A wire control cooling device with online recovery function and its use method

A technology for controlling cooling and waste heat recovery devices, applied in workpiece cooling devices, metal rolling, manufacturing tools, etc., can solve the problems of scale pollution, heat loss, etc., and achieve the effect of flexible process and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

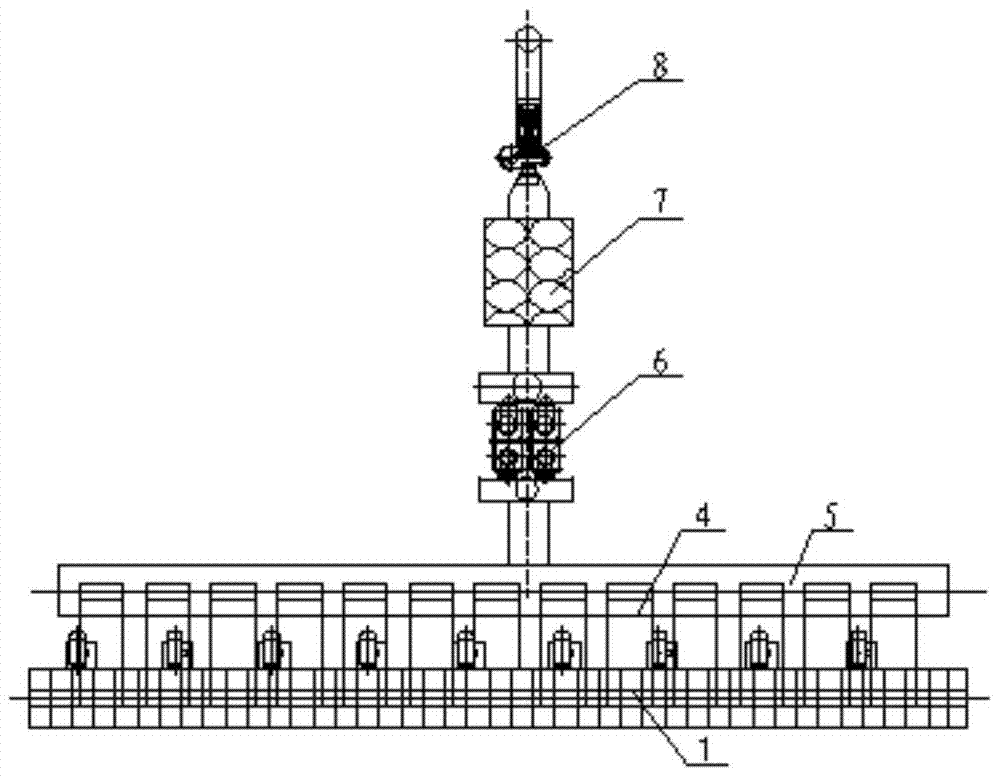

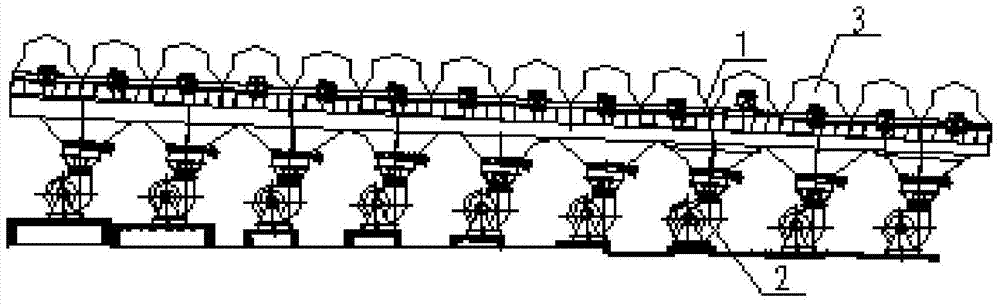

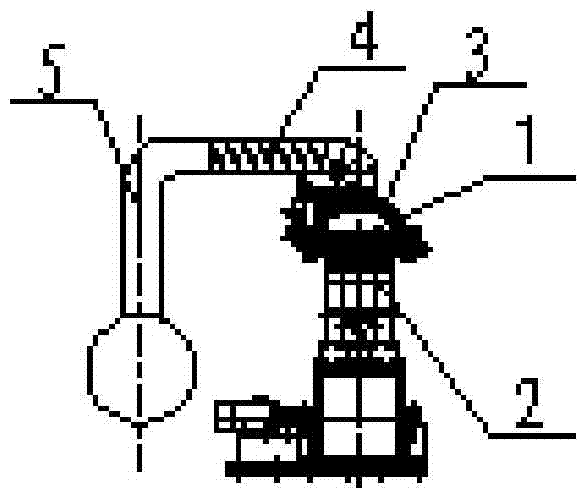

[0016] Figure 1-Figure 3 It is a specific embodiment of the present invention.

[0017] A wire rod control cooling device with online recovery function, including a conveying roller table 1, a cooling fan 2, an openable and closed heat preservation cover 3, a flexible air duct 4, a fixed air duct 5, a waste heat recovery device 6, and a scale recovery device 7 , induced draft fan 8. The cooling fan 2 is arranged under the conveying roller table 1, and the openable and closable heat preservation cover 3 is arranged above the conveying roller table 1. The openable and closable heat preservation cover 3 is connected with the flexible air duct 4, and the flexible air duct 4 is connected with the fixed air duct 5 , the fixed air duct 5 is equipped with a waste heat recovery device 6 and a scale recovery device 7, and an induced draft fan 8 is installed at the end of the fixed air duct 5.

[0018] The number of cooling fans 2 is 18.

[0019] The waste heat recovery device 6 adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com