Scattered evaporation type drying machine

A kind of dryer and evaporative technology, applied in the direction of dryer, drying, grain processing, etc., can solve the problem of glass ball being easily broken, and achieve the effect of good cleanliness and sufficient product collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

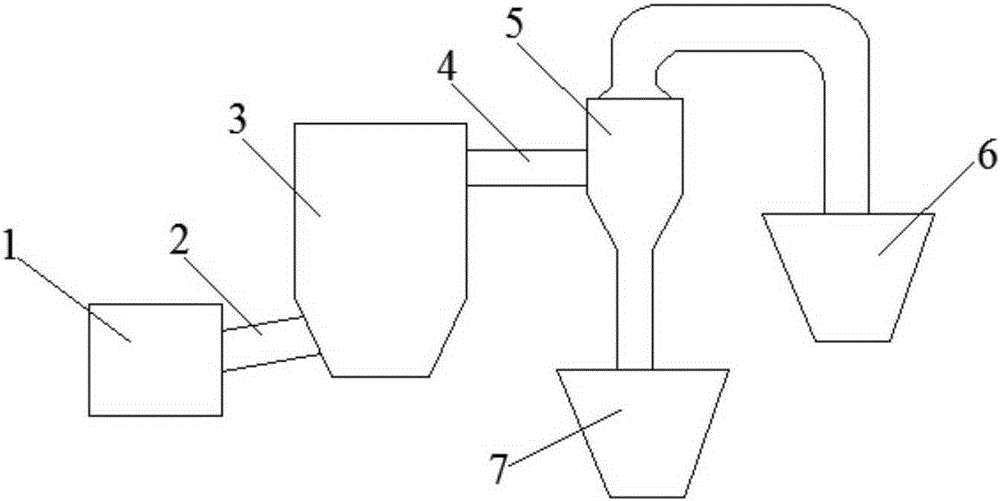

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0015] A evaporative drying machine, including a blower device 1, an air duct 2, a dryer 3, a connecting pipe 4, a feeding device 5, a dust collection box 6, and a particle collection box 7. The left side of the dryer 3 passes through the air duct 2 Connect with the blower device 1, the hot air blown from the blower device 1 enters the dryer 3 through the air pipe 2, and heats and dries the raw materials in the dryer 3, and the right side of the dryer 3 passes through the connecting pipe 4 and the unloading device 5 connection, the raw material is dried in the dryer 3 and enters the discharge device 5 from the connection pipe 4, and the dust with a lighter specific gravity in the discharge device 5 enters the dust collection box 6 from the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com