Vehicle-mounted iron ladle residual iron detection device and detection method

A detection device and iron ladle technology, applied in the field of iron and steel metallurgy, can solve the problems of interfering with the accuracy of the tapping amount, inability to judge, and restricting the accuracy of tapping and loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

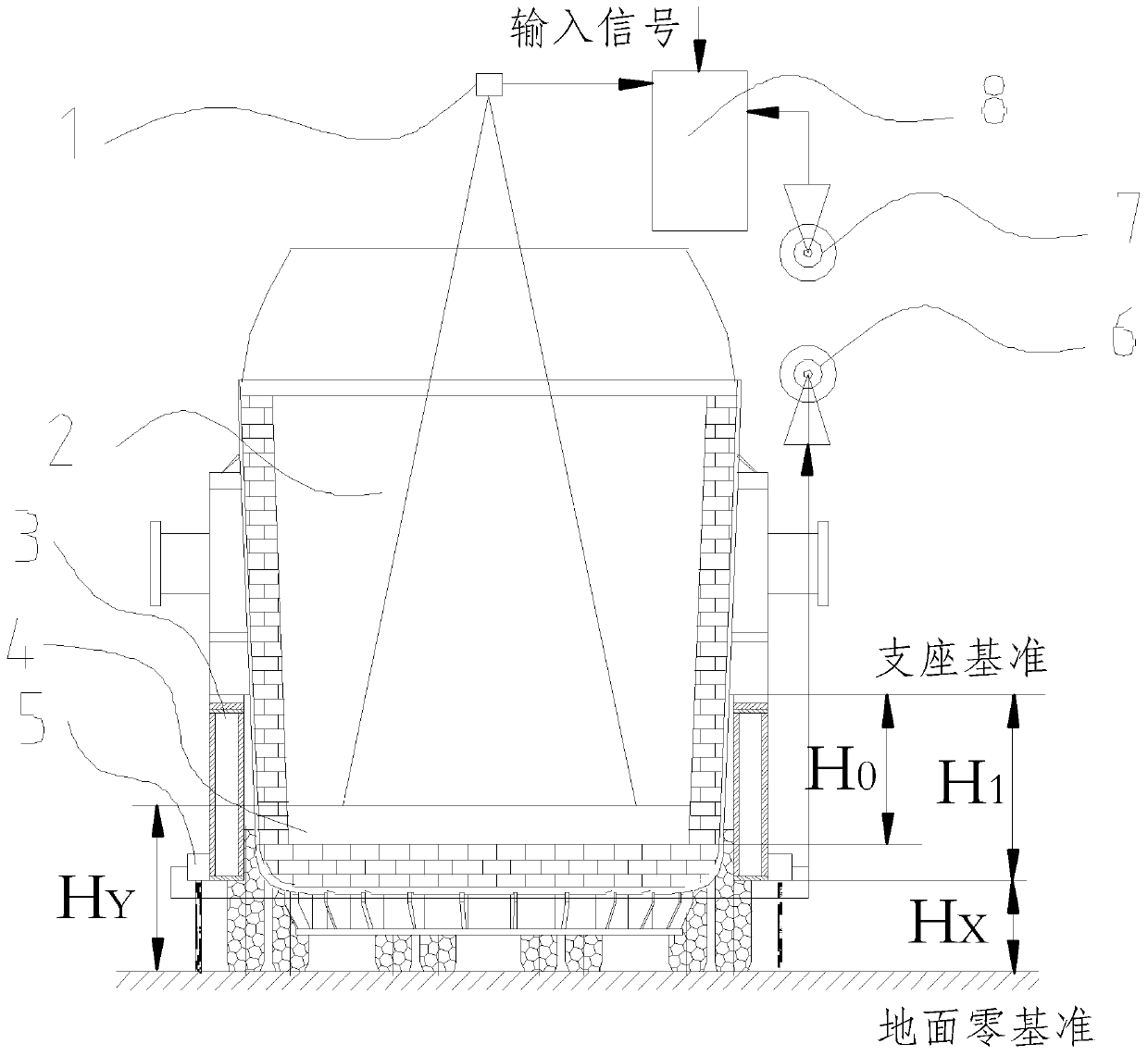

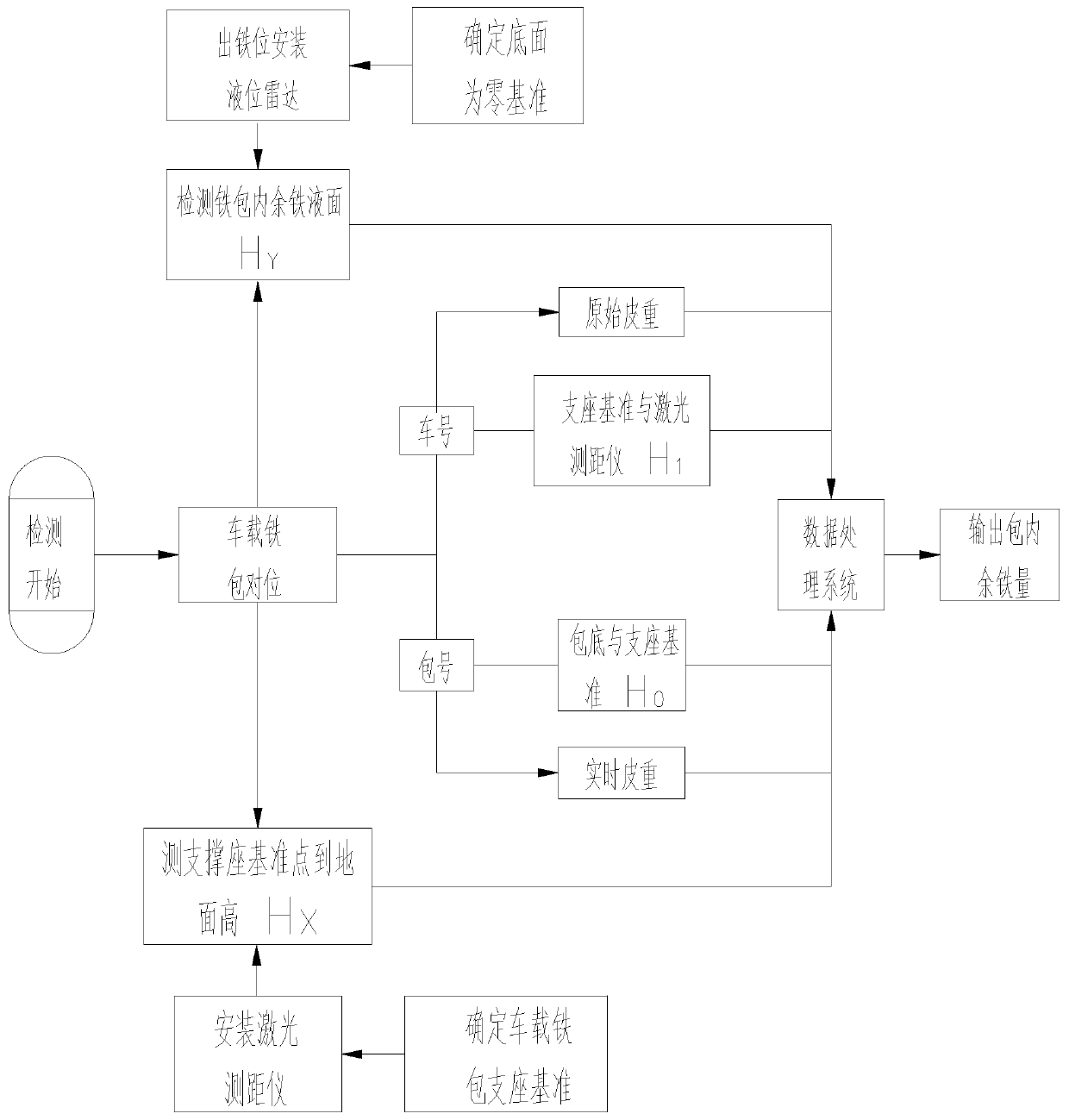

[0018] Such as figure 1 As shown, a vehicle-mounted iron-clad residual iron detection device includes a vehicle-mounted iron-clad support 3 for fixing the iron-clad 2 and a liquid level radar 1 fixed directly above the iron-clad 2, and the center of the reference point of the vehicle-mounted iron-clad support 3 A vehicle-mounted laser rangefinder 5 is installed below the line, the vehicle-mounted laser rangefinder 5 is connected with the vehicle-mounted data transmitter 6, the vehicle-mounted data transmitter 6 is wirelessly connected with the data receiver 7, the data receiver 7 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com