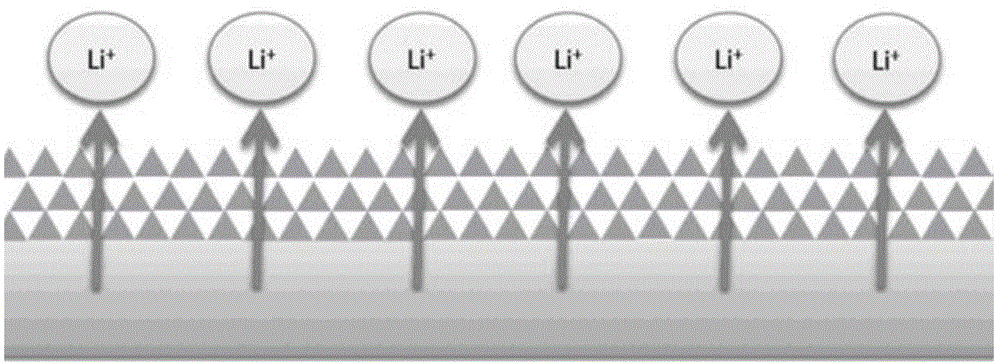

A composite diaphragm and lithium-ion technology, applied in secondary batteries, battery components, circuits, etc., can solve the problems of high-speed charging/discharging performance damage, battery performance degradation, and no positive improvement, etc., to achieve excellent Effects of charge/discharge characteristics, improvement of battery safety, and reduction of short-circuit phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The application also provides a preparation method of a composite diaphragm, comprising the following steps:

[0065] Mix the binder, organic solvent and garnet-type conductor material, and obtain a suspension after dispersion;

[0066] The suspension is coated on the surface of the diaphragm and dried to obtain a composite diaphragm.

[0067] The garnet type conductor material described in the present application is preferably a lithium ion conductor as shown in formula (I):

[0068] Li x A 3 B 2 C δ o 12±λ (I);

[0069] 3≤x≤8, 0≤λ≤1, 0≤δ≤1;

[0070] A is selected from Na, K, Mg, Ca, Sr, Ba, Sc, Y, Al, Cr, Fe, Mo, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm One or more of , Yb and Lu; when A is selected from more than one element, the sum of the atoms of each element is 3;

[0071] B is selected from one or more of Zr, Hf, Nb, Ta, W, In, Sb, Bi, Te, Y, Al, Cr, Fe, Mo, La, Sc, Ba, Sr, Ca, Sn and Mg species; when B is selected from more than one element, th...

Embodiment 1

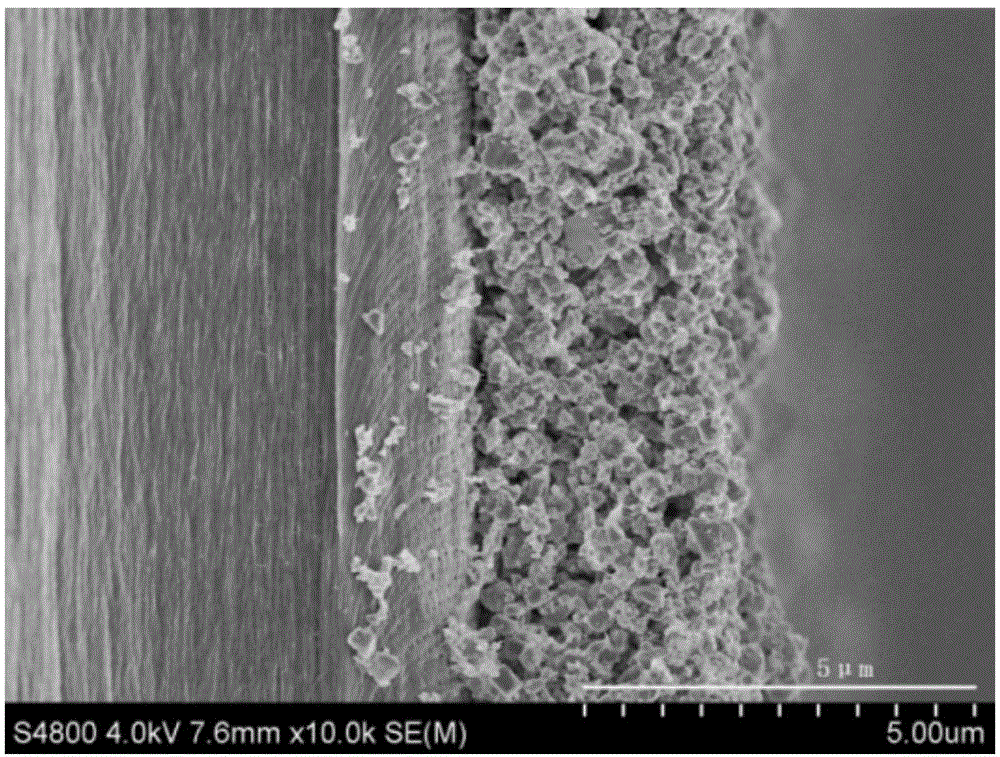

[0087] With an average particle size of 0.3 micron Li 3 Y 3 Te 2 o 12 It is a ceramic layer, and the mass ratio of binder, organic solvent and conductor material is 1:20:10. After the three are mixed and dispersed by planetary ball mill for 2 hours, the AFA-II automatic coating machine of Shanghai Pushen Chemical Machinery Co., Ltd. PP-PE-PP three-layer composite separator (celgard 2300) was coated on one side, dried in an oven at 60°C for 4 hours, then transferred to a vacuum oven at 60°C for 10 hours to obtain a ceramic composite separator. The thickness of the diaphragm before coating was 25 microns, and the thickness of the diaphragm after coating and drying was 27 microns, and the coating thickness was calculated to be 2 microns. Li 3 Y 3 Te 2 o 12 -PP-PE-PP composite membrane section scanning electron microscope photos image 3 As shown, the comparison of coating thickness, liquid absorption and conductivity data is shown in Table 1, organic battery separator and...

Embodiment 2

[0090] With an average particle size of 0.3 micron Li 5 La 3 Ta 2 o 12 It is a ceramic layer, and the mass ratio of binder, organic solvent and conductor material is 1:20:10. After the three are mixed and dispersed by planetary ball mill for 2 hours, the AFA-II automatic coating machine of Shanghai Pushen Chemical Machinery Co., Ltd. PP-PE-PP three-layer composite separator (celgard 2300) was coated on one side, dried in an oven at 60°C for 4 hours, then transferred to a vacuum oven at 60°C for 10 hours. get Li 5 La 3 Ta 2 o 12 Ceramic composite diaphragm. The comparison of coating thickness, liquid absorption rate and electrical conductivity data is shown in Table 1, and the comparison of heat shrinkage data is shown in Figure 8 , the curve ○ in the figure is the thermal shrinkage curve of the organic separator treated at the undetermined temperature, and the curve ● is the thermal shrinkage curve of the composite separator prepared in this example under the undeterm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com