Detection device and detection method of straight line guide rail pair

A technology of linear guide rail pairs and linear guide rails, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of long time consumption and large cumulative errors, and achieve the effects of low cost, easy operation, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

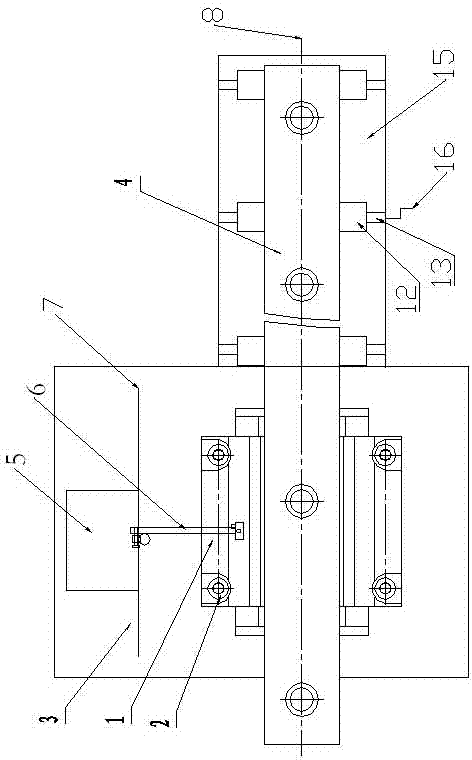

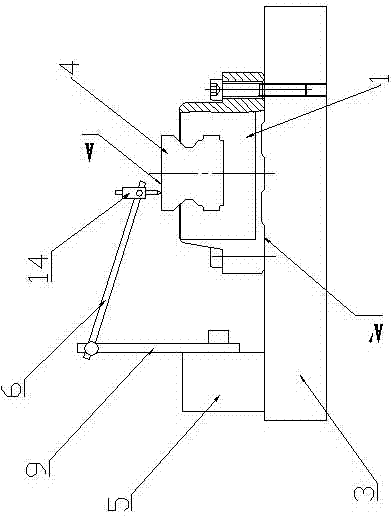

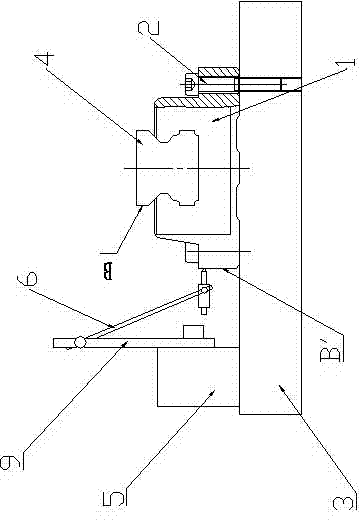

[0027] Such as figure 1 , figure 2 , Figure 4 As shown, the linear guide pair accuracy detection device of the present invention includes an iron detection platform 3 , a linear guide 4 , a slider 1 , a magnetic gauge base 5 , and a dial gauge 14 . The detection platform 3 is provided with a positioning hole, and the slider 1 of the linear guide rail is reversely installed on the positioning hole through the screw 2, and the recess of the slider 1 faces upward. The linear guide 4 is assembled on the slider 1 . A positioning line 7 parallel to the central axis 8 of the linear guide rail is provided on the detection platform 3 on one side of the linear guide rail 4 , and the magnetic gauge base 5 is placed on the positioning line 7 . Described magnetic table seat 5 vertical direction is connected with upright bar 9, is movably connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com