Liquid downward-jetting ultrasonic cleaning device

A technology of ultrasonic cleaning and drying device, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problems of cleaning the tortuous gaps inside the workpiece that cannot be cleaned, and achieves good cleanliness, The effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

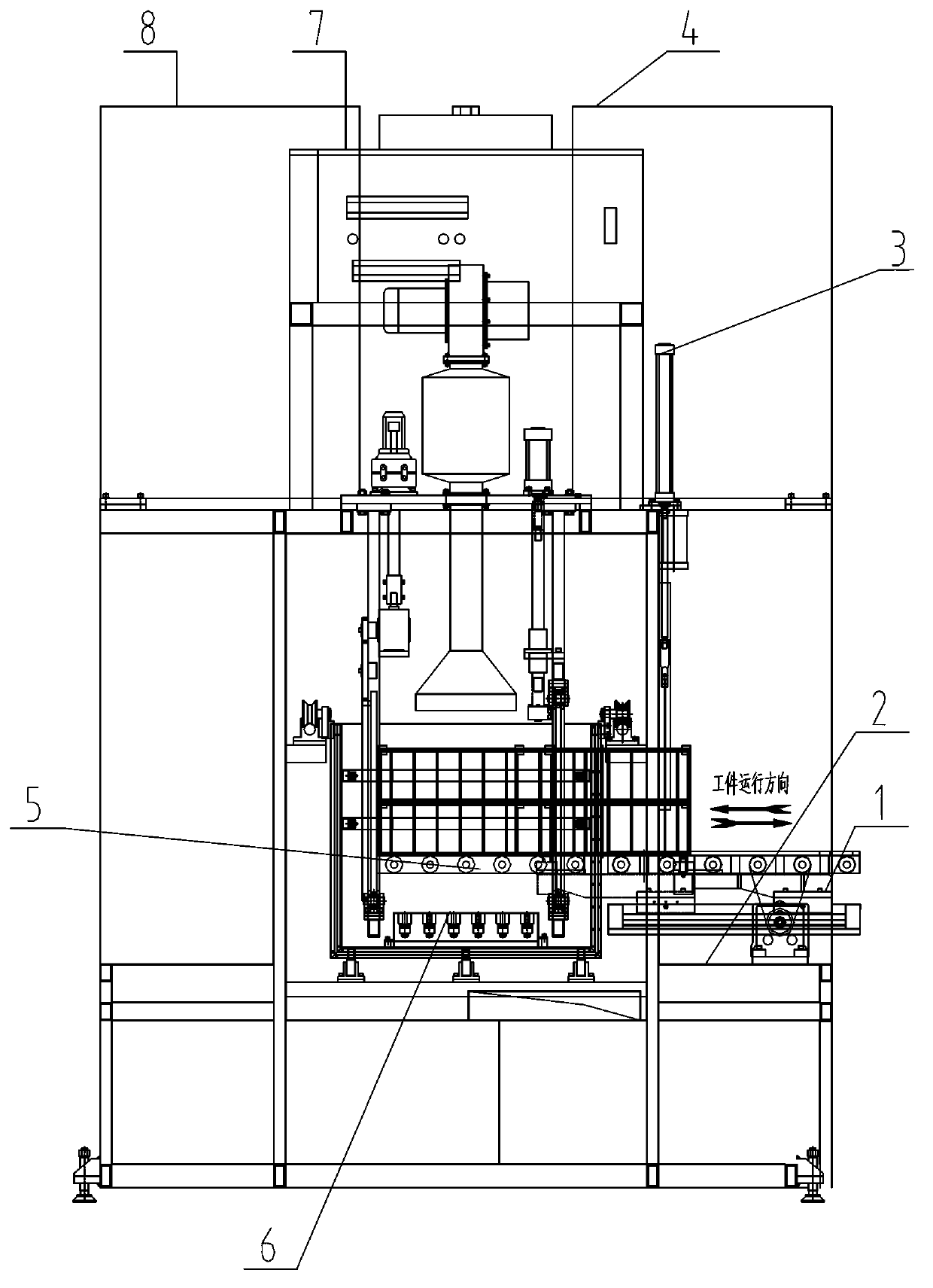

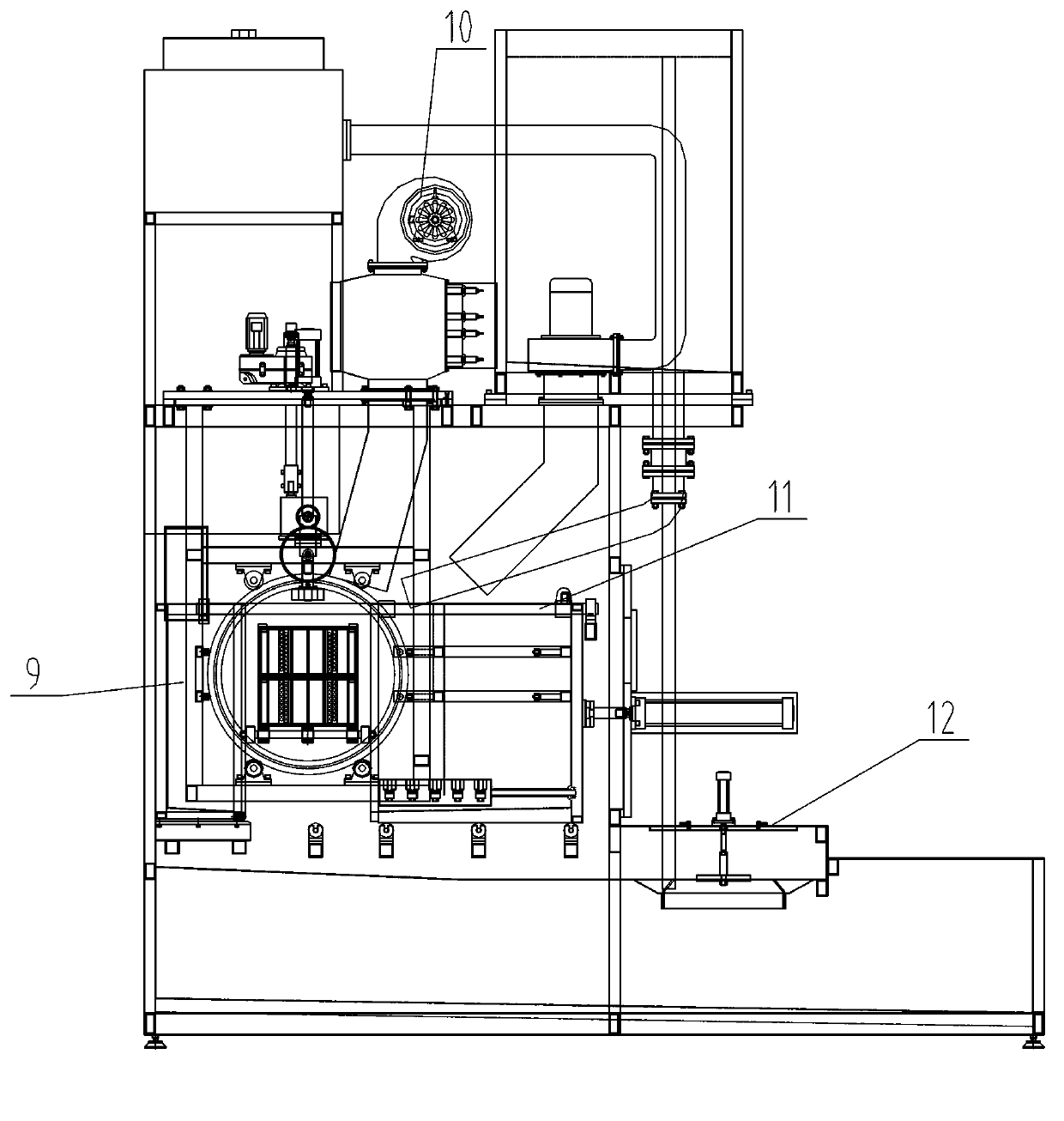

[0014] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods, as Figure 1 to Figure 2 As shown, a submerged jet ultrasonic cleaning device includes a frame, and the two sides above the frame are provided with a cleaning water reservoir 4 and a rinsing water reservoir 8, and between the cleaning water reservoir 4 and the rinsing water reservoir A condensation defogging system 7 is arranged between the water reservoirs 8, an automatic door 3 is arranged on one side of the frame, and an automatic feeding and discharging system 1 is arranged below the automatic door 3, and the automatic feeding and discharging system 1 A rotating system 5 is arranged above, and an ultrasonic assembly 6 is arranged below the rotating system 5. A fixed half tank 9 and a movable half tank 11 are arranged inside the rotating system 5, and an organic liquid tank 1 is arranged at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com