Method for induction heating fusion-cast welding of copper-tungsten mold

A technology of induction heating and induction coil, which is applied in the field of induction heating melting and casting welding in copper-tungsten molds, can solve the problems of slag inclusion at the bonding interface, unstable bonding strength and performance, and can not guarantee the welding rate, etc., and achieve stable bonding performance , Reduce interfacial stress, excellent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

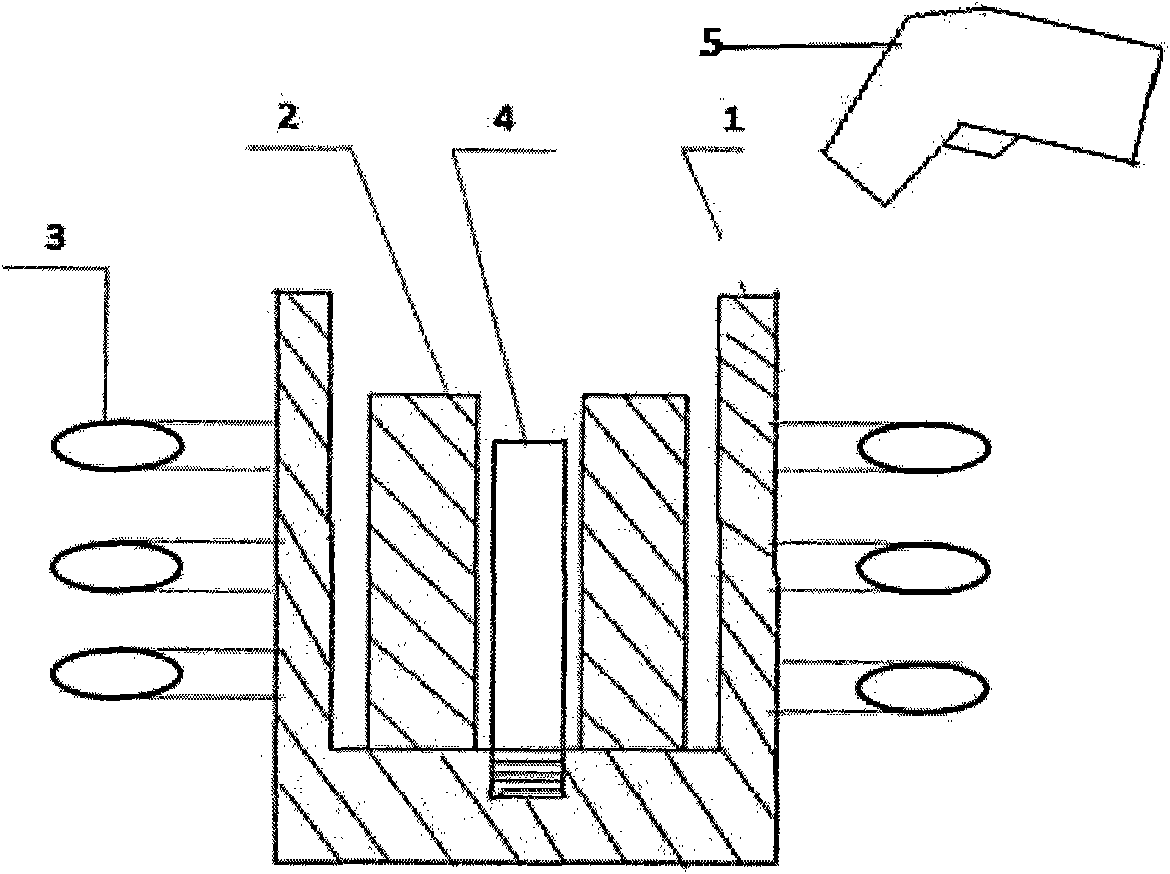

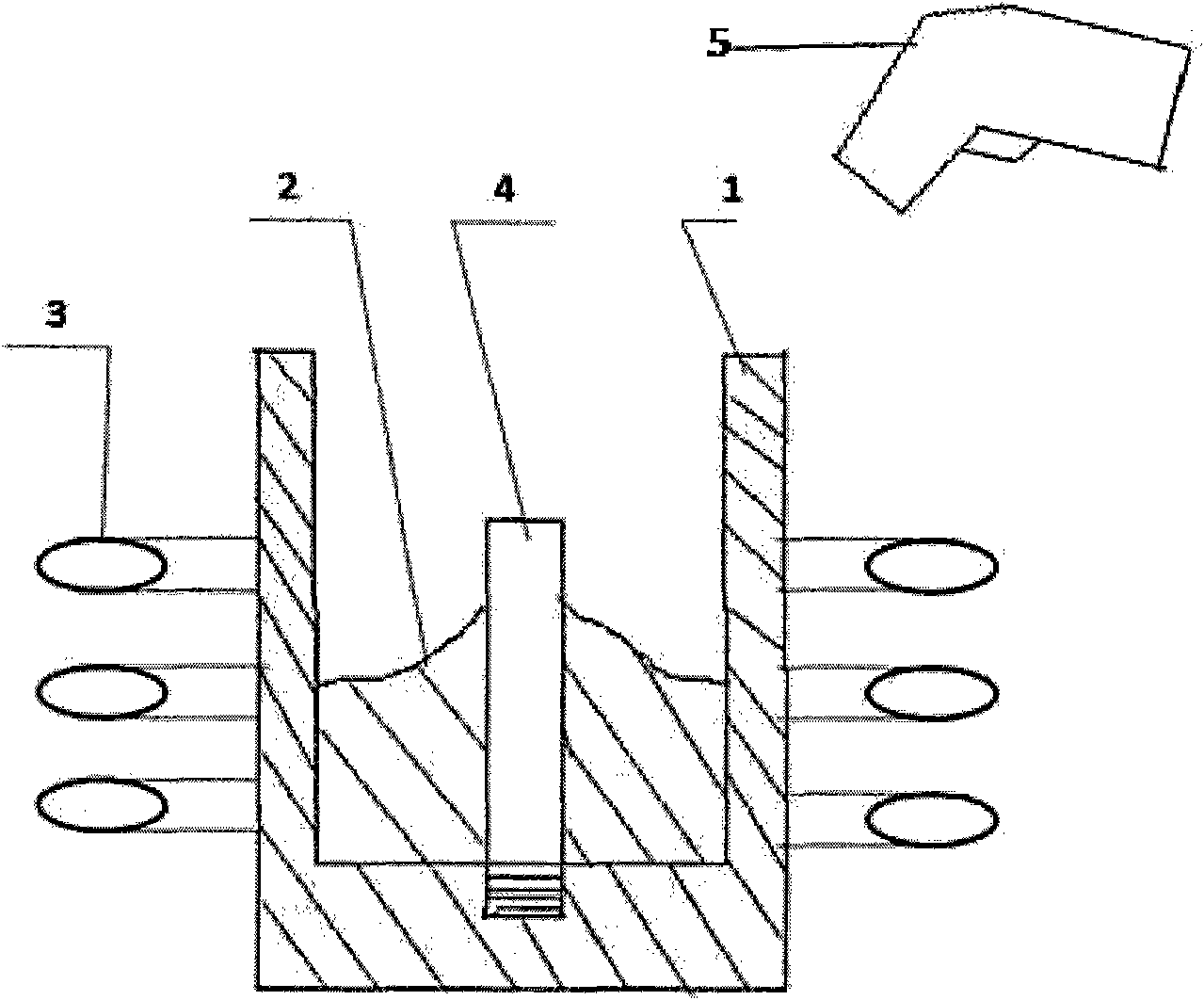

[0030] exist Deposit welding pure copper layer on the surface of powder metallurgy tungsten rod cylinder with diameter:

[0031] Process the graphite mould, the size of the molding die is: outer diameter 25mm, inner diameter 19mm, height 25mm, bottom thickness 6mm. Turn the external thread on the bottom of the tungsten rod, the specification is Same as at the bottom of the graphite forming die internal thread. Tungsten rods, copper rings and molds are cleaned before welding, firstly acetone cleaning to remove oil stains, followed by concentrated sulfuric acid (95%-97%): concentrated hydrochloric acid (38%): water = 15: 15: 70 (volume ratio ) ratio to prepare a cleaning solution for cleaning, and after cleaning, the fast connection between the tungsten rod and the molding die is realized through threads. Process the copper rod with an outer diameter of 18mm, an inner diameter of 6mm, and a height of 15mm, place it in the forming mold, and cover it outside the tungsten ro...

Embodiment 2

[0033] exist Deposit welding pure copper layer on the surface of powder metallurgy tungsten rod cylinder with diameter:

[0034] Process the graphite mould, the size of the molding die is: outer diameter 25mm, inner diameter 19mm, height 25mm, bottom thickness 6mm. Turn the external thread on the bottom of the tungsten rod, the specification is Same as at the bottom of the graphite forming die internal thread. Tungsten rods, copper rings and molds are cleaned before welding, firstly acetone cleaning to remove oil stains, followed by concentrated sulfuric acid (95%-97%): concentrated hydrochloric acid (38%): water = 15: 15: 70 (volume ratio ) ratio to prepare a cleaning solution for cleaning, and after cleaning, the fast connection between the tungsten rod and the molding die is realized through threads. Process the copper rod, the size is 18mm in outer diameter, 8mm in inner diameter, and 15mm in height, place it in the forming mold, and cover it outside the tungsten rod...

Embodiment 3

[0036] exist Deposit welding pure copper layer on the surface of powder metallurgy tungsten rod cylinder with diameter:

[0037] Process the graphite mould, the size of the molding die is: outer diameter 25mm, inner diameter 19mm, height 25mm, bottom thickness 6mm. Turn the external thread on the bottom of the tungsten rod, the specification is Same as at the bottom of the graphite forming die internal thread. Tungsten rods, copper rings and molds are cleaned before welding, firstly acetone cleaning to remove oil stains, followed by concentrated sulfuric acid (95%-97%): concentrated hydrochloric acid (38%): water = 15: 15: 70 (volume ratio ) ratio to prepare a cleaning solution for cleaning, and after cleaning, the fast connection between the tungsten rod and the molding die is realized through threads. Process the copper rod, the size is 18mm in outer diameter, 11mm in inner diameter, and 15mm in height, place it in the forming mold, and cover it outside the tungsten r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com