Patents

Literature

39 results about "Iron detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

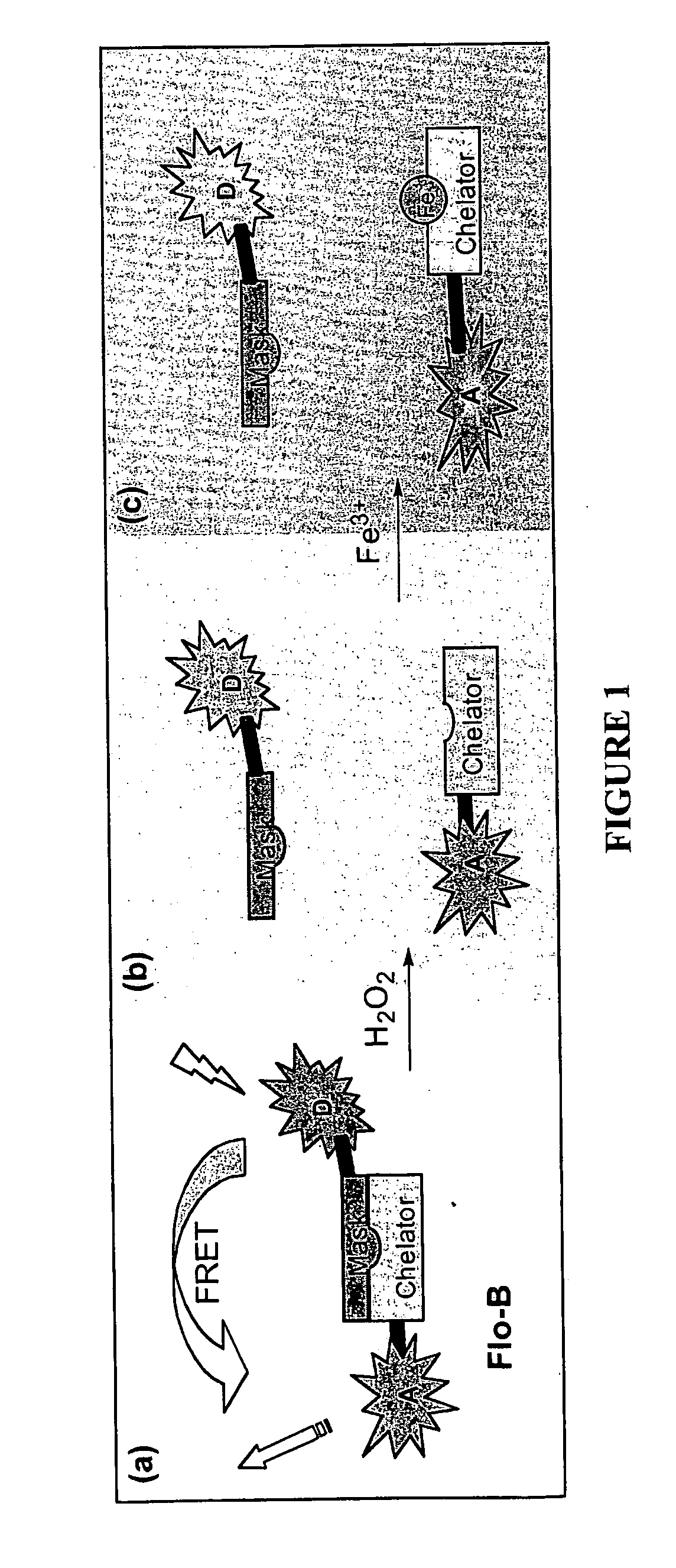

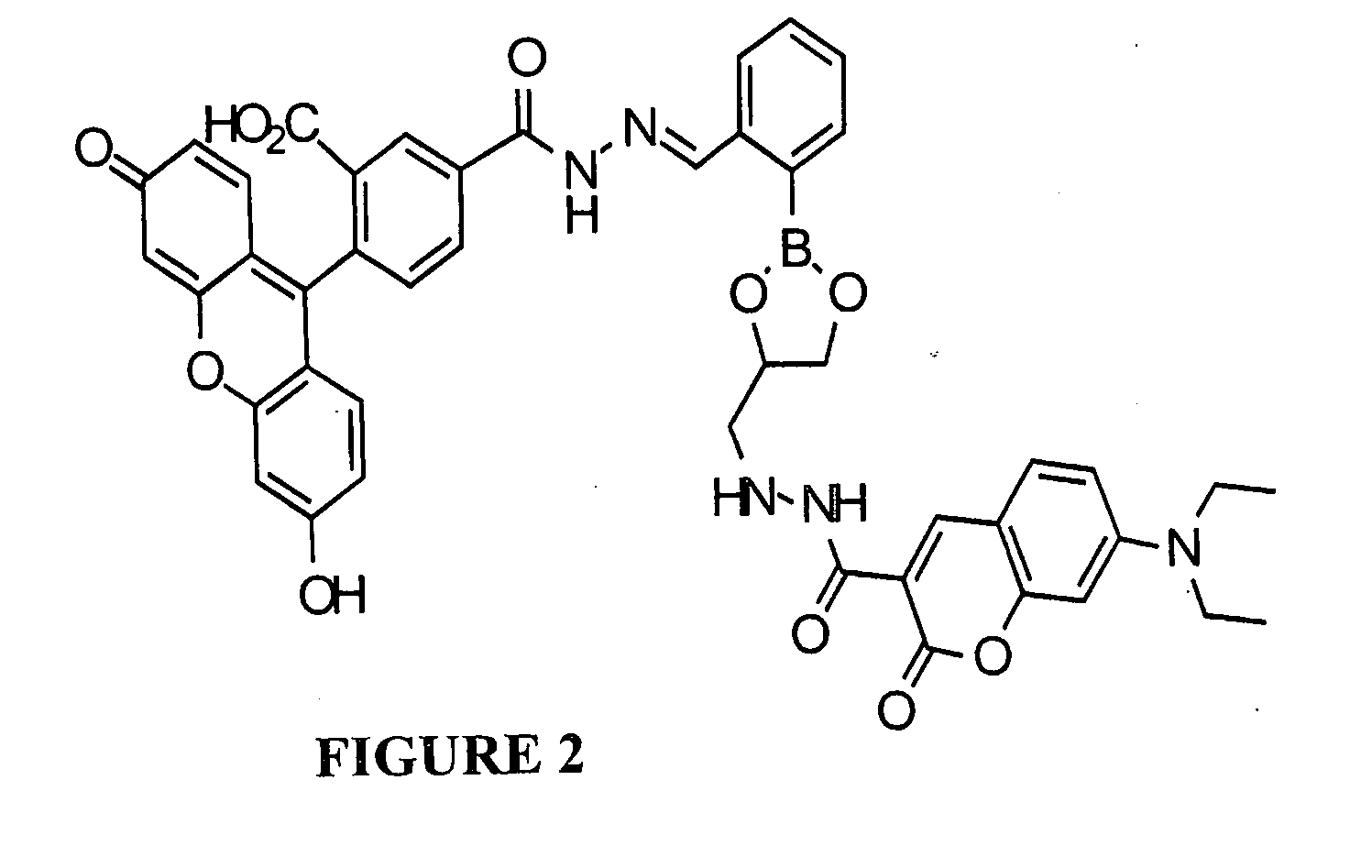

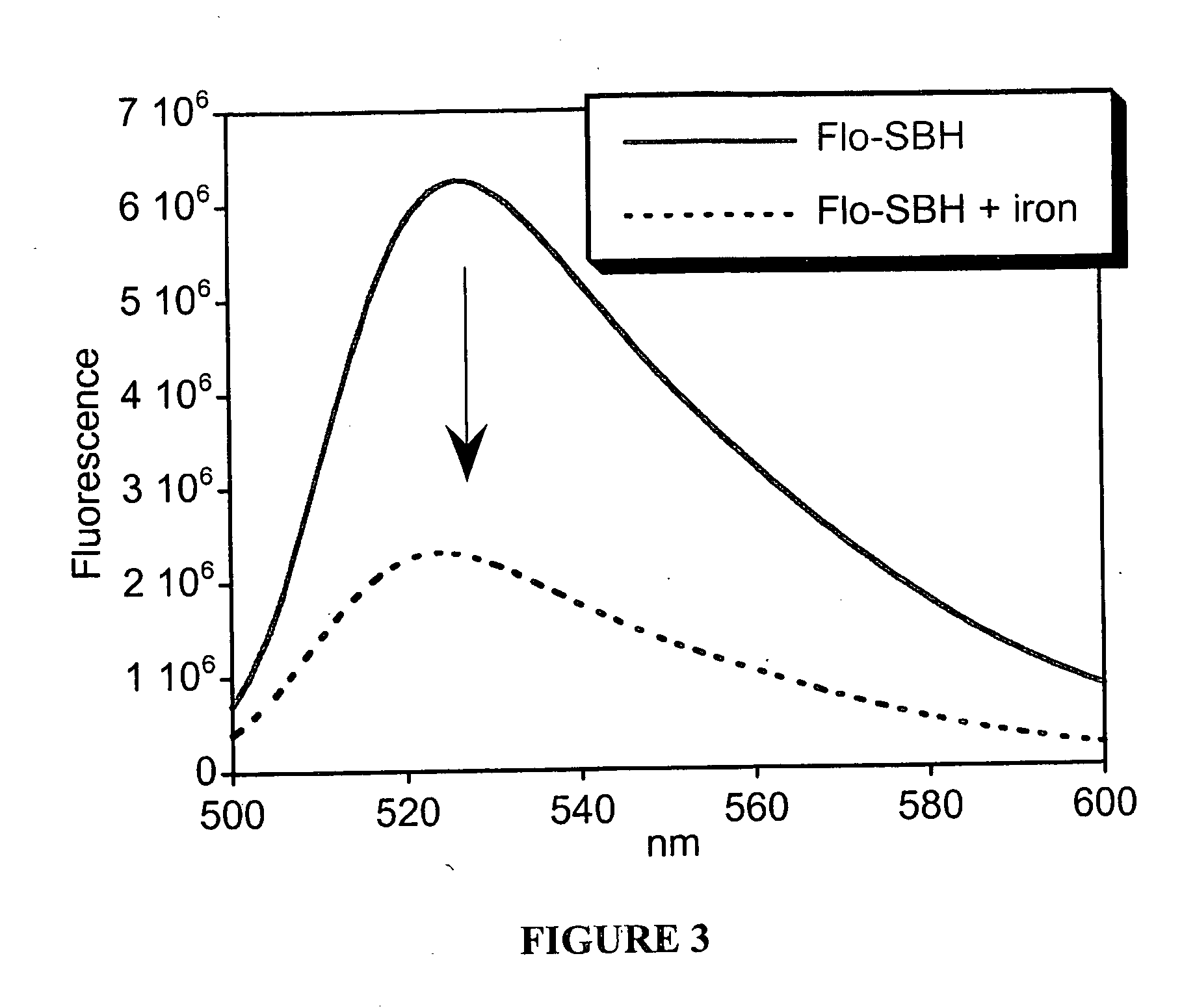

Fluorescent prochelators for cellular iron detection

InactiveUS20090253161A1Organic compound preparationMicrobiological testing/measurementFluorescenceCopper

Owner:DUKE UNIV

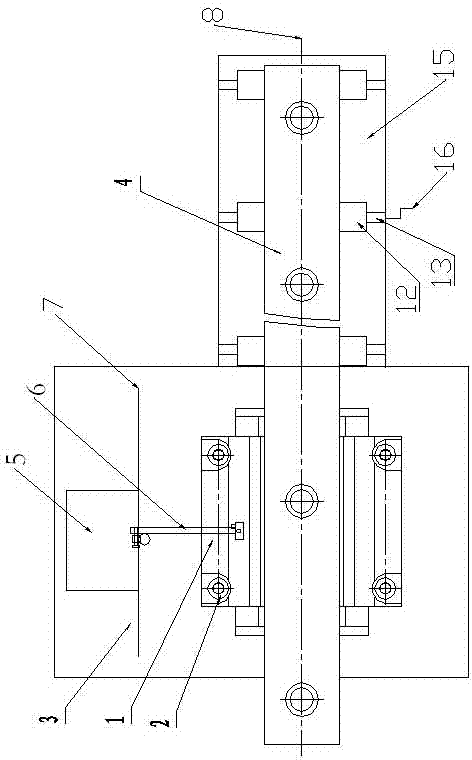

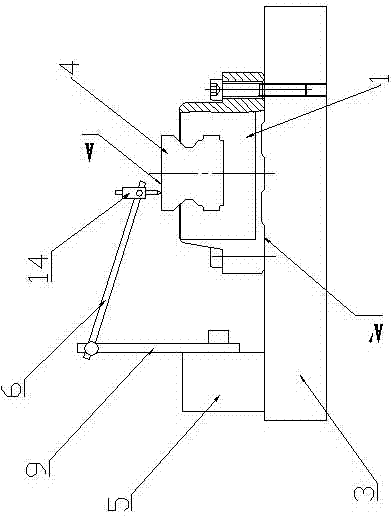

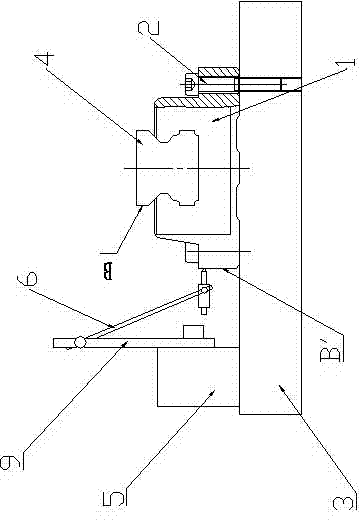

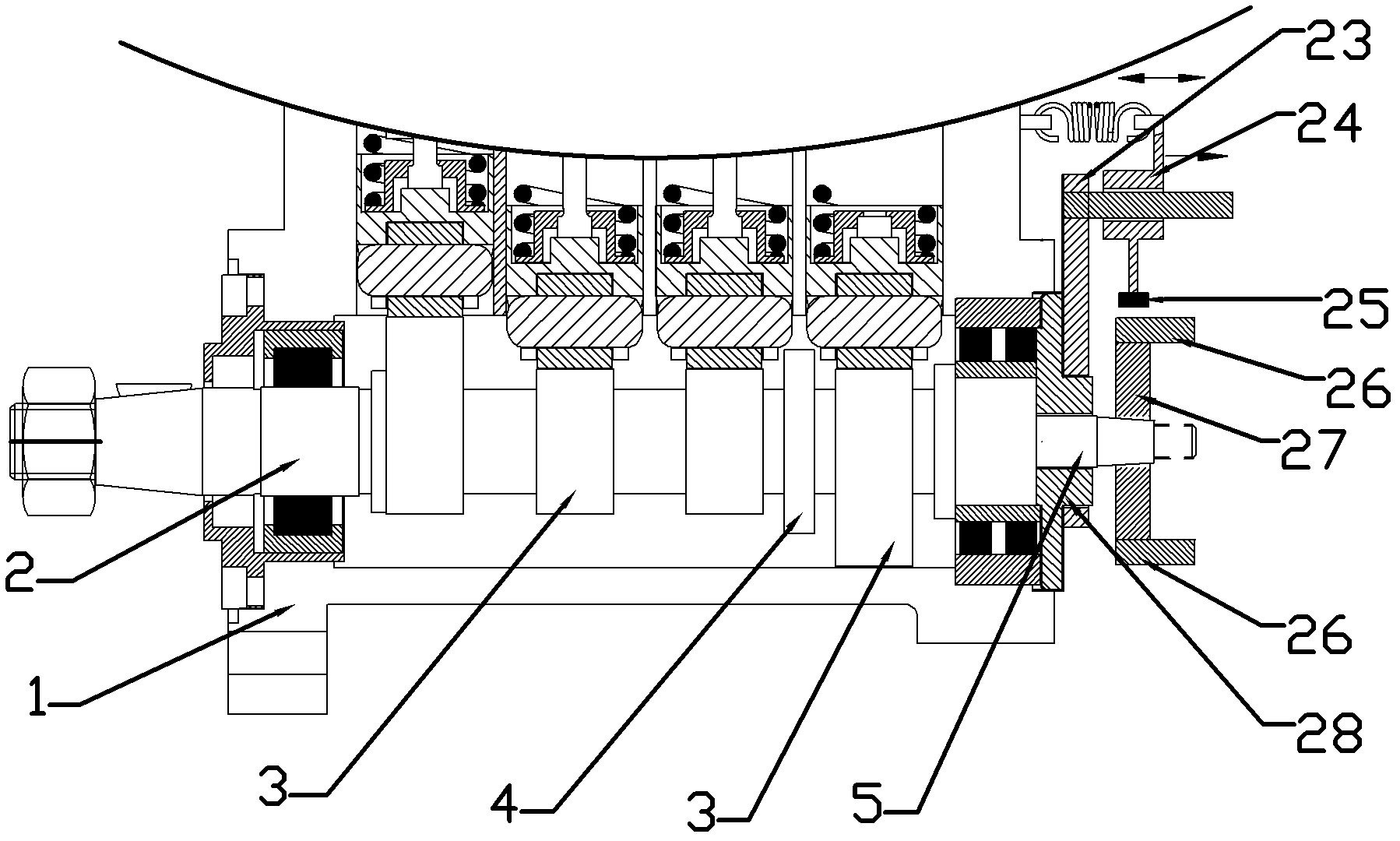

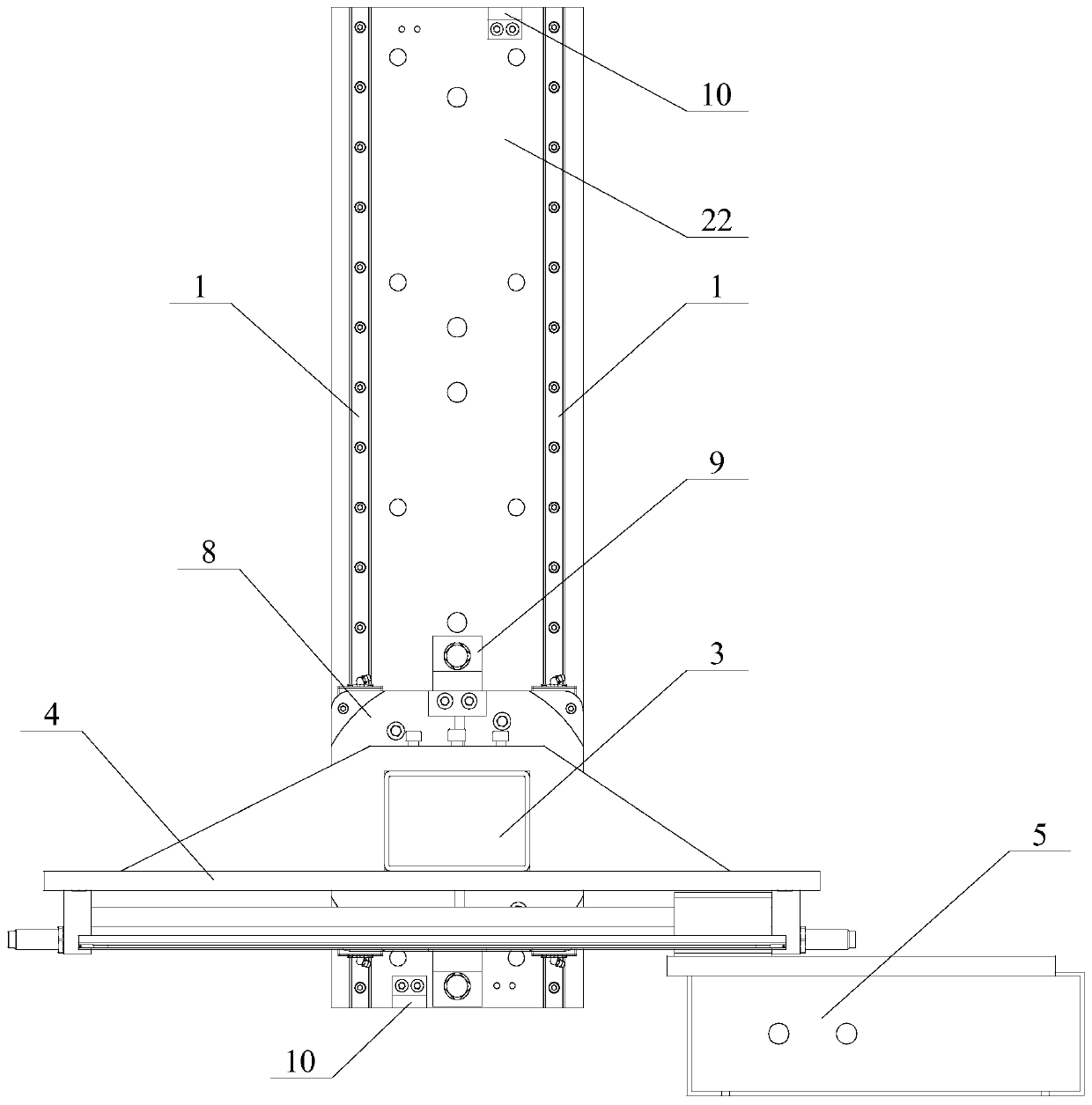

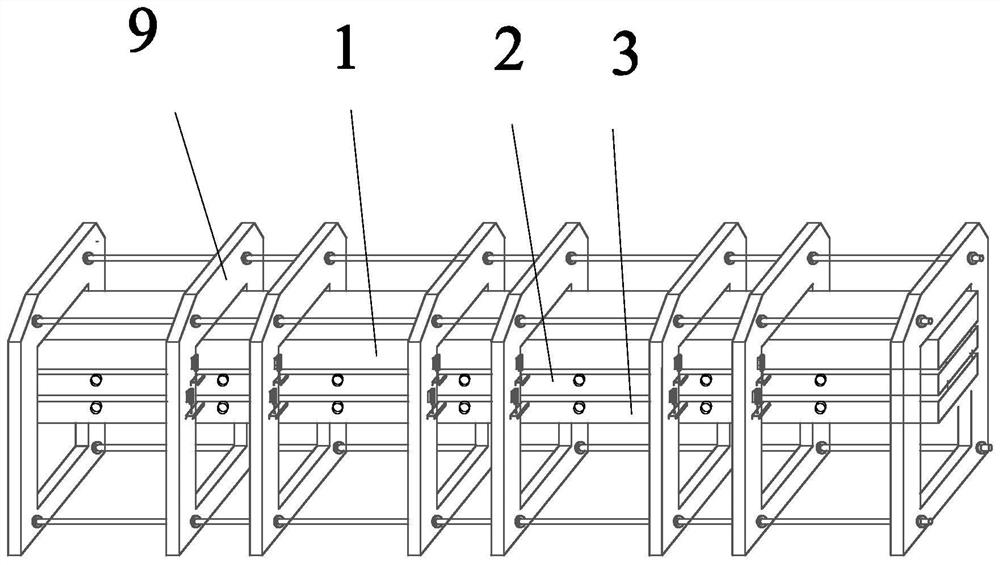

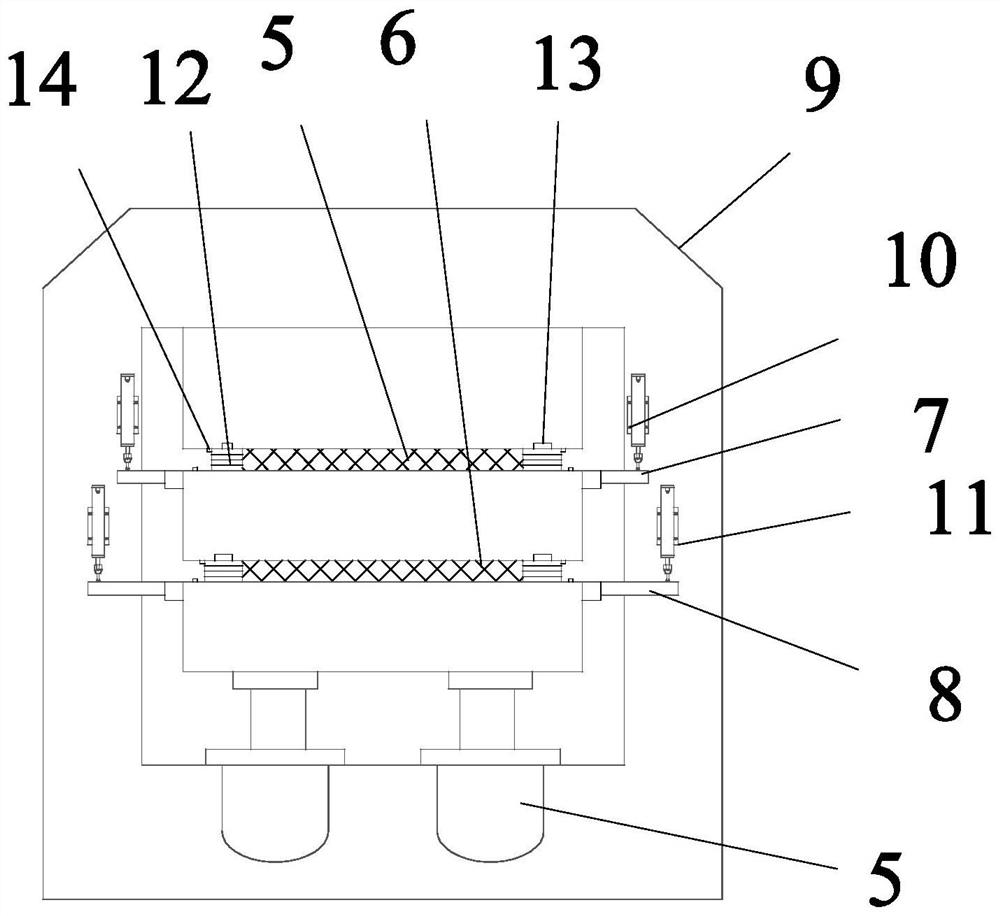

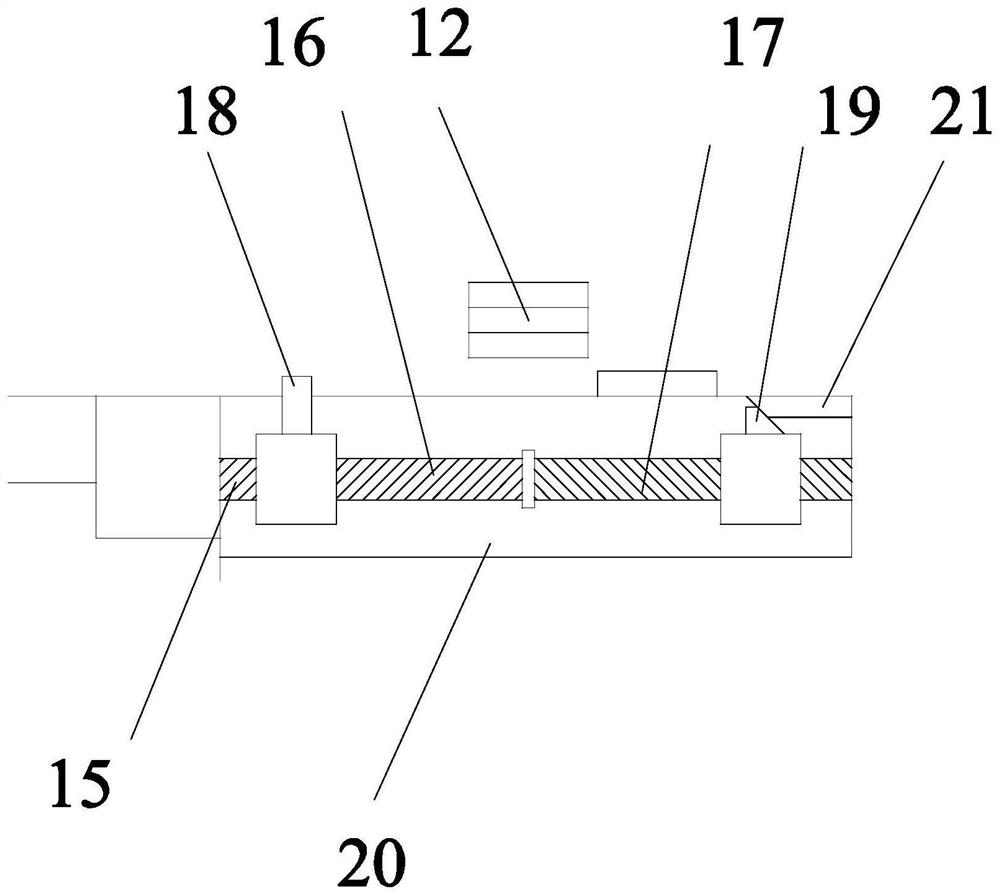

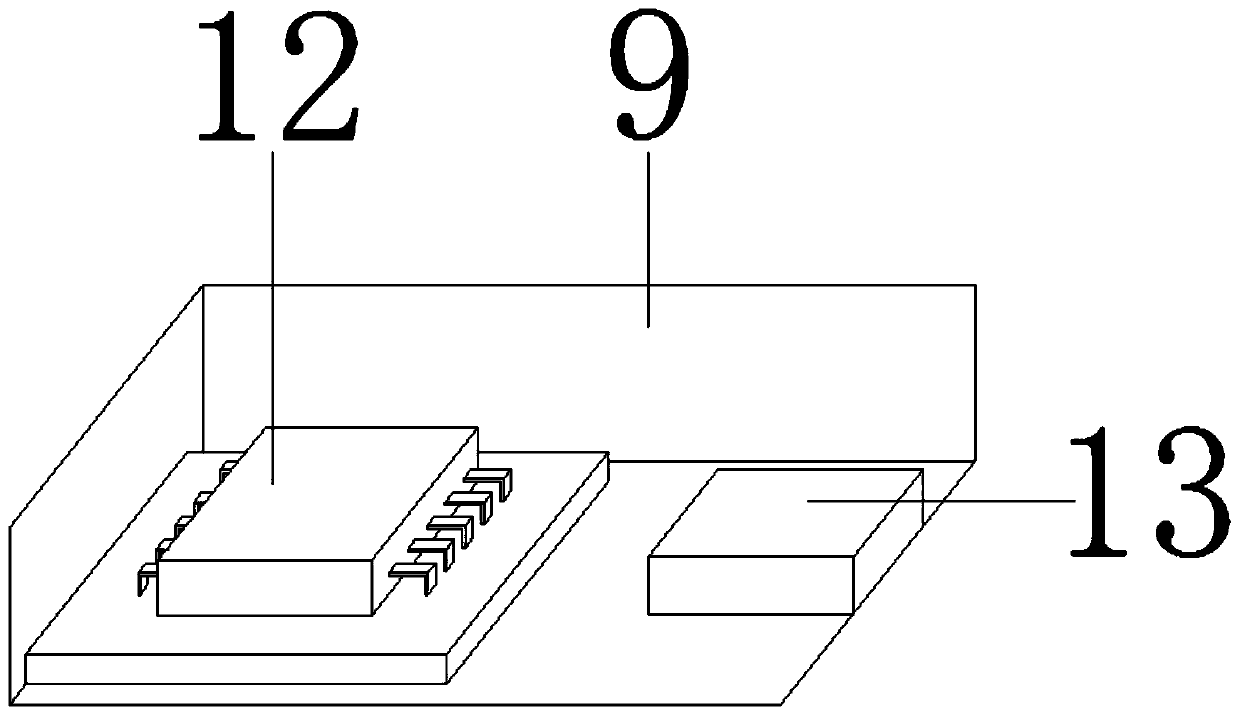

Detection device and detection method of straight line guide rail pair

InactiveCN103090759ASimple structureLow costAngles/taper measurementsMechanical roughness/irregularity measurementsIron detectionIndustrial engineering

The invention discloses a detection device and a detection method of a straight line guide rail pair. The detection device comprises a detection platform, a straight line guide rail, a slide block, a magnetic meter base and a dial indicator, and is characterized in that the detection platform is an iron detection platform provided with a positioning hole, the slide block of the straight line guide rail is reversely arranged on the positioning hole through a screw, and the straight line guide rail is assembled on the slide block. A positioning line is in parallel with the axial wire of the straight line guide rail and is arranged on one side of the detection platform straight line guide rail, and the magnetic meter base is arranged on the positioning line. An upright rod is connected along the vertical direction of the magnetic meter base, a cross rod is movably connected on the upright rod, and the dial indicator is movably arranged on the cross rod. A guide rail conveying bracket is arranged outside the detection platform and along the direction of the straight line guide rail. The detection device can quickly measure parameters of each combination surface in the straight line guide rail pair and can be widely applied to the accurate grinding process of the straight line guide rail pair.

Owner:山东赛尔机械导轨有限公司

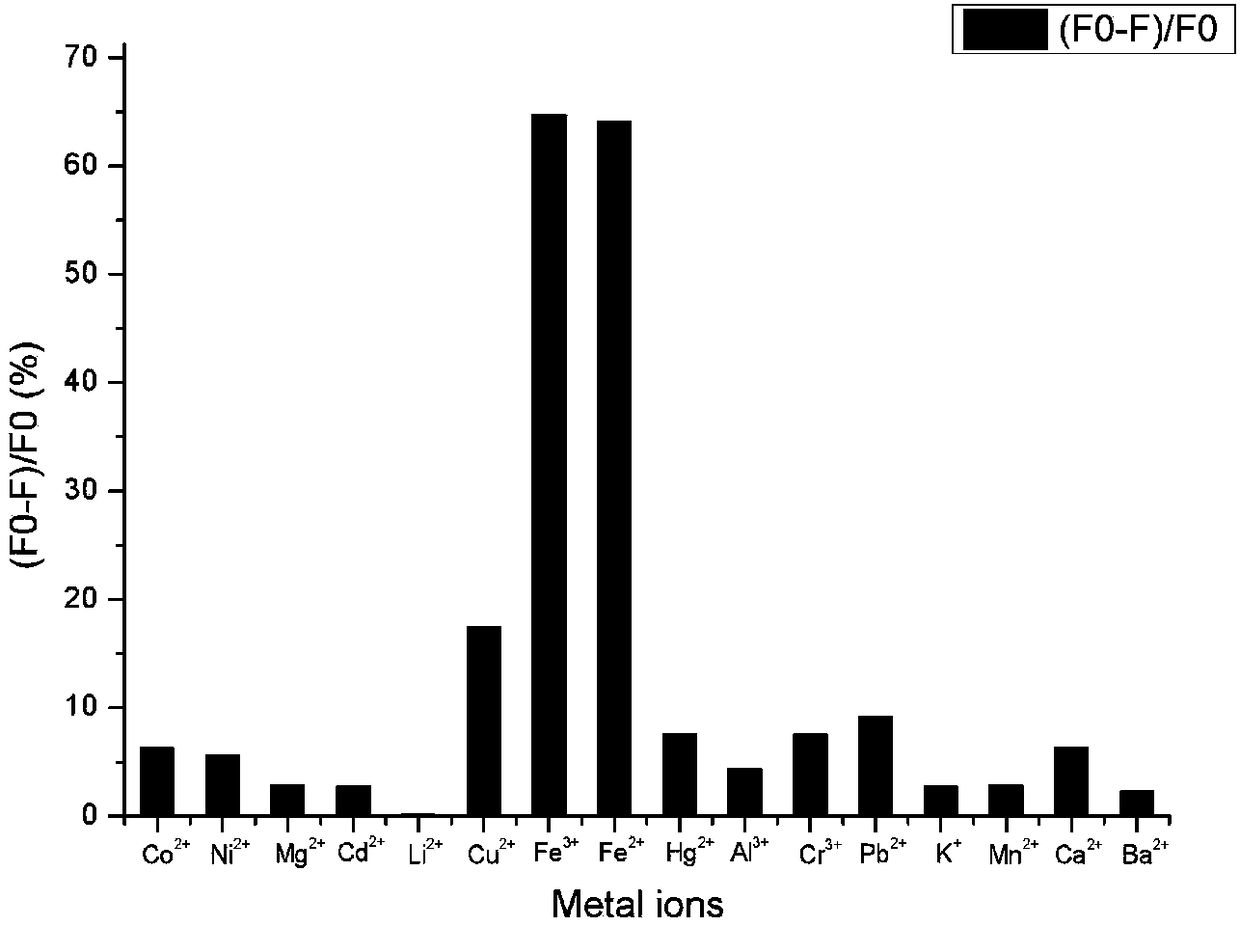

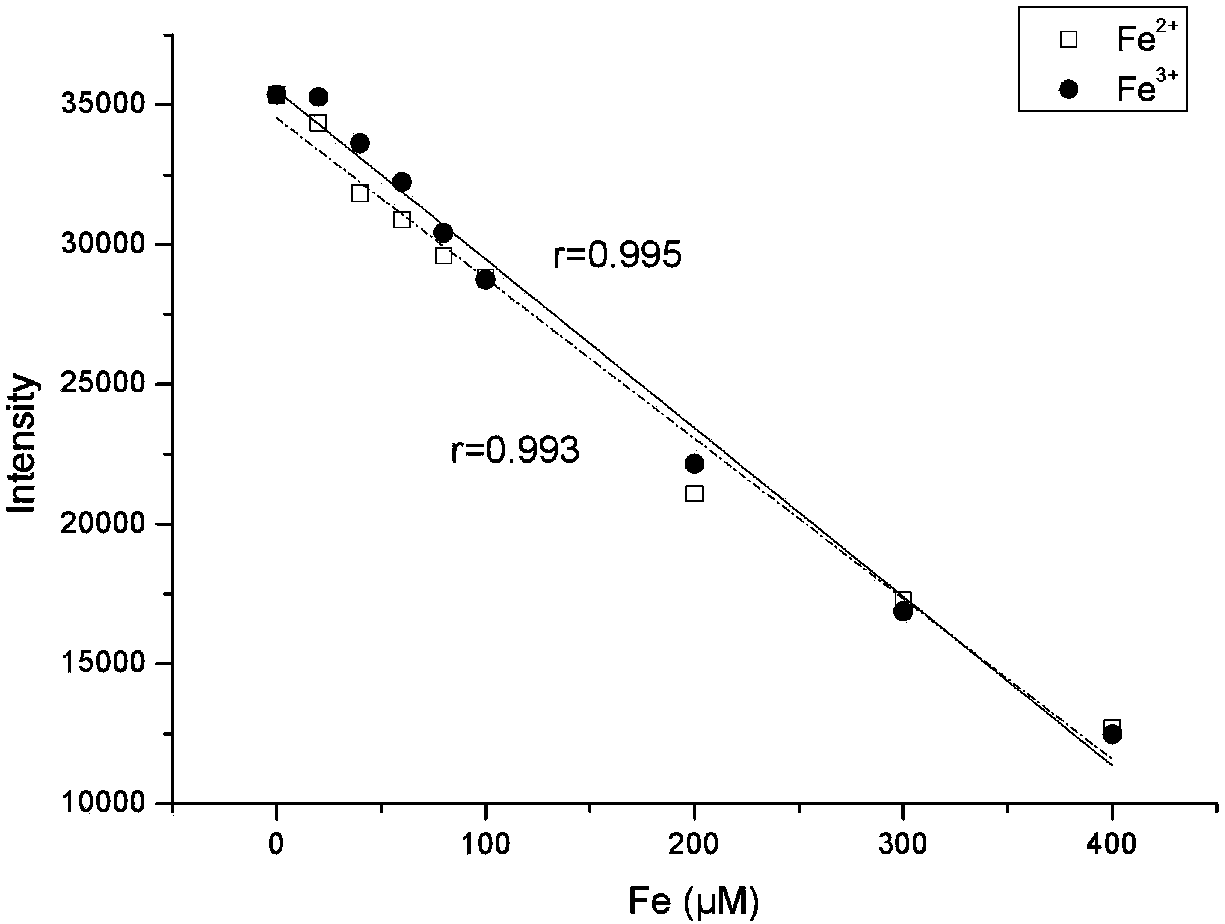

Method for rapidly detecting iron elements based on carbon quantum dot fluorescence method

The invention discloses a method for rapidly detecting iron elements based on a carbon quantum dot fluorescence method, and belongs to the technical field of rapid detection of trace elements by meansof a fluorescence method. Carbon quantum dots are prepared through L-ascorbic acid and ethyl alcohol, no further purification or surface modification is needed, and the method is suitable for detecting the iron elements including ferrous iron and ferric iron. The method has the advantages that the carbon quantum dot preparing process is simple, cost is low, and applied materials are green and free of toxin and have no toxic or side effects on the environment; the linear range of iron detection is wide from 0 micron to 400 micron, and the detection limit is as low as 2.52 micron; sample preprocessing is simple, and no strong acid digestion is needed; ferrous iron and ferric iron can be detected at the same time, and the application range is wide.

Owner:JIANGNAN UNIV

Method for detecting copper ion content and eliminating interference by zinc reagent and masking agent

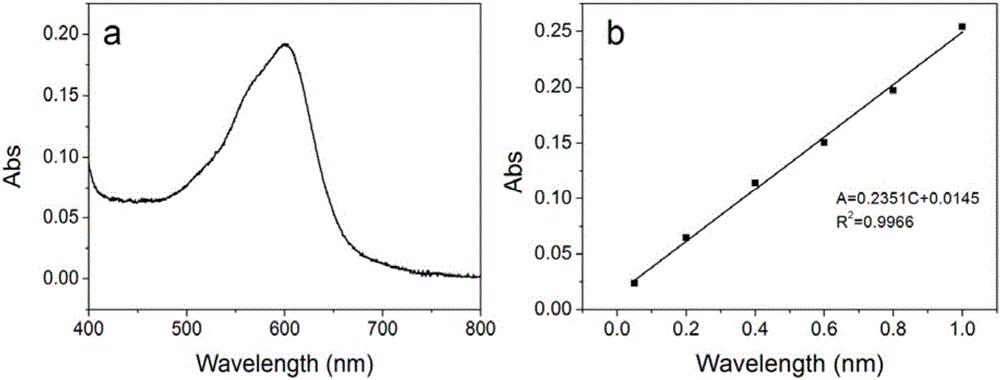

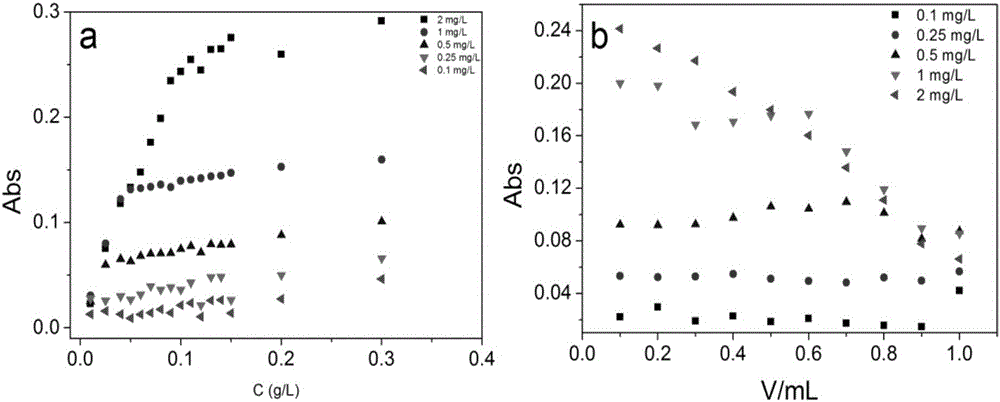

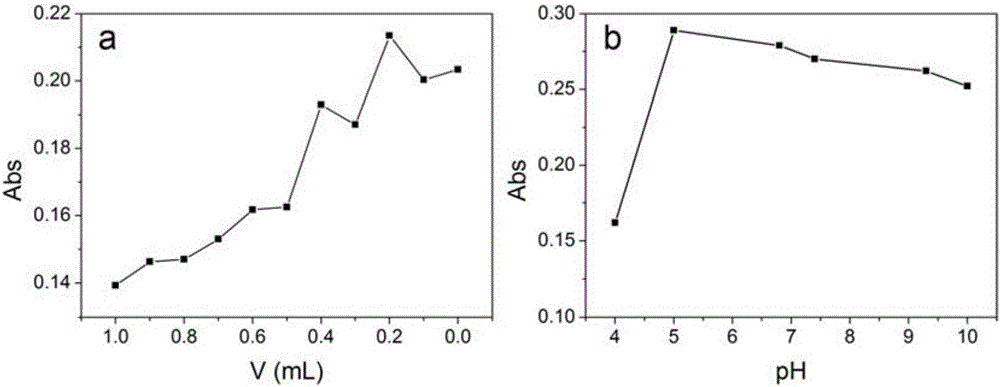

InactiveCN105784610AWhite space is easy to controlThe detection method is simplePreparing sample for investigationColor/spectral properties measurementsIon contentWavelength

The invention discloses a method for detecting the copper ion content and eliminating interference by a zinc reagent and a masking agent.The principle of the detection method is that the zinc reagent is in reaction with copper ions to produce a blue complex, characteristic absorption exists in the position of 60 nm wave length, and the absorbance value of the complex and the concentration are in certain linear relation in a certain concentration range, so that the content of the copper irons is calculated.At the same time, the zinc reagent is in reaction with zinc, nickel, lead, manganese and cobalt ions, and interference is caused to the copper iron detection.According to the method, the stability constant of the complex formed by metal irons and organic ligand is compared with the stability constant of the metal irons and the zinc reagent, so that a suitable masking agent is selected.The method does not involve a separation process, has the advantages that the treatment process is simple, the reagent blank is easy to control, and the masking agent has better interference resistance and good repeatability of the analysis result and is an import method for rapidly analyzing the copper ion content.

Owner:SUZHOU WENHAO MICROFLUIDIC TECH CO LTD

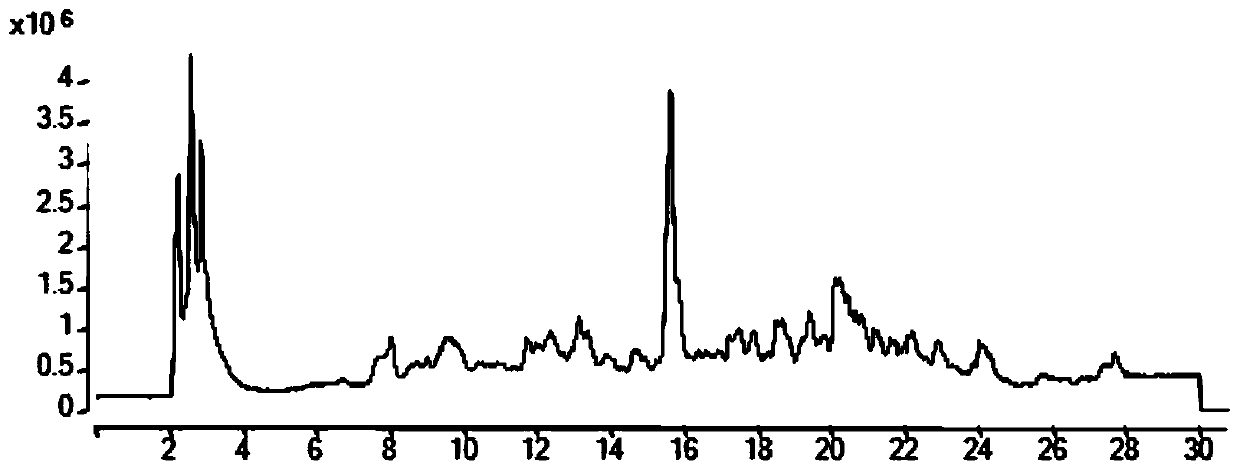

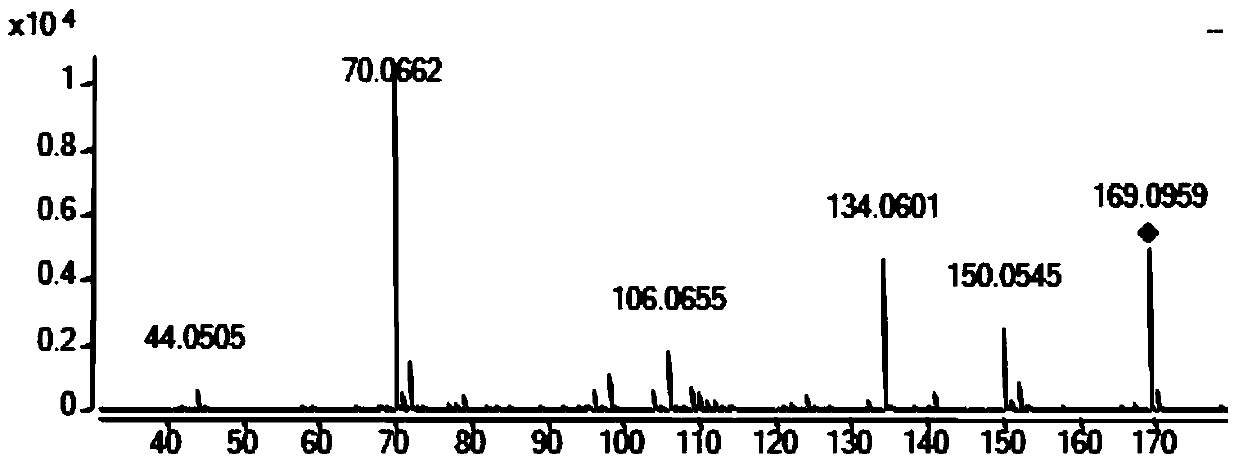

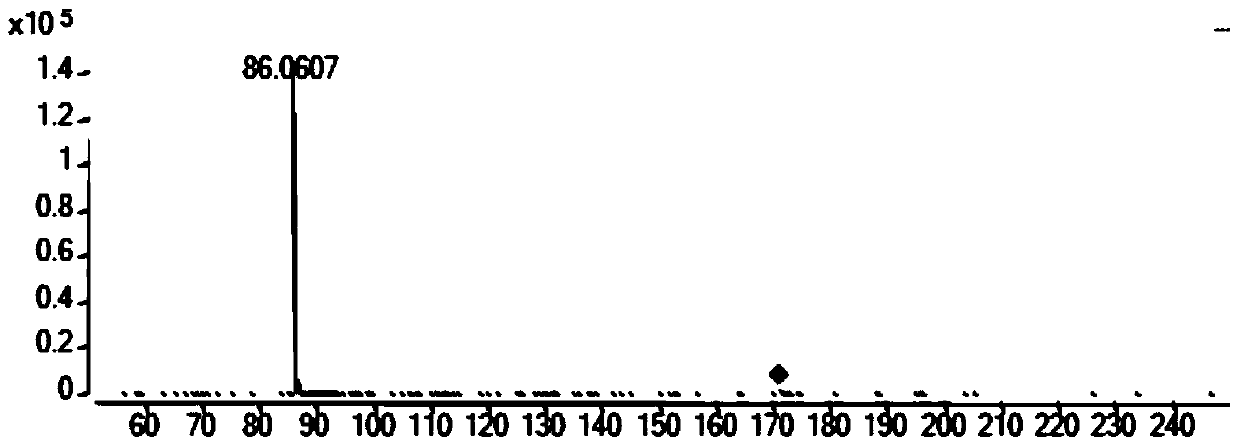

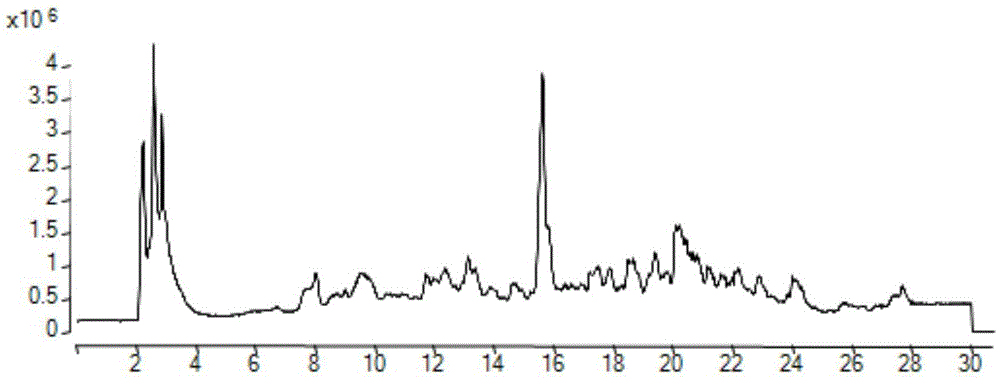

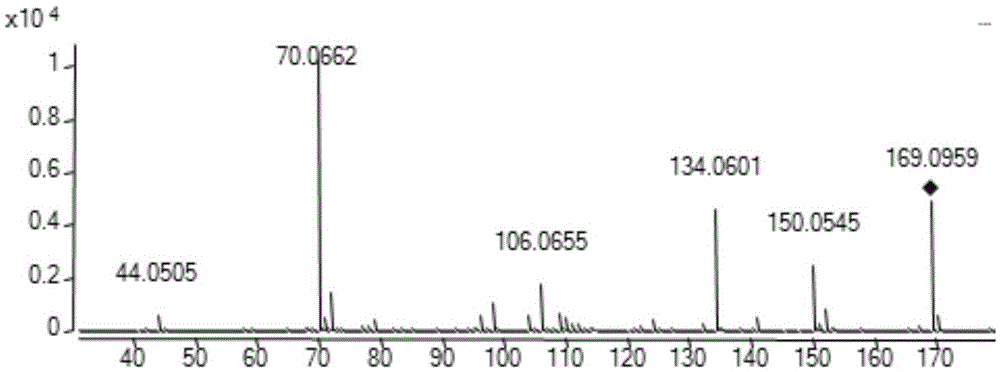

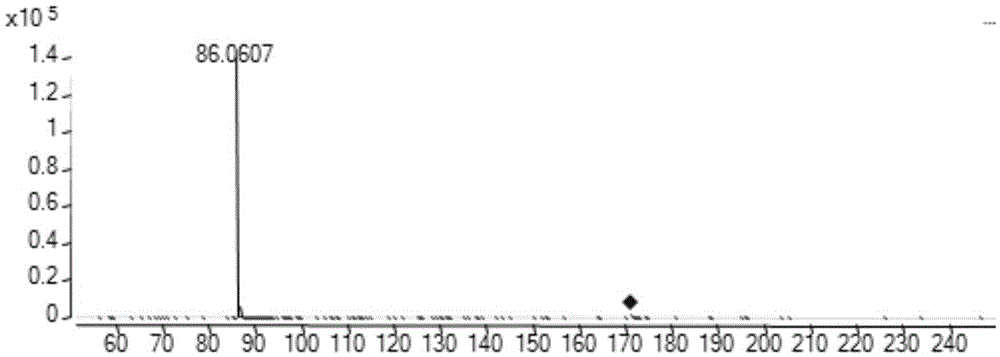

Method for testing cyclic dipeptide in white spirits

The invention relates to a method for testing cyclic dipeptide in white spirits. The method comprises the following steps: a, taking a white spirits sample, eluting with methanol after passing through an SPE-C18 column, and concentrating an eluent to 1 / 50-1 / 10 of the original volume of the white spirits sample at a temperature not higher than 60 DEG C to obtain a to-be-tested sample; b, loading the sample to be tested in step a to a liquid chromatograph-mass spectrometer, and after mass spectrum full-iron scanning, primarily obtaining possibly existing cyclic dipeptide through full-iron scanning peaks; c, then loading the sample to be tested in step a to the liquid chromatograph-mass spectrometer, and obtaining the characteristic ion peak of each possibly existing cyclic dipeptide after selected iron detection; d, further verifying whether the cyclic dipeptide obtained in step b exists in the white spirits or not according to the characteristic ion peak obtained in step c, and finally making a conclusion. The variety of the cyclic dipeptide in the white spirits sample can be accurately and rapidly tested by the method, and one more effective method is provided for the detection of the cyclic dipeptide in the white spirits.

Owner:WULIANGYE

In-line synthesis type high-pressure oil supply pump control system

InactiveCN102434344AReduce volumeLight in massFuel-injection pumpsFuel injection apparatusEngineeringHigh pressure

The invention discloses an in-line synthesis type high-pressure oil supply pump control system which comprises an integral pump body, wherein the middle of a drive shaft is provided with cams matched with plunger pumps, and each plunger pump only supplies high-pressure oil to an electric control fuel injector. The in-line synthesis type high-pressure oil supply pump control system is characterized in that a part of a drive shaft, extending from an oil supply pump rear cover, is a rotor shaft, a circular hole of a signal regulating plate is matched with a column body on the oil supply pump rear cover, the signal regulating plate is provided with signal regulating plate end face sensor opposite to a rotor end face permanent magnet, a rotor pole iron detection sensor opposite to a rotor pole iron is arranged on a sensor bracket. An electronic control unit (ECU) receives signals from the rotor pole iron detection sensor and the signal regulating plate end face sensor which are connected with the ECU, and the processed signals are sent to the corresponding electric control fuel injector through a transmission line. The invention has the characteristics of simple structure, good generality, easiness in debugging, low cost and easiness in production, is especially suitable for application on an electric control diesel engine, and can also be applicable to other oil pumping fields.

Owner:王晓燕

Selenium, zinc and iron fortified porridge and production method thereof

InactiveCN106107452ARealize "quantitative controllable"Nutritional diversityFood ingredient functionsControllabilityIron detection

The invention discloses selenium, zinc and iron fortified porridge and a production method thereof. The selenium, zinc and iron fortified porridge is mainly prepared from 1%-50% of selenium-enriched cereals, 0.1%-49% of zinc-enriched cereals and / or water and 0.1%-25% of an iron fortifying agent (NaFeEDTA). The selenium, zinc and iron fortified porridge has comprehensive nutrients and is simple to produce and low in cost; the cereals which are generally produced in rural areas and the iron fortifying agent are mainly used as the raw materials; quantitative controllability of selenium in selenium-enriched grains, fruits and vegetables, edible fungus eight-treasure porridge and eggs is realized through establishing knowledge intensive type automatic navigation and agricultural robots and vehicles, a selenium, zinc and iron detection system interactive with consumers, functional farms which include mulberry fields, tea gardens, orchards, rice fields, wheat fields, corn fields and the like and can realize three-dimensional planting and breeding, automatic navigation and production of selenium-enriched edible fungus eight-treasure porridge and eggs, interactive greenhouses and selenium-enriched supermarkets; chain operation of the selenium, zinc and iron fortified porridge in China is realized. Farmers are led to walk on a large-scale agriculture development path by technologies; and the selenium, zinc and iron fortified porridge and the production method thereof are convenient to popularize in rural areas, particularly 592 poor counties in China.

Owner:窦观一

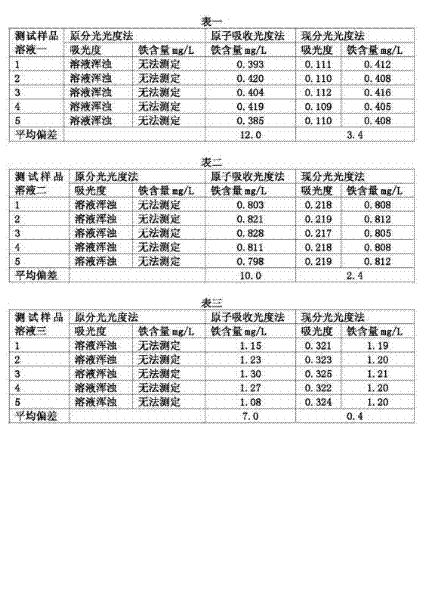

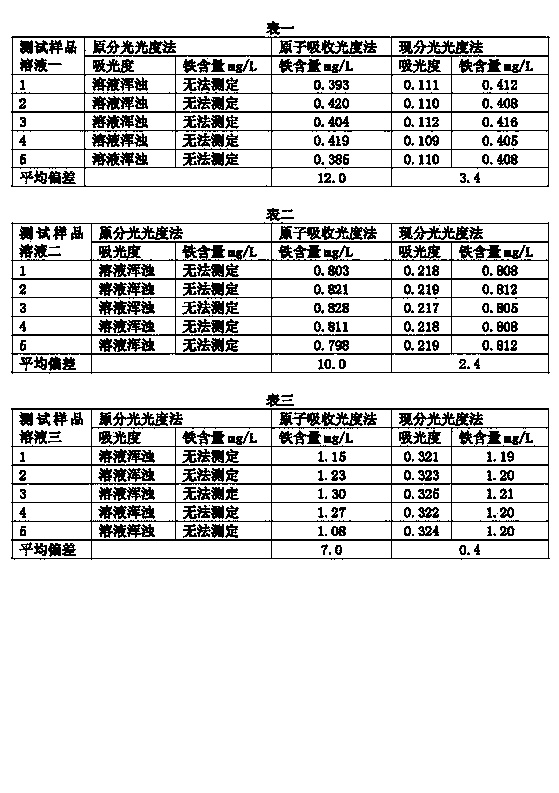

Determination method of trace iron in aluminum-containing phosphoric acid solution and aluminum masking agent therefor

ActiveCN102565045ASolve the accuracy problemSolve the costMaterial analysis by observing effect on chemical indicatorO-Phosphoric AcidAluminium hydroxide

The invention relates to the technical field of a determination method of trace iron in an aluminum-containing phosphoric acid solution, and particularly to a determination method of trace iron in an aluminum-containing phosphoric acid solution and an aluminum masking agent for the determination method. The determination method comprises two steps of drawing a standard work curve of iron content and testing the iron content in a test sample solution. The determination method of the invention is simple in operation, high in test accuracy, and good in reproducibility, not only overcomes the defect in the prior art of impossible to detect due to the present of white aluminum hydroxide precipitate, but also solves the problems of poor trace iron detection accuracy and high cost in the track iron determination process by the atomic absorption spectrophotometry, and effectively expands the application scopes of determinating iron content in the phosphoric acid with the phenanthroline spectrophotometric method.

Owner:石河子众金电极箔有限公司

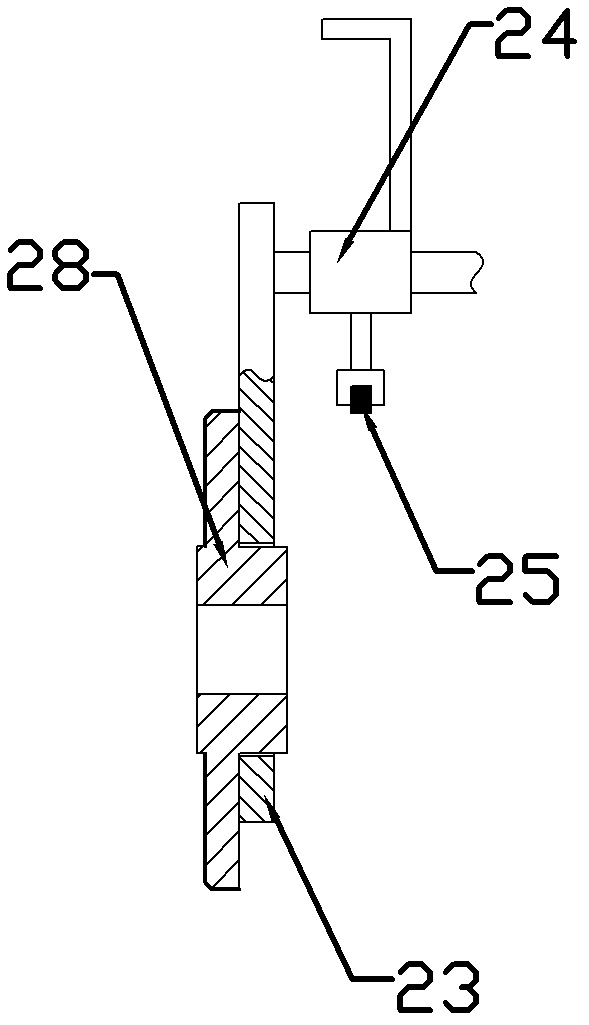

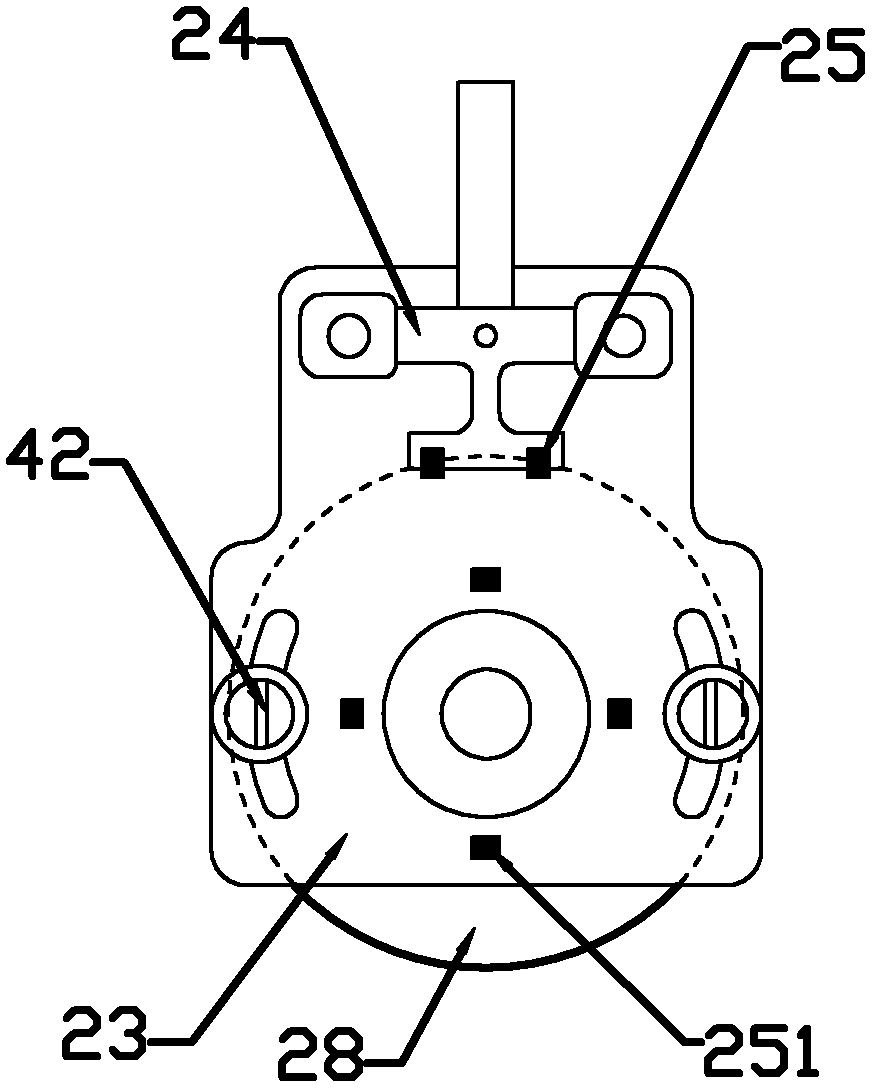

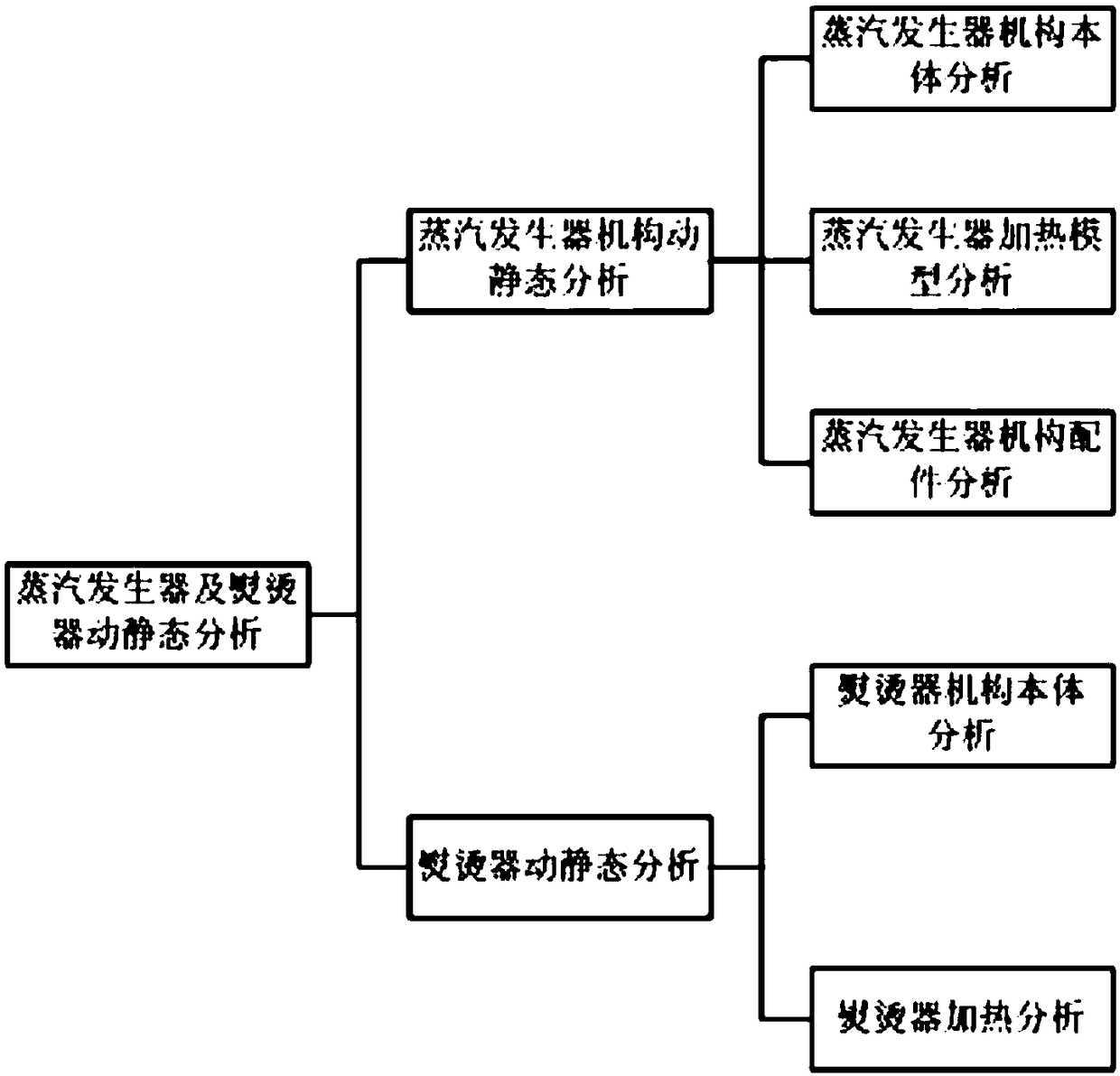

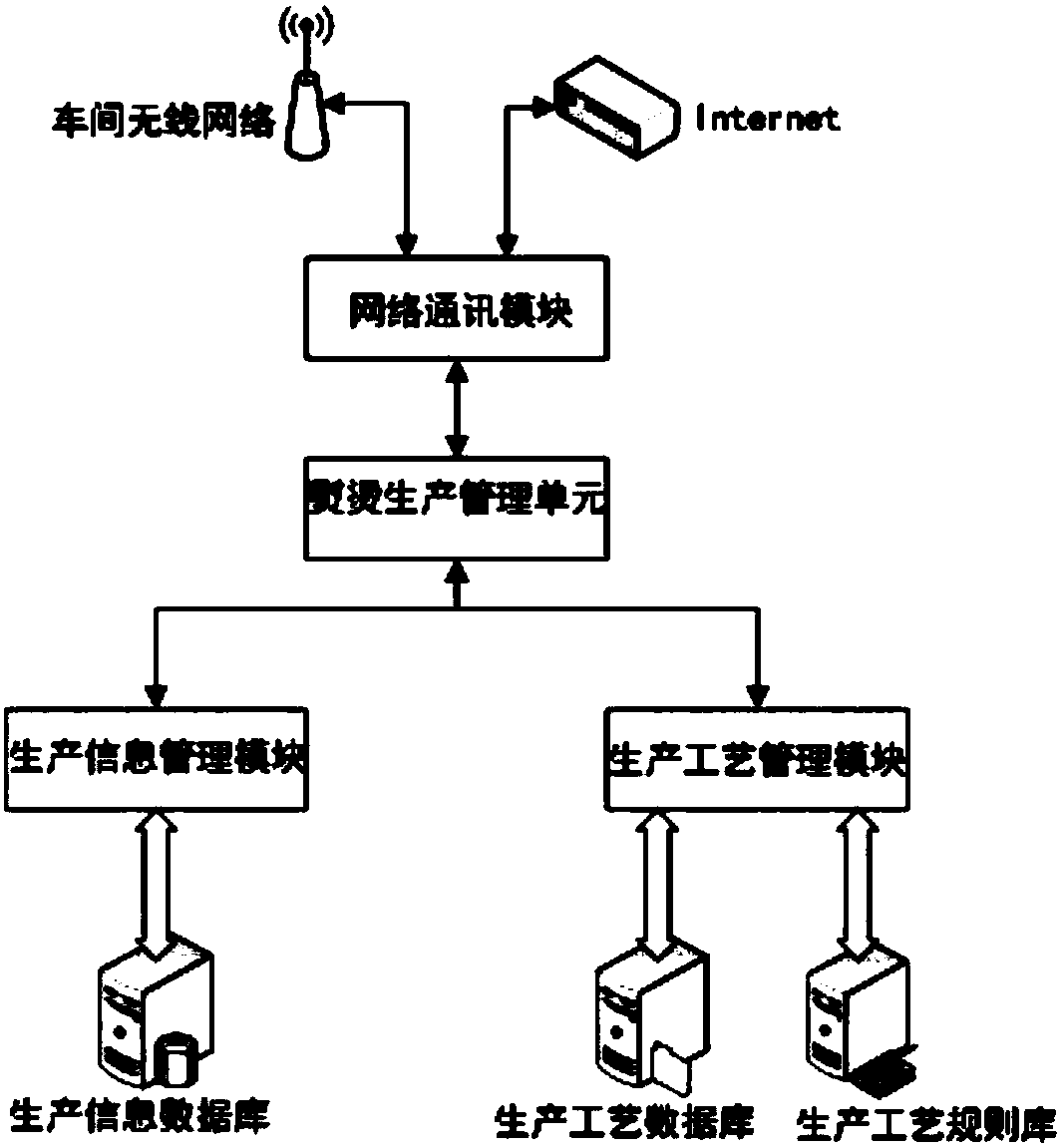

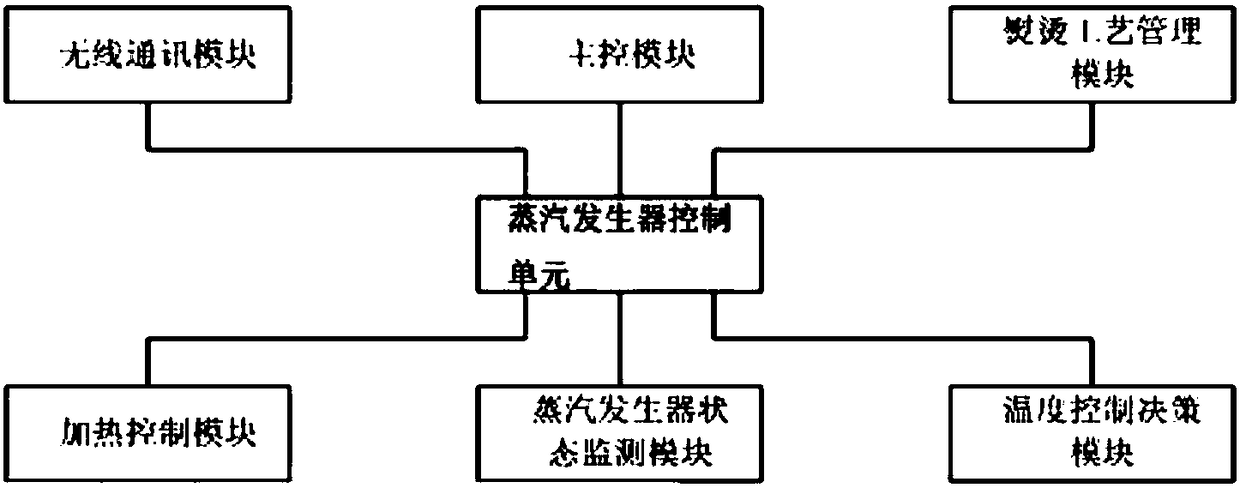

An ironing control system for an electric iron based on wireless communication

InactiveCN105046917BRealize processing and manufacturingReduce the impactTransmission systemsEnergy industrySteam pressureEngineering

The invention discloses an ironing control system of electric iron based on wireless communication. The ironing control system mainly comprises a finite element analyzing unit, an ironing detection unit, an ironing production management unit and a steam generator control unit. The finite element analyzing technology is adopted for analyzing the strength and the temperature field of a steam generator and an ironing machine body mechanism; according to the analysis and optimized design, the processing technology of the steam generator and the ironing machine is researched, so that the steam generator and the ironing machine can be processed and manufactured; due to the adoption of frequency conversion technology, the heating control of the steam generator can be realized, the influence relationship between the industrial fabric type and the factors such as fabric ironing temperature and steam pressure can be collected, a fabric ironing process database for the ironing industry can be constructed, the matching between different fabrics and the ironing temperatures can be realized, a fabric ironing production process decision based on intelligent technology can be constructed, the strategy that steam generator groups in a workshop are cooperated for heating control can be researched, so that the influence on a power grid can be reduced. The ironing control system plays the roles of energy conservation, emission reduction and low carbon.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for determining iron content in ferrovanadium solution by EDTA complexing-hydrogen peroxide chromogenic matrix matching spectrophotometry

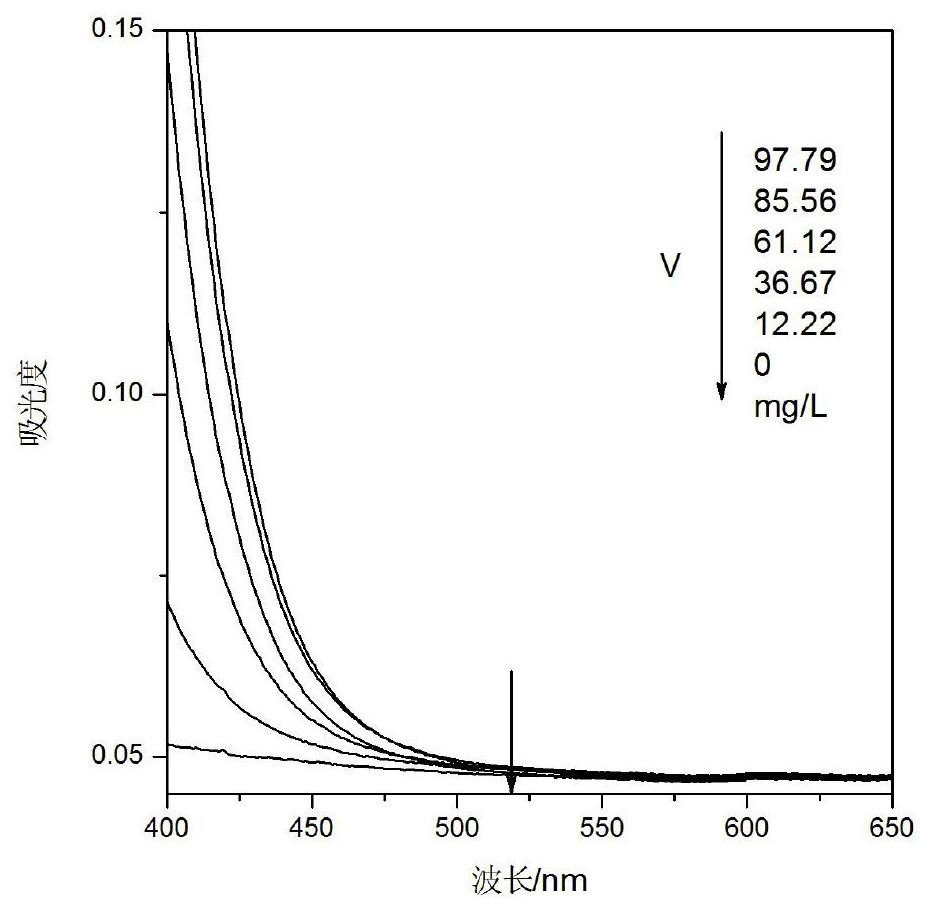

PendingCN112730292AGood colorEliminate detection noiseMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPhysical chemistryChromogenic

The invention provides a method for determining the iron content in a ferrovanadium solution by EDTA complexing hydrogen peroxide chromogenic matrix matching spectrophotometry. According to the method, EDTA, hydrogen peroxide and iron ions form a chromogenic group under the condition of an alkaline solution, a chromogenic signal is enhanced, the detection sensitivity is improved, interference of vanadium to iron detection is eliminated in a vanadium matrix matching mode, the detection accuracy is improved, accurate and rapid detection of the iron content in the ferrovanadium solution is achieved, and the method is suitable for industrial production; technical problems in the prior art are solved.

Owner:大连融科储能集团股份有限公司

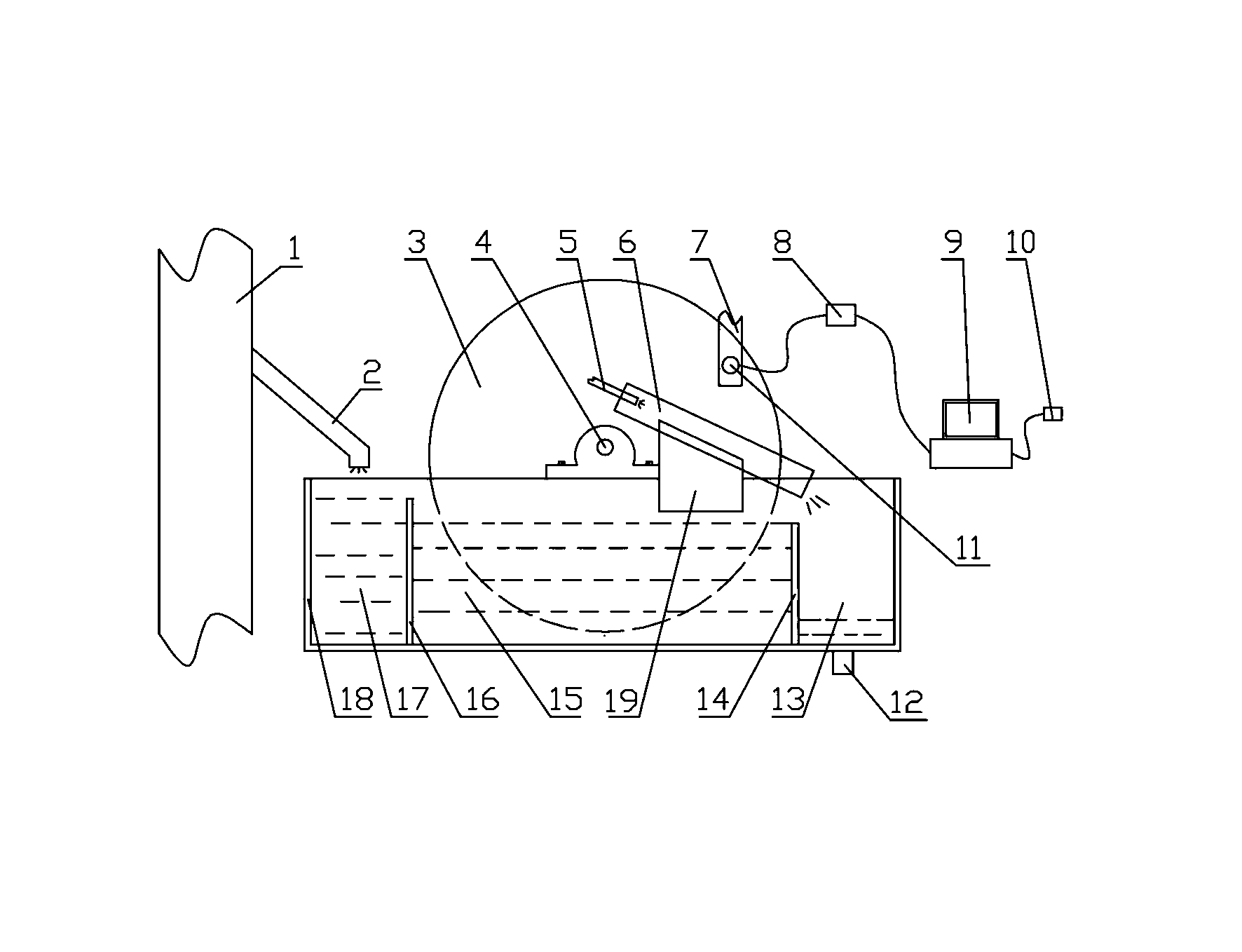

On-line magnetic iron detection and alarm device and method for magnetite tailings

ActiveCN103018278AReduce labor intensityTimely processingMaterial analysis by electric/magnetic meansFixed frameDrive shaft

The invention relates to an on-line magnetic iron detection and alarm device and method for magnetite tailings. The on-line magnetic iron detection alarm device comprises a tailing groove, a mine cutting pipe, a pulp groove, a magnetic separation device for pulp and a detection and early warning device, wherein the magnetic separation device for pulp is composed of a driving device, a driving shaft, a permanent magnetic separation disc, two mine discharging grooves and two water filling devices; the mine discharging grooves are fixed on the pulp groove through a support; the detection and early warning device is composed of a fixed frame, two thickness detection sensors, an analog and digital converter, a computer and a photoelectric alarm; and the two thickness detection sensors are respectively arranged on one outer sides of the two end faces of the permanent magnetic separation disc. The on-line magnetic iron detection and alarm device and method provided by the invention can timely detect the change of magnetic iron in the tailings and make preliminary judgment on an operation state of the magnetic separator, thus avoiding the situation that the content of the magnetic iron in the tailings is out of limits for a long time; and meanwhile, the on-line magnetic iron detection and alarm device and method can make preliminary judgment on a part out of limits and narrow an investigation range, so that the parts out of limits can be disposed in real time, and the labour intensity of operating staffs is relieved.

Owner:ANSTEEL GRP MINING CO LTD

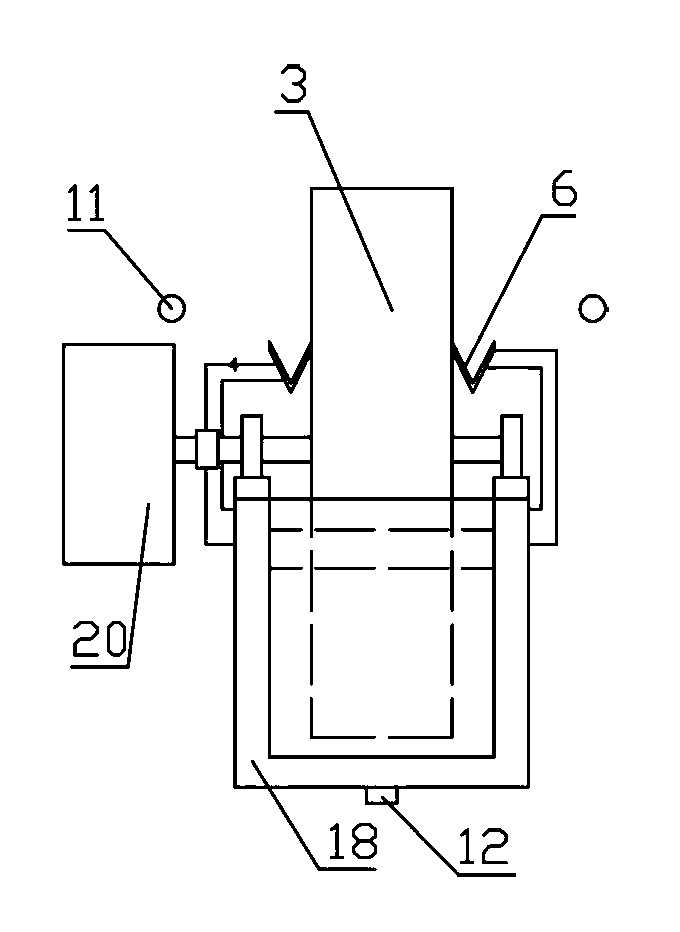

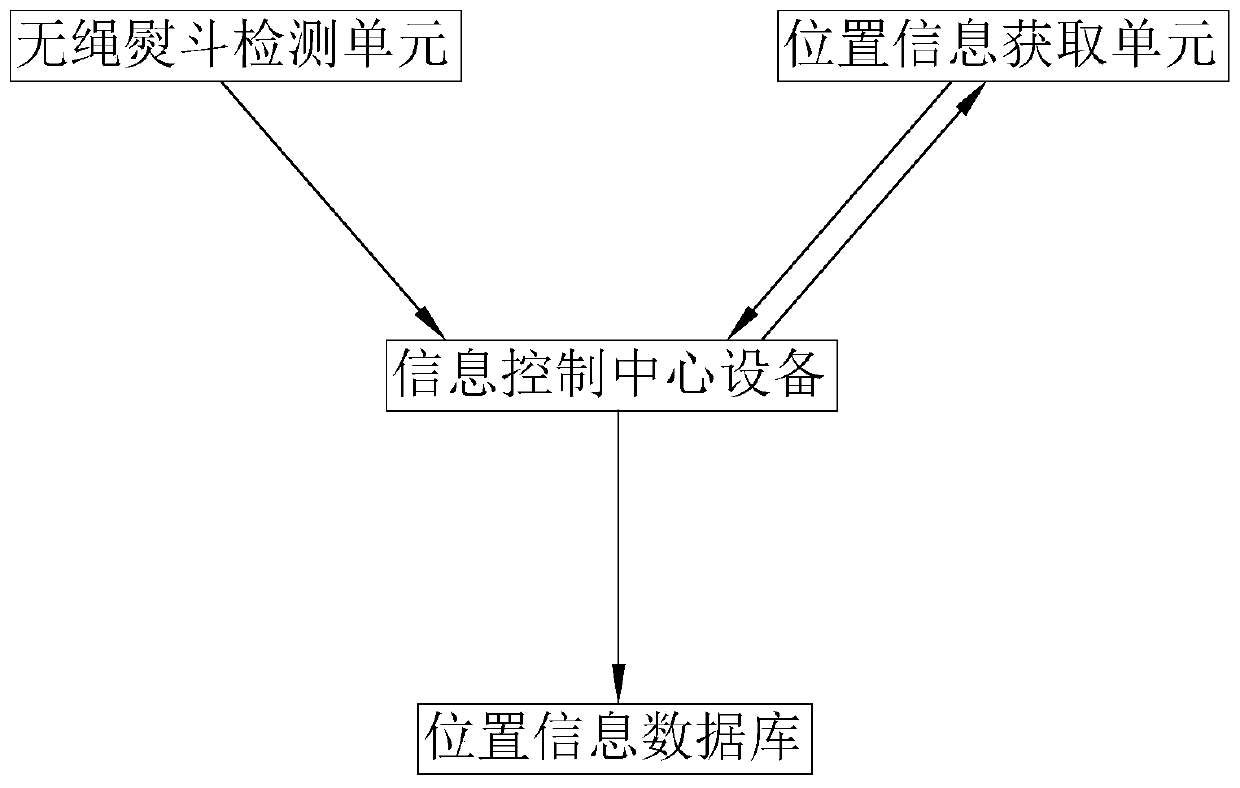

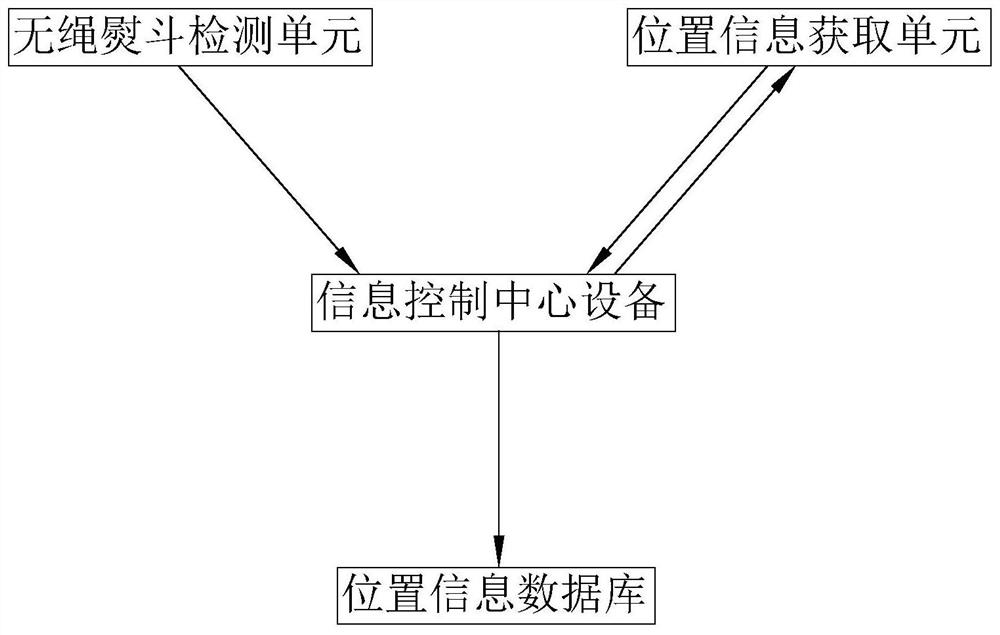

Ironing equipment comprising cordless iron and charging base

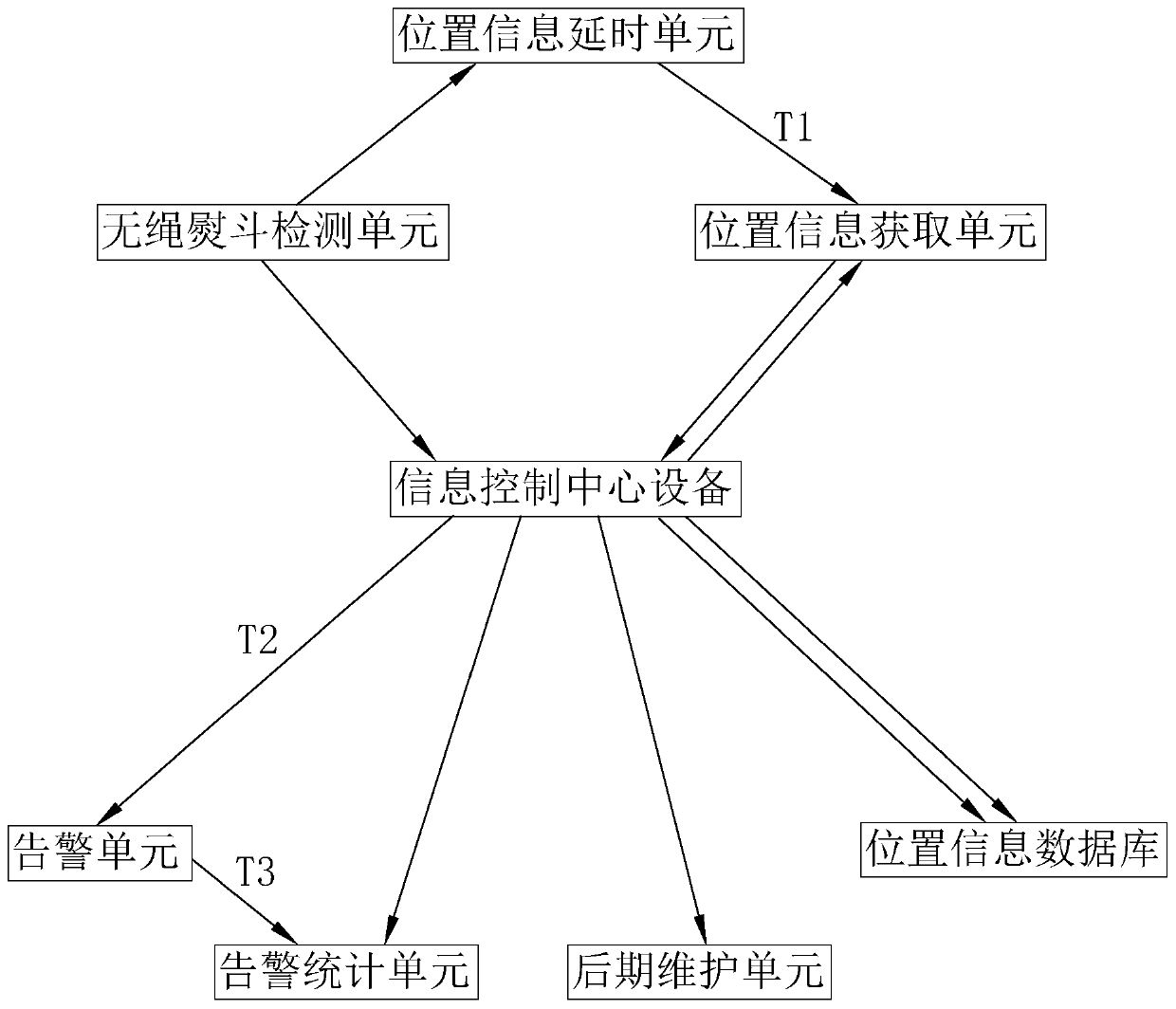

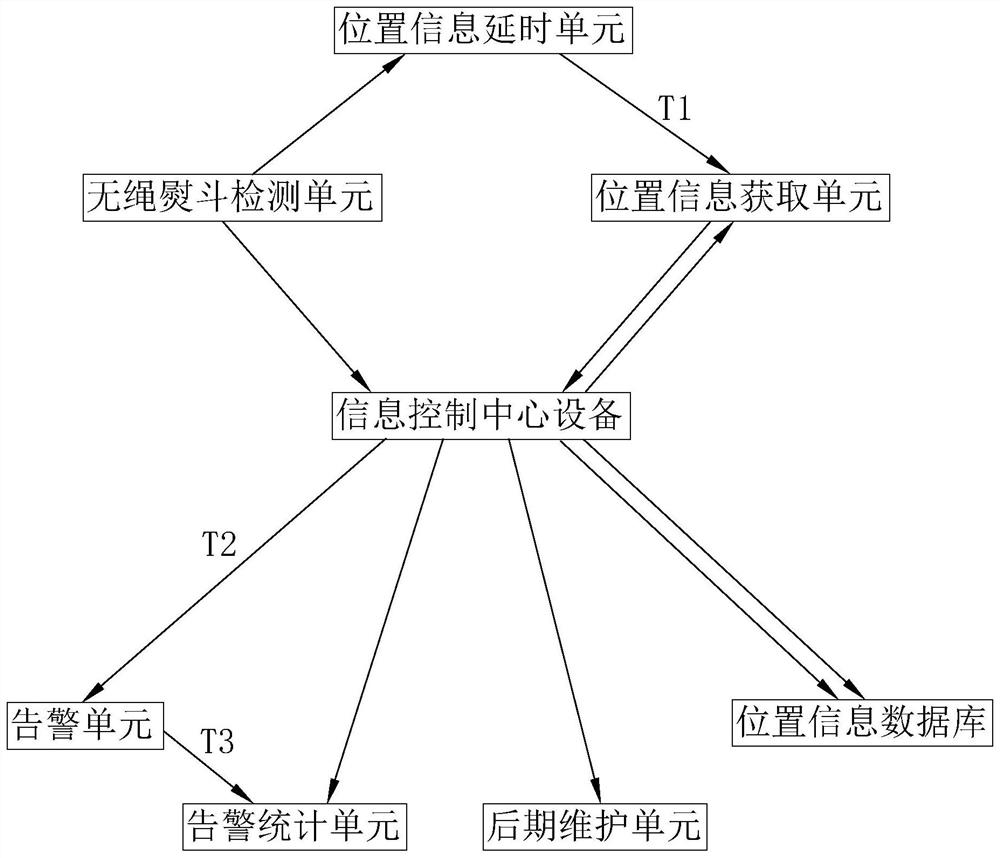

ActiveCN110144717AImprove performanceStable jobHand ironTextiles and paperInformation controlIron detection

The invention discloses ironing equipment comprising a cordless iron and a charging base, relates to the field of the ironing equipment and solves the problem of deviation of the placement position ofthe cordless iron arranged in the charging base. The technical scheme is that the ironing equipment comprises a cordless iron detection unit, a position information acquisition unit, a position information database and an information control center device; the cordless iron detection unit detects that the cordless iron is arranged on the charging base, the information control center device compares current position placement information of the cordless iron on the charging base with the cordless iron placement information in the position information database, and if the current position placement information of the cordless iron is not matched with the cordless iron placement information in the position information database, a user is reminded to adjust the placement position of the cordless iron. According to the ironing equipment comprising the cordless iron and the charging base, the placement position of the cordless iron is conveniently adjusted by the user in time, and normal charging of the cordless iron is realized.

Owner:CUORI ELECTRICAL APPLIANCES GRP

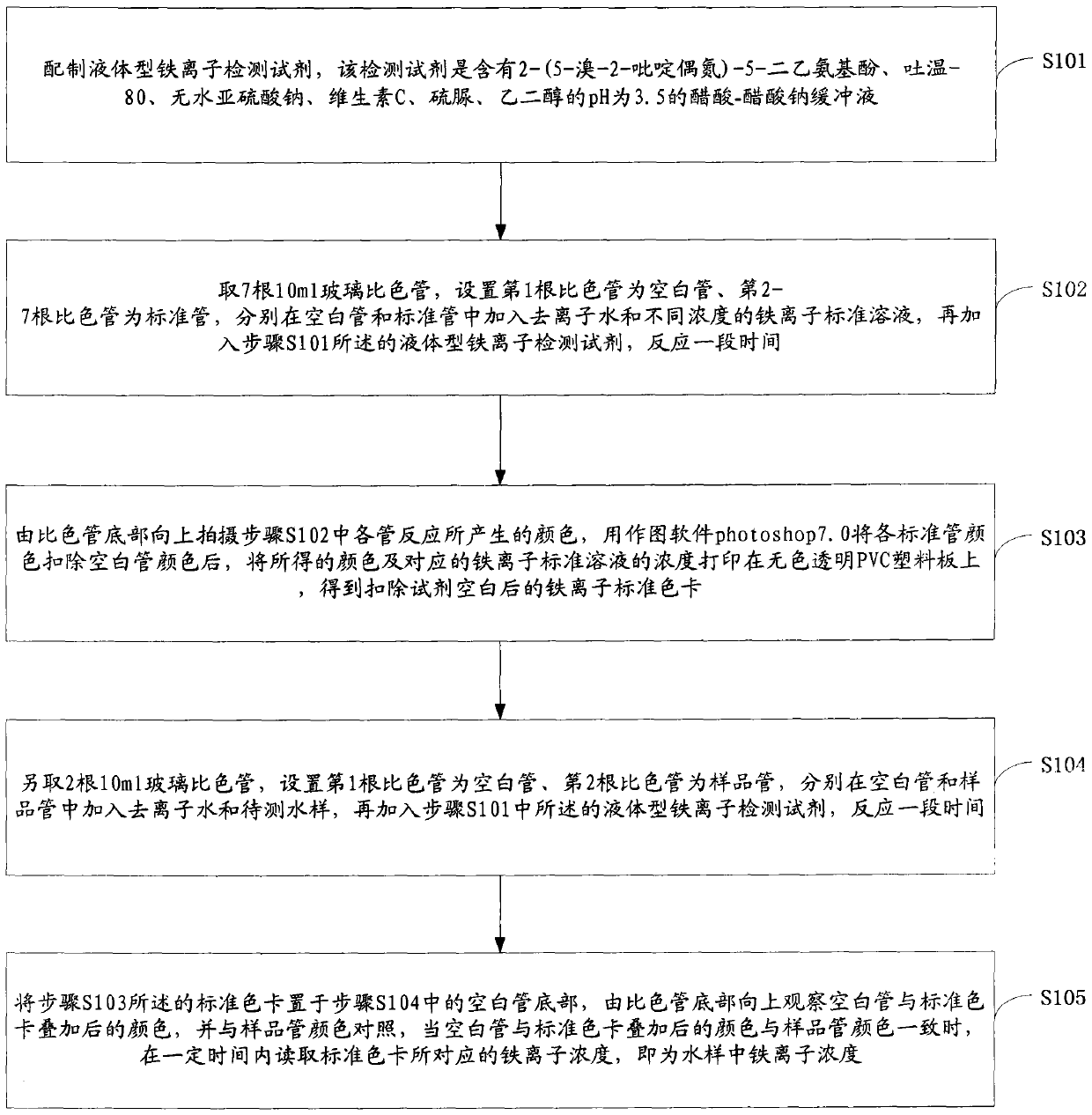

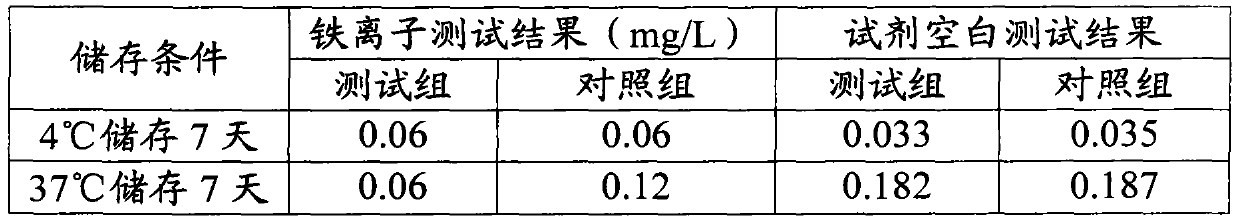

A rapid on-site detection method of iron ions in water that can eliminate the influence of reagent blank

ActiveCN105319209BEliminate the effects ofSimple methodMaterial analysis by observing effect on chemical indicatorPlastic filmIron detection

The invention discloses an on-site rapid detection method for iron ions in water capable of eliminating the influence of reagent blanks. The method prepares a liquid-type iron ion detection reagent, deducts the blank color of the reagent, and manufactures a standard color card with a transparent plastic plate as a supporting material. , Superimpose the color of the blank tube on the standard color card and compare it with the sample tube during detection, which has the advantages of simple method, high accuracy, and easy operation; using liquid iron ion detection reagent for detection can effectively control the entire detection process. It takes time; by superimposing the color of the blank tube on the standard color card and then comparing it with the sample tube for color comparison, it can effectively eliminate the adverse effects of reagent blank fluctuations on the accuracy of the test results, especially suitable for rapid on-site detection of iron ions in water .

Owner:WENZHOU MEDICAL UNIV

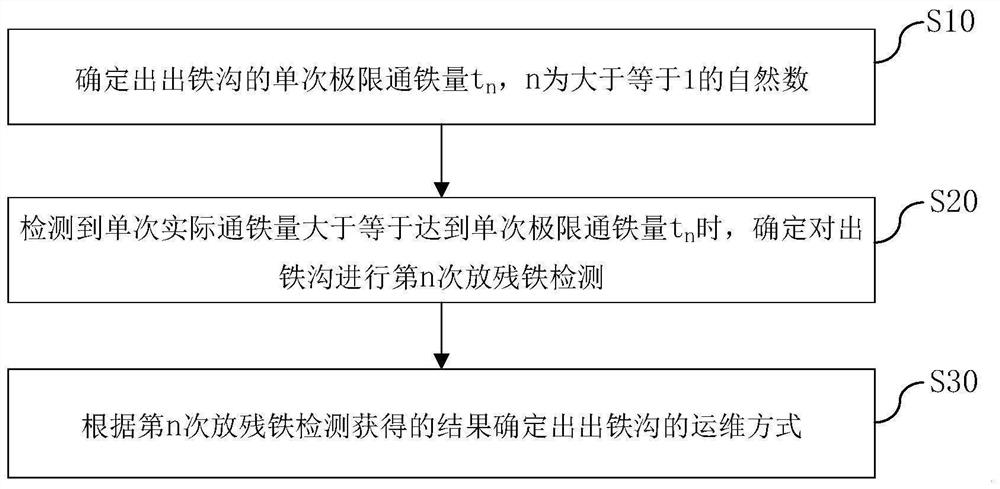

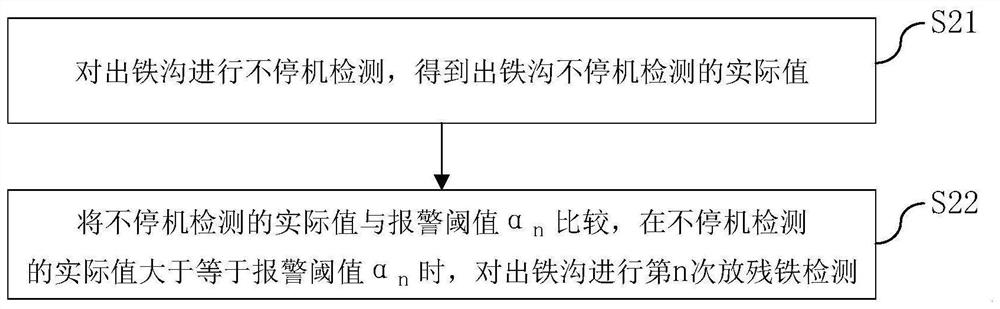

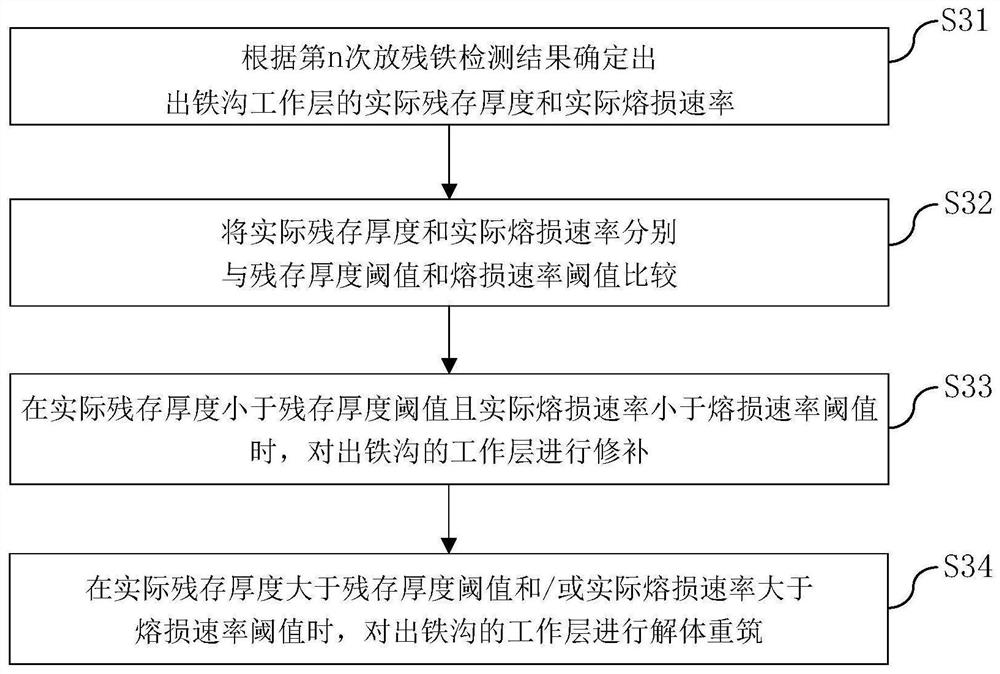

Blast furnace tapping channel operation and maintenance method and tapping channel

ActiveCN113337657AAvoid excessive melting lossAccurate judgmentSteel manufacturing process aspectsBlast furnace detailsProcess engineeringIron detection

The invention provides a blast furnace tapping channel operation and maintenance method and a tapping channel. The blast furnace tapping channel operation and maintenance method comprises the following steps that the single-time limit iron passing amount tn of the tapping channel is determined, wherein n is a natural number larger than or equal to 1; when detecting that the single-time actual iron passing amount is larger than or equal to the single-time limit iron passing amount tn, that the nth time of residual iron discharging detection is conducted on the tapping channel is determined; and the operation and maintenance manner of the tapping channel is determined according to the result obtained through the nth time of residual iron discharging detection. According to the technical scheme, the accuracy of the residual iron discharging detection opportunity is improved by setting the single-time limit iron passing amount tn, then the tapping channel is subjected to repairing, disassembling and rebuilding and the operation and maintenance manner of mutual combination according to the result of the nth time of residual iron discharging detection, tapping channel refractory materials are effectively and fully utilized through more detailed operation and maintenance manner division, the refractory material loss is reduced, and the service life of the tapping channel is prolonged.

Owner:MCC BAOSTEEL TECH SERVICE

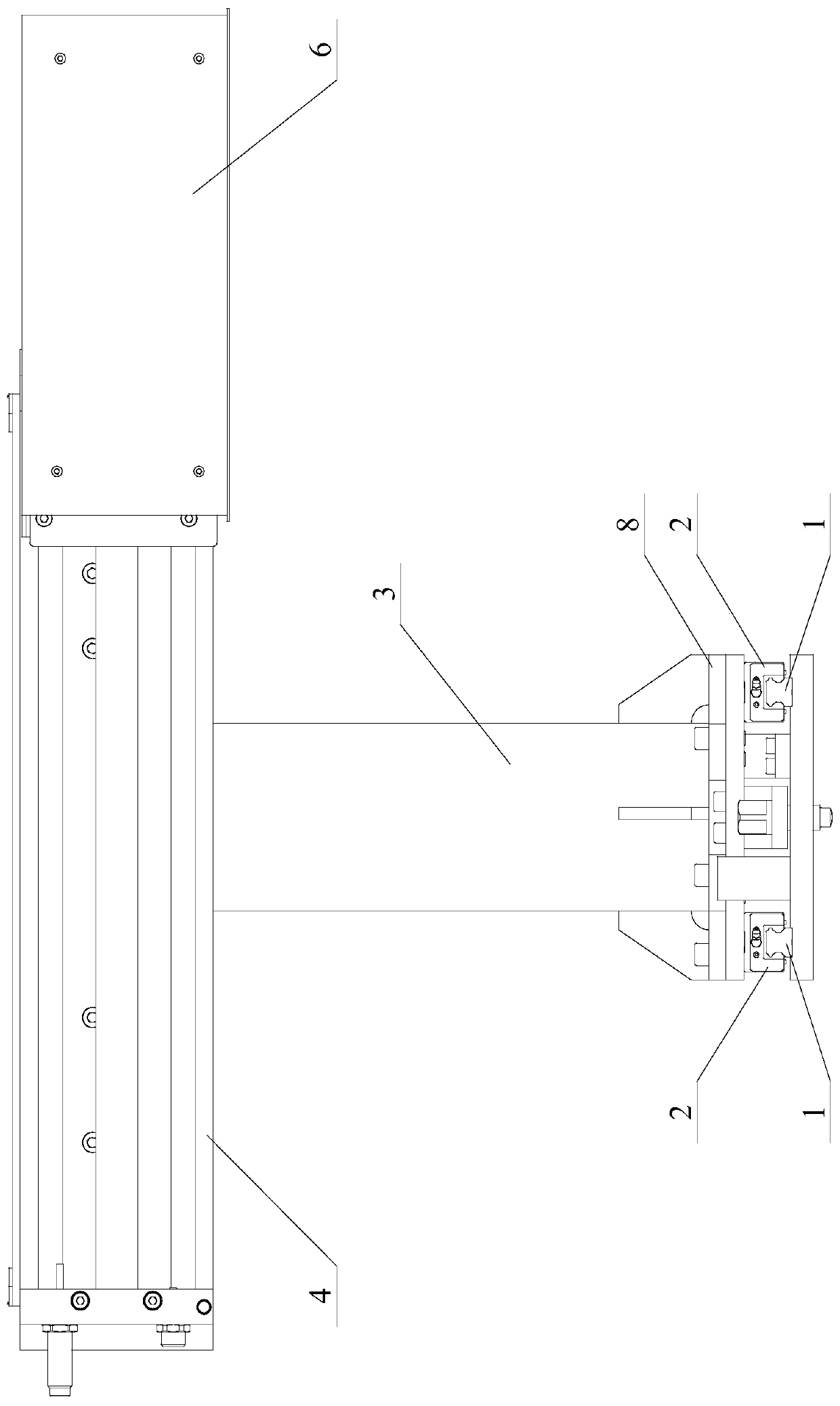

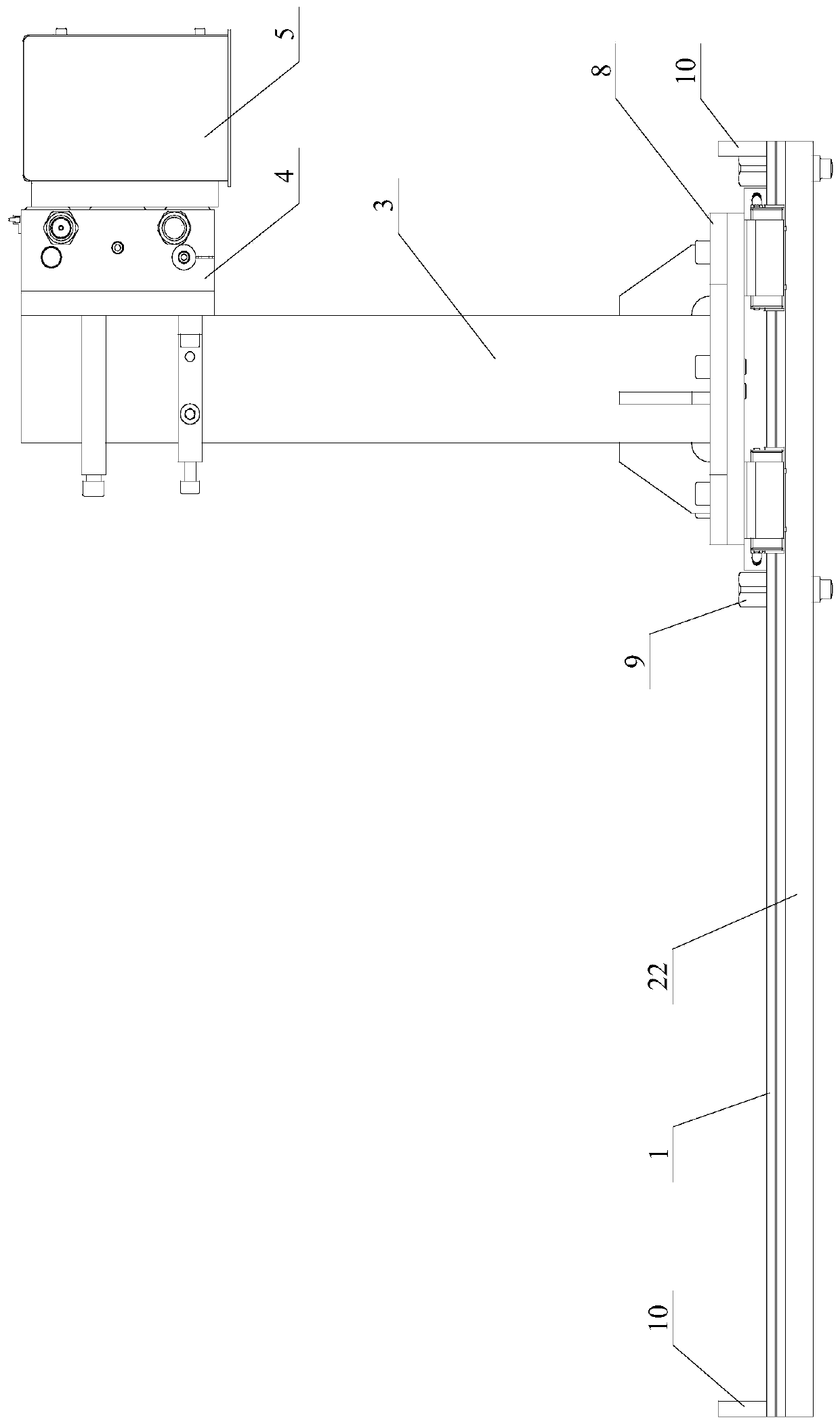

Depth detection device for high-temperature molten iron

PendingCN111457991AProcessing speedAvoid feedingMachines/enginesLevel indicatorsImaging processingThermal insulation

A depth detection device for high-temperature molten iron belongs to the technical field of high-temperature molten iron detection devices. According to the invention, a sensor is protected by using ahigh-temperature thermal insulation material, the sensor can resist 200 DEG C for 5 minutes, and the internal temperature of the sensor is always kept at about 50 DEG C. A blue laser is emitted to the liquid level position through an emitter and receives an image through a receiver. Image algorithm processing is carried out to obtain molten iron liquid level height data. When detection is needed,a pneumatic sliding table automatically extends out of a fixed sensor, returns to the original point after detection and is far away from the furnace opening, and the furnace opening is vacated at low temperature to facilitate work of a mechanical arm. Data obtained after laser detection are transmitted back to an industrial personal computer, the liquid level of molten iron is screened out through an image processing algorithm and then distributed to the mechanical arm, and molten iron casting work is conducted. When the furnace needs to be added with materials, cleaned or replaced, a sliding table fixing buckle is manually loosened, the sliding table and the whole set of equipment are pushed to move to the farthest end of double linear guide rails, so that the furnace is cleaned conveniently, and the detection device is protected.

Owner:山东万德自动化科技有限公司

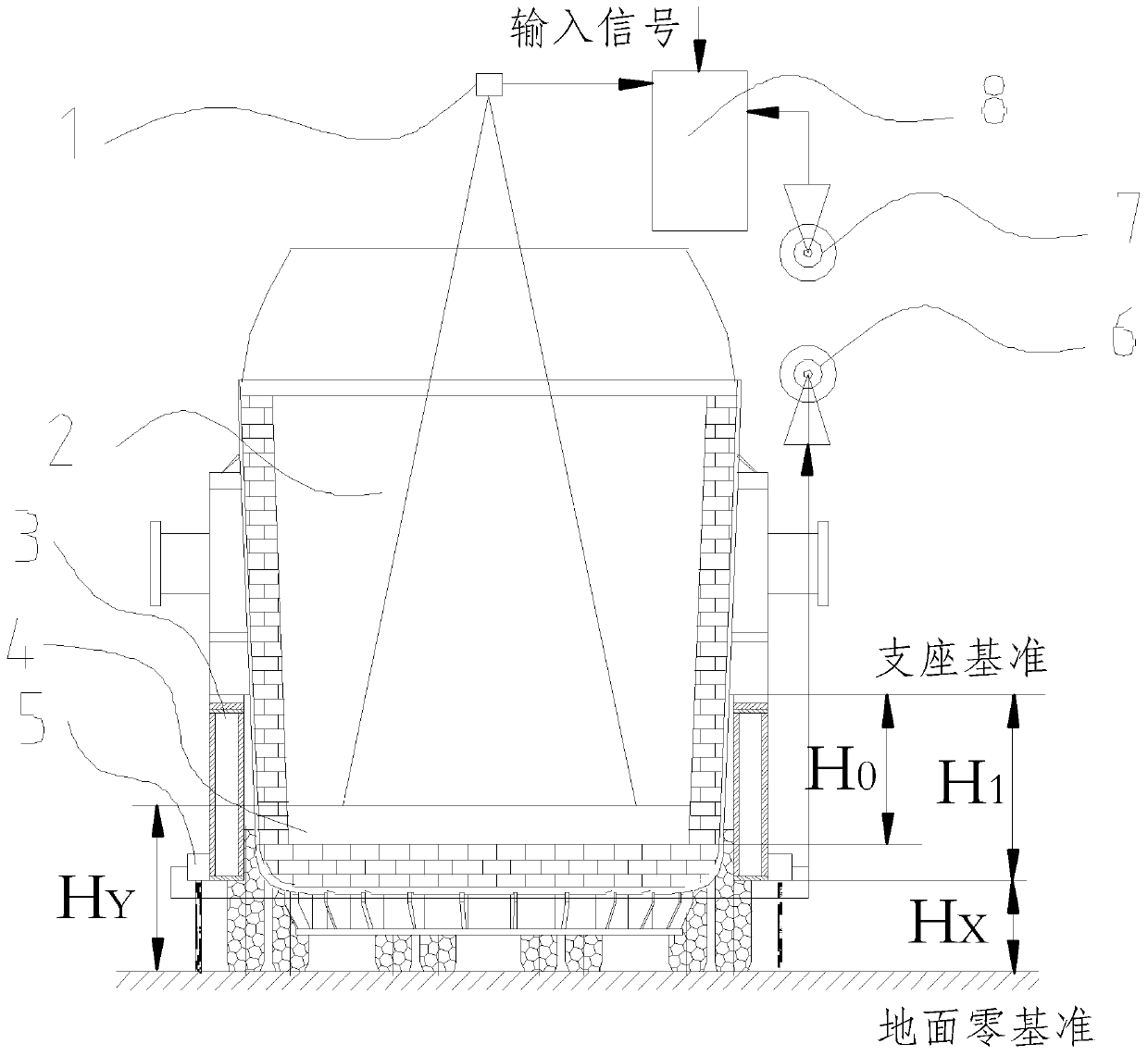

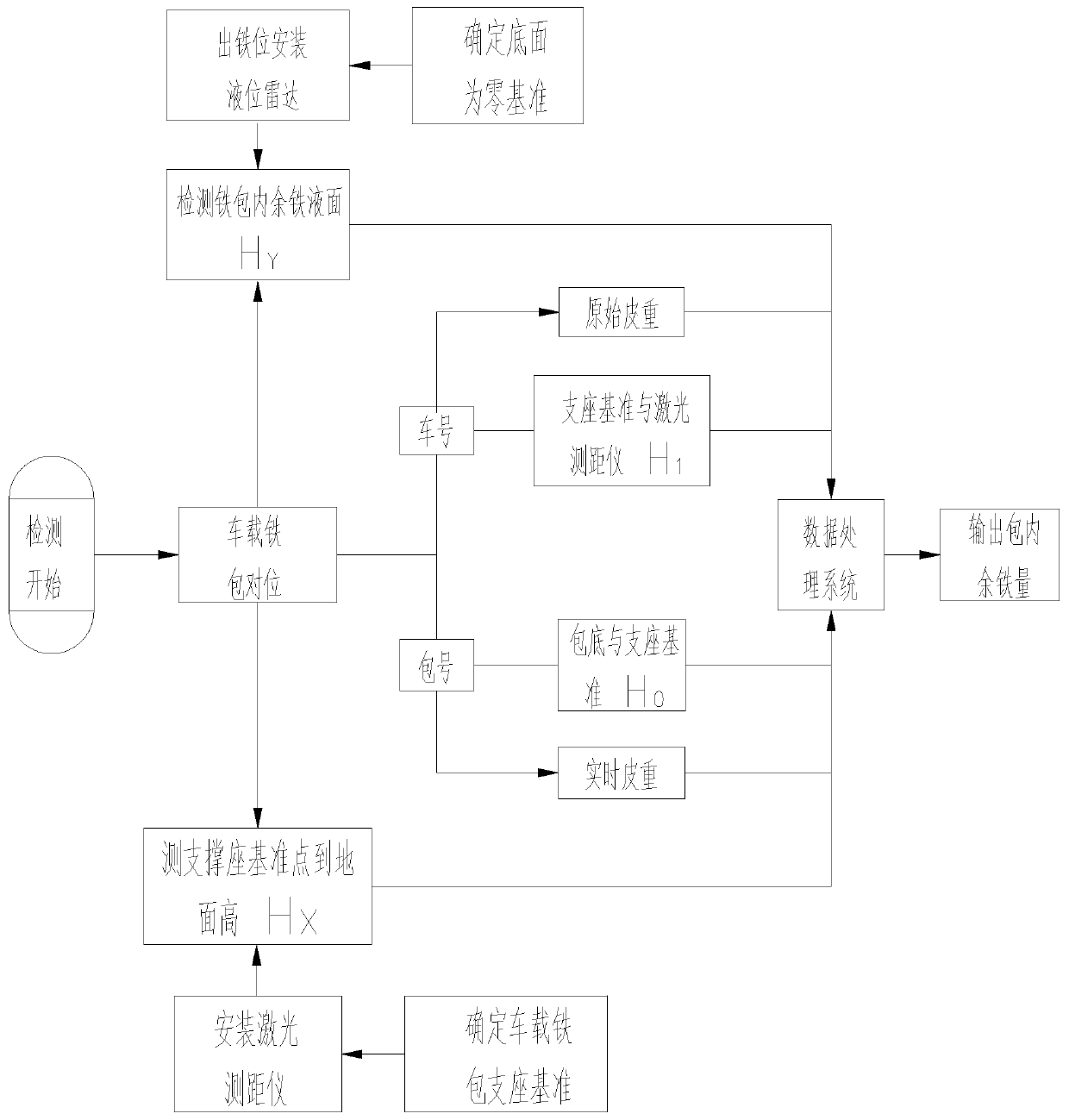

Vehicle-mounted iron ladle residual iron detection device and detection method

InactiveCN111412964ADynamic Accurate OutputPrecise control of iron outputMachines/enginesUsing optical meansData informationIron detection

The invention relates to a vehicle-mounted iron ladle residual iron detection device. The device comprises a vehicle-mounted iron ladle support used for fixing an iron ladle and a liquid level radar fixed over the iron ladle. A vehicle-mounted laser range finder is installed on the outer side of the vehicle-mounted iron ladle support, the vehicle-mounted laser range finder is connected with a vehicle-mounted data transmitter, the vehicle-mounted data transmitter is in wireless connection with a data receiver, the data receiver is connected with a control system, and the control system is further connected with a liquid level radar. The residual iron amount in the ladle can be calculated according to the obtained data information before iron packaging of the iron ladle, the ladle bottom height can be dynamically and accurately output after data processing and calculation of a control system, and a basis is provided for accurately calculating and controlling the liquid level and the tapping amount of molten iron in the iron ladle; the method can be widely used for accurately controlling the liquid level and the tapping amount of the iron ladle in the production process of transporting the molten iron to the bottom of the iron-steel interface automobile.

Owner:SD STEEL RIZHAO CO LTD

An ironing appliance including a cordless iron and a charging base

ActiveCN110144717BRealize image acquisitionHand ironTextiles and paperInformation controlIron detection

The invention discloses an ironing device including a cordless iron and a charging base, relates to the field of ironing equipment, and solves the problem that the user cannot know in time that there is a deviation in the position of the cordless funnel placed in the charging base; its technical solution Yes: Including a cordless iron detection unit, location information acquisition unit, location information database, and information control center equipment; the cordless iron detection unit detects that the cordless iron is placed on the charging base, and the information control center equipment places the cordless iron on the charging base The current location information of the cordless iron is compared with the location information of the cordless iron in the location information database. If the current location information of the cordless iron does not match the location information of the cordless iron in the location information database, a reminder that the location of the cordless iron needs to be adjusted is given; The invention provides an ironing device including a cordless iron and a charging base, which is convenient for the user to timely adjust the placement position of the cordless iron so that the cordless iron can be charged normally.

Owner:CUORI ELECTRICAL APPLIANCES GRP

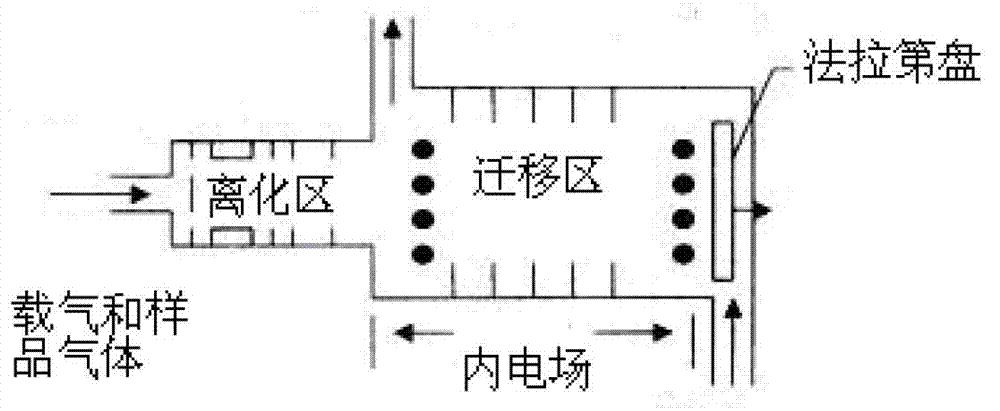

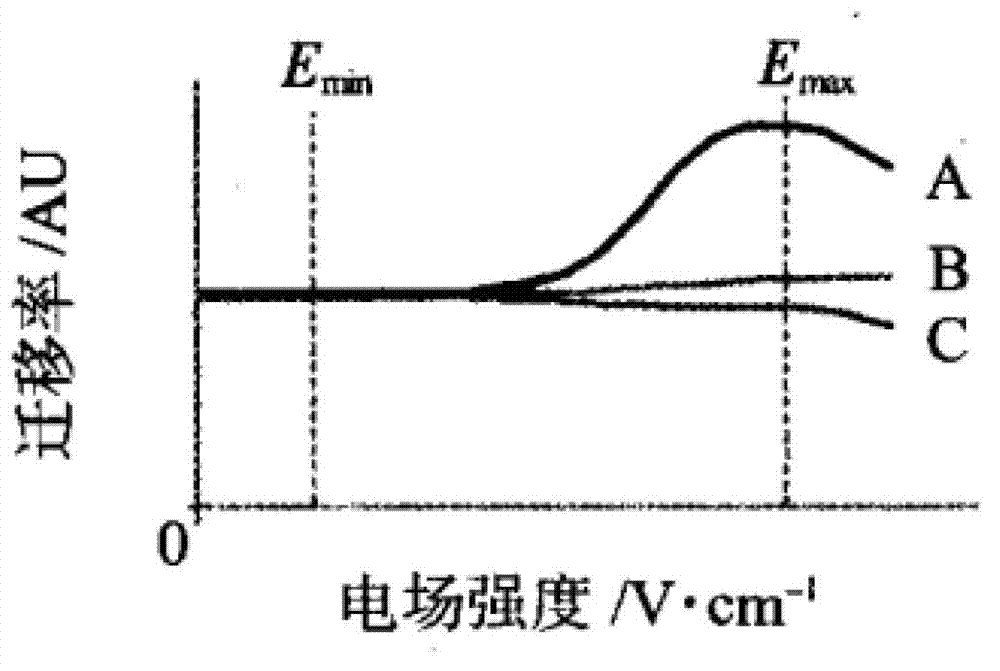

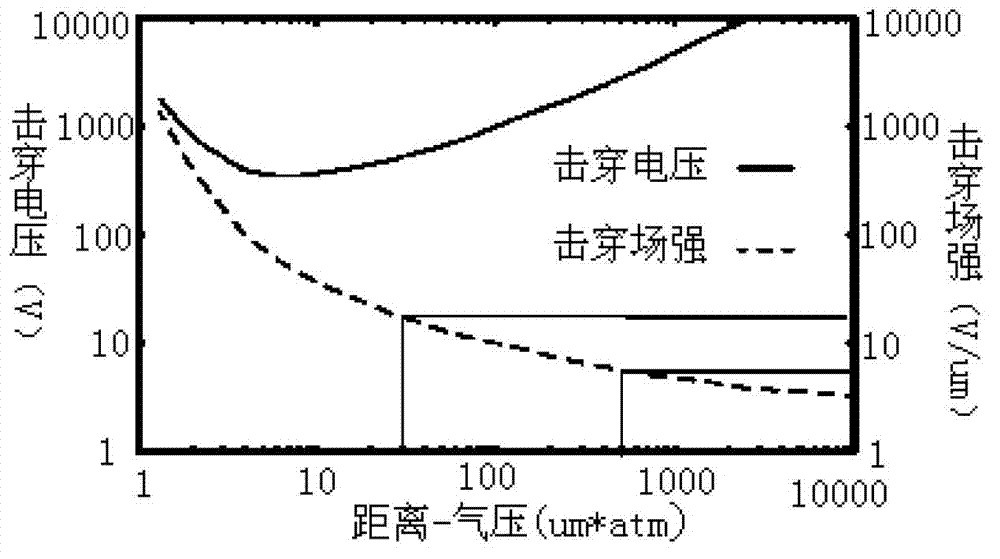

Migration tube filter of asymmetric high field strength ion mobility spectrometry analyzer and machining method of migration tube filter

InactiveCN102820200BReduce processing costsHigh ion detection accuracyElectron/ion optical arrangementsEtchingHigh pressure

The invention discloses a migration tube filter of an asymmetric high field strength ion mobility spectrometry analyzer and a realizing method of the migration tube filter. The method adopts the technologies of wet etching and silicon bonding. The FAIMS migration tube filter comprises a first silicon chip and a second silicon chip which are identical in structures and are mutually bonded; the first silicon chip comprises a silicon chip body as well as a first oxidizing layer, a first metal pattern layer, a second oxidizing layer, a second metal pattern layer, a third oxidizing layer and at least one group of cavities which are machined on the silicon chip body in sequence, wherein the first metal pattern layer comprises at least three groups of metal patterns which are insulated from one another; the second metal pattern layer comprises at least three groups of metal patterns which are insulated from one another; and the thicknesses of the first silicon chip and the second silicon chip are 30 to 100 micrometers. The method can adopt the wet etching technology on the basis of common high-voltage integrated circuit technology, and obtains acceptable FAIMS filtering area electric field under the effect of standard electric field electrodes. The method not only obviously reduces the machining cost of the FAIMS filter, but also obtains higher iron detection accuracy.

Owner:无锡中科沃谱瑞科技有限责任公司

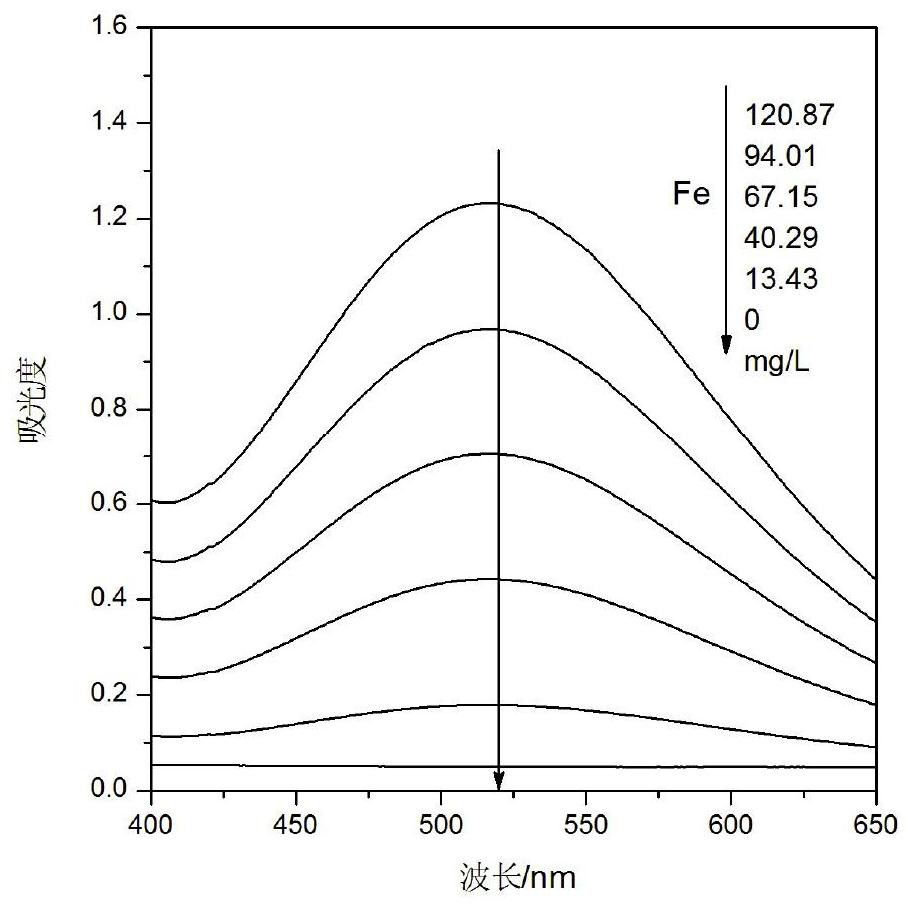

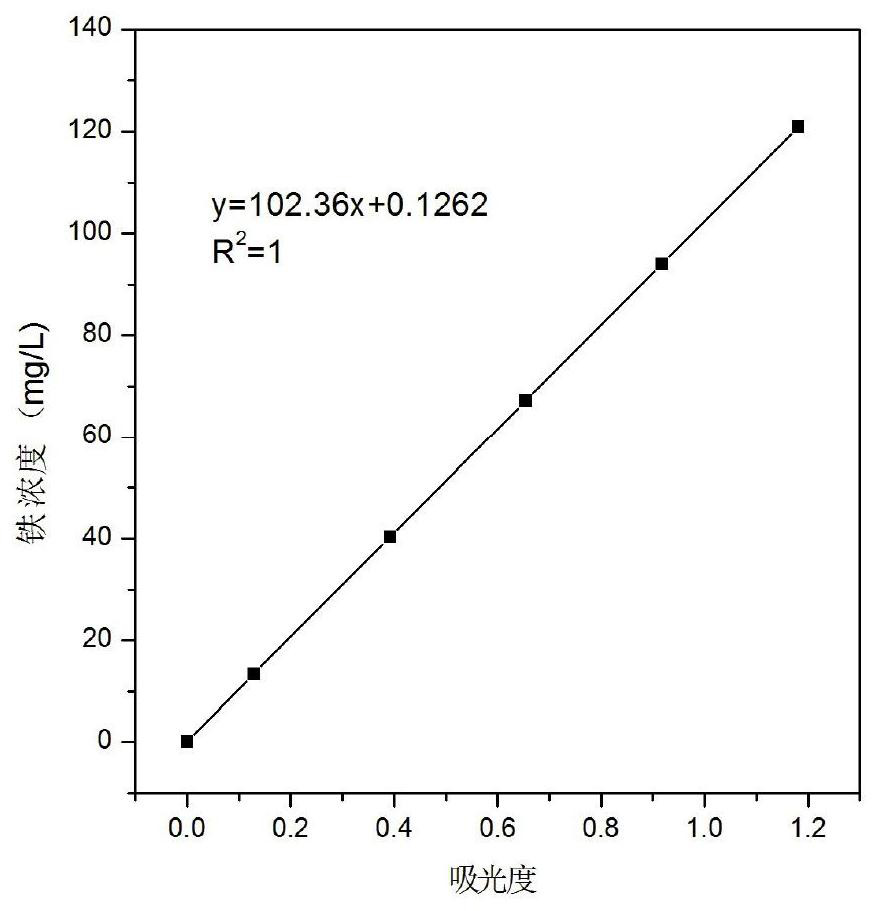

Determination method of trace iron in aluminum-containing phosphoric acid solution and aluminum masking agent therefor

ActiveCN102565045BSolve the accuracy problemSolve the costMaterial analysis by observing effect on chemical indicatorO-Phosphoric AcidAluminium hydroxide

The invention relates to the technical field of a determination method of trace iron in an aluminum-containing phosphoric acid solution, and particularly to a determination method of trace iron in an aluminum-containing phosphoric acid solution and an aluminum masking agent for the determination method. The determination method comprises two steps of drawing a standard work curve of iron content and testing the iron content in a test sample solution. The determination method of the invention is simple in operation, high in test accuracy, and good in reproducibility, not only overcomes the defect in the prior art of impossible to detect due to the present of white aluminum hydroxide precipitate, but also solves the problems of poor trace iron detection accuracy and high cost in the track iron determination process by the atomic absorption spectrophotometry, and effectively expands the application scopes of determinating iron content in the phosphoric acid with the phenanthroline spectrophotometric method.

Owner:石河子众金电极箔有限公司

Pad iron detection structure of press vulcanizer

ActiveCN114147886AAvoid manual operationImprove securityMeasurement devicesBeltsVulcanizationIron detection

The invention discloses a flat vulcanizing machine sizing block detection structure, which belongs to a vulcanizing machine structure, and comprises an upper vulcanizing plate, a middle vulcanizing plate, a lower vulcanizing plate and an outer frame, the two sides of the middle vulcanizing plate are respectively provided with a middle plate induction plate, and the two sides of the lower vulcanizing plate are respectively provided with a lower plate induction plate. The outer frame is provided with a middle plate displacement sensor used for detecting the displacement amount of the middle plate induction plate and a lower plate displacement sensor used for detecting the displacement amount of the lower plate induction plate, whether the position of the sizing block is accurate or not can be detected, if dislocation occurs, the position of the sizing block can be further adjusted, and therefore the situation that in the prior art, the sizing block is not prone to being damaged is avoided. And the vulcanization process is easy to cause the conditions of different product thicknesses and poor flatness.

Owner:ZHEJIANG SANWEI RUBBER ITEM CO LTD

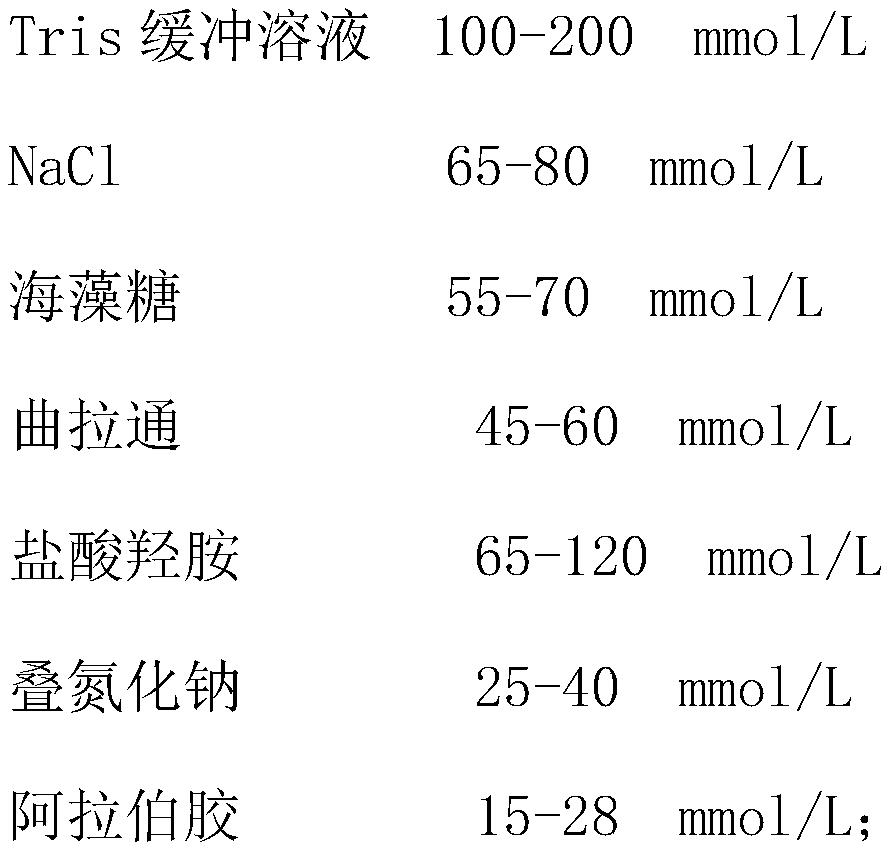

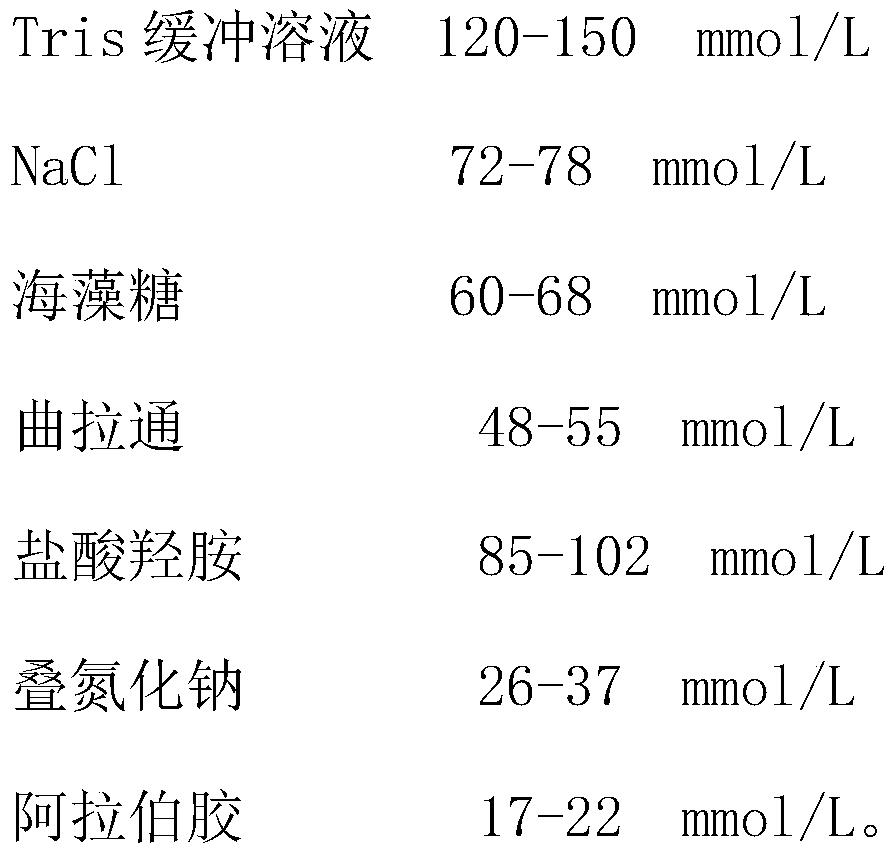

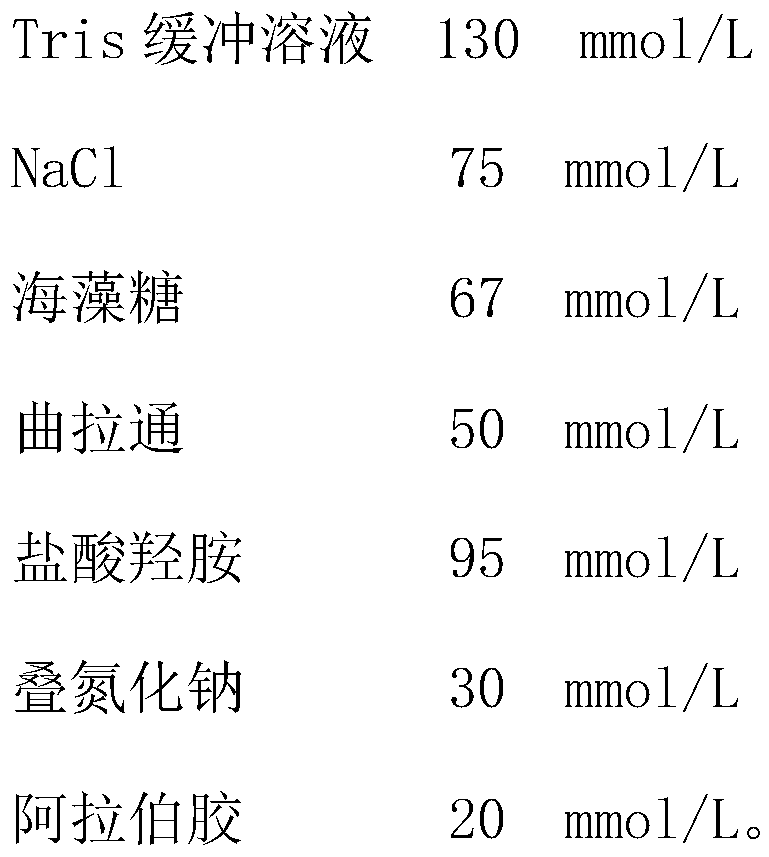

Total iron detection kit and preparation method thereof

PendingCN111122882ALow costEfficient detectionDisease diagnosisBiological testingHydroxylamineSodium azide

The invention discloses a total iron detection kit. The total iron detection kit comprises a reagent R1 and a reagent R2. The reagent R1 is prepared from the following components: a Tris buffer solution, NaCl, trehalose, triton, hydroxylamine hydrochloride, sodium azide and Arabic gum. The reagent R2 comprises the following components: a Tris buffer solution, a latex-coated ferrous azine solutionand ascorbic acid. The preparation method of the total iron detection kit comprises the following steps: A) preparing the reagent R1: adding purified water into a blending tank A, sequentially addingthe components of the reagent R1 into the blending tank, mixing and stirring, regulating the pH value of the solution, and filtering by using a microporous filter membrane to obtain the reagent R1; and B) preparing the reagent R2: adding purified water into a blending tank B, sequentially adding the components of the reagent R2 into the blending tank B, mixing and stirring, adjusting the pH valueof the solution, and filtering by using a microfiltration membrane to obtain the reagent R2. By adopting the scheme disclosed by the invention, the detection efficiency is improved, and the clinical disease detection cost is reduced.

Owner:四川纳海川生物科技有限公司

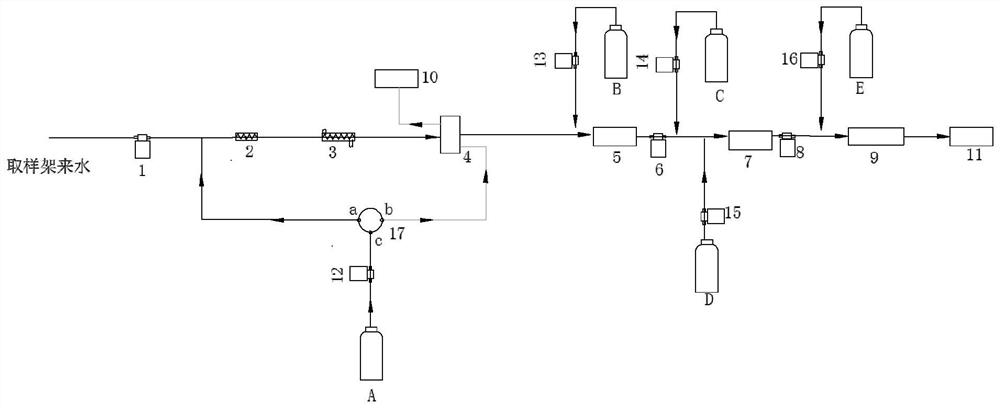

Online trace iron determination device and method based on phenanthroline spectrophotometry

PendingCN112179861AAvoid pollutionEasy to operateWithdrawing sample devicesPreparing sample for investigationHydroxylamineFlow cell

The invention discloses an online trace iron determination device and method based on phenanthroline spectrophotometry. The online trace iron determination device comprises a detection system, a dosing system and a control system. The detection system comprises a flow pump, a heater, a cooler, a concentration column, a first flow cell, a second flow pump, a second flow cell, a third flow pump, a visible light detector, a first waste liquid pool and a second waste liquid pool. The dosing system comprises a hydrochloric acid medicine tank, a hydroxylamine hydrochloride medicine tank, a phenanthroline medicine tank, an ammonia water medicine tank, an ammonium acetate medicine tank, a first micro pump, a second micro pump, a third micro pump, a fourth micro pump, a fifth micro pump and a tee joint. The control system comprises an interlocking control display screen, a first flow pump control module, a second flow pump control module, a third flow pump control module, a first micro pump control module, a second micro pump control module, a third micro pump control module, a fourth micro pump control module and a fifth micro pump control module. According to the invention, online trace iron detection of a thermal power plant water vapor system can be realized, The device and the method have the characteristics of rapidness, accuracy, reliability and the like, and greatly improve thedetection limit.

Owner:XIAN THERMAL POWER RES INST CO LTD

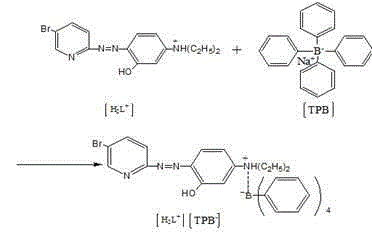

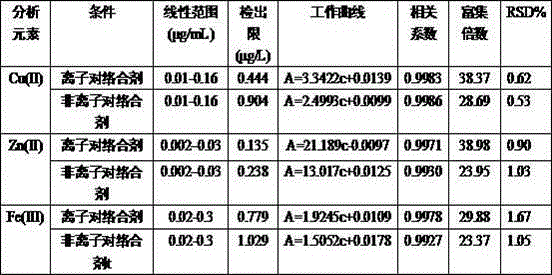

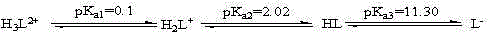

Method for determining trace copper, trace zinc and trace iron in mineral water through ion pair-cloud point extraction- cloud point extraction-flame atomic absorption spectrometry

InactiveCN105136694AImprove extraction efficiencyImprove anti-interference abilityPreparing sample for investigationColor/spectral properties measurementsIce waterActive agent

The present invention provides a method for determining trace copper, trace zinc and trace iron in mineral water through ion pair-cloud point extraction- cloud point extraction-flame atomic absorption spectrometry. The method comprises: S1, adding a surfactant solution, a 5-Br-PADAP-TPB positive 2-(5-bromo-2-pyridylazo)-5-diethylaminophenol-tetraphenylboron sodium solution and a proper amount of a buffer solution to a sample, and carrying out volume metering with water; S2, heating the mixture obtained in the S1, and carrying out centrifugation while hot; and S3, after completing the centrifugation, placing in an ice water bath, cooling, discarding the water phase, adding a diluent, and detecting by using a flame atomic absorption spectrometry method. According to the method of the present invention, the copper detection limit, the zinc detection limit and the iron detection limit respectively are 0.444 [mu]g / L, 0.135 [mu]g / L and 0.779 [mu]g / L.

Owner:GUANGDONG PHARMA UNIV

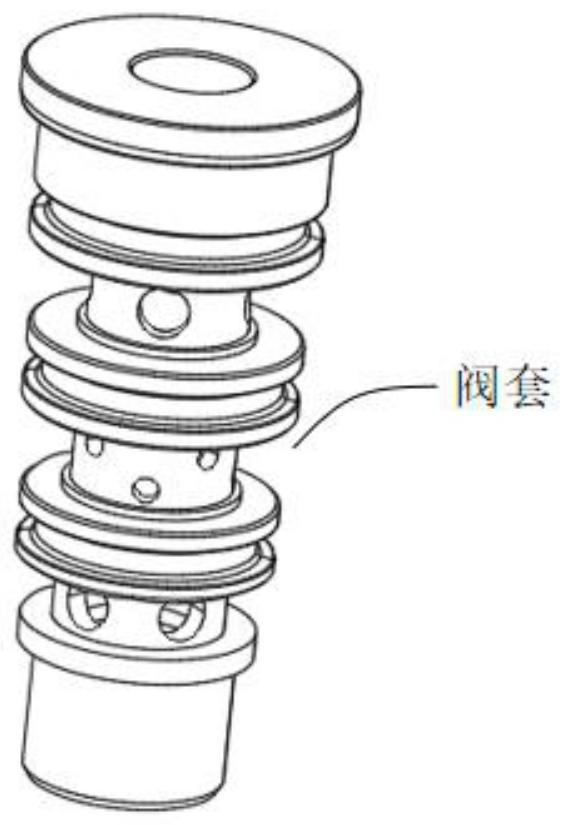

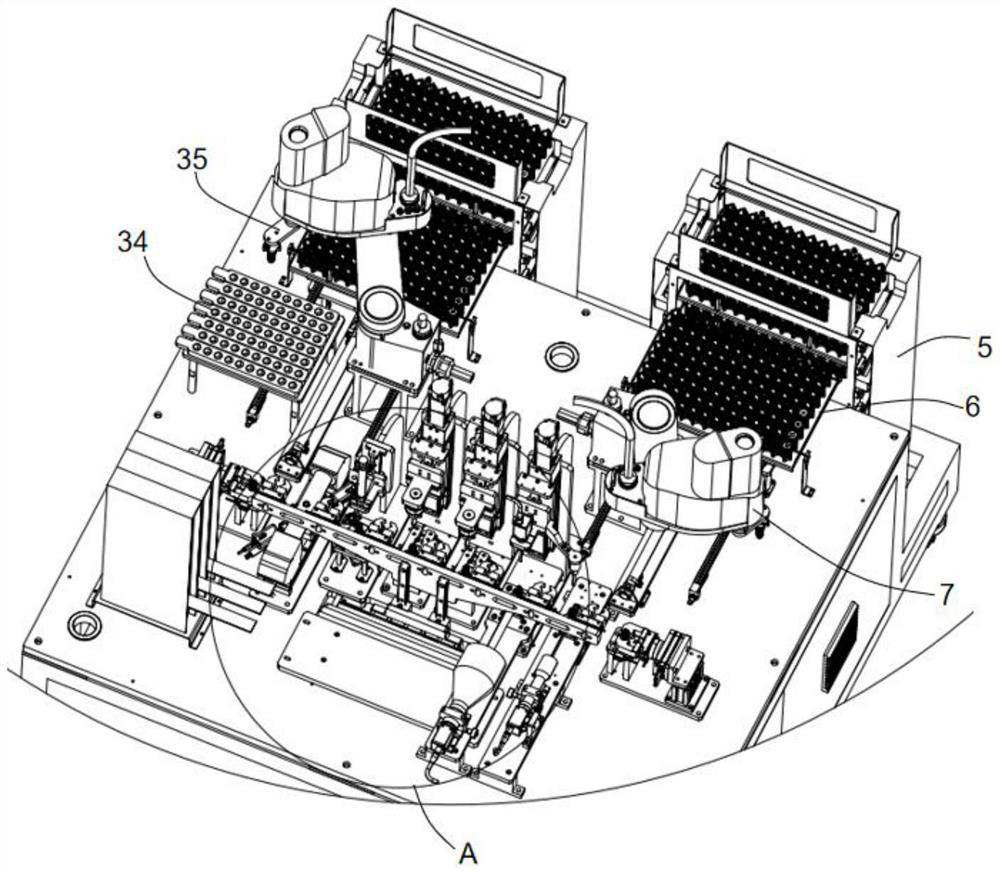

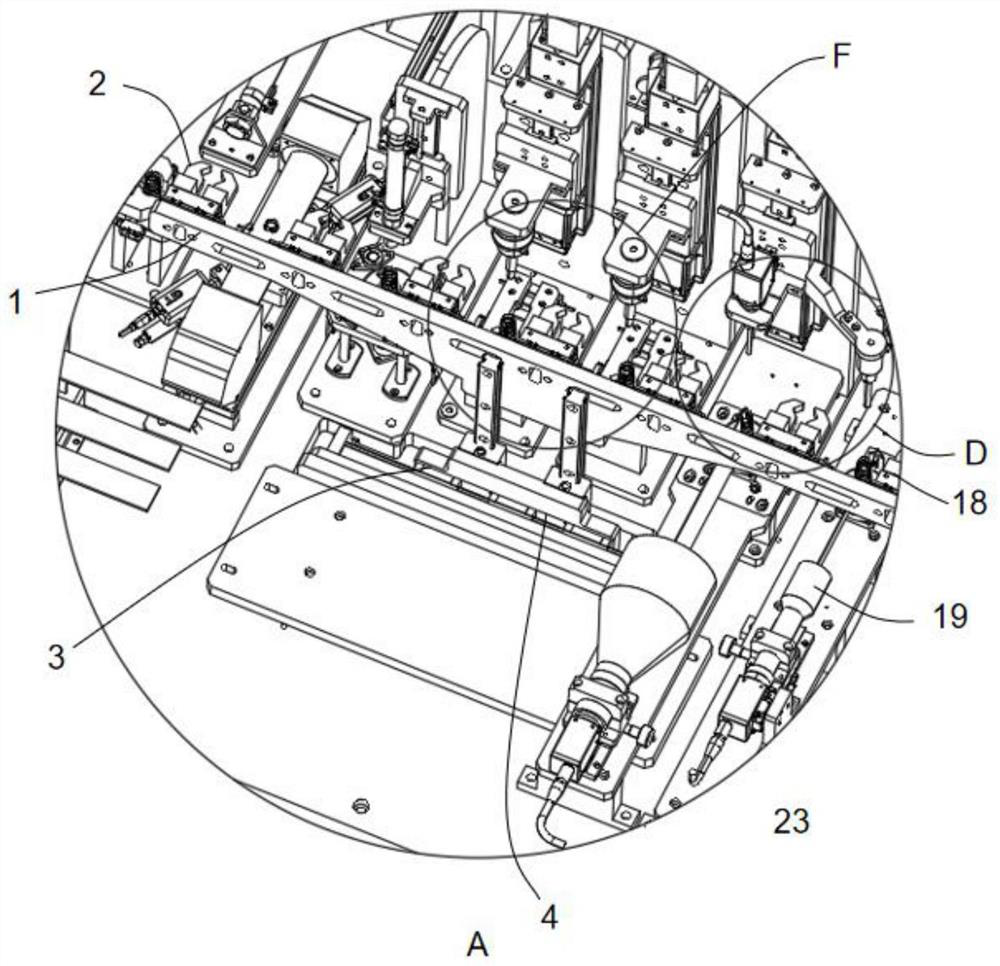

Full-automatic size detection machine for valve sleeve

PendingCN114295065APromote mass productionIncrease productivityUsing optical meansStructural engineeringIron detection

The invention discloses a full-automatic size detection machine for a valve sleeve. The full-automatic size detection machine comprises a feeding mechanism, a side face small hole scrap iron detection module, an inner hole groove scrap iron detection module, a first inner hole detection module, a second inner hole detection module, an inner diameter size detection module, a height and outer diameter size detection module, a conveying mechanism and a discharging mechanism. Angle adjusting modules are arranged between the feeding mechanism and the side face small hole scrap iron detection module, angle adjusting modules are arranged between the discharging mechanism and the height outer diameter size detection module, the conveying mechanism comprises a conveying plate, and conveying clamping jaws in one-to-one correspondence with the detection modules are horizontally arranged on the conveying plate in a sliding mode. A horizontal conveying air cylinder and a vertical conveying air cylinder are arranged below the conveying plate. By means of the mode, most bad factors such as missing detection and error detection caused by manual work can be effectively replaced, and the production efficiency is effectively improved.

Owner:无锡威孚奥特凯姆精密机械有限公司

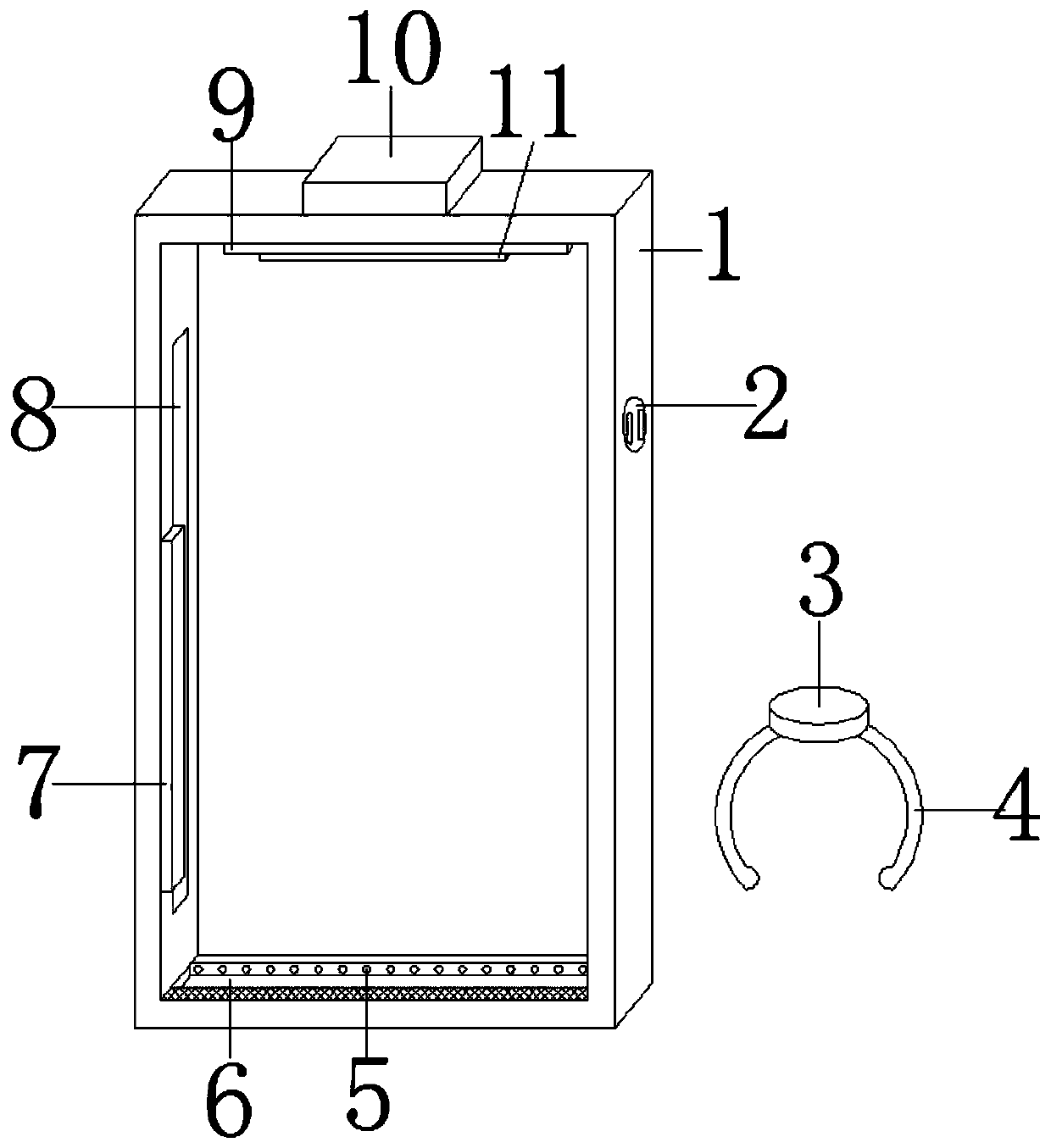

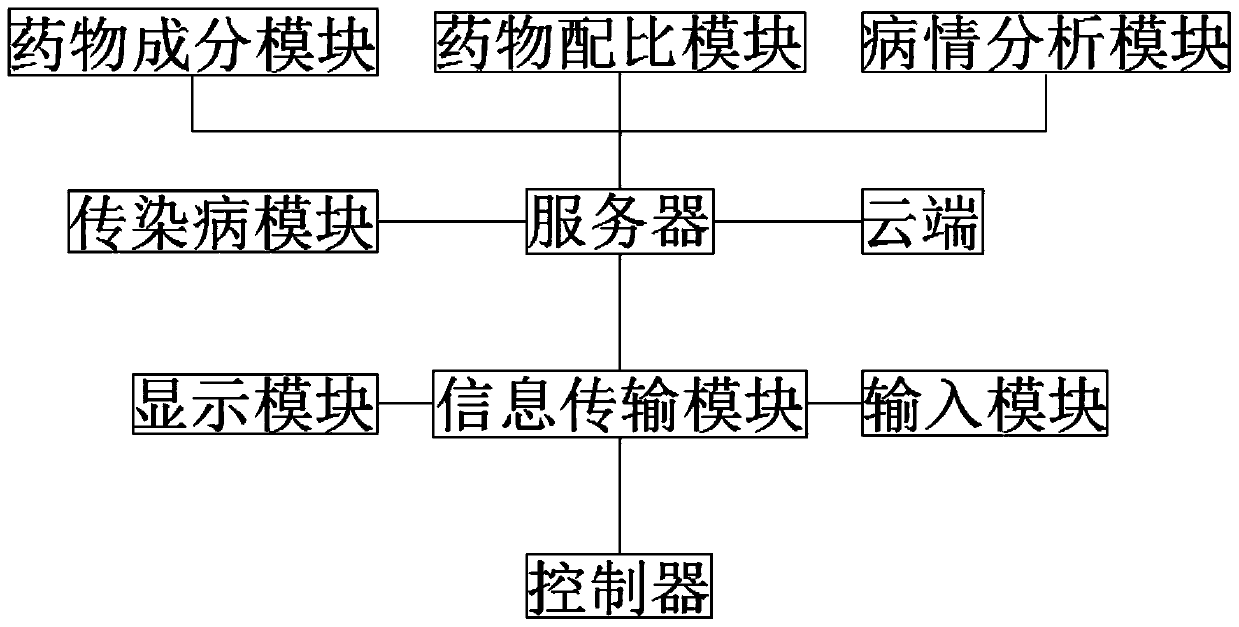

Biological data measuring device

InactiveCN110934584AGuaranteed to bowEasy to identifyUltrasonic/sonic/infrasonic diagnosticsDigital data information retrievalPhysical medicine and rehabilitationEngineering

Owner:TAIYUAN INST OF TECH

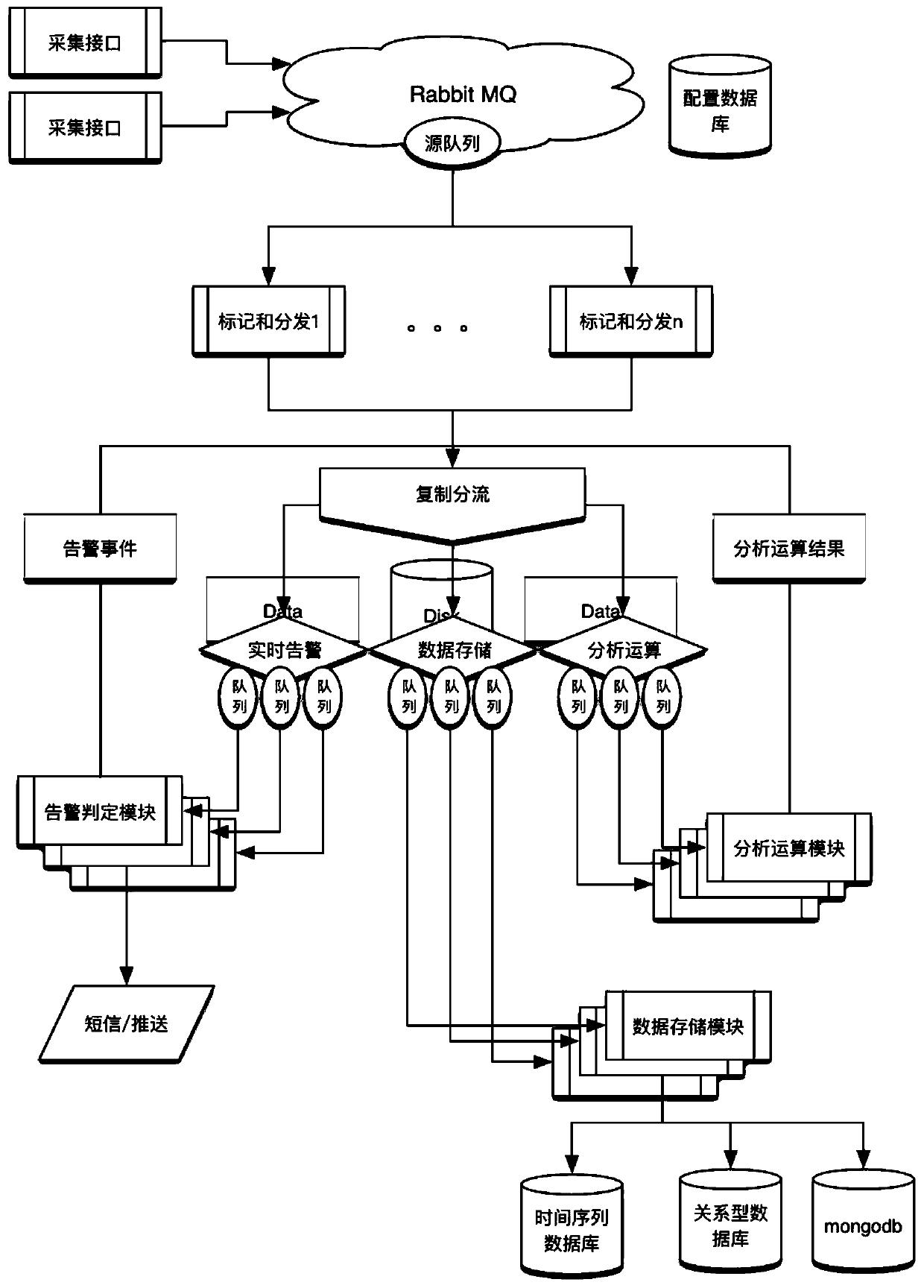

Industrial real-time data processing system and method

PendingCN111221315AImprove detection efficiencyReasonable decisionTotal factory controlSpecial data processing applicationsData packData processing system

The invention discloses an industrial real-time data processing method, which comprises the following steps: acquiring data to be processed, and packaging the acquired data to be processed according to an appointed data format; unpacking the packed data according to a routing strategy, and processing and distributing the unpacked data; receiving the processed data, analyzing the processed data according to a data analysis model, and outputting an analysis result; and receiving data, carrying out alarm analysis on the processed data according to an alarm strategy, carrying out alarm analysis onan analysis result according to the alarm strategy, and sending the alarm analysis result to a user terminal, wherein the received data comprises unpacked and processed data and analysis result data.On one hand, the molten iron detection efficiency is improved, and the detection accuracy is guaranteed, and on the other hand, it is guaranteed that a user can rapidly obtain the detection effect, and the user can make a timely and reasonable decision according to the detection effect.

Owner:恒创数字科技(江苏)有限公司

A kind of method for determining cyclic dipeptide in liquor

The invention relates to a method for testing cyclic dipeptide in white spirits. The method comprises the following steps: a, taking a white spirits sample, eluting with methanol after passing through an SPE-C18 column, and concentrating an eluent to 1 / 50-1 / 10 of the original volume of the white spirits sample at a temperature not higher than 60 DEG C to obtain a to-be-tested sample; b, loading the sample to be tested in step a to a liquid chromatograph-mass spectrometer, and after mass spectrum full-iron scanning, primarily obtaining possibly existing cyclic dipeptide through full-iron scanning peaks; c, then loading the sample to be tested in step a to the liquid chromatograph-mass spectrometer, and obtaining the characteristic ion peak of each possibly existing cyclic dipeptide after selected iron detection; d, further verifying whether the cyclic dipeptide obtained in step b exists in the white spirits or not according to the characteristic ion peak obtained in step c, and finally making a conclusion. The variety of the cyclic dipeptide in the white spirits sample can be accurately and rapidly tested by the method, and one more effective method is provided for the detection of the cyclic dipeptide in the white spirits.

Owner:WULIANGYE

Iron detection method for precious metals in solution

InactiveCN109781717AImprove recycling efficiencyIncrease profitMaterial analysis by observing effect on chemical indicatorEthyl acetateIron detection

The invention provides an iron detection method for precious metals in a solution, which comprises the following specific steps: extracting a 5ml exchanged solution into a clean 60ml separating funnel, adding hydrochloric acid, and standing; after heat disappears, adding ethyl acetate, fully oscillating for 1 minute, standing for layering, and carefully discharging a solution containing precious metal at the lower layer; adding hydrochloric acid, fully oscillating, standing for layering, and discharging a lower-layer solution; taking the lower-layer solution, finally dropwise adding KCNS, comparing the developing degree with a standard colorimetric plate, and judging the content of iron in the solution. Through judgment of a verification test, the content of precious metals in the exchangesolution can be determined clearly, so that the exchange degree of the precious metals in the solution is judged; the method is simple in process and convenient to operate, the waste liquid utilization rate is effectively increased, and the precious metal recycling efficiency is improved.

Owner:太原瑞麟贵金属回收有限公司

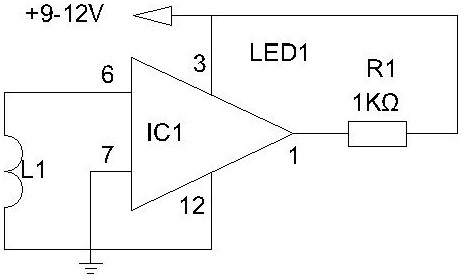

Magnetic core raw material iron content detection system

The invention provides a magnetic core raw material iron content detection system, which comprises a magnetic field sensor and an integrated block, wherein the sixth pin of the integrated block is connected with one end of the magnetic field sensor, the other end of the magnetic field sensor is connected with the seventh pin and the twelfth pin of the integrated block, the first pin of the integrated block is connected with one end of a first resistor, the other end of the first resistor is connected with one end of a light-emitting diode, and the other end of the light-emitting diode is respectively connected with a power supply and the third pin of the integrated block.

Owner:LOUDI CITY LITONG MAGNETOELECTRICITY SCI & TECH

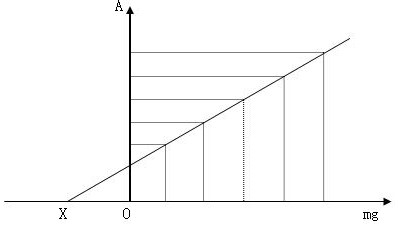

Method for measuring iron content in titanium alloy

PendingCN112161940ANo need to useLow costColor/spectral properties measurementsHydroxylamineEthylic acid

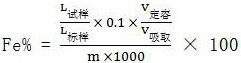

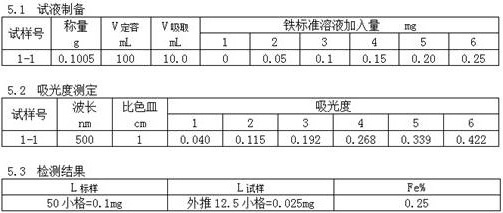

The invention relates to the technical field of metal iron detection, in particular to a method for determining the iron content in a titanium alloy. The method can conveniently detect the iron content, is low in cost, and comprises the following steps of (1) weighing 0.1 g of sample, putting into a 100mL steel dual-purpose bottle, adding 10mL of sulfuric acid, heating with soft fire until the sample is completely dissolved, cooling, adding 10mL of boric acid, diluting with water to a scale, and shaking up; (2) taking six 100mL volumetric flasks, respectively adding 10mL of the sample solution, then sequentially and accurately adding an iron calibration solution, respectively adding 30mL of water, 10mL of a hydroxylamine hydrochloride solution, 5mL of an ammonium citrate solution, 25mL ofan ammonium acetate solution and 1, 10-diazaphenanthrene, adding water to dilute to a scale, shaking up every time when one solution is added, and standing for 20-30 minutes for color development; (3)taking water as a reference, and measuring the absorbance at the wavelength of 500 nm by using a 1cm cuvette; and (4) drawing a straight line of a test value by taking the absorbance as a vertical coordinate and the added pure iron standard quantity as a horizontal coordinate, then extending the straight line to cross the horizontal coordinate at a point X, solving the length of the X and an original point O, and calculating according to a formula.

Owner:无锡市金义博检测技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com