Semi-closed automatic car washing machine

A car washing machine and semi-enclosed technology, applied in the field of car washing machines, can solve problems such as inconvenient replacement of brushes, and achieve the effects of improving service life, avoiding damage and improving cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

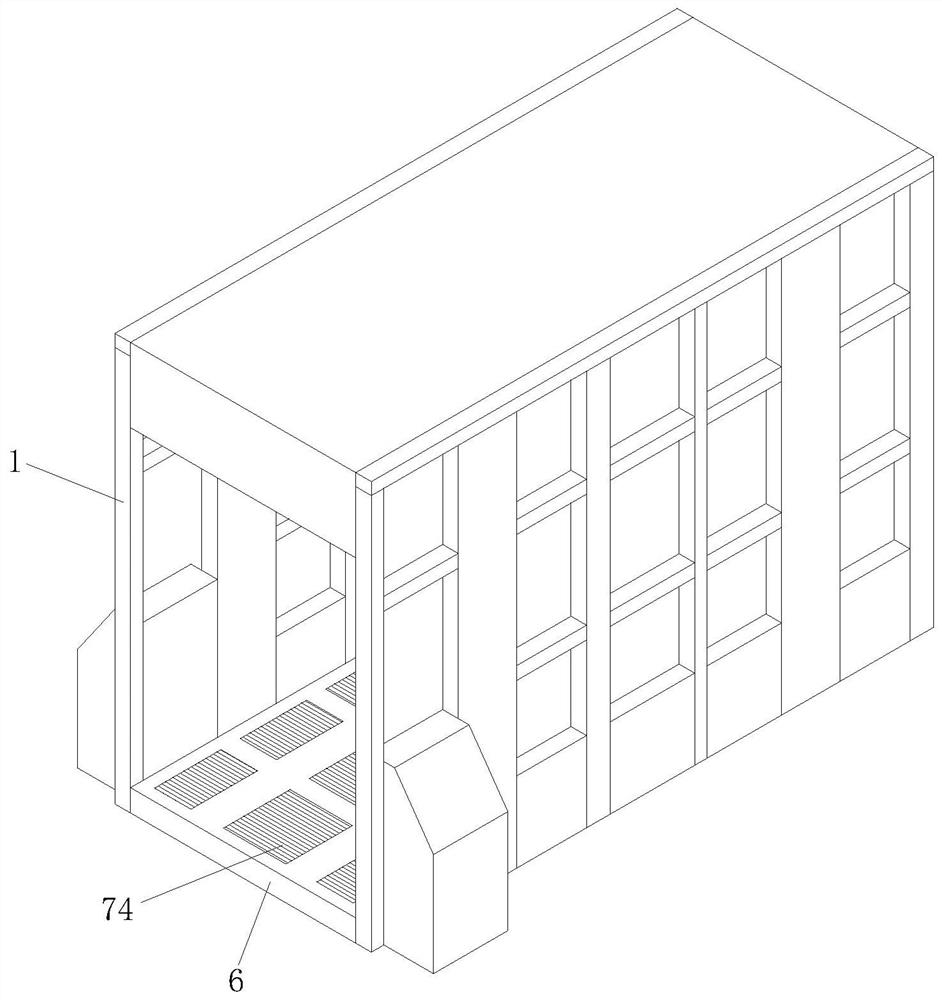

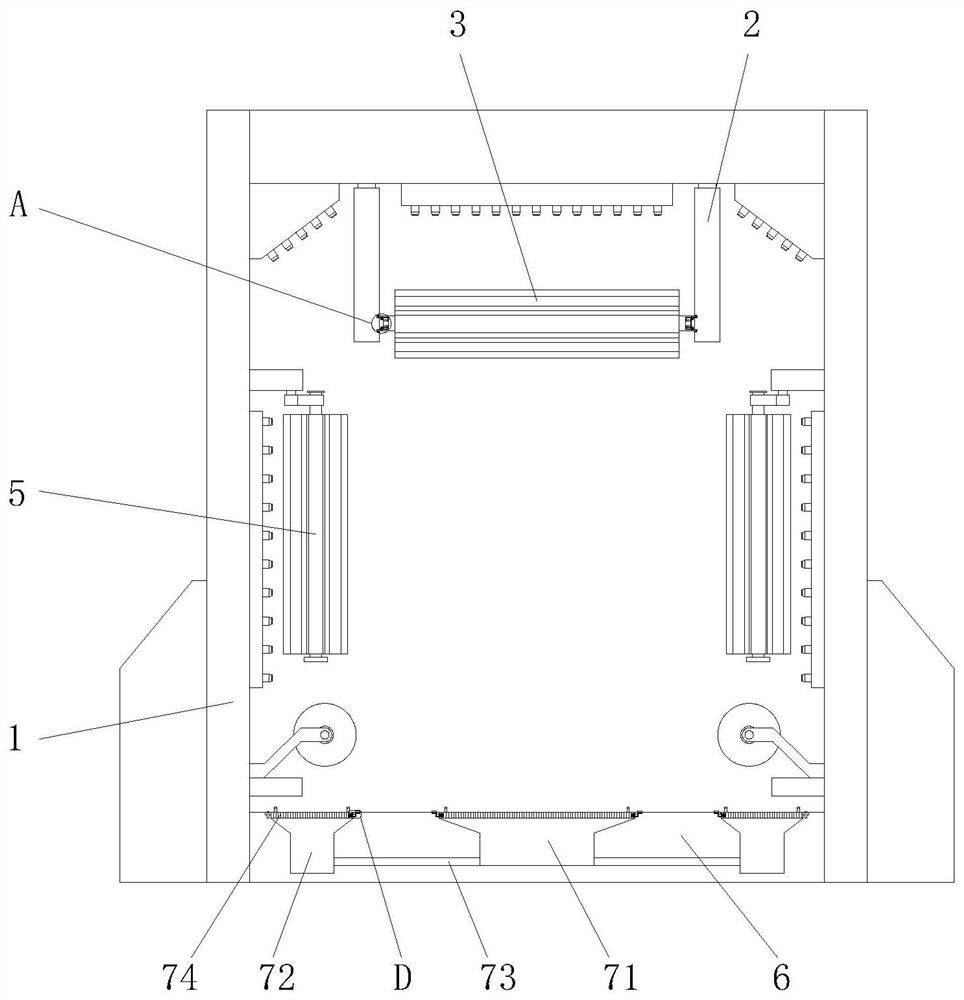

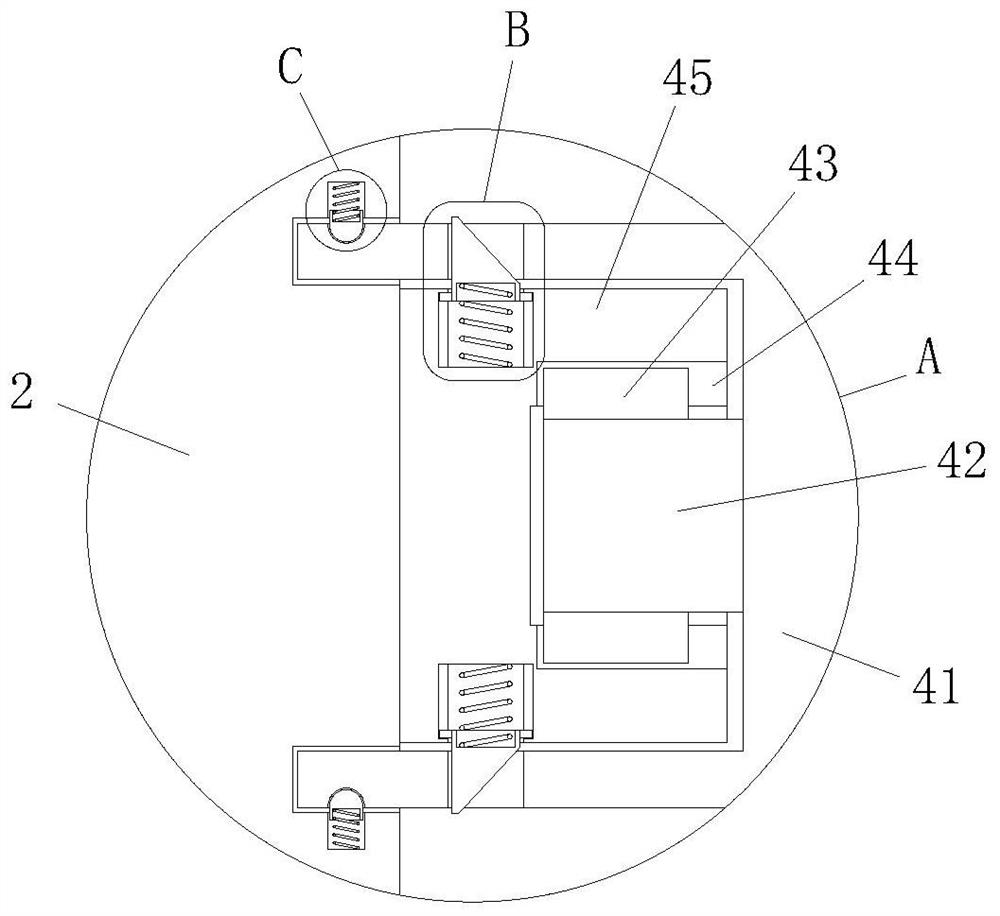

[0030] see Figure 1-6 As shown, a semi-enclosed automatic car washing machine includes a protective wall 1, a mechanical arm 2, a brush 3, a side cleaning module 5 and a base 6; as described, the inner top of the protective wall 1 is fixedly connected with a mechanical arm 2. The bottom end of the mechanical arm 2 is provided with a brush 3, and both sides of the protective wall 1 are provided with lateral cleaning modules 5, and the bottom end of the protective wall 1 is provided with a base 6, and the brush 3 and the mechanical arm 2 are provided with a connection mechanism; the connection mechanism includes a fixed shaft 41, a sleeve block 42, an insert block 43, a slot 44, a connecting shaft 45, a limit assembly and a positioning assembly, and the fixed shaft 41 One side is fixedly connected to both sides of the hair brush 3, and the side of the fixed shaft 41 away from the hair brush 3 is arranged inside the mechanical arm 2, and the cover block 42 is fixedly connected t...

Embodiment 2

[0050] see Figure 7 As shown, compared with Example 1, as another embodiment of the present invention, both sides of the clamping block 413 close to the end of the engaging cavity 414 are fixedly connected with movable blocks 416, and the movable blocks 416 are slidably connected to the movable groove 417 The inside of the movable groove 417 is provided on both sides of the inside of the engaging cavity 414; when working, the movable block 416 slides inside the movable groove 417 along with the movement of the locking block 413, and passes through the locking block 413 and the locking cavity. The combination of 414 has the effect of reducing the contact area between the block 413 and the inner wall of the engaging cavity 414, thereby reducing the friction between the block 413 and the inner wall of the engaging cavity 414, and preventing the block 413 from moving due to The frictional force is too large and stuck, so that the block 413 moves more smoothly.

[0051] Working p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com