Package body for enhancing glass surface processing agent, glass product and manufacturing method thereof

A surface treatment agent and a technology for strengthening glass, which are applied to the packaging body of the strengthening glass surface treatment agent, the glass product with the strengthening glass surface treatment agent layer and its manufacture, the cleaning agent packaging body, the disposable bag-shaped cleaning bag packaging body or In the field of container packaging, it can solve the problems such as functional effect affecting consumers' use of similar products, glass surface stripes and beads, and reducing the sensitivity of touch panels, etc., to achieve the effect of maintaining driving safety line of sight, easy operation and use, and maintaining clear and cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

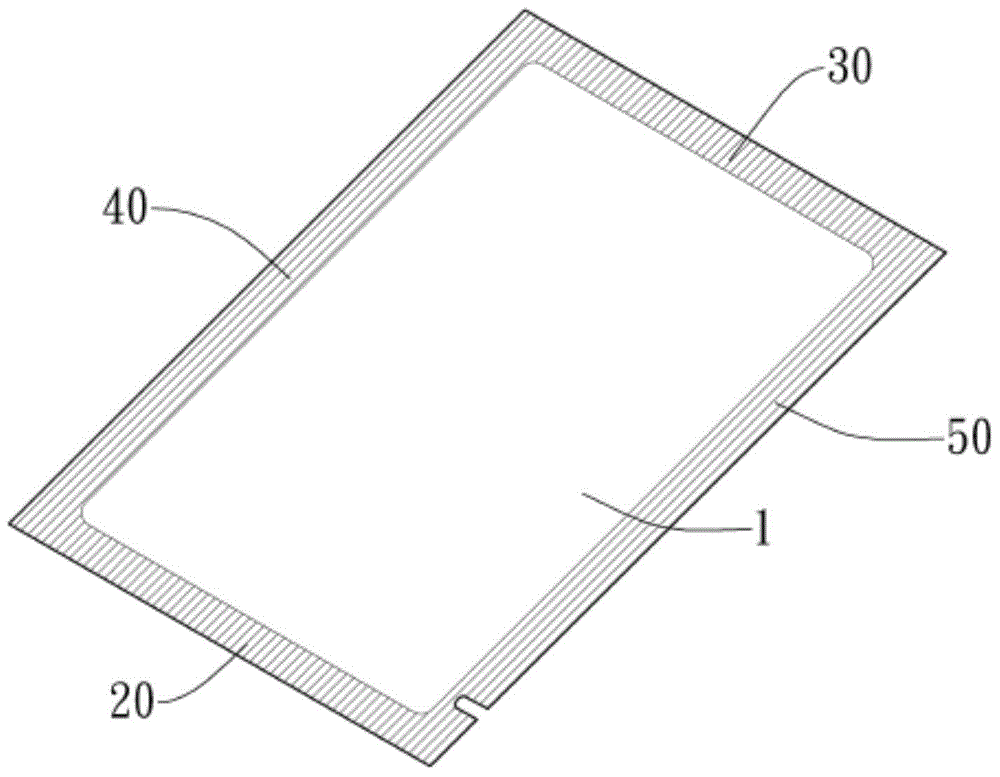

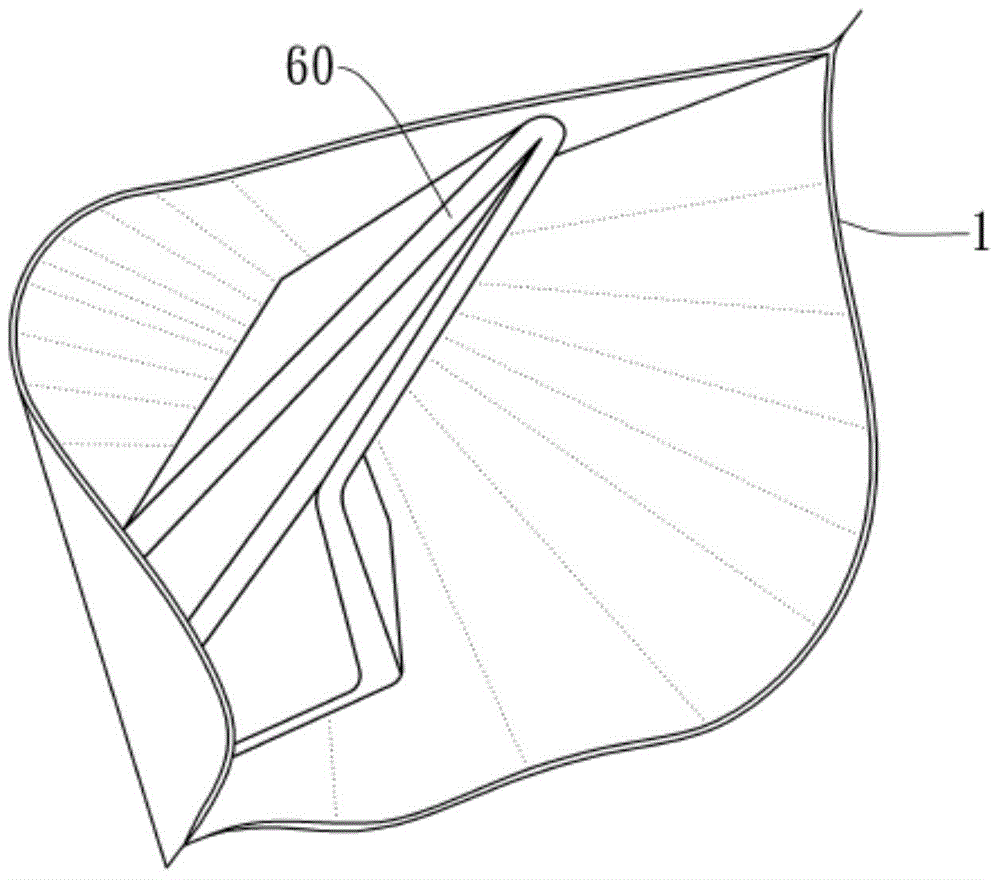

[0035] see figure 1 and figure 2 , figure 1 It is a schematic view of the appearance of Example 1 of the packaging body of the surface treatment agent for strengthened glass of the present invention, figure 2 It is a schematic diagram of the inside of the package after the package of the strengthened glass surface treatment agent is disassembled. In this embodiment, the packaging body of the strengthened glass surface treatment agent includes a hollow closed bag body 1 of appropriate size and shape as the packaging body. Bags, plastic zipper bags, etc., are sealed and packaged in a heat-pressing manner, so that the four sides of the hollow closed bag body 1 form heat-pressed edge-sealing one 20, edge-sealing two 30, edge-sealing three 40, and edge-sealing four 50. A gap is formed at a place of the heat-pressed edge 4 50 close to the heat-pressed edge 1 20 to facilitate the user to tear the package.

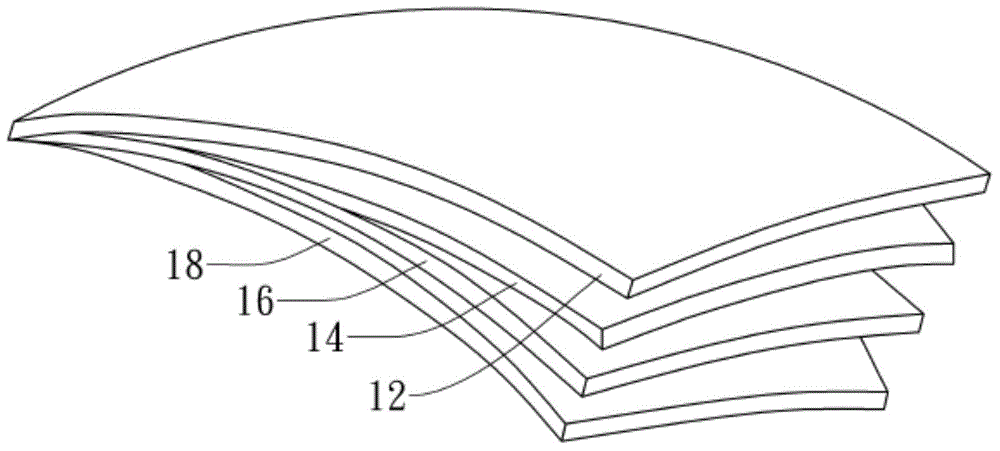

[0036] see image 3 , the bag body 1 has a four-layer structure, inclu...

Embodiment 2

[0044] Figure 4 It is a schematic appearance diagram of Example 2 of the package of the surface treatment agent for strengthened glass of the present invention. In this embodiment, the packaging body of the strengthened glass surface treatment agent is in the form of a spray container. For example, a spray bottle 4 can be used as the packaging body, and the chemical solution 42 containing the above-mentioned fluorine-based compound is used as a container for carrying the strengthened glass surface treatment agent. The carrier is accommodated in the spray bottle 4 . In addition, in this embodiment, plastics such as HDPE and PET, or glass or metal spray bottle containers can also be used to contain the chemical solution 42 of the fluoride compound. During use, use a dry wipe or alcohol-containing cleaning cloth to remove the dirt on the surface of the strengthened glass, and then evenly spray (spray coating) the surface treatment agent of this embodiment on the clean glass, and ...

Embodiment 3

[0047] This embodiment provides a glass product with a layer of the surface treatment agent for strengthened glass, which is obtained by forming a film with the surface treatment agent for strengthened glass of the present invention on the surface of the strengthened glass. In this embodiment, the strengthened glass is a glass panel, and the carrier carrying the strengthened glass surface treatment agent is bonded to the surface of the glass panel in the form of a thin film to form a strengthened glass surface treatment agent layer. The above-mentioned fluorine-based compounds are applied to the surface of the strengthened glass cleaned by chemical agents, atmospheric plasma (AP Plasma) and other processes by spray coating using continuous machine equipment, and then polished and smoothed, baked and cured, and the appearance The process of inspection and packaging, and then forming the glass product with the strengthened glass surface treatment agent film of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com