Method for measuring iron content in titanium alloy

A technology of quantitative measurement and titanium alloy, which is applied in the direction of color/spectral characteristic measurement, etc., can solve the problem of high measurement cost and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

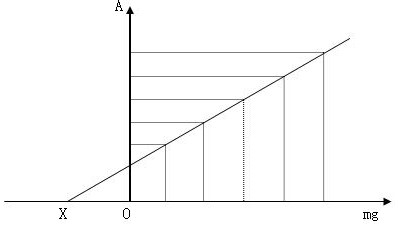

Method used

Image

Examples

Embodiment Construction

[0021] A method for determining the amount of iron in a titanium alloy, characterized in that it comprises the following steps:

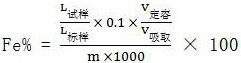

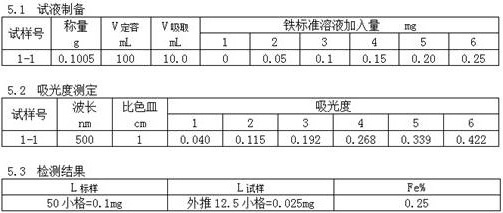

[0022] (1) Weigh 0.1g of the sample, put it into a 100mL dual-purpose steel bottle, add 10mL of sulfuric acid, the sulfuric acid is made of concentrated sulfuric acid with a density of 1.84cm3 / ml, a concentration of 98%, and distilled water at a volume ratio of 1:1 Prepared, heat on low heat until the sample is completely dissolved, add 10mL of boric acid with a mass concentration of 50g / L after cooling, dilute to the mark with water, and shake well;

[0023] (2) Take six 100mL volumetric flasks, add 10mL of the sample solution, and then accurately add the iron calibration solution 0mL, 0.5mL, 1mL, 1.5mL, 2mL, 2.5mL in sequence, and then add 30mL of water at a mass concentration of 100g / 10 mL of hydroxylamine hydrochloride solution in 1 L, 5 mL of ammonium citrate solution with a mass concentration of 100 g / L, and 25 mL of ammonium acetate solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com