Determination method of trace iron in aluminum-containing phosphoric acid solution and aluminum masking agent therefor

A method of determination, a technology of trace iron, which is applied in the direction of material analysis through observation of the influence of chemical indicators, and analysis through the chemical reaction of materials, which can solve the problems of the influence of aluminum ion detection process and achieve poor detection accuracy. , Solve the effect of high cost and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

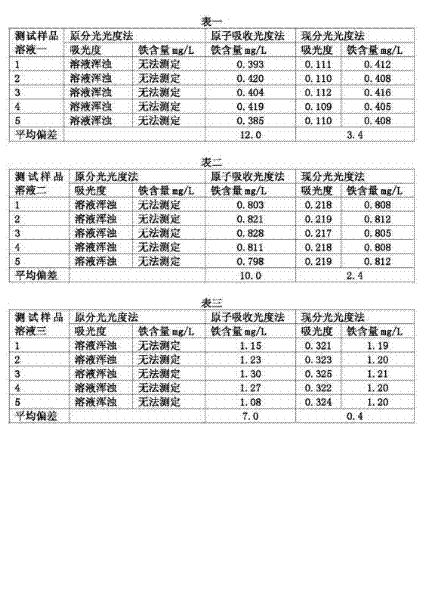

Examples

Embodiment 1

[0015] Embodiment 1, the assay method of trace iron in this aluminum-containing phosphoric acid solution is carried out according to the following steps:

[0016] The first step is to test known iron-containing solutions with a spectrophotometer and draw a standard working curve of iron content: take no less than 3 iron content standard solutions, add 1% to 10% hydroxylammonium hydrochloride 1ml to 10ml, 10% to 50% triammonium citrate 1ml to 10 ml, adjust the pH value to 4 to 6, add 0.1% to 1% o-phenanthroline 1ml to 10ml, and mix each time the above reagent is added , heated to 60°C to 85°C in a water bath, kept at constant temperature for 5 minutes to 30 minutes, removed and cooled to room temperature, diluted to the mark with pure water, and mixed well; wavelength λ=510nm, tested its absorbance with a spectrophotometer; is the ordinate, and the iron content is the abscissa, draw the standard working curve;

[0017] The second step, the determination of iron content i...

Embodiment 2

[0018] Embodiment 2, the difference with embodiment 1 is: embodiment 2 is in the first step or / and the second step, is that the acetic acid of 5.5 to 6.0 and sodium acetate buffer adjust the pH value to 4 to 6 with pH.

Embodiment 3

[0019] Embodiment 3, the difference with Embodiment 1 and 2 is: the addition amount of the acetic acid-sodium acetate buffer solution of embodiment 3 is 5.0ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com