Sintering ore air draft type circulating cooling system and process thereof

A circulating cooling system and a drafting technology, applied in the field of ironmaking, can solve the problems of low boiler thermal efficiency, difficult to efficiently recover and utilize sensible heat of sintered ore, and high power consumption of fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

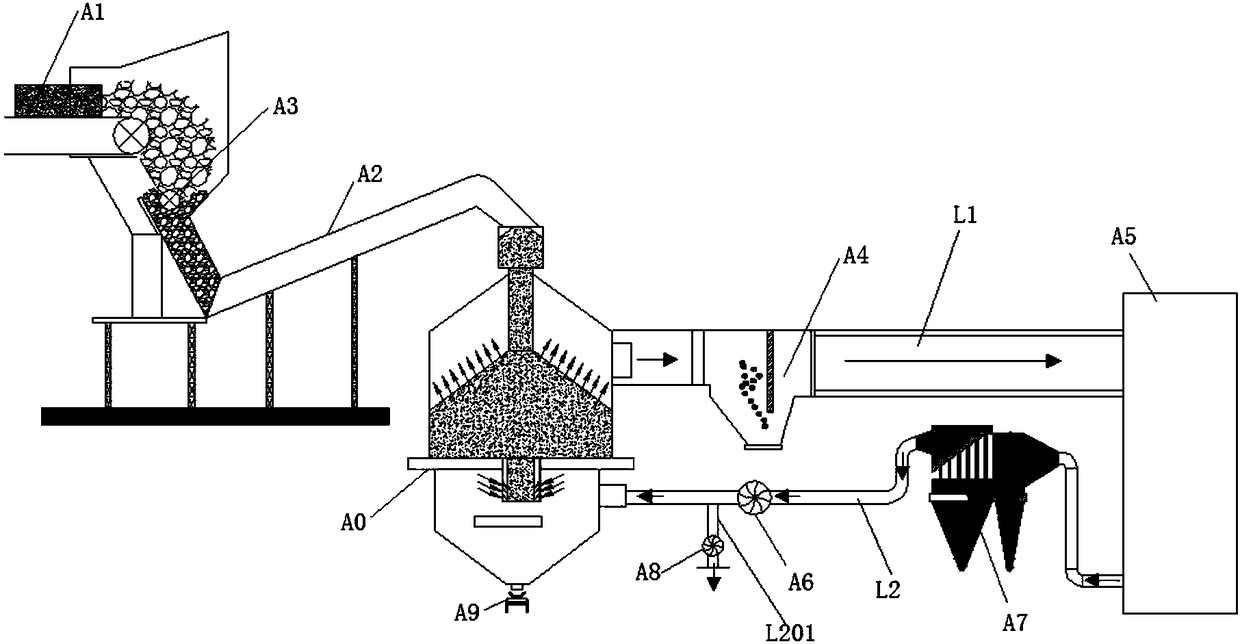

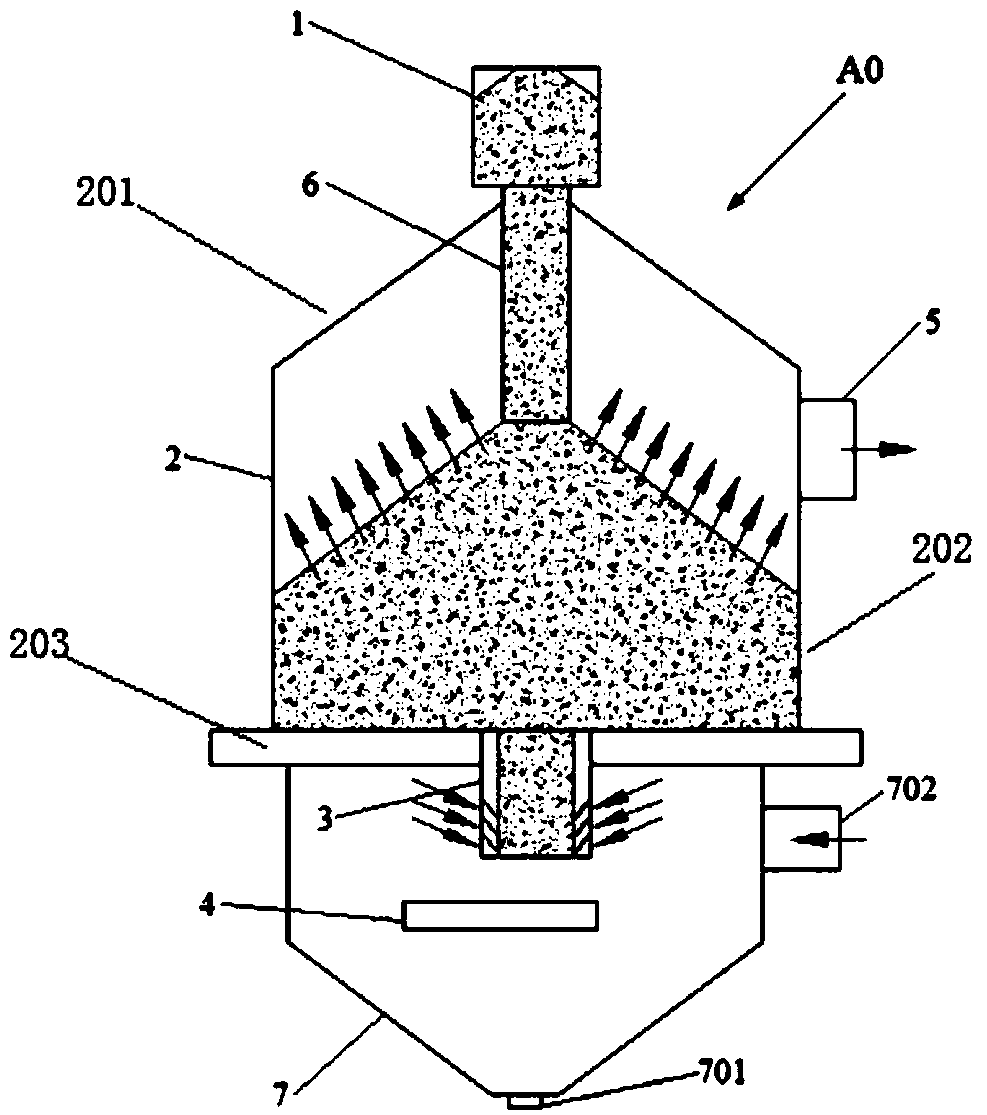

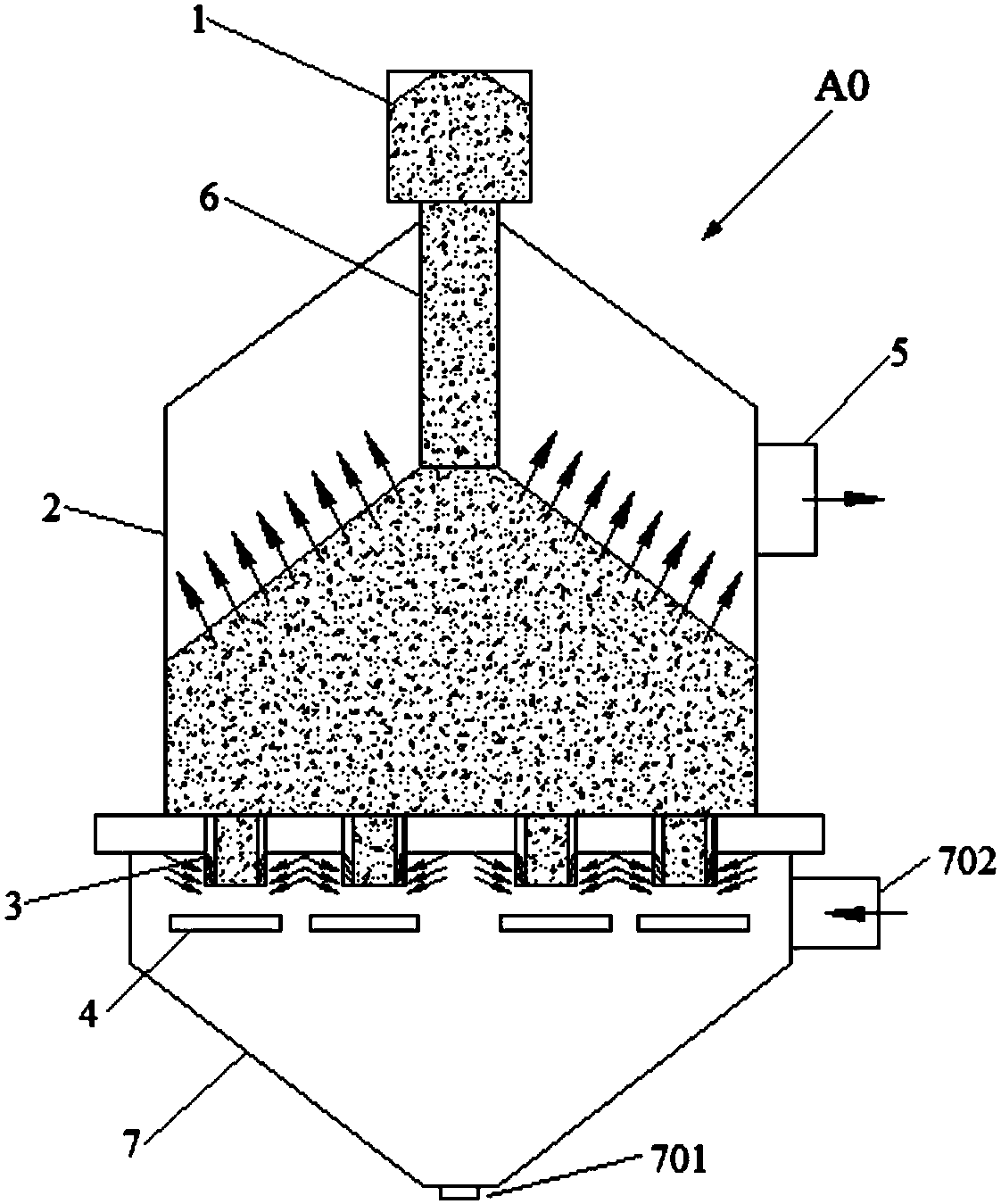

[0157] like figure 1 As shown, a sinter ventilation circulation cooling system, the system includes ventilation vertical cooling furnace A0, waste heat boiler and power generation system A5, circulation exhaust fan A6, hot air delivery channel L1, cold air delivery channel L2. Among them: the draft vertical cooling furnace A0 includes a silo 1, a tower body 2, an air inlet and discharge device 3, a discharge device 4, and a discharge chute 7. The tower body 2 includes a tower top 201 , a tower wall 202 and a tower bottom 203 . The tower top 201 is arranged on top of the tower wall 202 . The tower bottom 203 is provided at the bottom of the tower wall 202 . The feed bin 1 is arranged above the tower top 201 and communicates with the inside of the tower body 2 . The air intake and discharge device 3 is arranged below the tower bottom 203 and communicates with the inside of the tower body 2 . The discharge device 4 is arranged below the air intake and discharge device 3 . Th...

Embodiment 2

[0159] Repeat Example 1, except that the system further includes: sintering machine A1, hot sinter conveying device A2. The discharge port of the sintering machine A1 is connected to the feed port of the silo 1 through the hot sinter conveying device A2. The system also includes: Crusher A3; Crusher A3 is a single-roll crusher; Crusher A3 is set at the discharge port of sintering machine A1, and the discharge port of Crusher A3 is connected to the silo through hot sinter conveying device A2 1 feed port.

Embodiment 3

[0161] Embodiment 2 is repeated, except that the first dust remover A4 is provided on the hot air conveying channel L1. A second dust collector A7 is also provided on the cold air conveying channel L2. The second deduster A7 is arranged upstream of the circulation exhaust fan A6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com