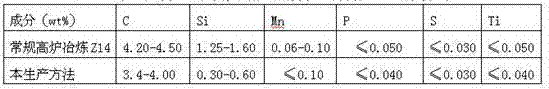

A kind of production method of hypoeutectic casting pig iron

A production method and technology of casting pig iron, applied in blast furnaces, furnace types, furnaces, etc., can solve problems such as uneconomical, difficult to guarantee the quality of scrap steel, and performance degradation, and achieve the effects of saving electricity, reducing the overall coke ratio, and increasing the temperature of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The process steps of the production method of this hypoeutectic cast iron are as follows.

[0031] 600m 3 High-grade blast furnace smelting, high-alkali sinter 66.61wt% in raw materials, pellets 33.39wt%, high-alkali sinter basicity controlled at 1.98; Si control 0.3-0.50% during blast furnace smelting, R 2 Control 1.15~1.20, control Ti≤0.040%; molten iron detection C is 4.5%, Si is 0.43%, Mn is 0.08%, P is 0.034%, S is 0.014%, and Ti is 0.036%.

[0032] After the iron is tapped, the molten iron is pulled to the hypoeutectic pig iron production workshop, the molten iron in the molten iron tank is poured into the ladle (9 tons), and then the molten iron in the ladle is hoisted to the front of the 10-ton frequency conversion electric furnace, and the molten iron is added to the furnace. Then add 1.2 tons of scrap steel, send electricity to raise the temperature for 30 minutes, measure the temperature, the temperature is 1380 °C, take a spectrum sample for a...

Embodiment 2

[0033] Embodiment 2: The process steps of the production method of this hypoeutectic cast iron are as follows.

[0034] 600m 3High-grade blast furnace smelting, high-alkali sinter 68.29wt% in raw materials, pellets 31.71wt%, high-alkali sinter basicity controlled at 1.93; Si control 0.3-0.5% during blast furnace smelting, R 2 Control 1.15~1.20, control Ti≤0.040%; molten iron detection C is 4.38%, Si is 0.36%, Mn is 0.075%, P is 0.025%, S is 0.025%, and Ti is 0.022%.

[0035] After the iron is tapped, the molten iron is pulled to the hypoeutectic pig iron production workshop, the molten iron in the molten iron tank is poured into the ladle (9 tons), and then the molten iron in the ladle is hoisted to the front of the 10-ton frequency conversion electric furnace, and the molten iron is added to the furnace. Then add 1.6 tons of scrap steel, send electricity to raise the temperature for 30 minutes, measure the temperature, the temperature is 1380°C, take a spectrum sample for an...

Embodiment 3

[0036] Embodiment 3: The process steps of the production method of this hypoeutectic cast iron are as follows.

[0037] 600m 3 High-grade blast furnace smelting, high-alkali sinter 69.61wt% in raw materials, pellets 30.39wt%, high-alkali sinter basicity controlled at 1.95; Si control 0.3-0.50% during blast furnace smelting, R 2 Control 1.15~1.20, control Ti≤0.040%; molten iron detection C is 4.25%, Si is 0.22%, Mn is 0.055%, P is 0.029%, S is 0.010%, and Ti is 0.028%.

[0038] After the iron is tapped, the molten iron is pulled to the hypoeutectic pig iron production workshop, the molten iron in the molten iron tank is poured into the ladle (9 tons), and then the molten iron in the ladle is hoisted to the front of the 10-ton frequency conversion electric furnace, and the molten iron is added to the furnace. Then add 2.04 tons of scrap steel, send electricity to raise the temperature for 30 minutes, measure the temperature, the temperature is 1380°C, take a spectrum sample for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com