Zinc-based solder for aluminum/copper brazing and preparing method thereof

A copper brazing and brazing technology, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of poor corrosion resistance and poor manufacturability of joints, and achieve good corrosion resistance and shear resistance. The effect of high strength and good wettability

Inactive Publication Date: 2013-09-25

UNIV OF SCI & TECH BEIJING +1

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The object of the invention is to propose a zinc-based solder for aluminum / copper brazing, aiming at the problems of poor manufacturability and poor corrosion resistance of the joint for Zn-Al-based brazing Al / Cu joints

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0011] The present invention will be further described below with examples, but the present invention is not limited to these examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

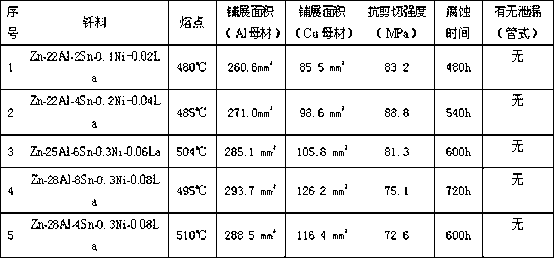

A zinc-based solder for aluminum / copper brazing and a preparing method thereof can be applied to furnace brazing and flame brazing of aluminum / copper dissimilar metals and belong to the field of solders. According to mass percent, the zinc-based solder contains 22-28% of aluminum, 1-8% of tin, 0.1-0.3% of nickel, 0.01-0.1% of raw earth lanthanum, and the balance zinc. The zinc-based solder is formed by simple substances of Zn, Al, Sn, Ni and intermediate alloy Al-La. The preparing method includes the following steps: 1 calculating and weighing raw materials; 2 smelting Zn-Al-Sn-Ni alloy; 3 adding the intermediate alloy Al-La; 4 performing heat preservation; 5 performing cooling and taking out the solder. The melting point of the zinc-based solder is 480-510 DEG C. When the zinc-based solder is used for brazing Al / Cu joints, the brazing manufacturability is good and the joints are good in corrosion resistance and high in strength.

Description

technical field [0001] The invention relates to a zinc-based solder for aluminum / copper brazing and a preparation method thereof, belonging to the field of brazing materials of aluminum / copper dissimilar metals. Background technique [0002] In the field of brazing of Al / Cu dissimilar metals, Zn-Al-based brazing Al / Cu joints have higher shear strength than Al-based and Sn-based brazing joints, and are an ideal Al / Cu joint. Brazing solder. However, there are still two problems in brazing Al / Cu dissimilar joints with Zn-Al solder: (1) The wettability between Zn-Al-based solder and Cu base metal is poor (the spreading area is small), and the Al / Cu The joint forming mainly depends on the wetting between the solder and the Al base material, and the manufacturability of the solder is poor; (2) The corrosion potential of the Zn-Al solder is lower than that of the Al and Cu base materials, which is easy to cause Al / Cu corrosion. The electrochemical corrosion of joints, the cor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/28C22C1/03

Inventor 黄继华羊浩杨文静王奇李德华曹珍珍

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com