Vertical-type cooling machine with rectifying device and cooling method

A rectifying device and cooling machine technology, applied in sinter cooling machine and sinter cooling, vertical cooling machine and cooling field, can solve the problems of high air leakage rate of cooling machine, reduce the quality of hot exhaust gas, uneven distribution of material particle size, etc., to achieve Improve the uniformity of cooling, improve the quality of hot exhaust gas, and evenly distribute the airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

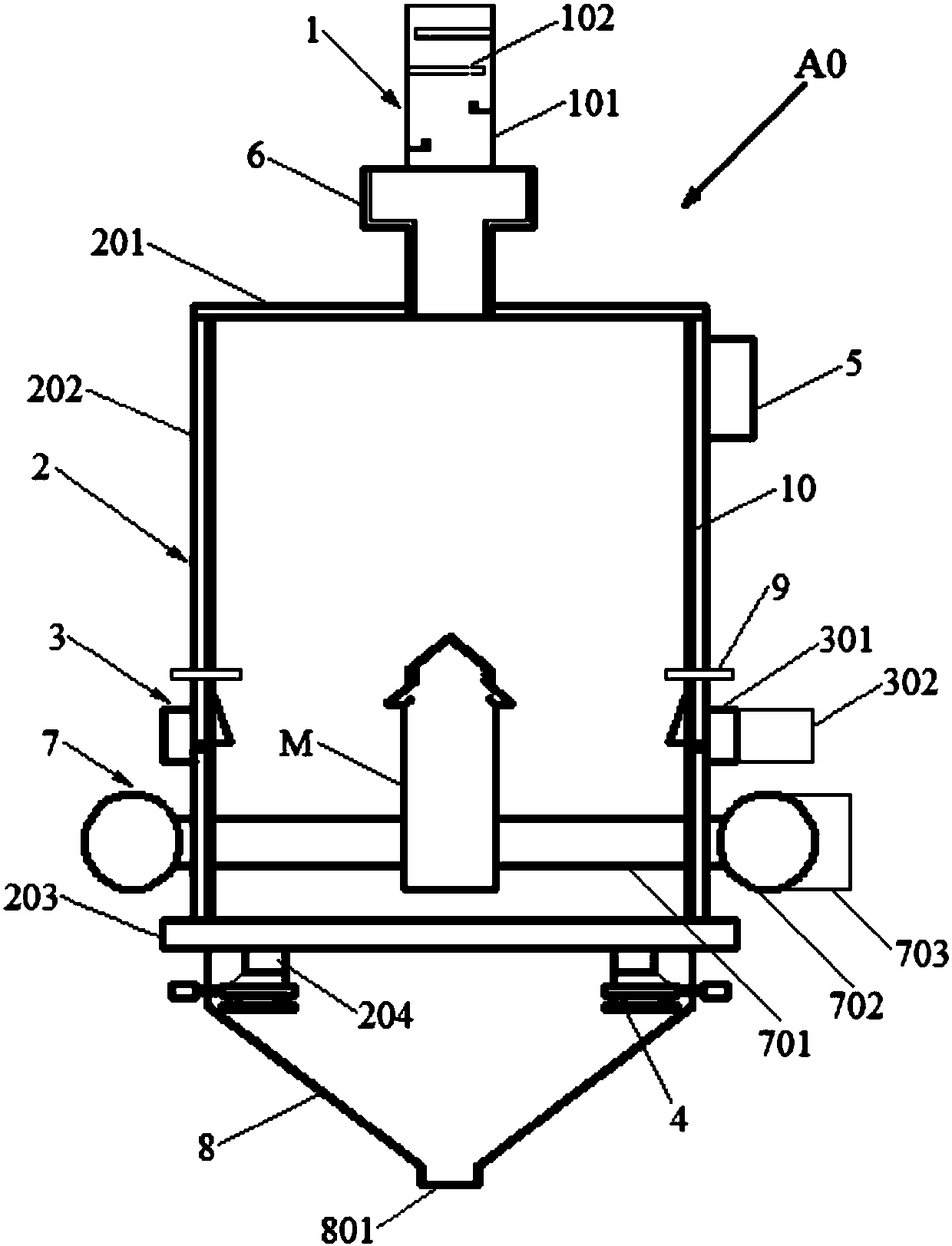

[0089] Such as figure 1 As shown, a vertical cooling machine with a rectifying device, the vertical cooling machine A0 includes a rectifying device 1, a tower body 2, a side air supply device 3, and a discharge device 4. The tower body 2 includes a tower top 201, a tower wall 202, and a tower bottom 203. The tower top 201 is arranged on the top of the tower wall 202. The tower bottom 203 is arranged at the bottom of the tower wall 202. The rectifying device 1 is arranged above the tower top 201 and communicates with the inside of the tower body 2. The side air supply device 3 is arranged in the middle and lower part of the tower wall 202. The bottom 203 is provided with a discharge port 204. The discharge device 4 is arranged below the discharge opening 204. The upper part of the tower wall 202 is provided with a hot air outlet 5. The vertical cooler A0 also includes a cloth device 6. The distributing device 6 is arranged between the rectifying device 1 and the tower body...

Embodiment 2

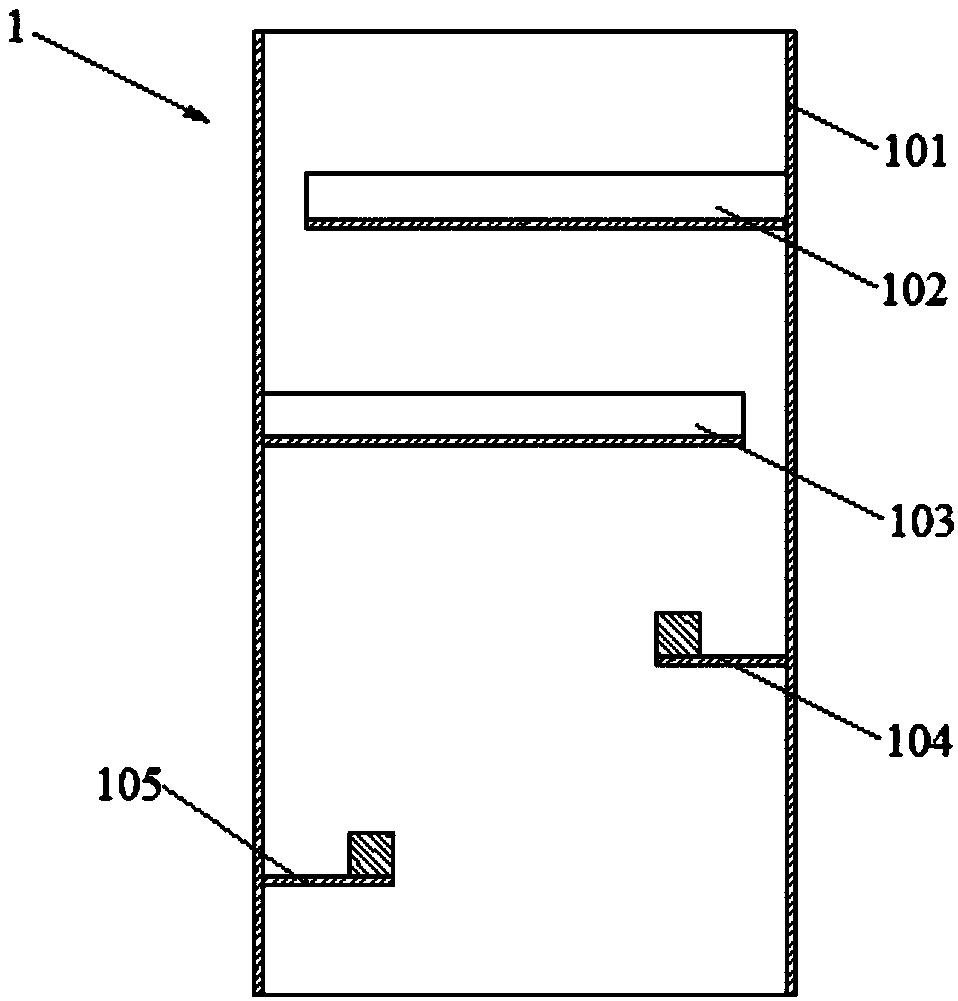

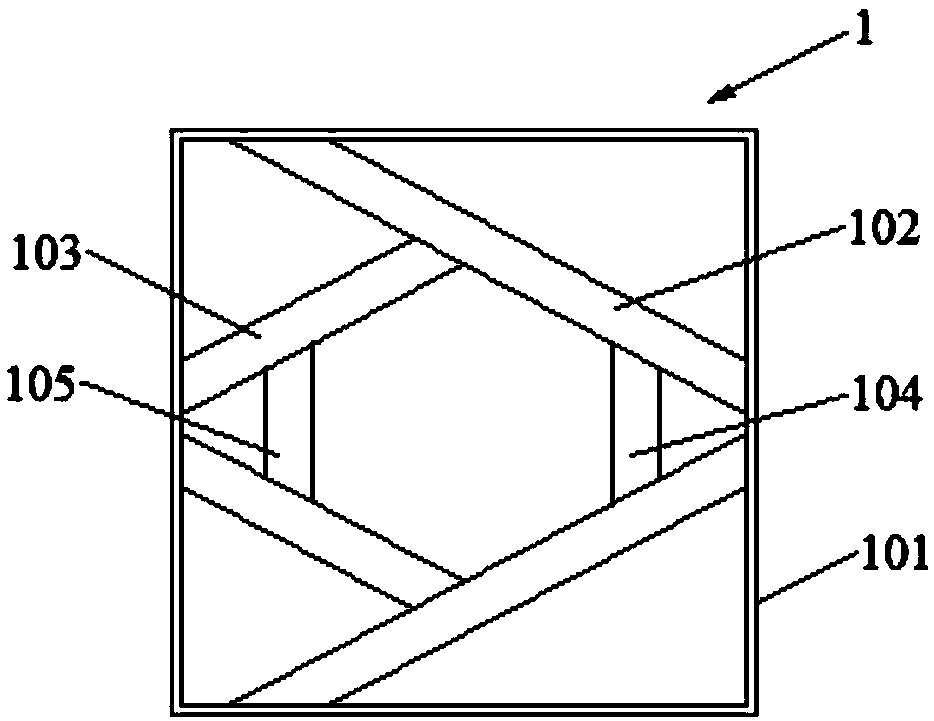

[0097] Such as Figure 5 As shown, embodiment 1 is repeated, except that the rectifying device 1 further includes a second baffle 103. The second baffle 103 is disposed on the inner wall of the housing 101 opposite to the first baffle 102, and the second baffle 103 is located below the first baffle 102. The second baffle 103 is also a concave structure, and its concave opening direction is opposite to the first baffle 102.

Embodiment 3

[0099] Such as Figure 2-3 As shown in 6-7, embodiment 2 is repeated, except that the rectifying device 1 further includes a third baffle 104. The third baffle 104 is arranged on the inner wall of the housing 101 opposite to the second baffle 103, and the third baffle 104 is located below the second baffle 103. The third baffle 104 has a plate-shaped structure. The rectifying device 1 further includes a fourth baffle 105. The fourth baffle 105 is disposed on the inner wall of the housing 101 opposite to the third baffle 104, and the fourth baffle 105 is located below the third baffle 104. The fourth baffle 105 also has a plate-shaped structure. The third baffle 104 and the fourth baffle 105 are provided with protrusions at one end of the edge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com