Novel hydrophobic silica aerogel composite separator for lithium ion battery

A lithium-ion battery and silicon dioxide technology, applied in electrical components, battery pack parts, circuits, etc., can solve the problems of difficulty in ensuring the wettability of diaphragms and organic electrolytes, and achieve light weight, improved electrochemical performance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

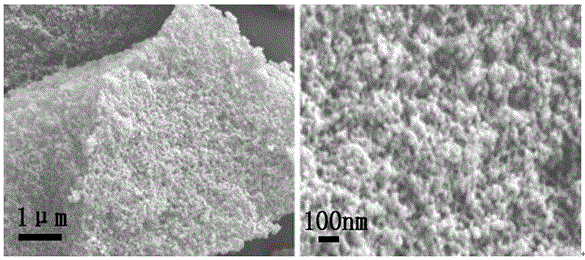

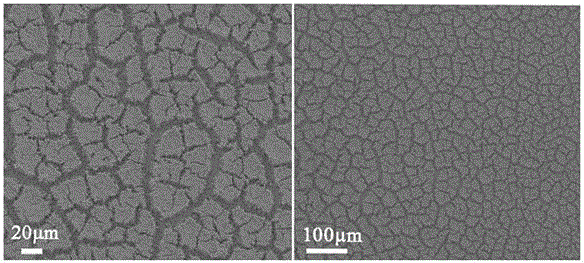

[0027] Weigh 0.3646 g of the prepared hydrophobic silica airgel (such as figure 1 ) and 0.1823 g PVDF (polyvinylidene fluoride) were added to the beaker, and an appropriate amount of 1-methyl-2-pyrrolidone was added, stirred for 2 hours and then ultrasonicated for 20 minutes, and then the resulting slurry was coated on the PP (polypropylene) diaphragm, Adjust the scraper parameters of the coating machine (Pengxiang Yunda PX-TB-W type) to 180 μm, and the scraper moving speed to 7.5 cm / min for coating, and put the coated composite diaphragm into a 70°C normal pressure drying oven After drying for 24 h, a 43 μm-thick silicon dioxide gas-condensed composite membrane can be obtained, such as figure 2 shown.

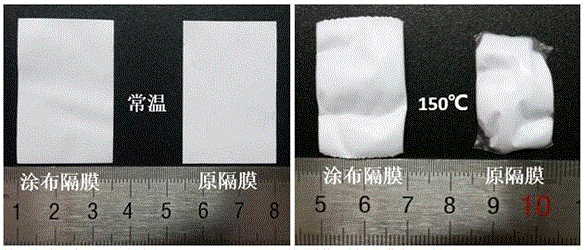

[0028] I. Conduct heat resistance tests on composite separators, such as image 3 As shown, under the condition of 150 ℃, the shrinkage rate of the composite diaphragm is only 33% of the original diaphragm, II. the wettability test of the electrolyte is carried out to the c...

Embodiment 2

[0030] Weigh 0.4376 g of the prepared hydrophobic silica airgel and 0.055 g of PVDF (polyvinyl fluoride) into a beaker, add an appropriate amount of N,N-dimethylformamide (DMF), stir for 2 hours, and then sonicate for 20 Minutes later, the resulting slurry is coated on the PP (polypropylene) diaphragm, adjust the scraper parameter of the coating machine to 150 μm, and the scraper moving speed is 7.5 cm / s for coating, and put the coated PP diaphragm into a 60°C Dry in a vacuum oven for 24 h to obtain a 33 μm-thick silicon dioxide gas-condensed composite diaphragm.

[0031] I. Carry out the heat resistance test on the composite diaphragm. Under the condition of 150℃, the shrinkage rate of the composite diaphragm is only 57% of the original diaphragm. II. Carry out the wettability test of the electrolyte on the composite diaphragm, which shows that the composite diaphragm is better than the original PP The wettability of the diaphragm has been significantly improved. III. With li...

Embodiment 3

[0033] Weigh 0.2520 g of the prepared hydrophobic silica airgel and 0.076 g of PVDF (polyvinylidene fluoride) into the beaker, add an appropriate amount of 1-methyl-2-pyrrolidone, stir for 2 hours and then ultrasonic for 20 minutes, then The obtained slurry is coated on the PE (polyethylene) diaphragm, the parameter of the scraper of the coating machine is adjusted to 100 μm, and the moving speed of the scraper is 7.5 cm / s for coating, and the coated PE diaphragm is placed in a 60°C normal pressure drying In the oven, dry for 24 h to obtain a 30 μm-thick silicon dioxide gas-condensed composite diaphragm.

[0034] I. Test the heat resistance of the composite diaphragm. Under the condition of 120°C, the shrinkage rate of the composite diaphragm is only 57% of the original diaphragm. II. Conduct the wettability test of the electrolyte on the composite diaphragm, which shows that the composite diaphragm is better than the original PE The wettability of the separator has been signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com