System and Method for Finishing Basement Walls

a technology for basement walls and basement air, applied in cellars, heating types, domestic heating details, etc., can solve the problems of high humidity and mold growth, and achieve the effect of keeping the humidity level of the basement air low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

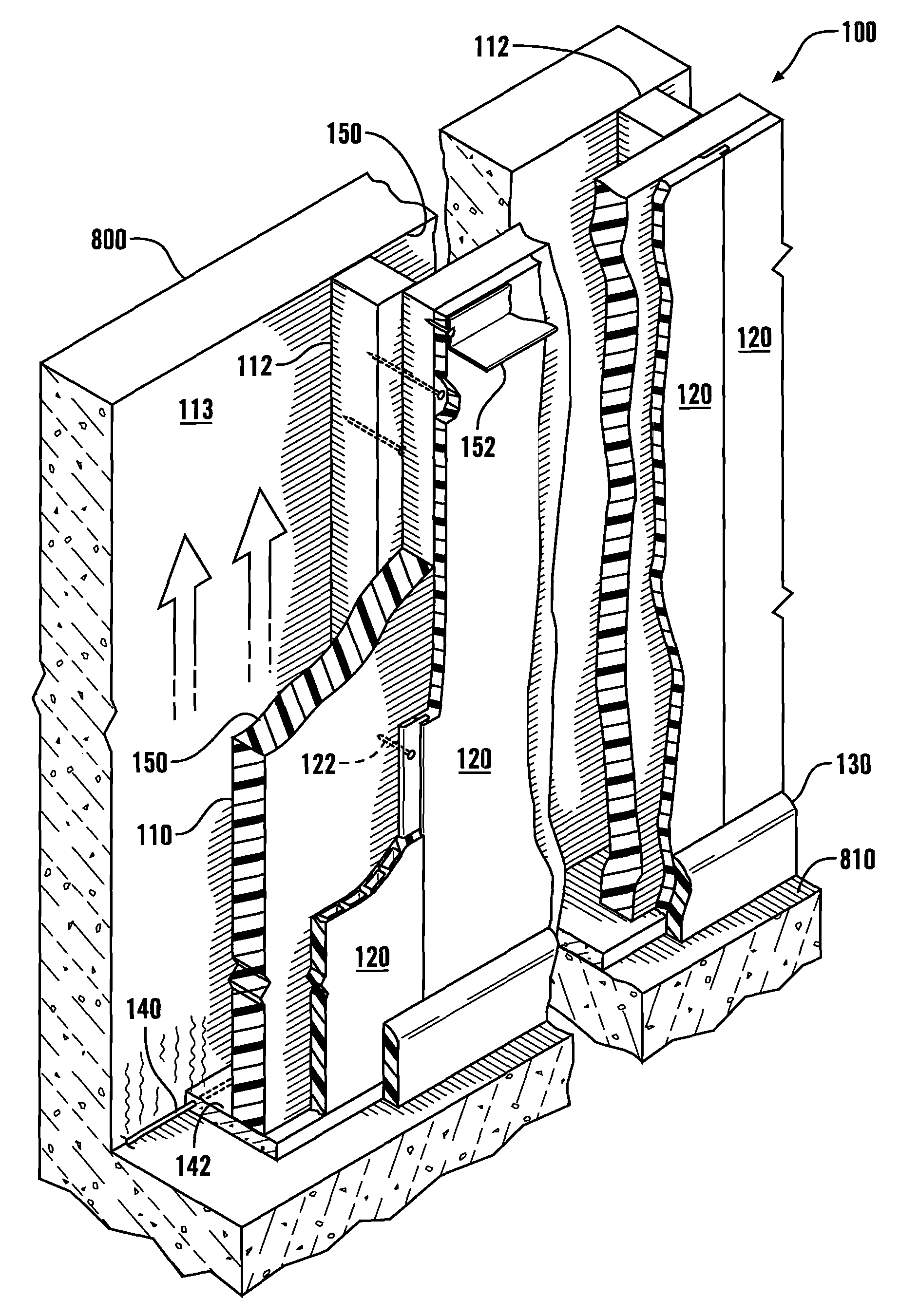

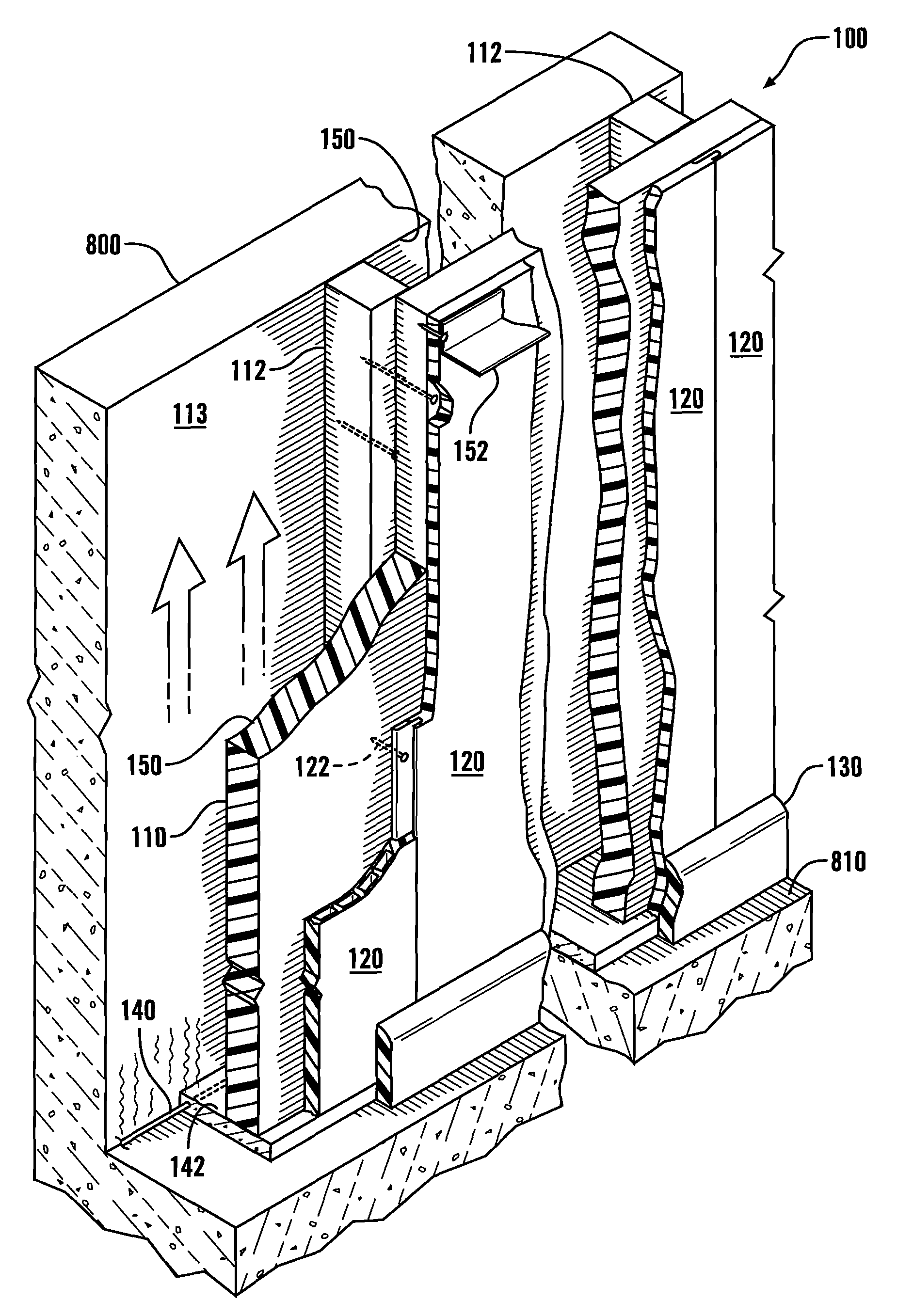

[0007]Referring now specifically to the FIGURE, a detailed description of the present invention is given. However, the present invention can assume numerous other embodiments, as will become apparent to those skilled in the art.

[0008]In the FIGURE, a cutaway view of one version of the finishing system 100 of the present invention is depicted. The finishing system 100 of the present invention generally comprises a first panel 110, a second panel 120, base trim 130, and a heating means 140.

[0009]The first panel 110 is attached to furring strips 112 installed on an interior surface 113 of a concrete or masonry basement wall 800 so as to create air cavities 150 enclosed therebetween. The air cavities 150 remain in communication with the upper story of a house.

[0010]The first panel 110 is made of a waterproof and insulating material such as polystyrene board, such as THERMAX® one inch thick panel. The furring strips 112 are likewise made of a waterproof material (e.g., HDPE recycled plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com