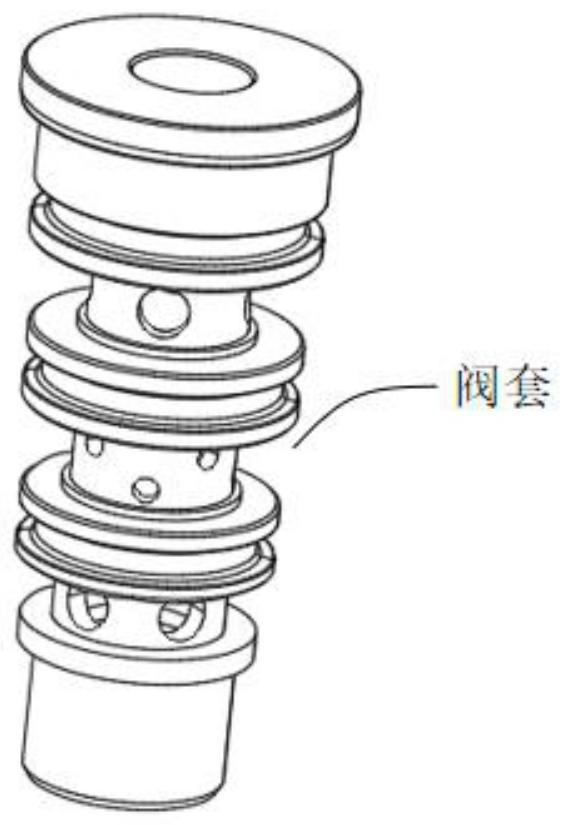

Full-automatic size detection machine for valve sleeve

A fully automatic and detection machine technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of missing detection, increasing labor costs, wrong detection, etc., and achieve the effect of standardization of detection and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

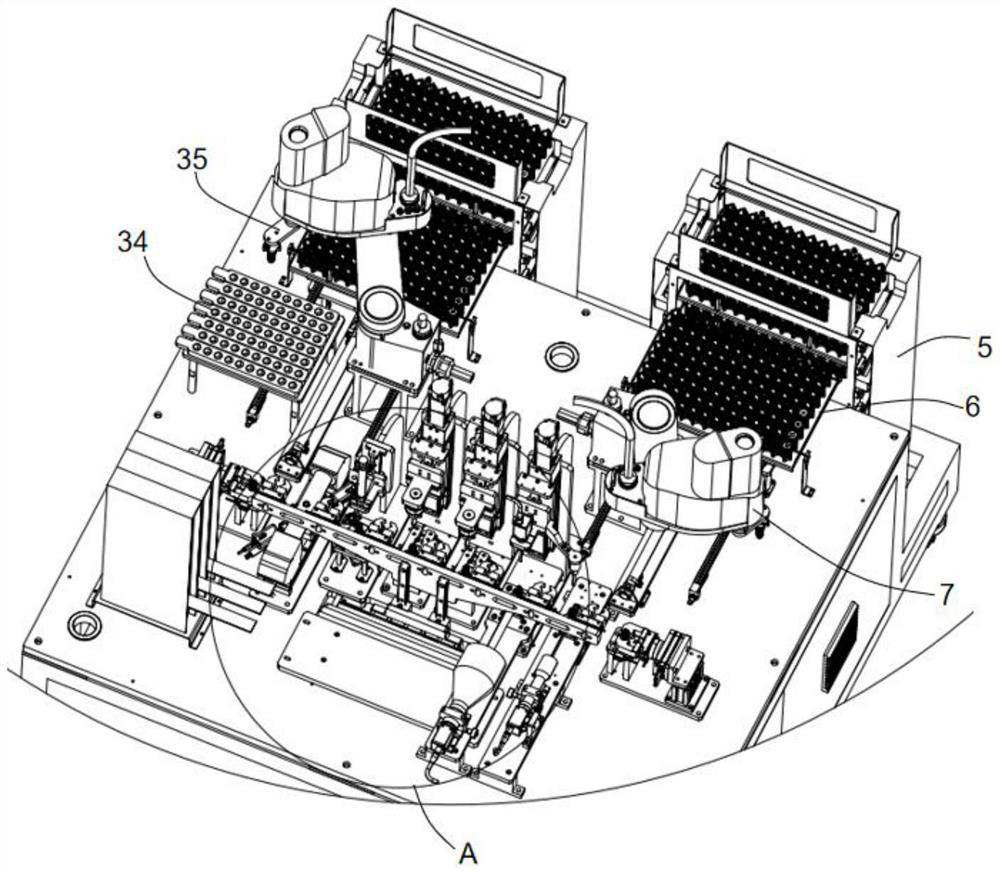

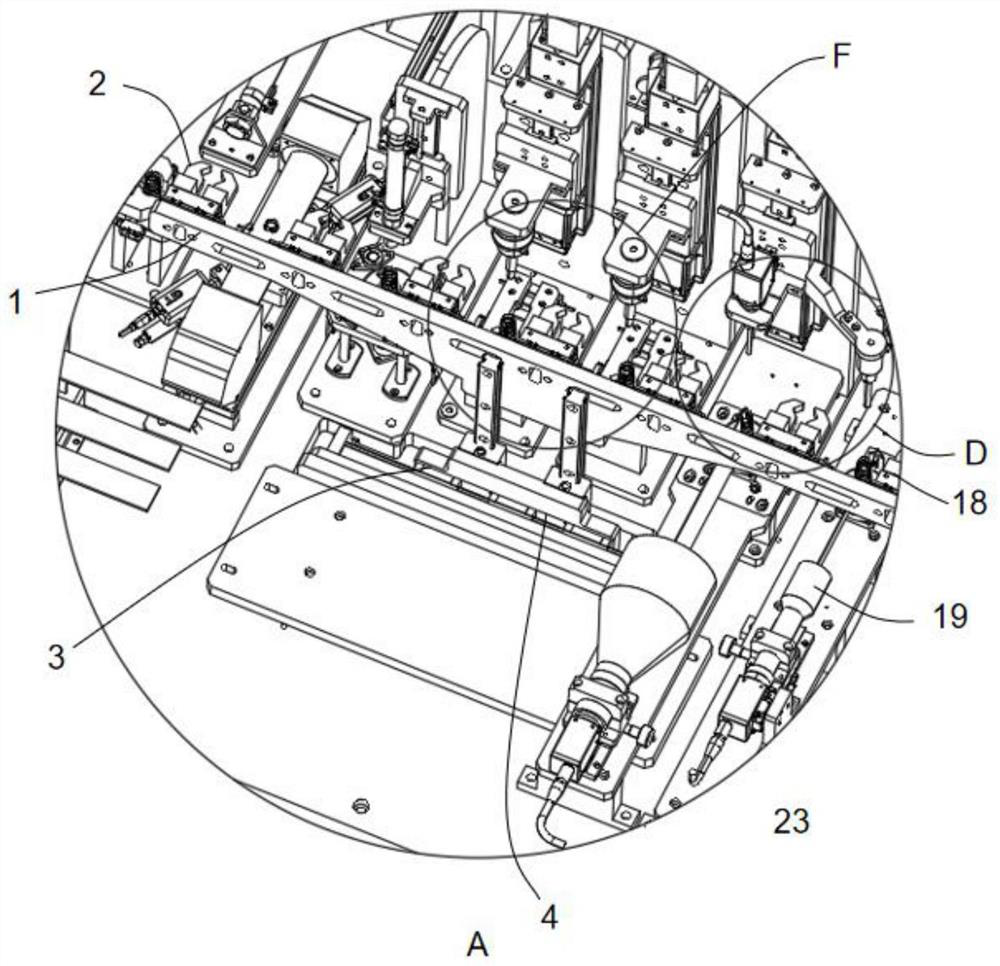

[0031] like figure 1 and figure 2 As shown, a fully automatic size detection machine for valve sleeves, including a feeding mechanism, a side small hole iron chip detection module, an inner hole groove iron chip detection module, a first inner hole detection module, a second inner hole detection module, an inner diameter The size detection module, the height and outer diameter size detection module, the transmission mechanism and the unloading mechanism complete the feeding of valve sleeve products through the feeding mechanism, and detect the iron filings in the small holes on the side of the valve sleeve through the side small hole iron filing detection module. Detect the iron filings in the groove of the inner hole of the valve sleeve through the iron chip detection module of the inner hole groove. The inner hole of the valve sleeve includes two inner holes with different diameters, which pass through the first inner hole detection module and the second inner hole detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com