Technology for coating ZrO2/Fe2O3 composite film on surface of diamond by sol-gel method

A sol-gel method and a composite thin film technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high production cost, limited protection performance of diamond abrasives, weak bonding force between the film layer and the ceramic bond, etc. Improved wettability, enhanced holding force, and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

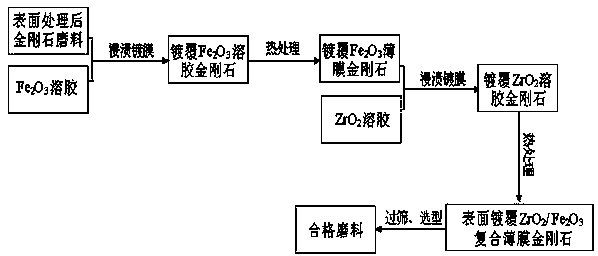

[0026] see figure 1 , in the embodiment of the present invention, a ZrO coating on the diamond surface by sol-gel method 2 / Fe 2 o 3 The technique of composite film, comprises the following steps:

[0027] (1) Surface treatment of diamond abrasives: first immerse diamond abrasives in hot sulfuric acid with a temperature of 80°C and a concentration of 98%, activate the surface for 1 hour, and then rinse the surface of the abrasive with deionized water. Until the cleaning solution is neutral, finally use ultrasonic waves with a frequency of 80KHz to clean the surface of the abrasive in an anhydrous ethanol medium for 1 hour, and dry the cleaned diamond abrasive at 70°C for use;

[0028] (2) Preparation of Fe 2 o 3 Sol and coated Fe 2 o 3 Thin film: will analyze pure FeCl 3 The powder is dissolved in HCl solution with a concentration of 1mol / L to prepare FeCl 3 Concentration of 5wt% solution, high-speed stirring for 1 hour, and then under high-speed stirring conditions t...

Embodiment 2

[0032] see figure 1 , in the embodiment of the present invention, a ZrO coating on the diamond surface by sol-gel method 2 / Fe 2 o 3 The technique of composite film, comprises the following steps:

[0033] (1) Surface treatment of diamond abrasives: first immerse diamond abrasives in hot sulfuric acid at a temperature of 90°C and a concentration of 99%, activate the surface for 1.5 hours, and then rinse the surface of the abrasives with deionized water. Until the pH of the cleaning solution is 7.0, finally use ultrasonic waves with a frequency of 90KHz to clean the surface of the abrasive in an anhydrous ethanol medium for 1.5 hours, and dry the cleaned diamond abrasive at 80°C for use;

[0034] (2) Preparation of Fe 2 o 3 Sol and coated Fe 2 o 3 Thin film: will analyze pure FeCl 3 The powder is dissolved in HCl solution with a concentration of 1.5mol / L to prepare FeCl 3 Concentration of 6wt% solution, high-speed stirring for 1.5 hours, and then under high-speed stirr...

Embodiment 3

[0038] see figure 1 , in the embodiment of the present invention, a ZrO coating on the diamond surface by sol-gel method 2 / Fe 2 o 3 The technique of composite film, comprises the following steps:

[0039] (1) Surface treatment of diamond abrasives: first immerse diamond abrasives in hot sulfuric acid with a temperature of 70°C and a concentration of 90%, activate the surface for 0.5 hours, and then rinse the surface of the abrasive with deionized water. Until the pH of the cleaning solution is 6.5, finally use ultrasonic waves with a frequency of 70KHz to clean the surface of the abrasive in an anhydrous ethanol medium for 0.5 hours, and dry the cleaned diamond abrasive at 60°C for use;

[0040] (2) Preparation of Fe 2 o 3 Sol and coated Fe 2 o 3 Thin film: will analyze pure FeCl 3 The powder is dissolved in HCl solution with a concentration of 0.5mol / L to prepare FeCl 3 Concentration of 4wt% solution, high-speed stirring for 0.5 hours, and then under high-speed stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com