Thin-layer rust-preventative oil for engine part and method for preparing same

An anti-rust oil and engine technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as the inability to meet the sealing of multi-metal assemblies, and achieve the effect of good application effect, good cleanability, and no change in surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Raw material composition and mass percent are:

[0052] Barium Sulfate Petroleum 2%

[0053] Barium Dinonylnaphthalene Sulfonate 5%

[0054] Dodecenylsuccinic acid 0.85%

[0055] Benzotriazole 0.3%

[0056] Dibutyl phthalate 3.3%

[0057] Polyisobutylene 5%

[0058] Aviation lubricating oil balance;

[0059] Pour the aviation lubricating oil into the oil tank with heating equipment, heat it to 110-120°C for full dehydration, and then lower it to room temperature; then slowly add the rest of the raw materials into the oil tank, and stir continuously to dissolve them completely. After the materials are evenly mixed, the anti-rust oil of the present invention is obtained.

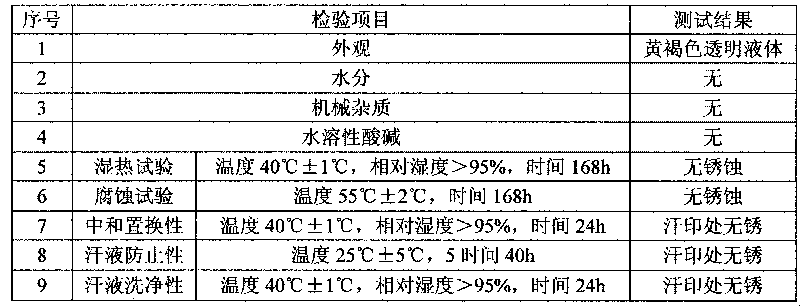

[0060] Apply the prepared anti-rust oil to parts made of aluminum alloy, iron, carbon steel, copper alloy, magnesium alloy, silver alloy, and parts with phosphating surface, blue surface, and silver-plated surface. The test results are shown in Table 1.

Embodiment 2

[0062] Raw material composition and mass percent are:

[0063] Barium Sulfate Petroleum 2.5%

[0064] Barium Dinonylnaphthalene Sulfonate 6.0%

[0065] Dodecenylsuccinic acid 0.8%

[0066] Benzotriazole 0.5%

[0067] Dibutyl phthalate 5.0%

[0068] Polyisobutylene 4.0%

[0069] Aviation lubricating oil balance;

[0070] Pour the aviation lubricating oil into the oil tank with heating equipment, heat it to 110-120°C for full dehydration, and lower it to room temperature; then slowly add the rest of the raw materials into the oil tank, and stir continuously to dissolve them completely. After the materials are uniformly mixed, the anti-rust oil of the present invention is obtained.

[0071] Apply the prepared anti-rust oil to parts made of aluminum alloy, iron, carbon steel, copper alloy, magnesium alloy, silver alloy, and parts with phosphating surface, blue surface, and silver-plated surface. The test results are shown in Table 1.

Embodiment 3

[0073] Raw material composition and mass percent are:

[0074] Petroleum Barium Sulfate 2.2%

[0075] Barium Dinonylnaphthalene Sulfonate 5.0%

[0076] Dodecenylsuccinic acid 0.6%

[0077] Benzotriazole 0.2%

[0078] Dibutyl phthalate 2.2%

[0079] Polyisobutylene 3.0%

[0080] Aviation lubricating oil balance;

[0081] Pour the aviation lubricating oil into the oil tank with heating equipment, heat it to 110-120°C for full dehydration, and then lower it to room temperature; then slowly add the rest of the raw materials into the oil tank, and stir continuously to dissolve them completely. After the materials are evenly mixed, the anti-rust oil of the present invention is obtained.

[0082] Apply the prepared anti-rust oil to parts made of aluminum alloy, iron, carbon steel, copper alloy, magnesium alloy, silver alloy, and parts with phosphating surface, blue surface, and silver-plated surface. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com