High temperature resistant lithium titanate battery and formation and aging method thereof

A lithium titanate battery, high-temperature-resistant technology, applied in the field of lithium-ion batteries, to achieve the effects of good wettability, increased service life, and improved charge and discharge stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high-temperature-resistant lithium titanate battery with a capacity of 20Ah, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte, and an aluminum-plastic film outer packaging.

[0035] The active material on the positive electrode sheet is LiNi with a particle size of 6um 0.5 co 0.3 mn 0.2 o 2 Ternary material, the active material on the negative electrode sheet is lithium titanate with a particle size of 0.9um, the thickness of the wet-process PE separator is 16um, the porosity is 45%, and the air permeability is 15cm 3 / sec; the solvent of the electrolyte is dimethyl carbonate and diethyl carbonate, and the electrolyte contains LiPF 6 , the concentration is 1.2mol / L, and the electrolyte also contains carboxylate methyl propionate and boron-containing additive trimethyl borate, the mass fraction of carboxylate in the electrolyte is 33%, and the boron-containing additive is in the electrolyte The mass fraction in is 1%.

...

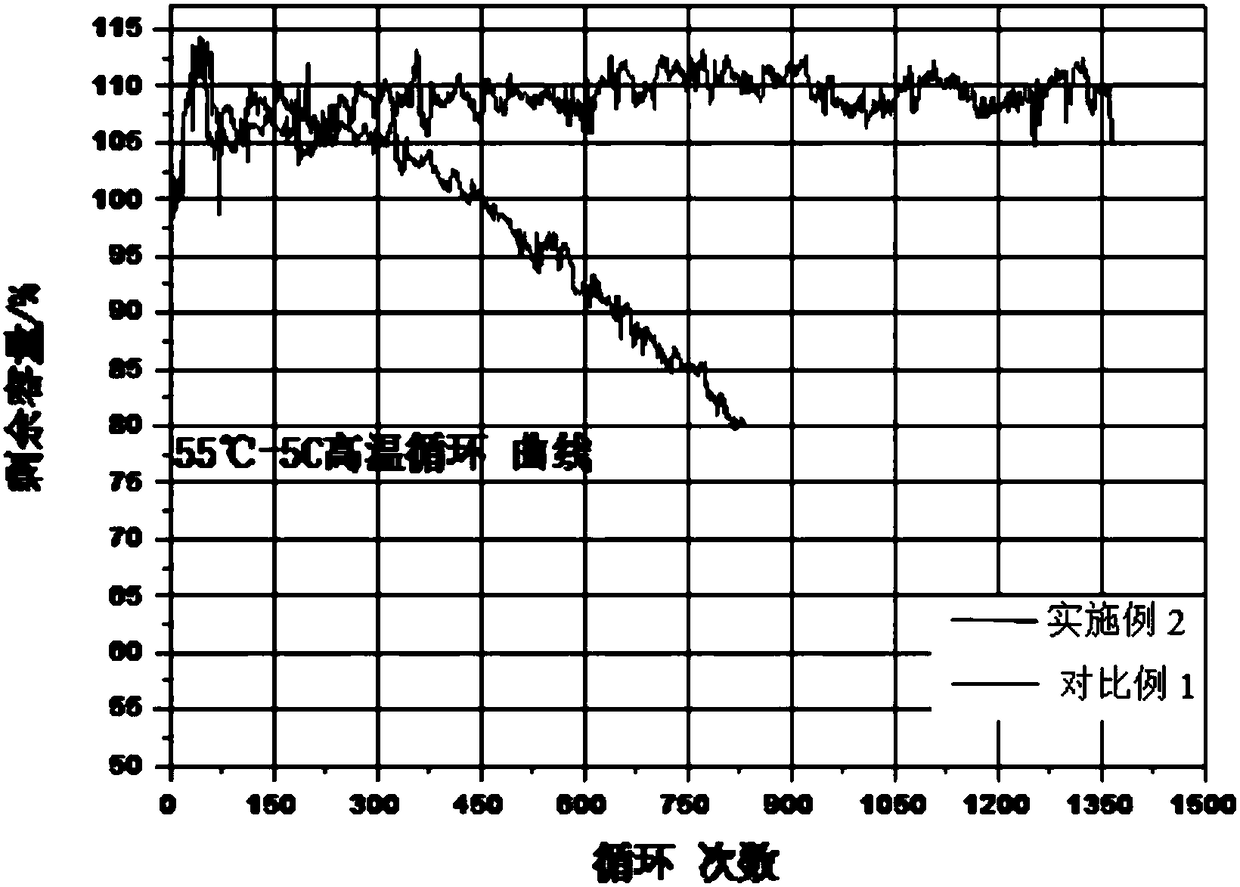

Embodiment 2

[0043] A high-temperature-resistant lithium titanate battery with a capacity of 20Ah, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte, and an aluminum-plastic film outer packaging.

[0044] The active material on the positive electrode sheet is LiNi with a particle size of 6um 0.5 co 0.3 mn 0.2 o 2 Ternary material, the active material on the negative electrode sheet is lithium titanate with a particle size of 1.2um, the thickness of the wet-process PE diaphragm is 12um, the porosity is 50%, and the air permeability is 20cm3 / sec; The solvent is propylene carbonate and diethyl carbonate, the electrolyte contains lithium salt, the concentration of LiPF6 is 1.3mol / L, and the electrolyte also contains carboxylate ethyl acetate and boron-containing additive B 2 o 3 , the mass fraction of the carboxylate in the electrolytic solution is 35%, and the mass fraction of the boron-containing additive in the electrolytic solution is 2%.

...

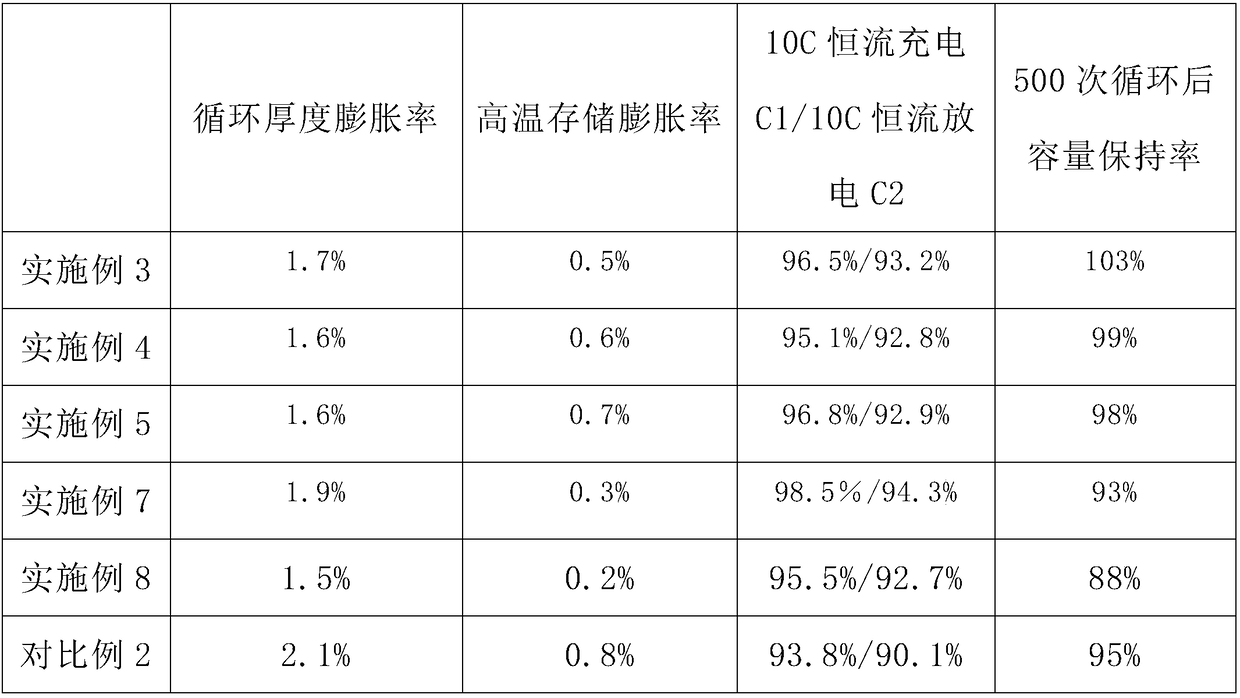

Embodiment 3

[0052] A high-temperature-resistant lithium titanate battery with a capacity of 20Ah, including a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte, and an aluminum-plastic film outer packaging.

[0053] The active material on the positive electrode sheet is LiNi with a mass fraction of 70% 0.33 co 0.33 mn 0.33 o 2 Ternary materials and a mass fraction of 30% lithium manganese iron phosphate, the active material on the negative electrode sheet is lithium titanate with a particle size of 2um, the thickness of the wet-process PE diaphragm is 15um, the porosity is 50%, and the air permeability is 30cm 3 / sec; the solvent of the electrolyte is propylene carbonate and dimethyl carbonate, and the electrolyte contains lithium salt, LiPF 6 Concentration is 1.8mol / L, also contains carboxylate propyl formate and boron-containing additive triethyl borate in electrolyte, the mass fraction of carboxylate in electrolyte is 38%, the boron-containing additiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com