Wear-resistant anti-corrosion electric arc spraying cored wire for protecting surface of copper matrix

A powder core wire, arc spraying technology, applied in coating, fusion spraying, metal material coating technology and other directions, can solve the problems of low bonding strength, decreased thermal conductivity of tuyere, poor bonding between reinforcement layer and substrate, etc. Antioxidant properties are improved, bonding strength is improved, and bonding strength is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The outer cladding is made of a copper-aluminum alloy strip with a width of 10mm and a thickness of 0.2mm (the mass percentage of aluminum is 2%) to make a powder core wire material of Ф2mm, and the filling rate of the powder core is 32%. The mass percentages of the medicinal powder components of the core silk material are as follows: metal chromium: 1%; metal zirconium: 0.5%; metal silver: 0.1%; metal copper: 98.4%.

[0018] The powder core wire made according to the above specifications is arc sprayed on the pure copper substrate, and then the sprayed coating formed by heat treatment has a HV hardness of 215, a softening temperature of 805°C, a bonding strength of 60MPa, and a thermal conductivity of 86% of pure copper.

Embodiment 2

[0020] The outer cladding is made of a copper-aluminum alloy strip with a width of 10mm and a thickness of 0.2mm (the mass percentage of aluminum is 2.5%) to make a powder core wire material of Ф2mm, and the filling rate of the powder core is 34%. The mass percentages of the medicinal powder components of the core silk material are as follows: metal chromium: 1.2%; metal zirconium: 0.8%; metal silver: 0.3%; metal copper: 97.7%.

[0021] The powder core wire made according to the above specifications is arc sprayed on the pure copper substrate, and then the spray coating formed by heat treatment has a HV hardness of 229, a softening temperature of 806°C, a bonding strength of 57MPa, and a thermal conductivity of 84% of pure copper.

Embodiment 3

[0023] The outer cladding is made of a copper-aluminum alloy strip with a width of 10mm and a thickness of 0.2mm (the mass percentage of aluminum is 3%) to make a powder core wire material of Ф2mm, and the filling rate of the powder core is 35%. The mass percentages of the ingredients of the powder core wire medicinal powder are as follows: metal chromium: 1.5%; metal zirconium: 1%; metal silver: 0.5%; metal copper: 97%.

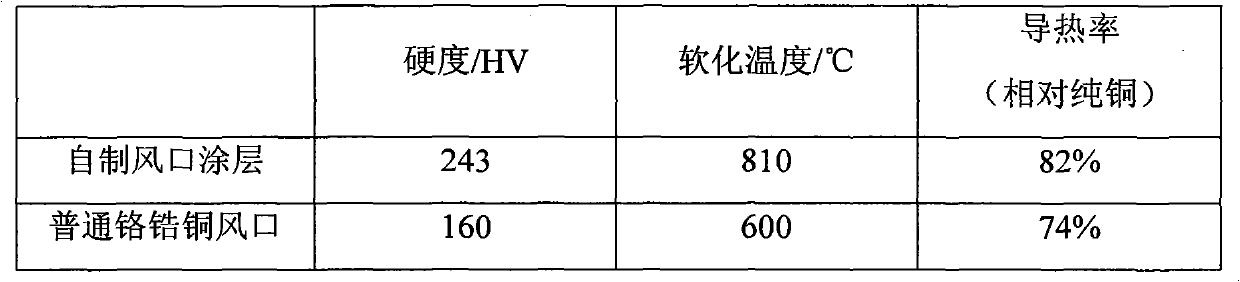

[0024] The powder core wire made according to the above specifications is arc sprayed on the pure copper substrate, and then the sprayed coating formed by heat treatment has a HV hardness of 243, a softening temperature of 810°C, a bonding strength of 54MPa, and a thermal conductivity of 82% of pure copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com