Titanium dioxide-multi-walled carbon nano-tube-polydimethylsiloxane composite functional material as well as preparation method and application thereof

A technology of polydimethylsiloxane and multi-walled carbon nanotubes, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problem of large amount of nitric acid and increased work intensity , high acidity and other problems, achieve good molecular concentration and interaction, save production costs, clean and non-toxic reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

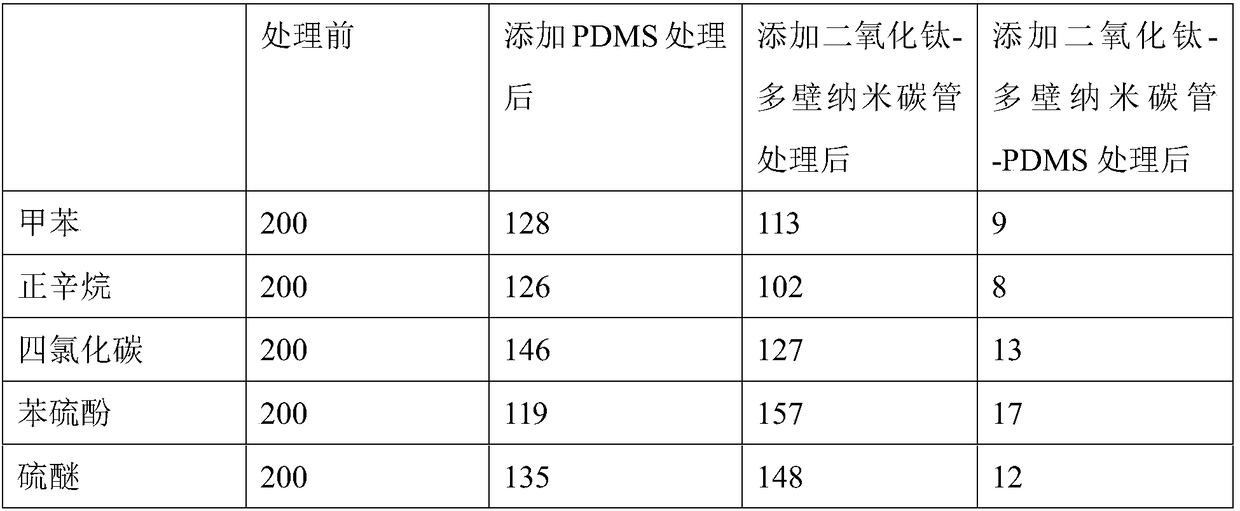

Examples

Embodiment 1

[0067] A titanium dioxide-multi-wall carbon nanotube-polydimethylsiloxane composite functional material, which is based on polydimethylsiloxane, and titanium dioxide-multi-wall carbon nanotube dry powder, prepared by a microfluidic method made microspheres.

[0068] Preparation method embodiment one

[0069] A preparation method of titanium dioxide / multi-walled carbon nanotubes / polydimethylsiloxane composite functional material, comprising the steps of:

[0070]1) Acidification and oxidation treatment of multi-walled carbon nanotubes, mixing 5g of multi-walled carbon nanotubes to a volume of 125ml with a concentration of 98% sulfuric acid kept stirring in a 250ml flask until a homogeneous solution appeared, and then added dropwise at a concentration of 30% hydrogen peroxide with a volume of 62.5ml was stirred and refluxed at 120°C for 24 hours; after the reaction, it was diluted with water until the pH returned to neutral, separated by filtration, and dried at 80°C for 2 days...

Embodiment 4

[0090] A preparation method of titanium dioxide / multi-walled carbon nanotubes / polydimethylsiloxane composite functional material, comprising the steps of:

[0091] 1) Acidification and oxidation treatment of multi-walled carbon nanotubes, mixing 5g of multi-walled carbon nanotubes to a volume of 125ml with a concentration of 98% sulfuric acid kept stirring in a 250ml flask until a homogeneous solution appeared, and then added dropwise at a concentration of 30% hydrogen peroxide with a volume of 62.5ml was stirred and refluxed at 120°C for 24 hours; after the reaction, it was diluted with water until the pH returned to neutral, separated by filtration, and dried at 80°C for 2 days to obtain acidified and oxidized polysaccharides. walled carbon nanotubes;

[0092] 2) Mix 35 mg of acidified and oxidized multi-walled carbon nanotubes with 0.5 wt % 2 ml of sodium p-dodecylbenzenesulfonate aqueous solution, sonicate for 12 hours, then pour into 20 ml of isopropanol and stir evenly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com