Method for producing alloy iron roll

A production method and alloy cast iron technology, applied in the field of metallurgical cast iron rolls, can solve problems such as large fluctuations in composition, production space and capital occupation, and many oxidation inclusions, so as to eliminate the hazards of severe rust and oxidation, solve genetic problems, and improve metallurgical quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The alloy cast iron roll production method adopts the following production steps:

[0021] (1) Raw material preparation: select clean, no inclusions, no oily cast iron roll chips 70wt%-100wt%, scrap steel 0-30wt%; the oily chips should be roasted at a high temperature of 800°C-1000°C; Scrap steel is clean and less rusty, thickness ≥ 5mm, and does not contain harmful components of Sb and Sn; analyze the chemical composition of the chips and scrap steel, according to the composition requirements, burning loss, recovery rate, and purity of the additives of the alloy cast iron roll to be poured To determine the amount of added recarburizer and or alloy; the alloy includes ferrosilicon and or ferrochrome and or ferromolybdenum and or ferromanganese and or ferrosilicon and or nickel; the recarburizer is waste graphite electrode block , Electrode powder or commercially available recarburizer, moisture <0.5% or baked at 100°C-200°C for 6-8 hours.

[0022] (2) Furnace charging ...

Embodiment 2

[0028] The alloy cast iron roll production method adopts the following production steps:

[0029] (1) Raw material preparation: with embodiment 1, most of chip briquetting process, to reduce oxidation phenomenon;

[0030] (2) Furnace with excess water: slag the remaining water in the intermediate frequency induction furnace, add carburant to the melt; spread a layer of briquette chips and loose chips with a thickness of 200-300mm on the carburant Cuttings, to ensure that the cuttings are tightly loaded into the furnace; scrap steel and or cuttings are added to the briquetting cuttings; the cuttings and or scrap steel are pressed with a pressing iron;

[0031] (3) Turn on the furnace and heat up. As the chips in the furnace gradually melt, put the remaining briquetting chips into the furnace in turn. The chips cannot be added to the furnace beyond the furnace mouth; the top of the chips is pressed with a weight;

[0032] (4) After all the raw materials are melted into molten i...

Embodiment 3

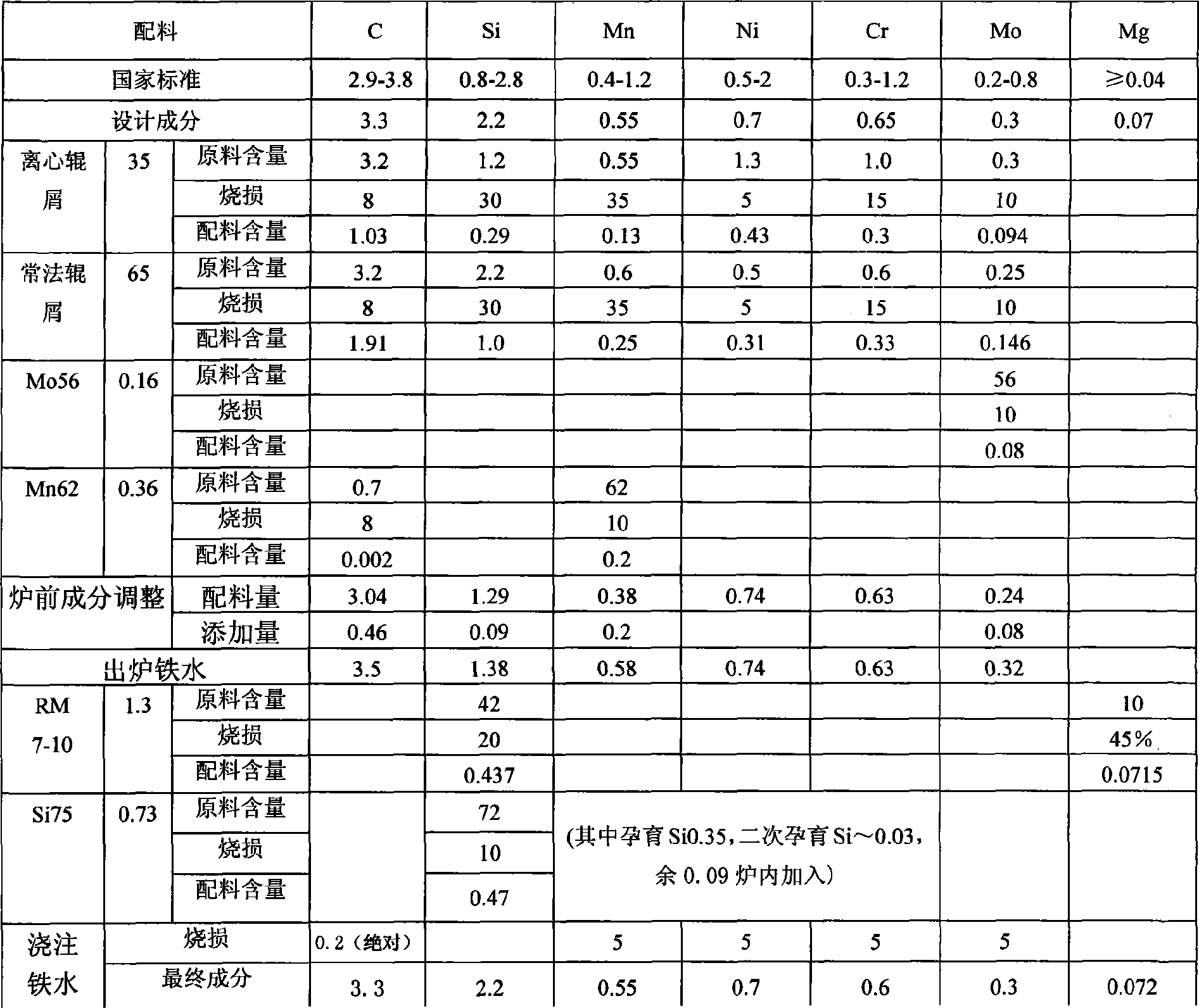

[0036] Specifications are , The material is the production method of the alloy ductile graphite infinite chilled cast iron roll of medium NiCrMo, the casting blank weight is 550kg, the net weight is 343kg, and the molten iron weight is 650kg. It adopts the following production steps:

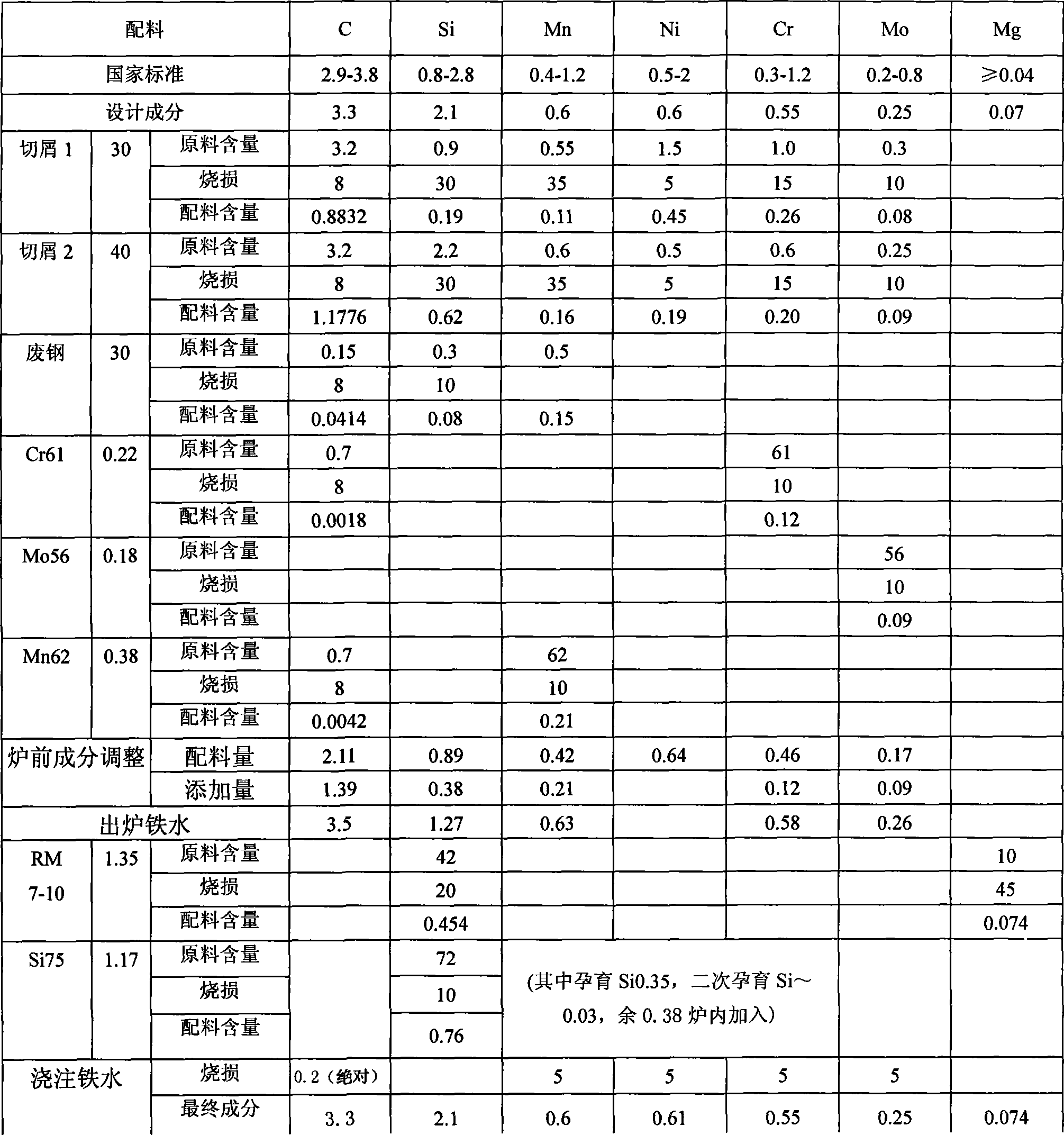

[0037] (1) Raw material preparation: get high NiCrMo roll chips 1, account for 30wt% of batching weight, low and medium NiCrMo roll bar chips 2, account for 40wt% of batching weight, scrap steel 30wt%; Block treatment; scrap steel is clean and less rusty, thickness ≥ 5mm, and does not contain harmful components of Sb and Sn; analyze the chemical composition of chips and scrap steel, and calculate the carburizer and or alloy that needs to be added according to the design composition requirements of the alloy cast iron roll that needs to be poured , the amount of recarburizer and or alloy added is determined according to its purity, burning loss, and recovery rate, see Table 1 for details.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com