Sinter cooler with radiation heat recoverer and cooling method

A cooler and recycler technology, applied in the field of ironmaking, can solve the problems of low utilization rate of waste heat, large air leakage rate of the cooler, material wear at the feed port, etc., and achieves high waste heat recovery efficiency, small equipment maintenance, and sealing reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

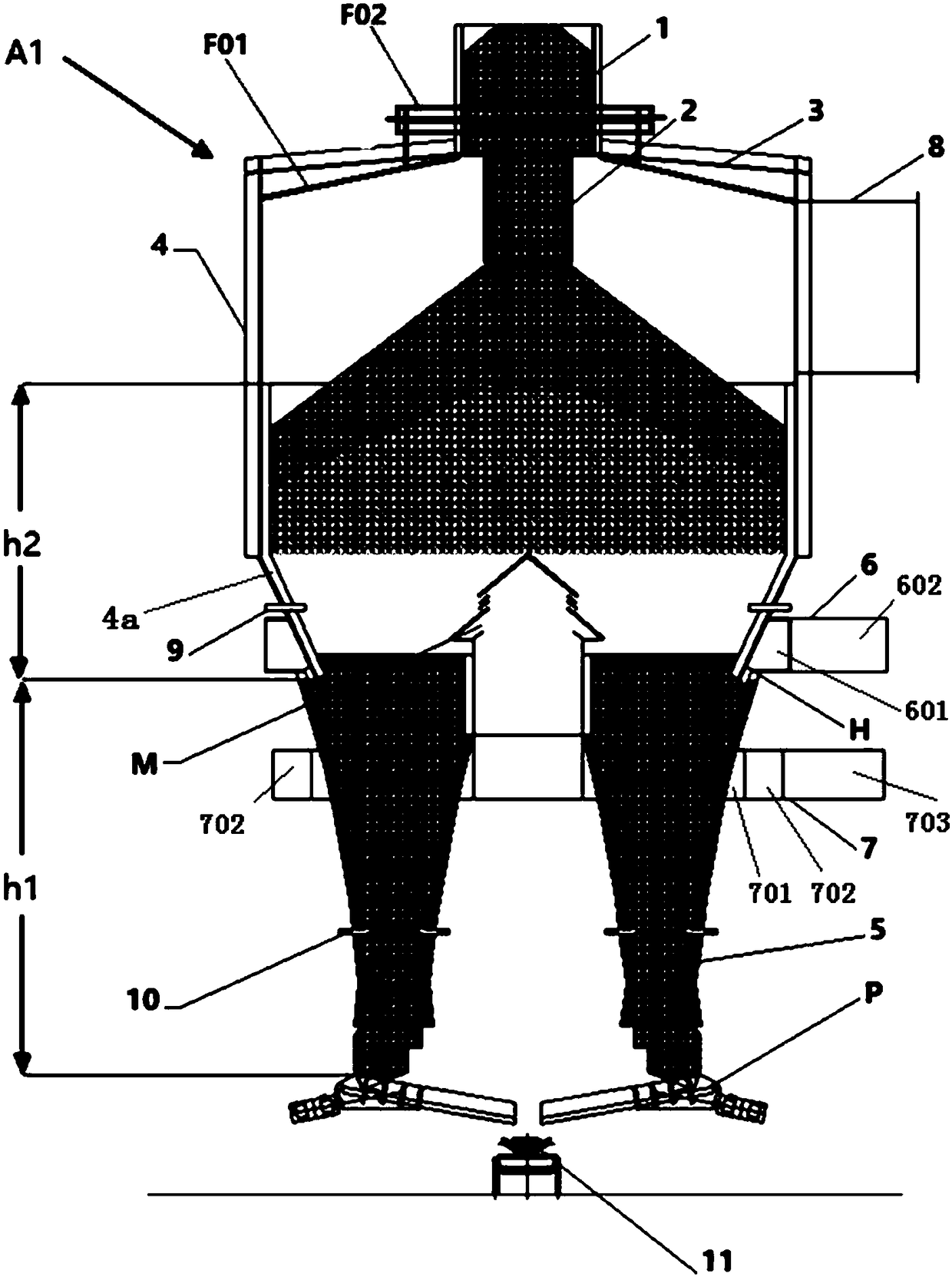

[0120] The height of the tower body consisting of the top cover and the tower wall is 9 meters, and the outer diameter of the tower body is 13 meters. The height of the discharge cone is 7 meters. Under the top cover and close to the top cover, a ring-shaped second radiant heat recovery device F01 is formed by assembling a plurality of ring-shaped hollow plates.

[0121] The diameter of the hood is 2.5 meters. The inner diameter of the wind ring is about 11 meters.

[0122] The daily processing capacity of sinter is 8600 tons / day. The temperature of the sintered ore before entering the silo is about 700°C, and the temperature of the hot air at the hot air outlet 8 reaches about 498°C. The recovered heat is used to generate electricity, and the power generation is about 36 kWh.

[0123] Compared with the prior art annular cooler, the advantages are: high power generation, low air leakage rate, small dust emission, simple and reliable equipment, and better sealing performanc...

Embodiment 2

[0126] The device is the same as in Example 1, except that the second radiant heat recoverer F01a is further arranged at the front end of the hot air outlet 8; a tube-and-tube heat exchanger is adopted, such as Figure 13 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com