An ironing control system for an electric iron based on wireless communication

An electric iron ironing and control system technology, which is applied in the direction of electric program control, hand iron, signal transmission system, etc., can solve the problems of large design structure, difficult steam pressure, and difficult control of steam quality, so as to improve the technical level and reduce the The effect of grid influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples.

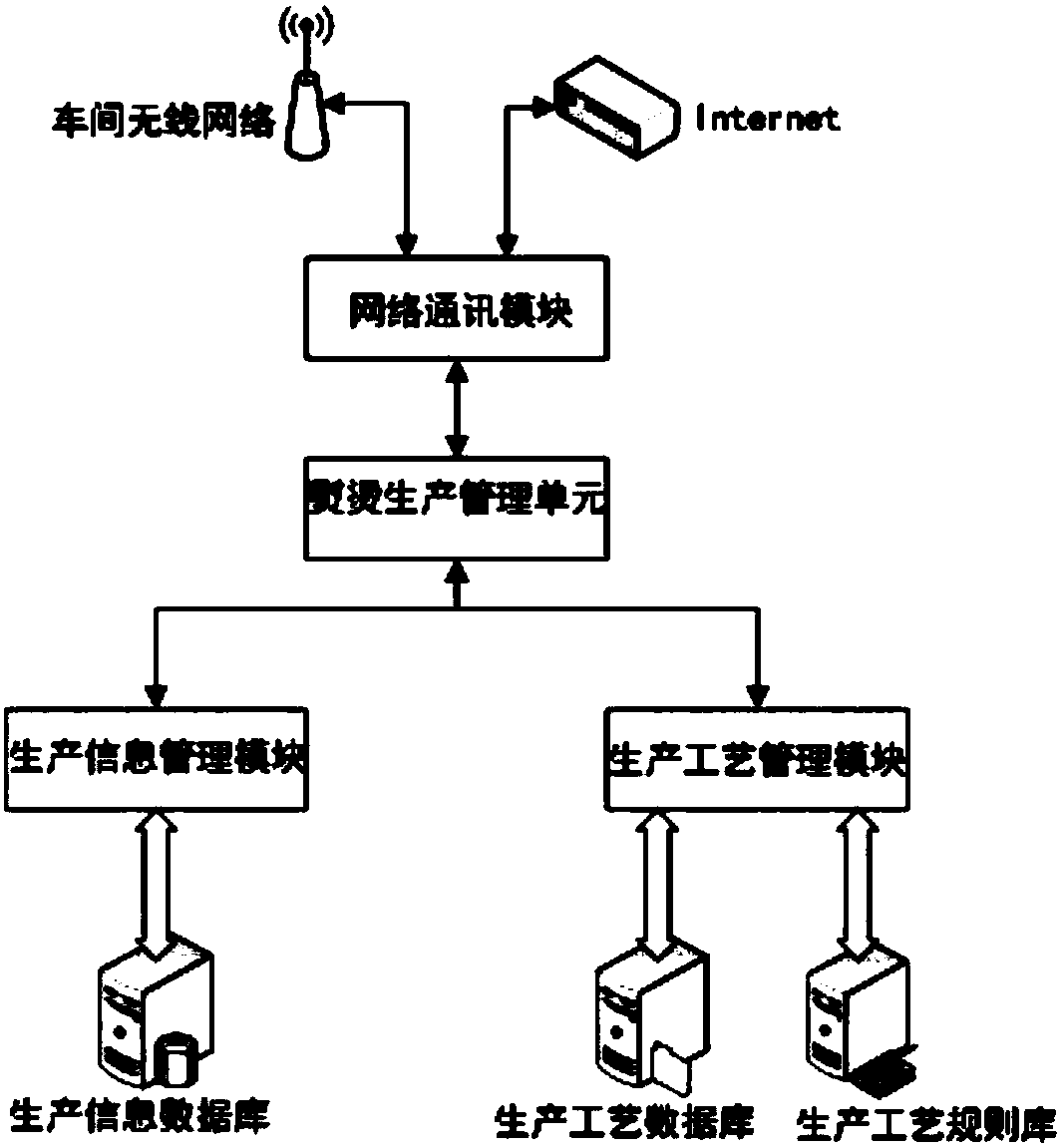

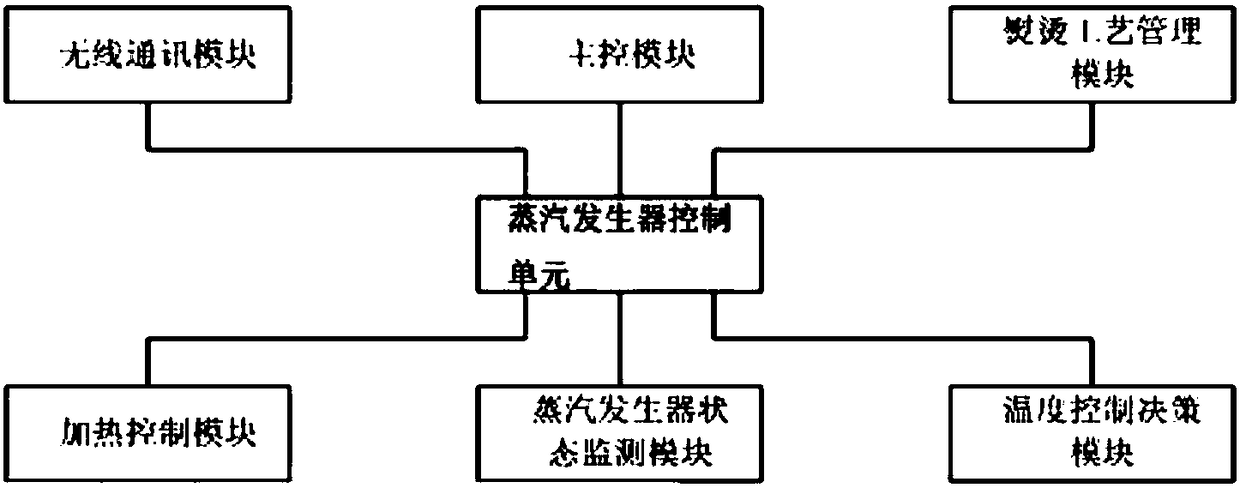

[0030] The wireless communication-based electric iron ironing control system described in this embodiment includes the following components:

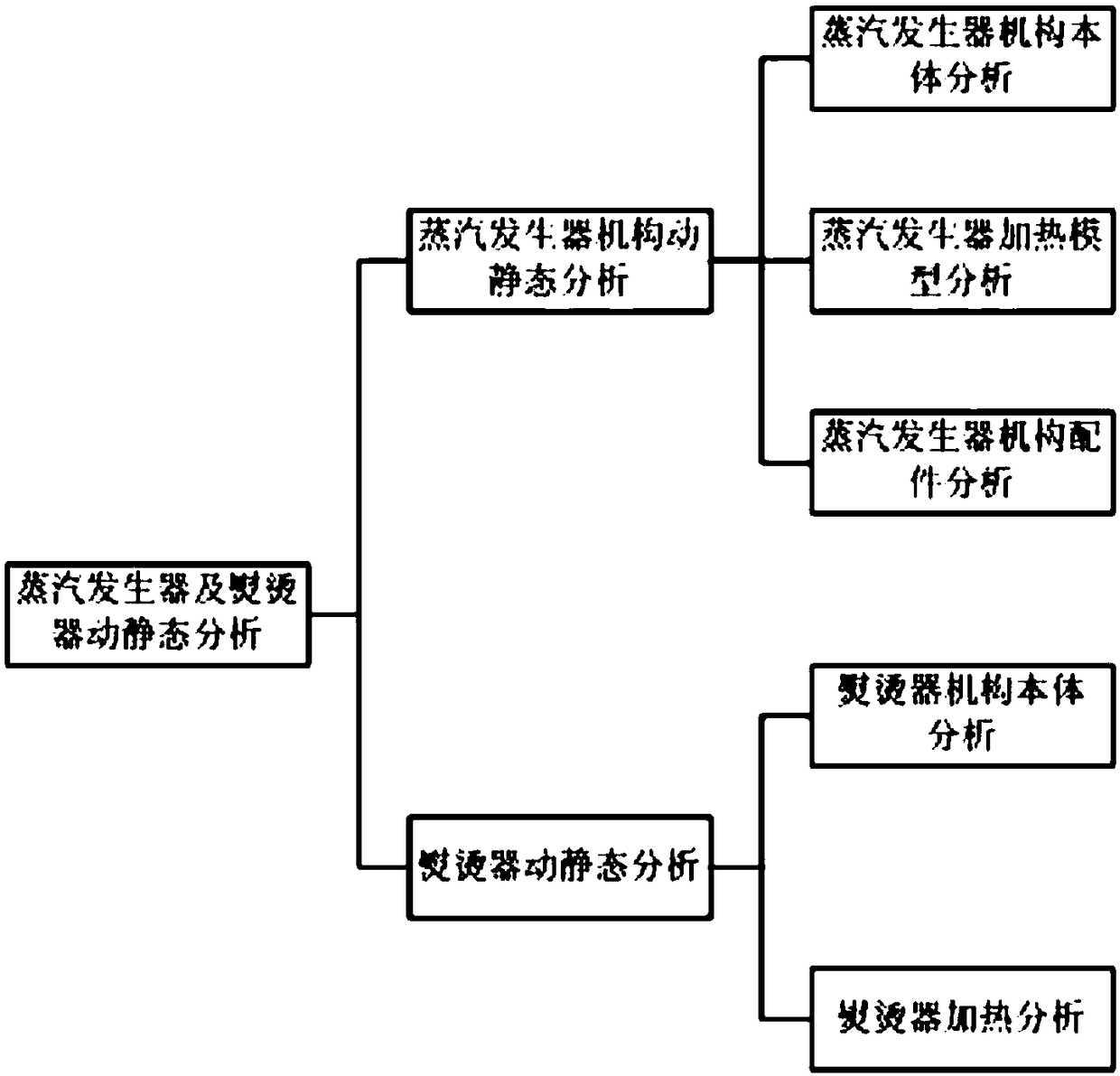

[0031] Finite element analysis unit for dynamic and static analysis of steam generators and ironing machines, such as figure 1 As shown, including the dynamic and static analysis of the steam generator mechanism and the ironing machine, according to the three-dimensional solid model, the modal and deformation analysis of the relevant mechanism is carried out in the finite element environment to verify the rationality of the design; wherein, the The dynamic and static analysis of the steam generator mechanism includes the analysis of the main body of the steam generator mechanism, the analysis of the heating model of the steam generator and the analysis of the accessories of the steam generator mechanism. The dynamic and static analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com