A kind of preparation method of rod-shaped purple tungsten

A violet tungsten, rod-shaped technology, applied in the field of powder metallurgy, can solve the problems of affecting the mechanical properties of alloys, coarse inclusions, poor particle size distribution uniformity, etc., and achieve the effects of uniform composition, low cost, and favorable industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

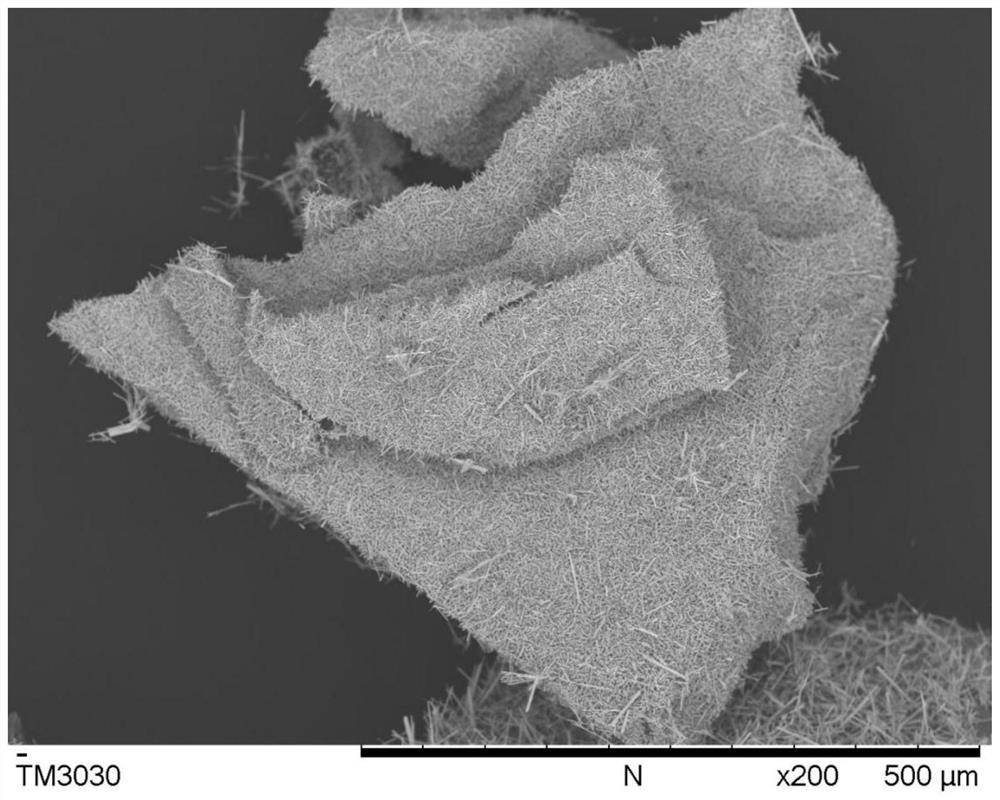

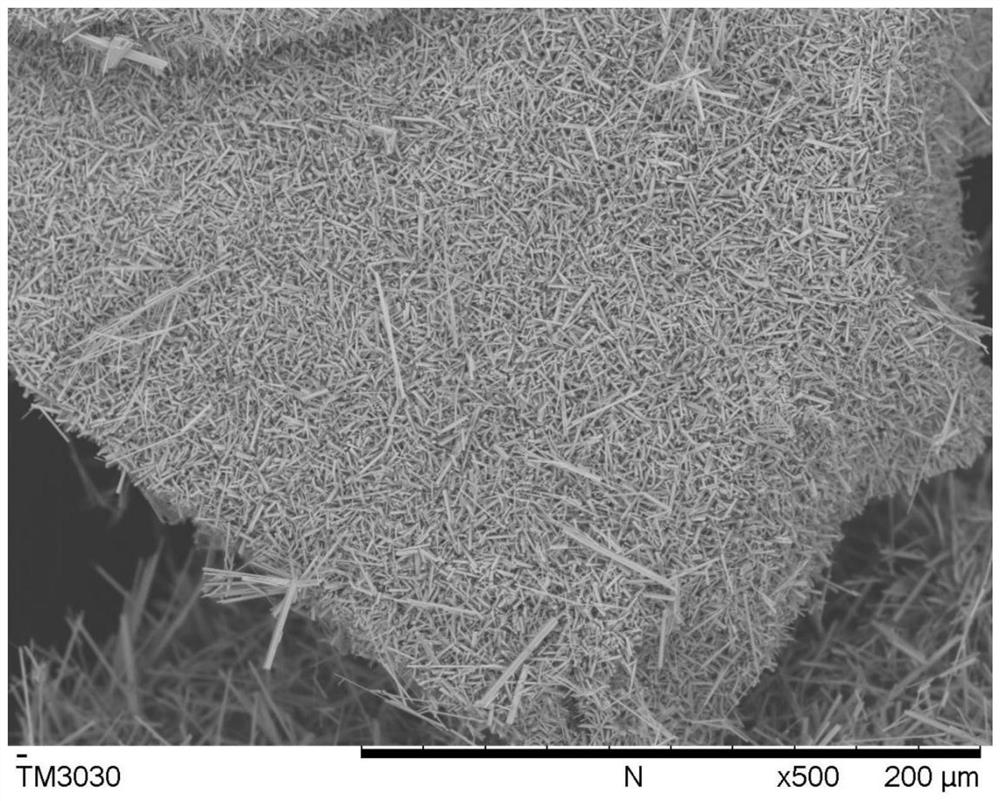

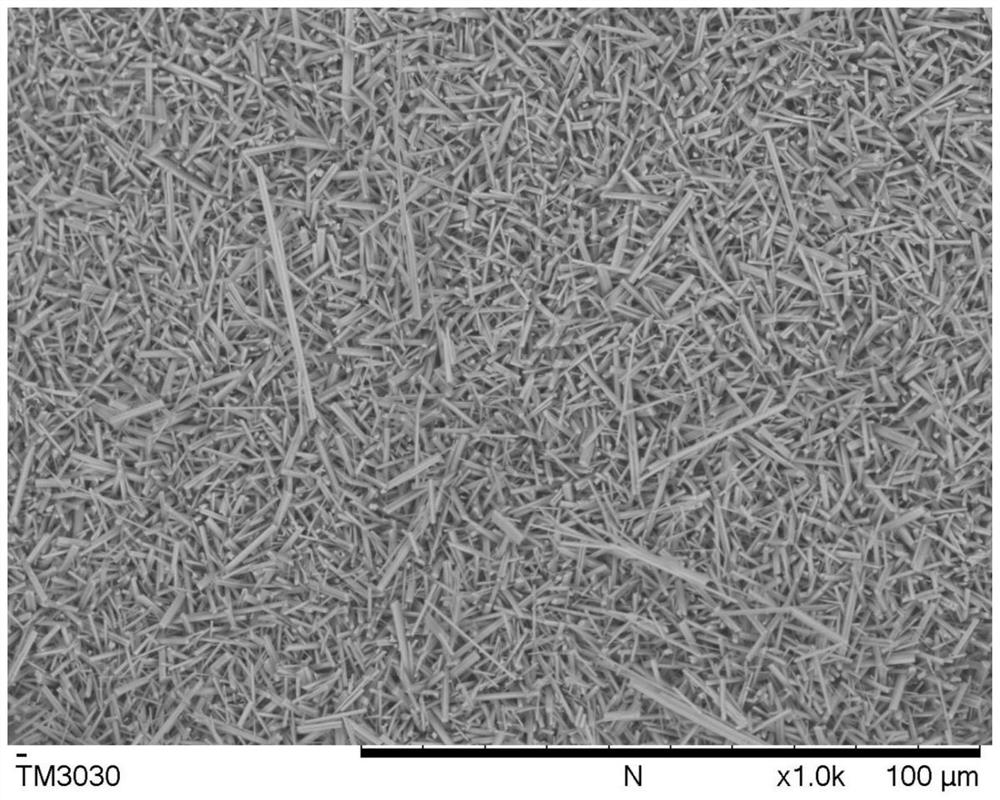

[0030] A preparation method of rod-shaped violet tungsten in the embodiment of the present invention is specifically carried out according to the following steps:

[0031] S1, weigh tungsten powder with a particle size of 3-5 μm and hydrogen peroxide in a molar ratio of 1:1-8, wherein the hydrogen peroxide concentration is 30 wt.%.

[0032] S2, dissolving the tungsten powder in hydrogen peroxide, and after all the tungsten powder is dissolved, a tungsten solution containing peroxytungstic acid is obtained.

[0033] S3, according to the W:C molar ratio of the tungsten powder and the carbon-containing sugars as 4-24:1, weigh the carbon-containing sugars, add the weighed carbon-containing sugars, and stir evenly.

[0034] S4, after mixing evenly, put it in an oven to dry, the oven drying temperature is 80-160°C, and the drying time is 3-15h, the amorphous carbon is homogeneously compounded with peroxytungstic acid, which effectively avoids the formation of needle-shaped violet tu...

Embodiment 1

[0043] A preparation method of rod-shaped violet tungsten is specifically carried out according to the following steps:

[0044] S1, weigh tungsten powder with a particle size of 3-5 μm and hydrogen peroxide in a molar ratio of 1:1, wherein the hydrogen peroxide concentration is 15 wt.%.

[0045] S2, dissolving the tungsten powder in hydrogen peroxide, and after all the tungsten powder is dissolved, a tungsten solution containing peroxytungstic acid is obtained.

[0046] S3, weigh the starch according to the W:C molar ratio of tungsten powder and starch as 4:1, pour the weighed starch into the tungsten solution containing peroxytungstic acid, and stir evenly.

[0047] S4, after mixing evenly, put it into an oven for drying, and the oven drying temperature is 80°C and the time is 15h.

[0048] S5, after drying, the obtained powder is ground to obtain a precursor powder.

[0049] S6, heat treatment of the precursor powder under the protection of an inert atmosphere such as nit...

Embodiment 2

[0051] A preparation method of rod-shaped violet tungsten is specifically carried out according to the following steps:

[0052] S1, weigh tungsten powder with a particle size of 3-5 μm and hydrogen peroxide in a molar ratio of 1:6, wherein the concentration of hydrogen peroxide is 30 wt.%.

[0053] S2, dissolving the tungsten powder in hydrogen peroxide, and after all the tungsten powder is dissolved, a tungsten solution containing peroxytungstic acid is obtained.

[0054] S3, weigh the sucrose according to the W:C molar ratio of tungsten powder and sucrose as 15:1, pour the sucrose into the tungsten solution containing peroxytungstic acid, and stir evenly.

[0055] S4, after mixing evenly, put it into an oven for drying, and the oven drying temperature is 160° C. and the time is 3 hours.

[0056] S5, after drying, the obtained powder is ground to obtain a precursor powder.

[0057] S6, heat treatment of the precursor powder under the protection of an inert atmosphere such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com