Variable area mass or area and mass species transfer device and method

a technology of species transfer and variable area mass, which is applied in the direction of indirect carbon-dioxide mitigation, combustion process, lighting and heating apparatus, etc., can solve the problems of inefficiency of species transfer device, long time-consuming and laborious, and course is at the expense of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

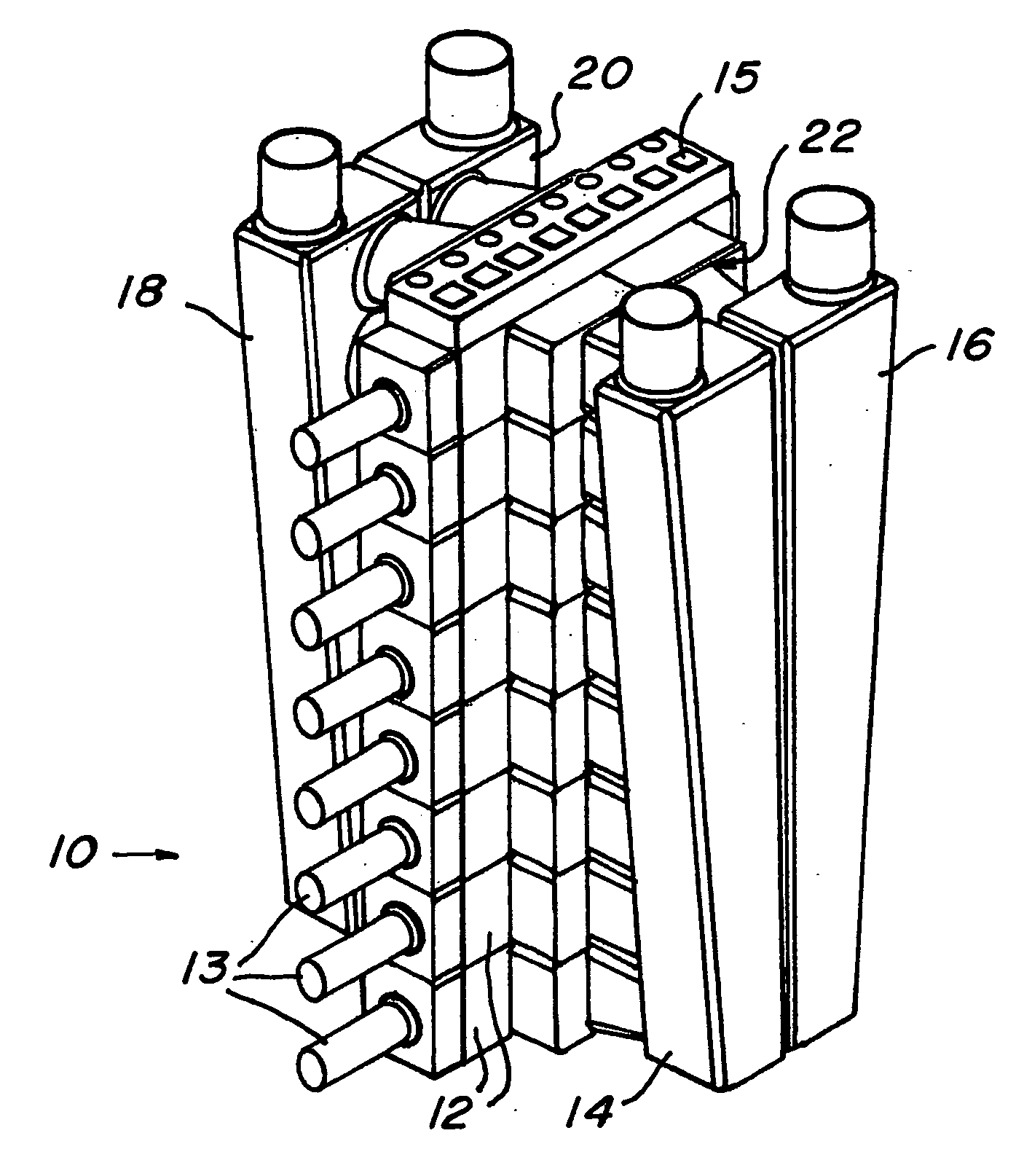

embodiment 10

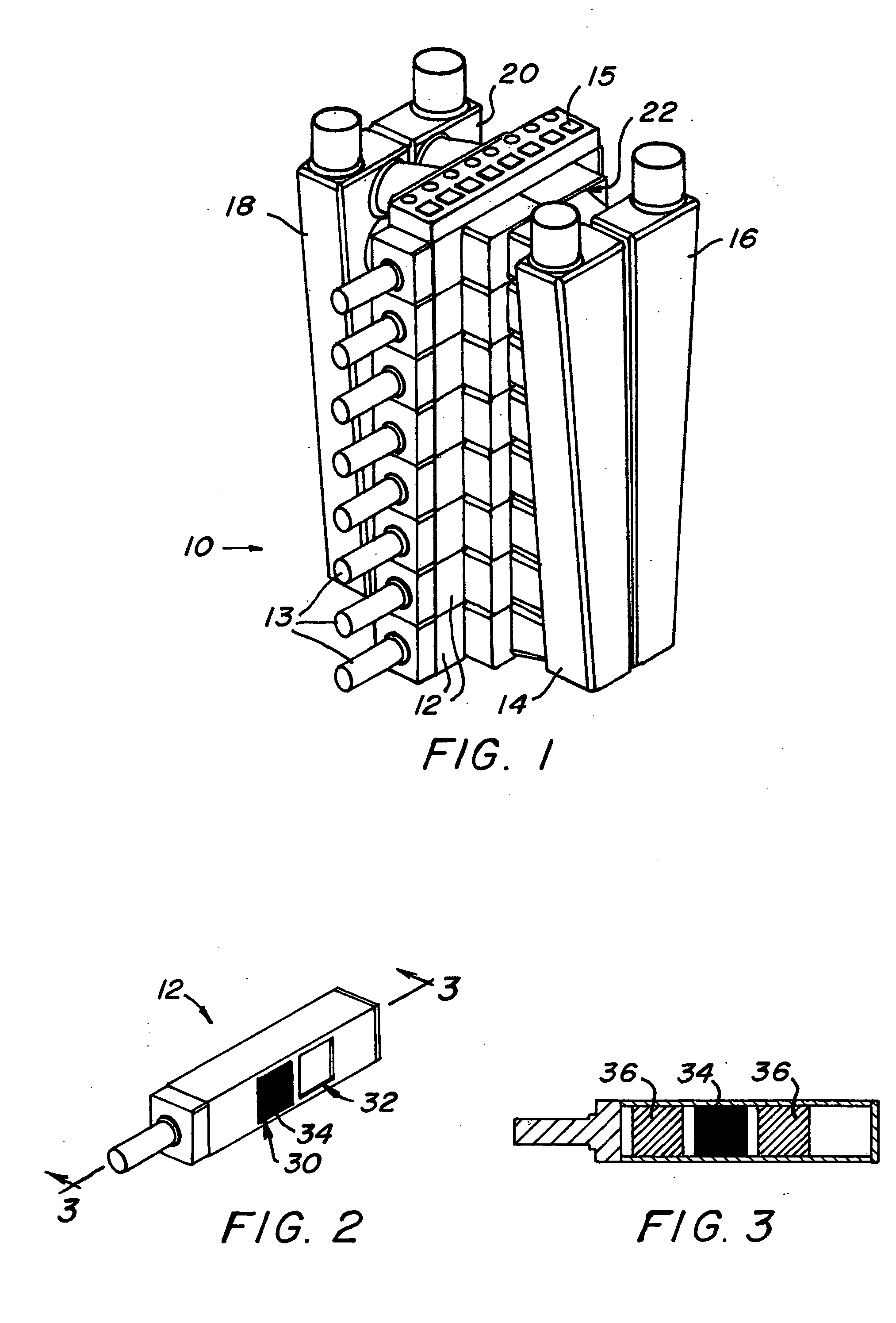

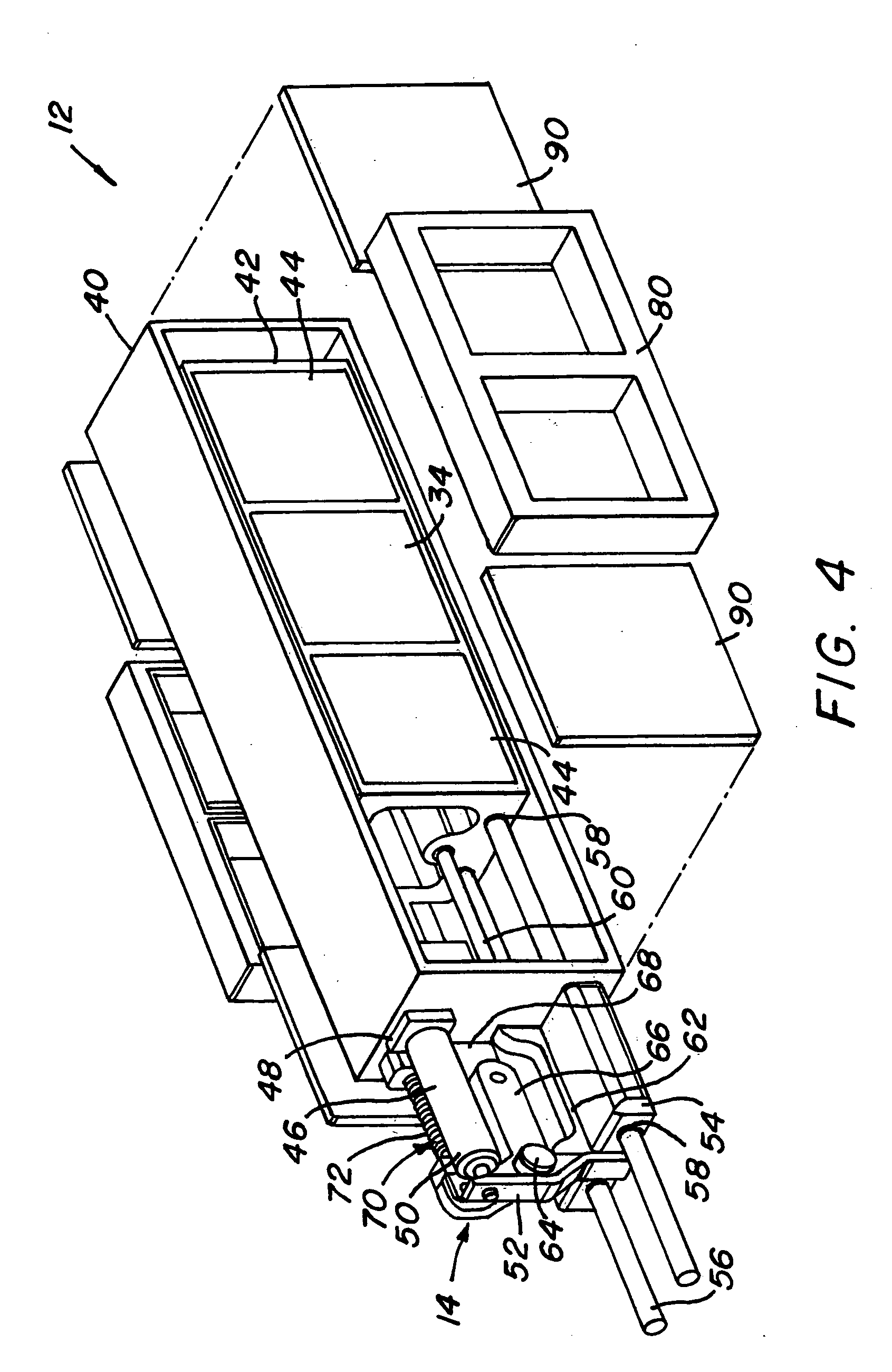

[0032] Referring to FIG. 1, a schematic perspective view of a first regenerator embodiment 10 is illustrated. The species transfer device 10 comprises a plurality of species transfer modules 12 (see FIG. 2 and FIG. 3). Modules 12 are actuatable by one or more actuators 13 (shown on each module 12 in this illustration but could be configured as one actuator to more of the modules at the expense of some variability or could be configured as more than one actuator for any module if desired) and controlled by a sequence-and-dwell controller 15 that determines the desired position of a particular module 12 and the period of time each particular mass should stay in a given fluid stream.

[0033] In fluid communication with the species transfer modules 12 are manifolds 14, 16, and 18 and 20. Manifolds 14 and 18 and manifolds 16 and 20 are in communication with each other through the intermediary of the species transfer modules 12. Each manifold pair is capable of conducting a fluid stream, an...

embodiment 210

[0047] Referring now to FIGS. 14, 15 and 16 a “rotary” species transfer device embodiment 210 exhibiting the properties of variability identified above is illustrated. For this device there are again four manifolds 214, 216, 218 and 220 wherein a first flow-stream passageway 230 is defined between manifolds 214 and 218 while a second flow-stream passageway 232 is defined between manifolds 216 and 220. In this example of the rotary species transfer device 210 four species transfer modules 212 are illustrated. Each module includes a rotor 242 comprising a species transfer mass 234 (see FIG. 15) rotatable about an axis of rotation, which brings the species transfer mass 234 into alignment with one or the other of passageways 230 or 232 or can be positioned out of alignment with either of these passageways (see FIG. 17) for blanking off a particular module 212.

[0048] Rotors 242 are driven by actuators 213, which comprise, in the illustrated embodiment, a motor 246 having a drive wheel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com