Energy-saving and temperature-control type hot-blast stove

A hot blast stove and warm-type technology, which is applied in the field of indoor heating in winter, can solve the problems of inability to adjust the temperature of the heat-carrying air flow in time, narrow ventilation duct space, and low heat exchange efficiency, so as to save power consumption, save energy, and improve heat exchange The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

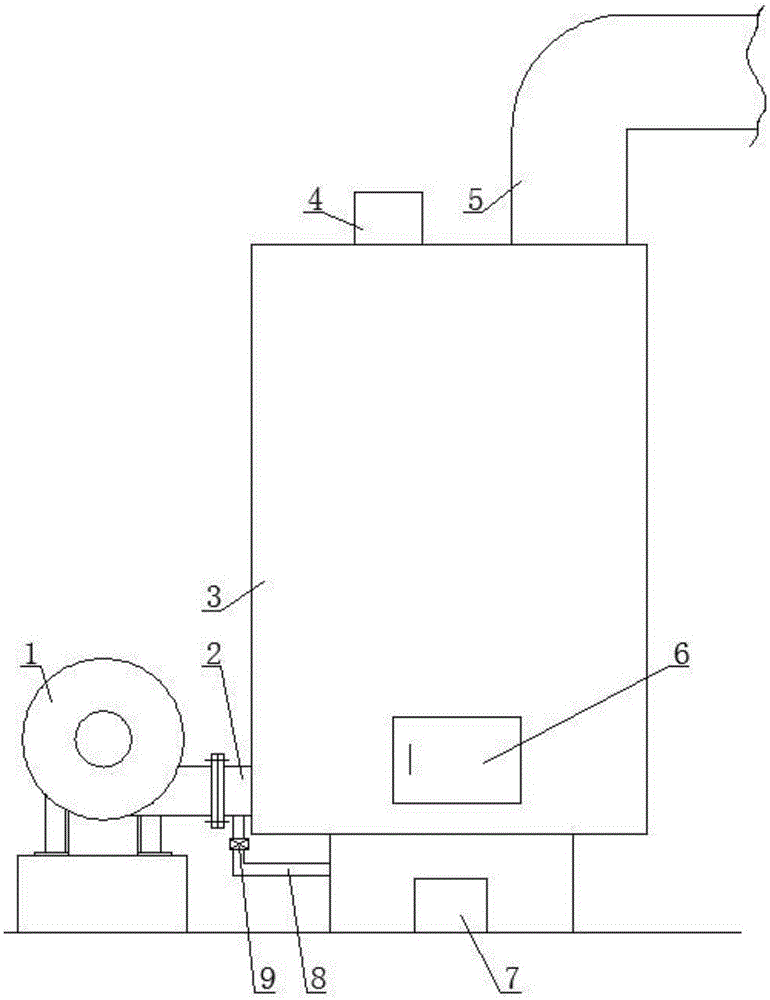

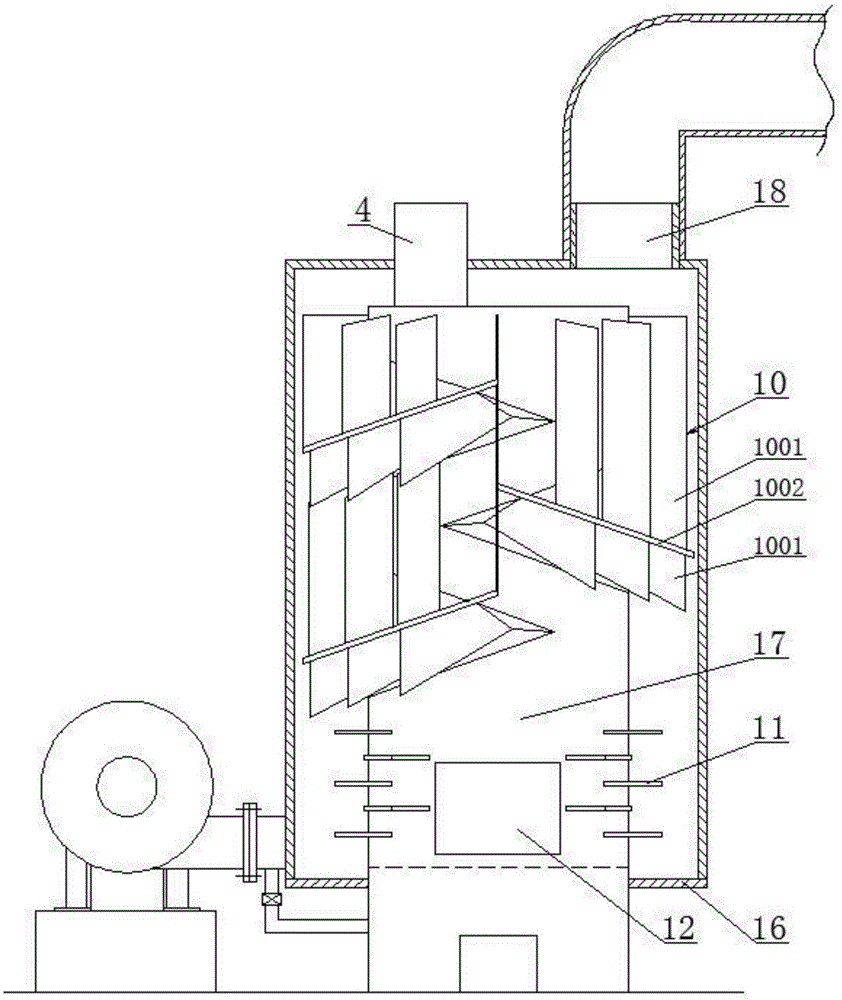

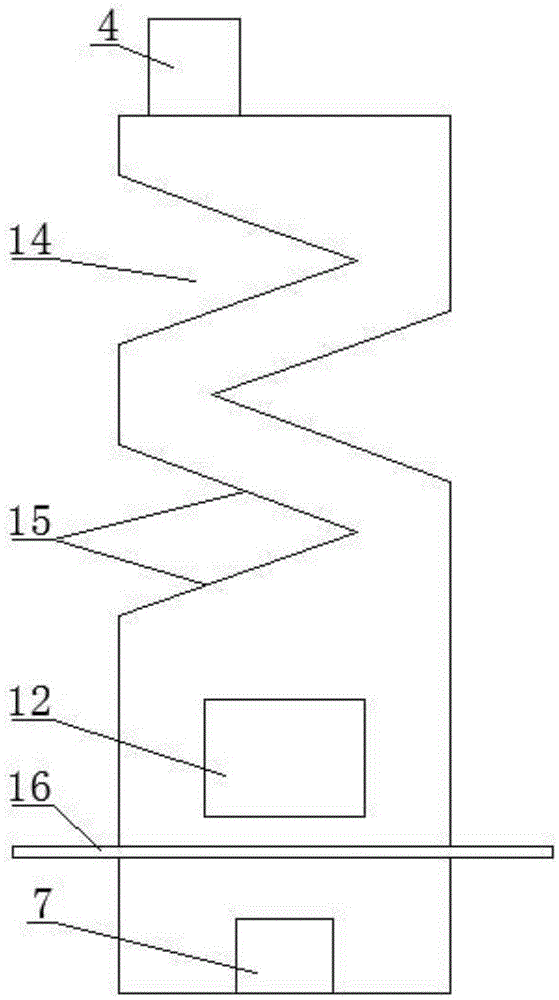

[0020] As shown in the figure, the energy-saving temperature-controlled hot blast stove includes an outer shell 3 and an inner tank 17, and the lower part of the inner tank 17 is a combustion chamber and an ash release chamber. The upper part of the liner 17 is provided with a broken-line flue 13, the end of the broken-line flue 13 is provided with a flue gas outlet 4, the outer wall of the broken-line flue 13 is provided with a plurality of radiators 10, and the lower part of the shell 3 An air inlet 2 is provided and a centrifugal blower 1 is connected to the outside of the air inlet 2, and a branch pipe 8 is connected to the side wall of the air inlet 2. The other end of the branch pipe 8 passes through the shell 3 and is inserted into the ash discharge chamber. The pipeline 8 is provided with a solenoid valve 9 or a manual slide valve controlled by an indoor temperature sensor. The top of the casing 3 is provided with a hot air outlet 18, the hot air outlet 18 is located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com