Patents

Literature

43results about How to "Achieve height change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

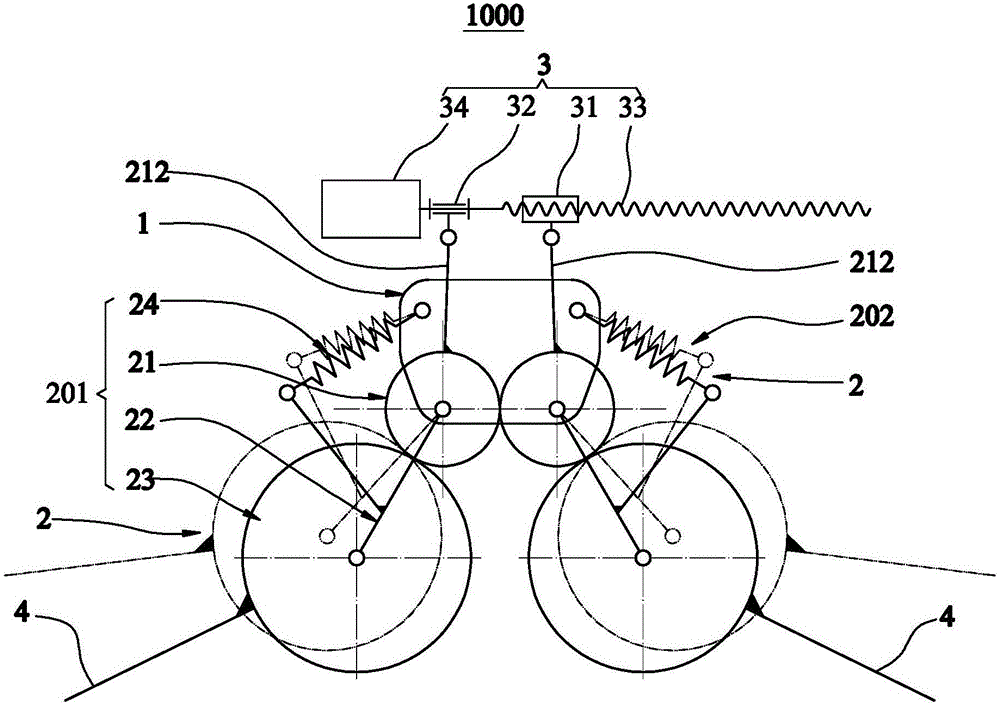

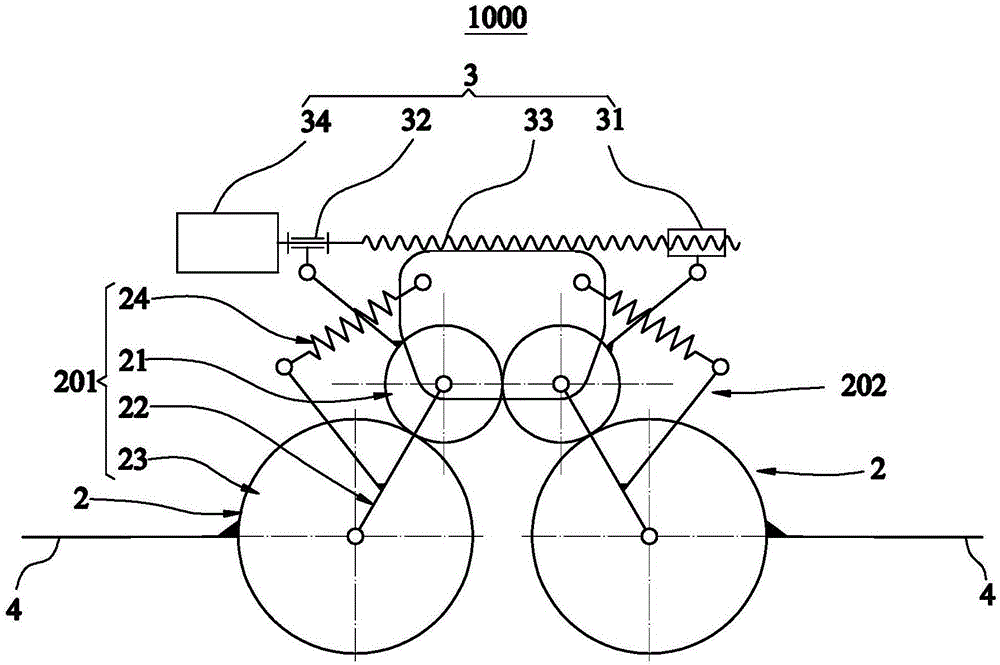

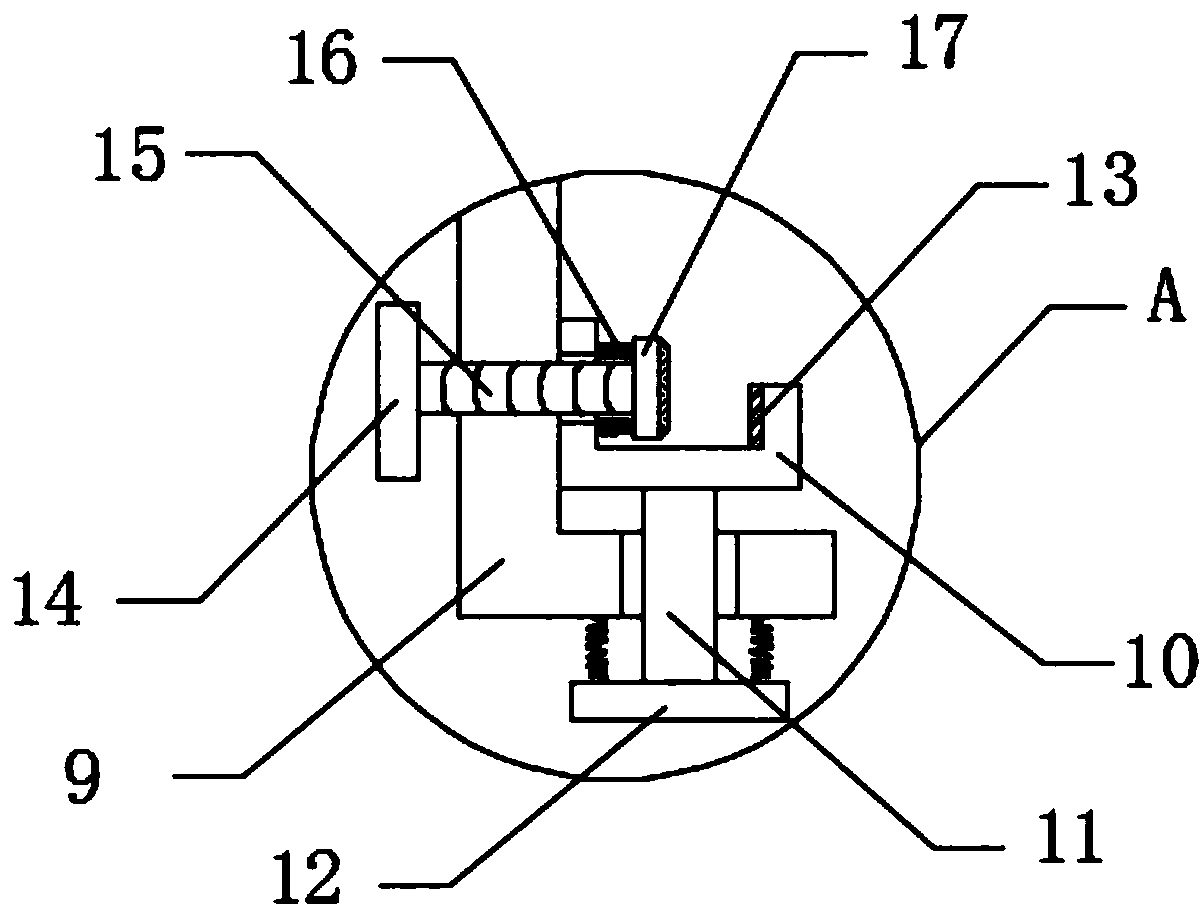

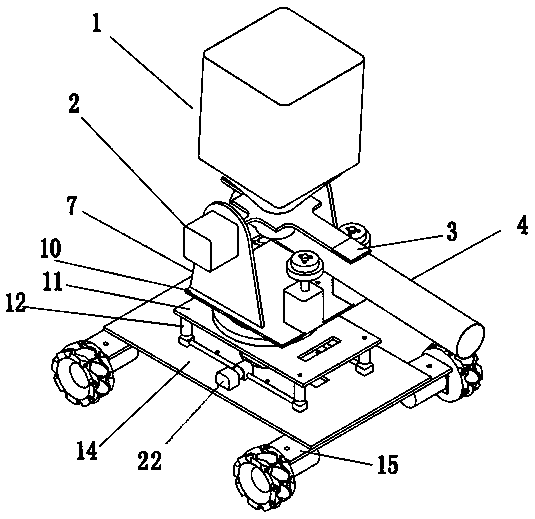

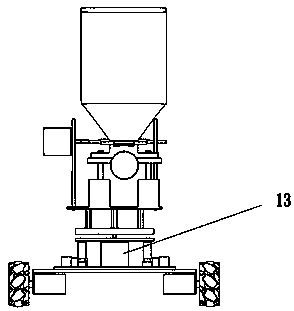

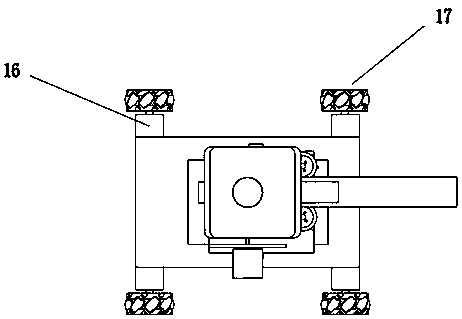

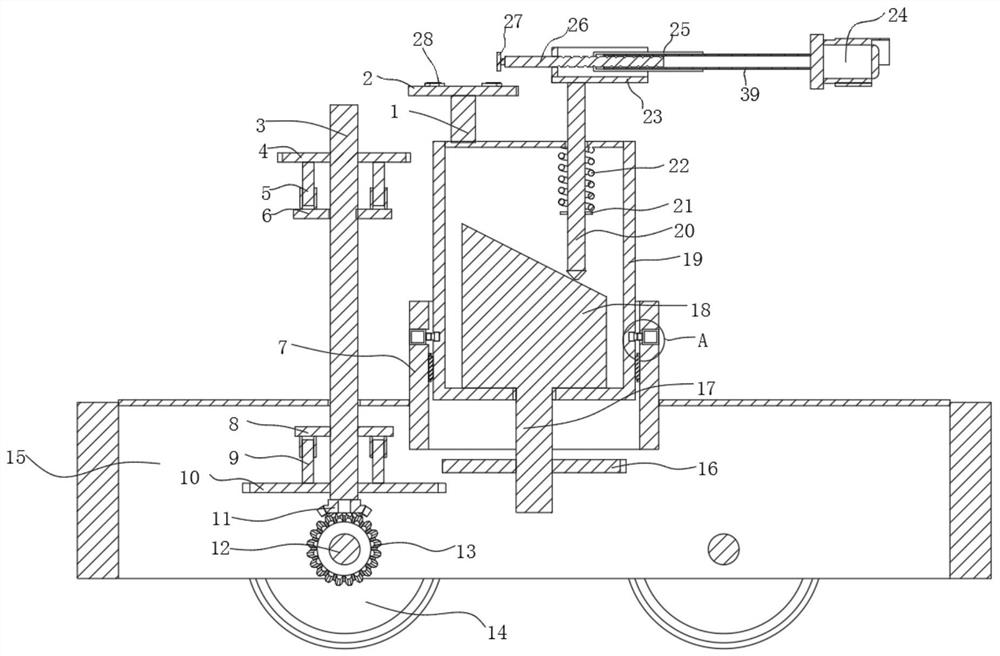

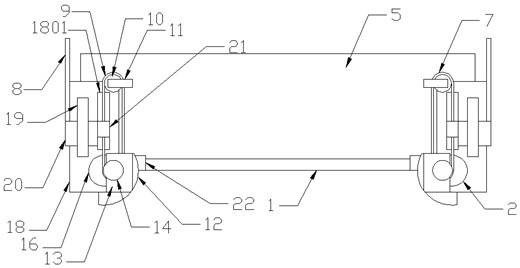

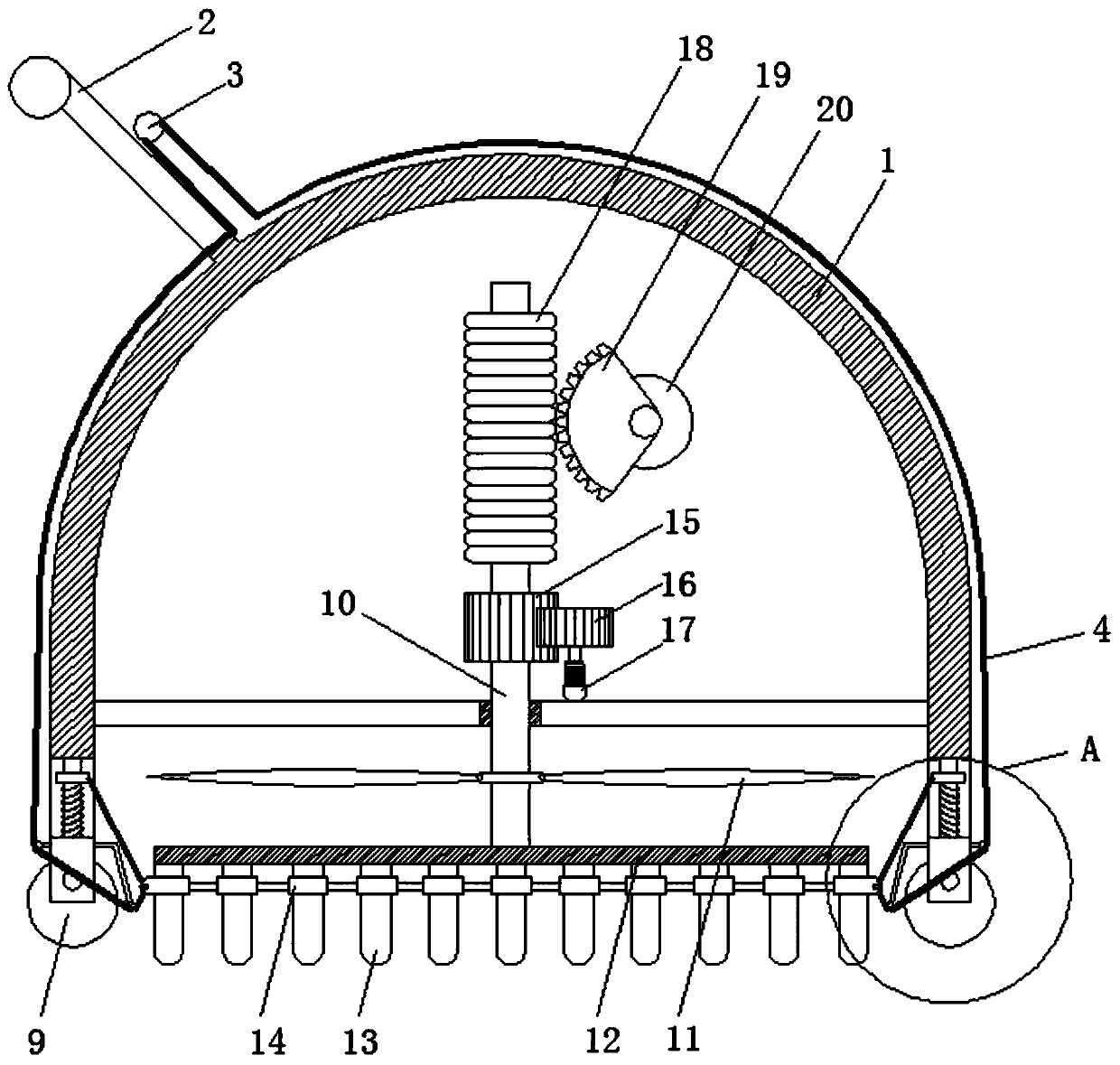

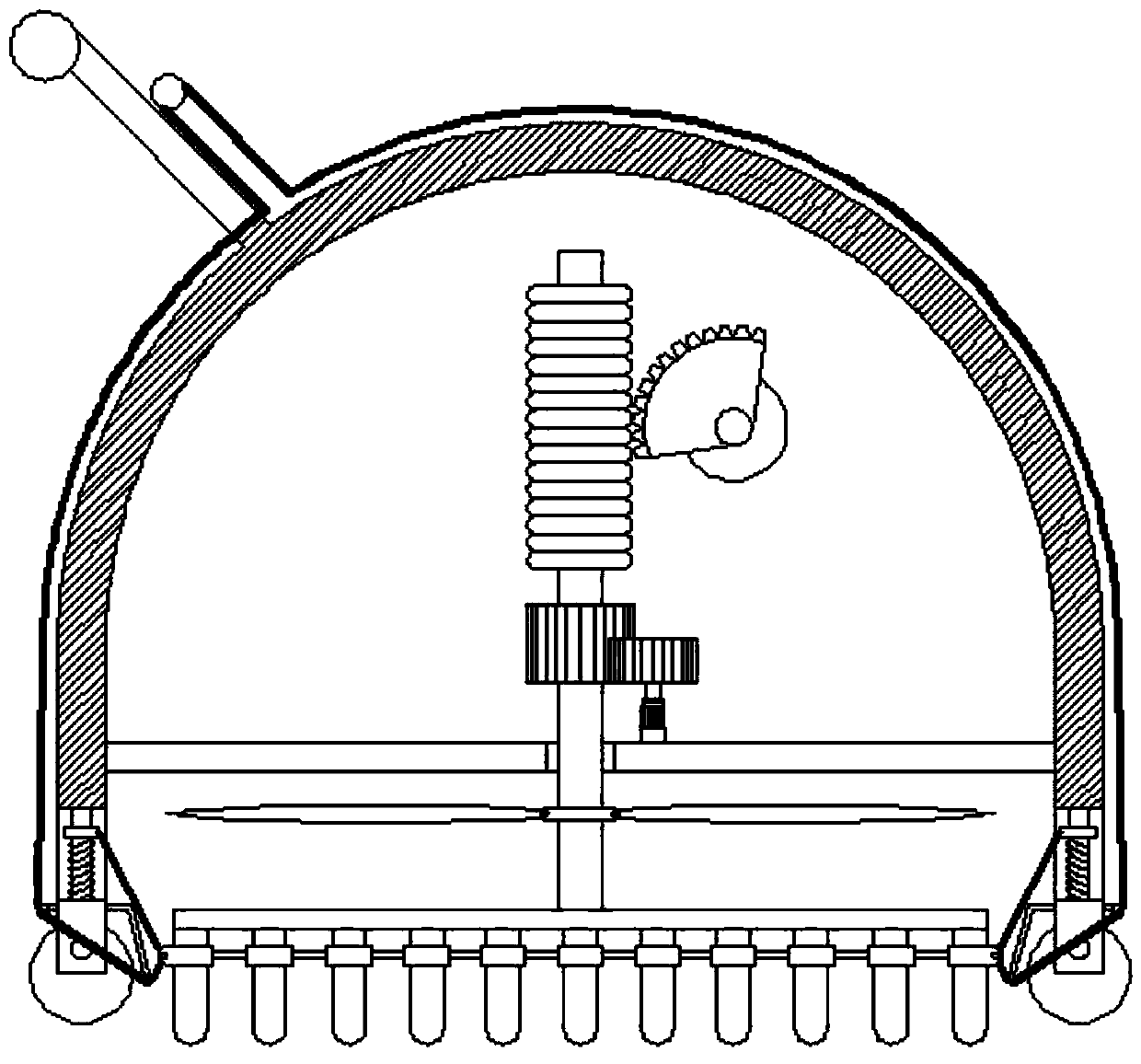

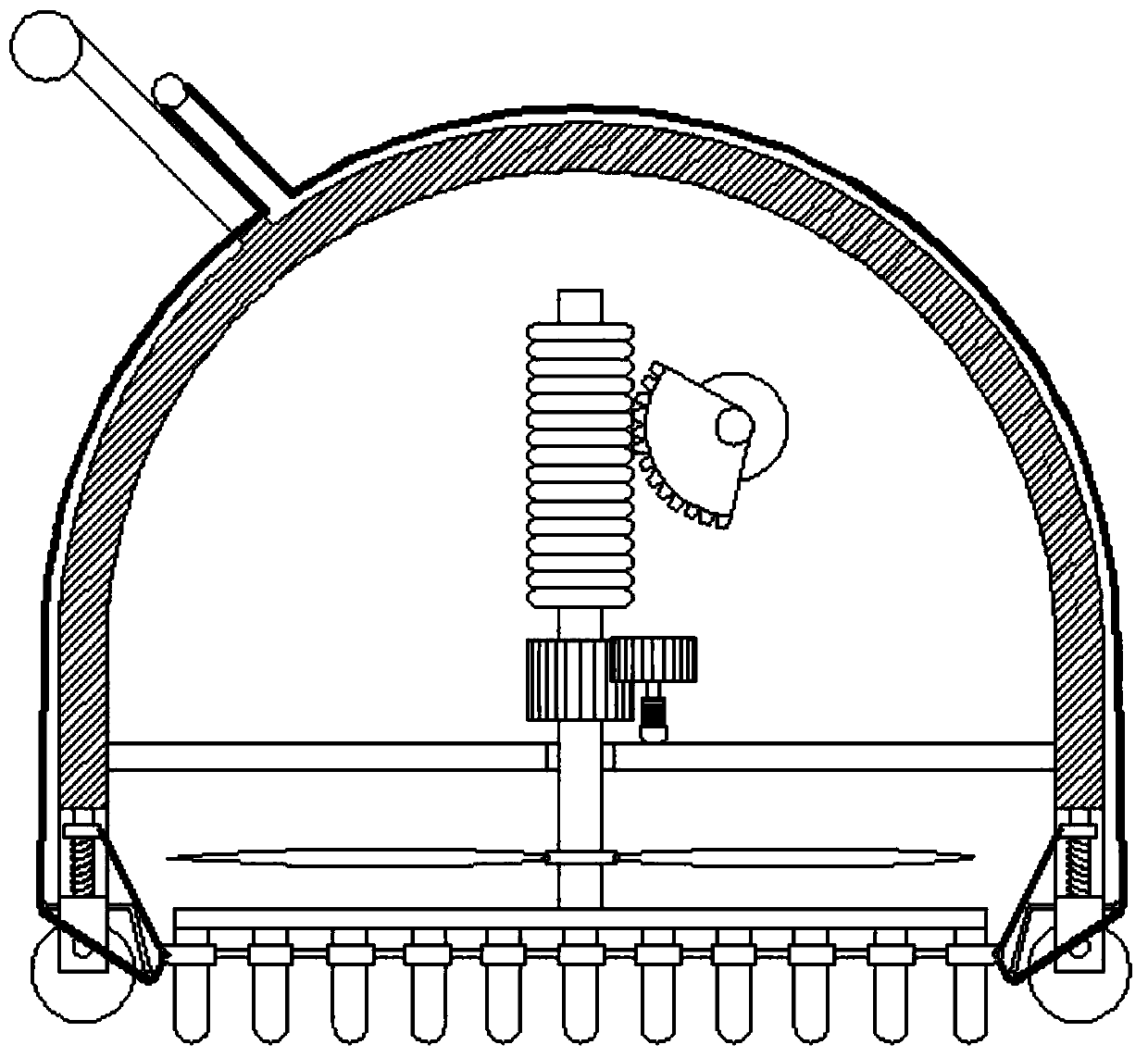

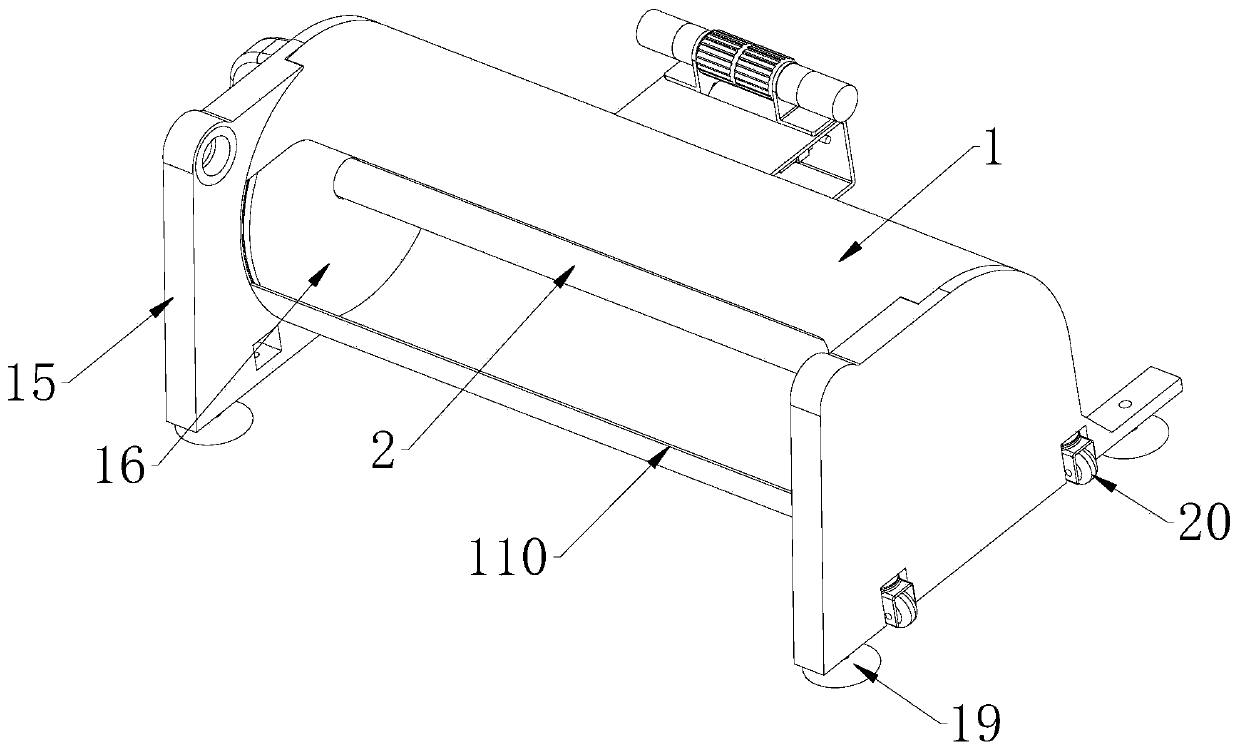

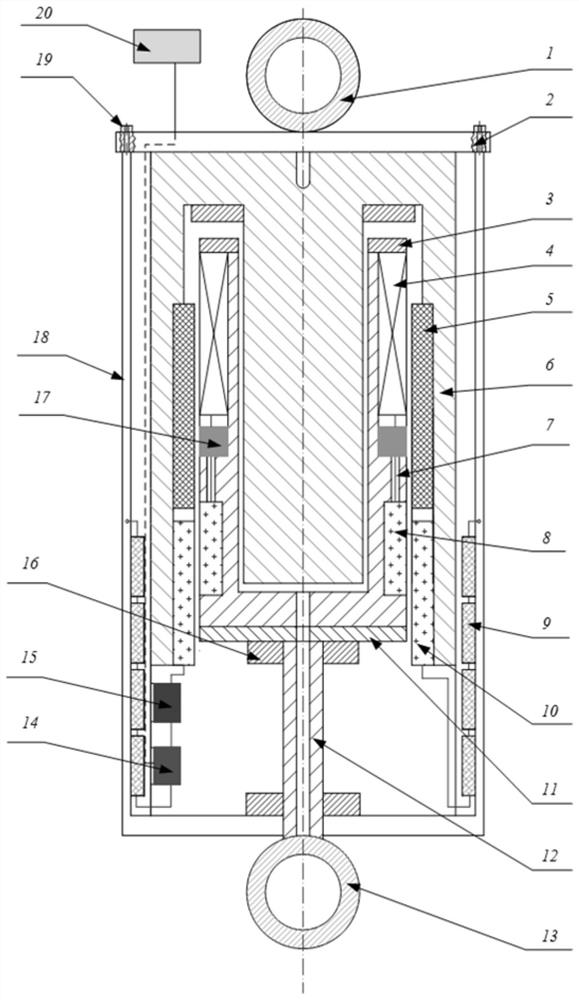

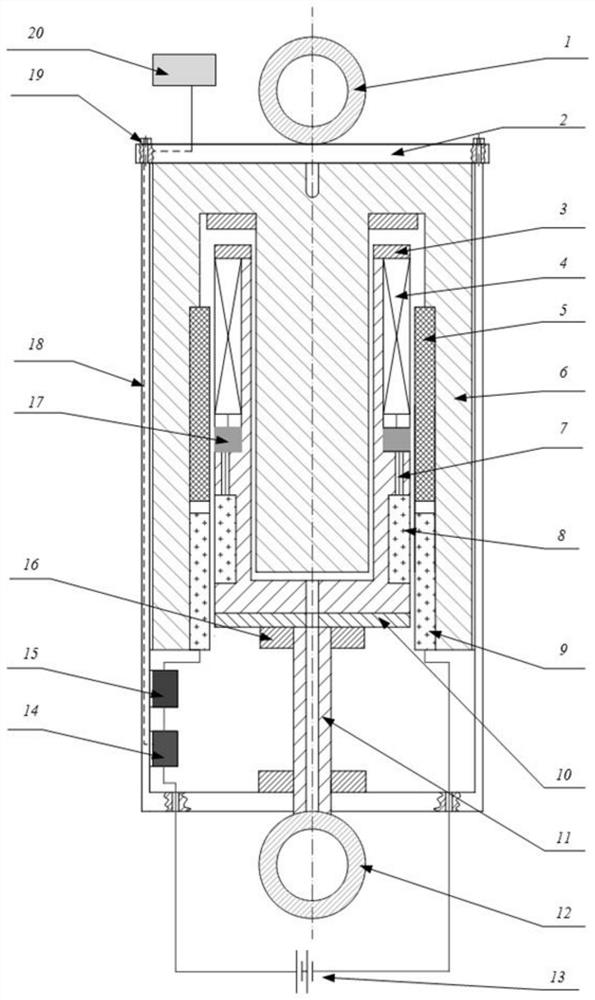

Screw driving deformation shock-absorption walking part and firefighting movable platform with same

ActiveCN106184438AHeight adjustableWith shock absorption functionResilient suspensionsEndless track vehiclesFirefightingAngle modulation

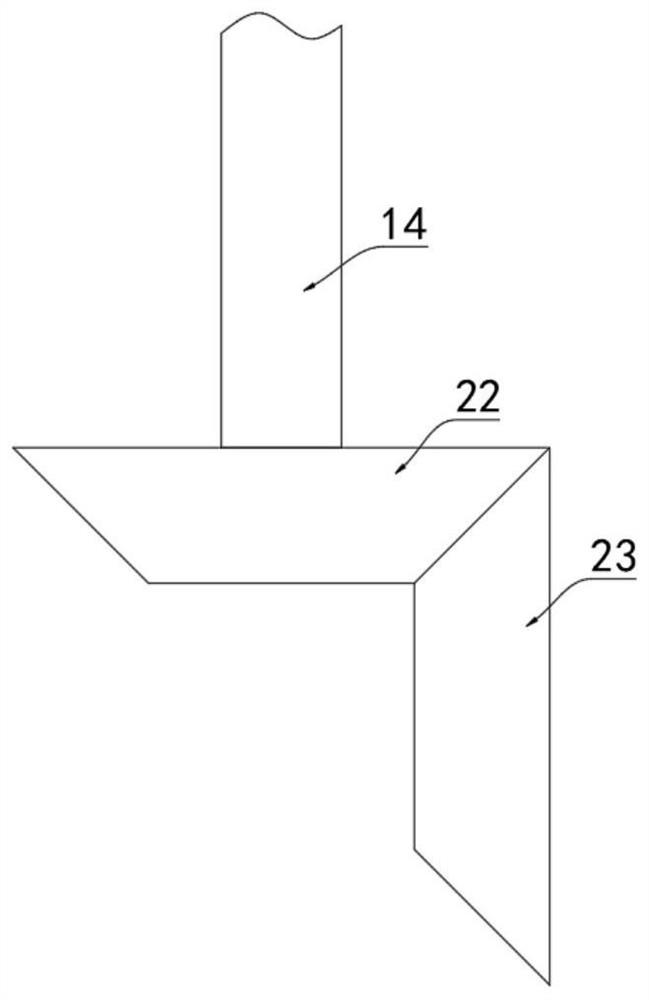

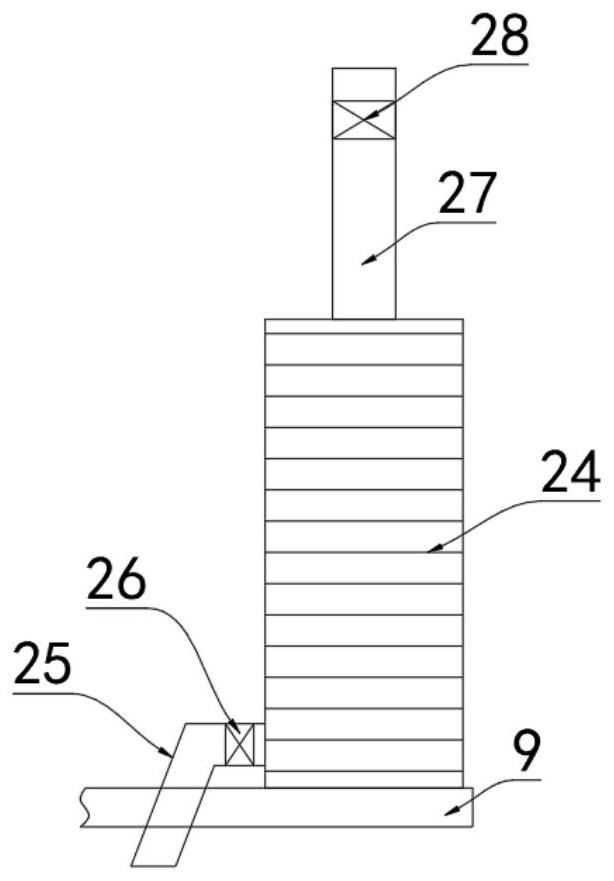

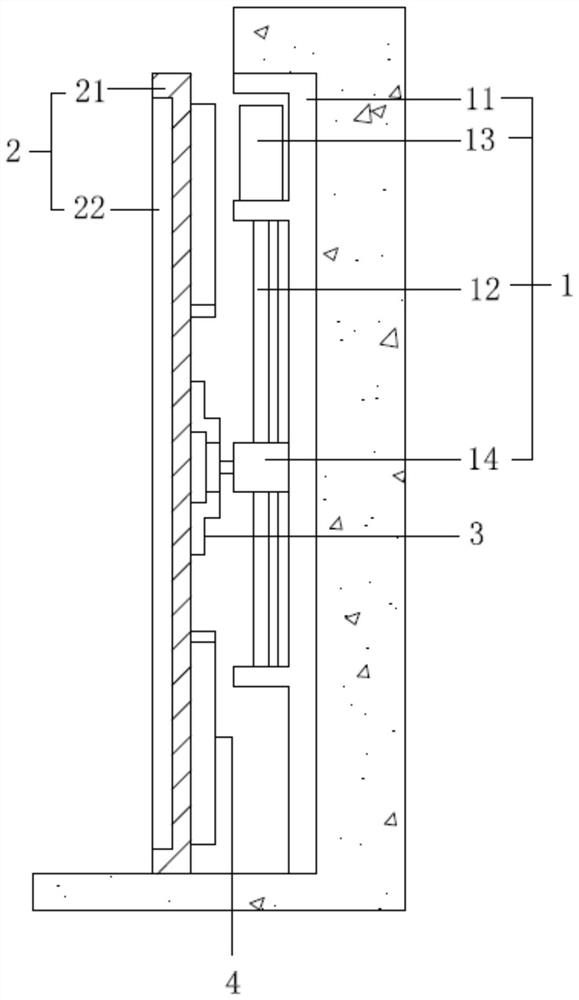

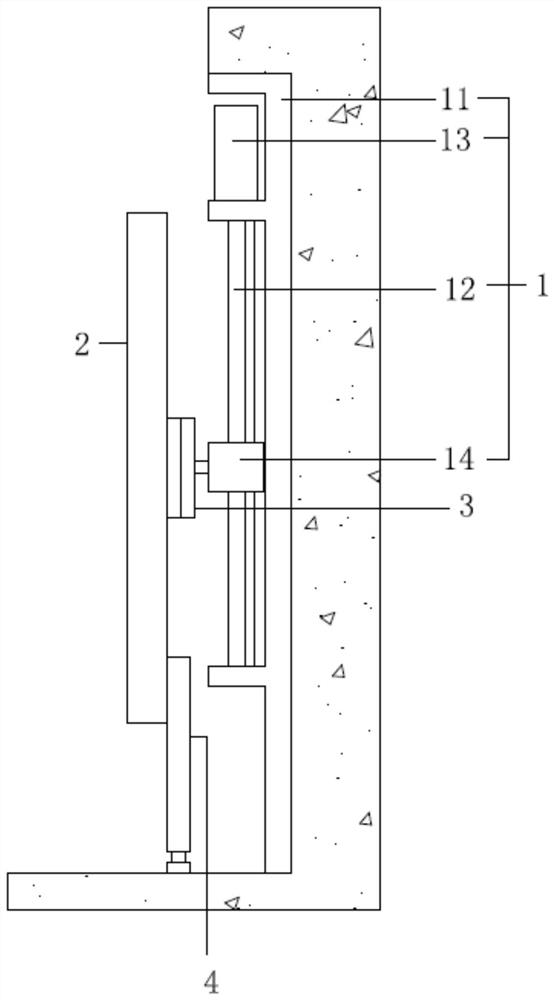

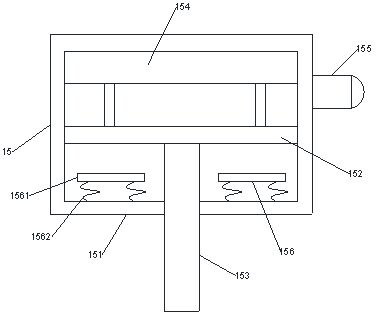

The invention discloses a screw driving deformation shock-absorption walking part. The screw driving deformation shock-absorption walking part comprises a rack, epicyclic gear train assemblies, an angle modulation device and walking assemblies. The two epicyclic gear train assemblies are arranged symmetrically and comprise sun gears, rotary arms, planet gears and shock-absorption elements. The shock-absorption elements are connected with the rack and the rotary arms correspondingly. A nut block of the angle modulation device is connected with one sun gear. A shaft seat block is connected with the other sun gear, the distance between the nut block and the shaft seat block can be changed under the action of a screw, the two sun gears, the planet gears meshing with the sun gears and the walking assemblies connected with the planet gears are driven to rotate reversely, and thus deformation of the walking part is achieved. When the two walking assemblies are subjected to outer impact, due to existing of the shock-absorption elements, the rotary arms can swing elastically within a certain range, and thus the walking part has shock-absorption performance. In addition, the invention further provides a firefighting movable platform which comprises the screw driving deformation shock-absorption walking part and can be used for design of a firefighting robot.

Owner:CHINA UNIV OF MINING & TECH

Communication equipment bracket

InactiveCN108040158AEasy to adjust the angleWide applicabilityVehicle componentsTelephone set constructionsMotherboardArchitectural engineering

The invention discloses a communication equipment bracket which comprises a main board, wherein a placement groove is formed in the main board; a first screw is rotationally connected in the placementgroove; a handle is arranged on one side of the main board; one side of the handle penetrates through the top of the main board and is fixedly connected with the first screw; a threaded block is connected on the first screw in a sliding and sleeving manner; a chute corresponding to the threaded block is formed in the inner bottom of the main board; a linkage plate is fixedly connected to one side, which is far away from the inner bottom of the main board, of the threaded block; a fixing block is fixedly connected onto the linkage plate; a movable rod is arranged on one side of the fixing block; a clamping groove corresponding to the movable rod is formed in the fixing block; the movable rod is rotationally connected with the inner side wall of the clamping groove by virtue of a rotating shaft; the movable rod is rotationally connected with the linkage plate by virtue of a turnbuckle; and a U-shaped bracket is fixedly connected to one end, which is far away from the fixing block, of the movable rod. The communication equipment bracket disclosed by the invention is capable of fixing communication equipment of different sizes and performing angle and height adjustment, and is wide inapplicability.

Owner:南京云清普为通信科技有限公司

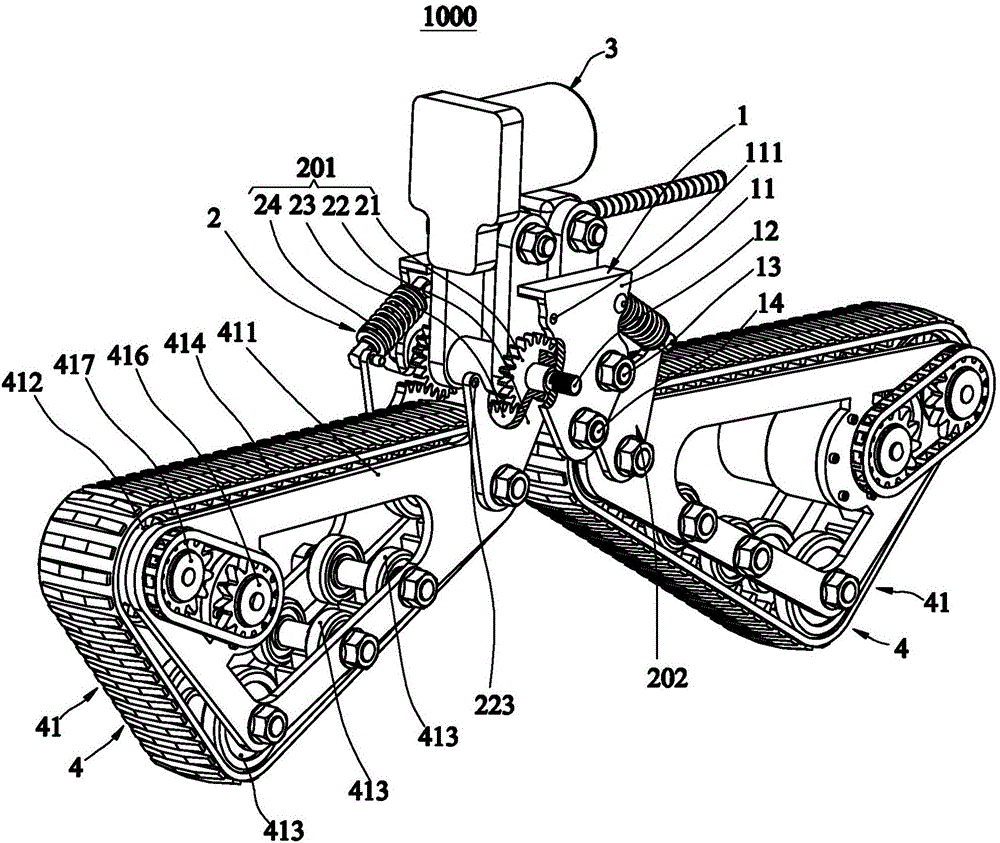

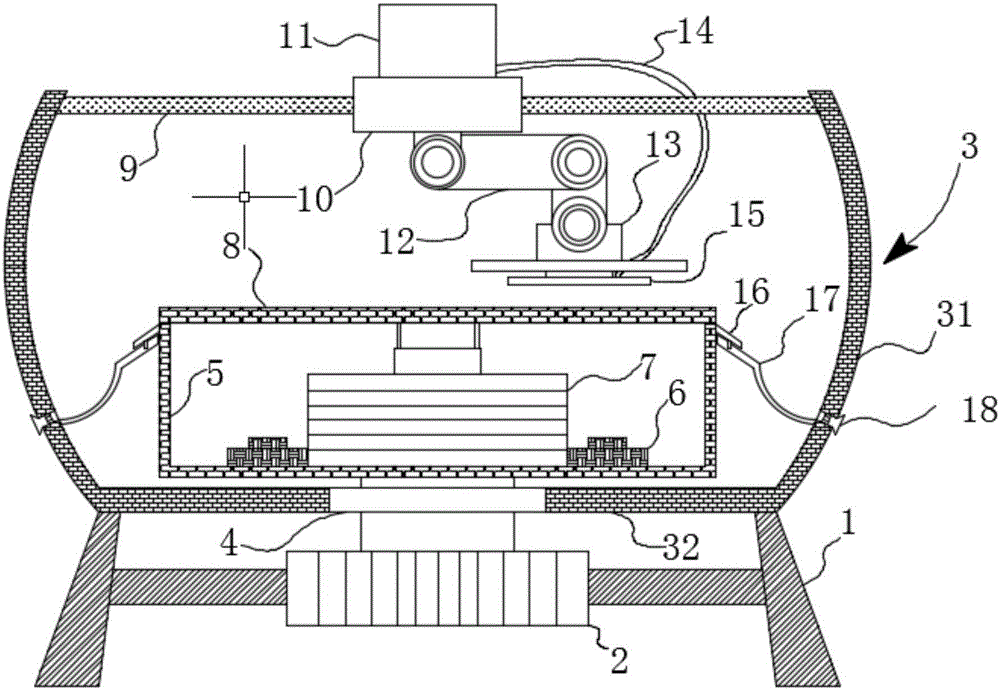

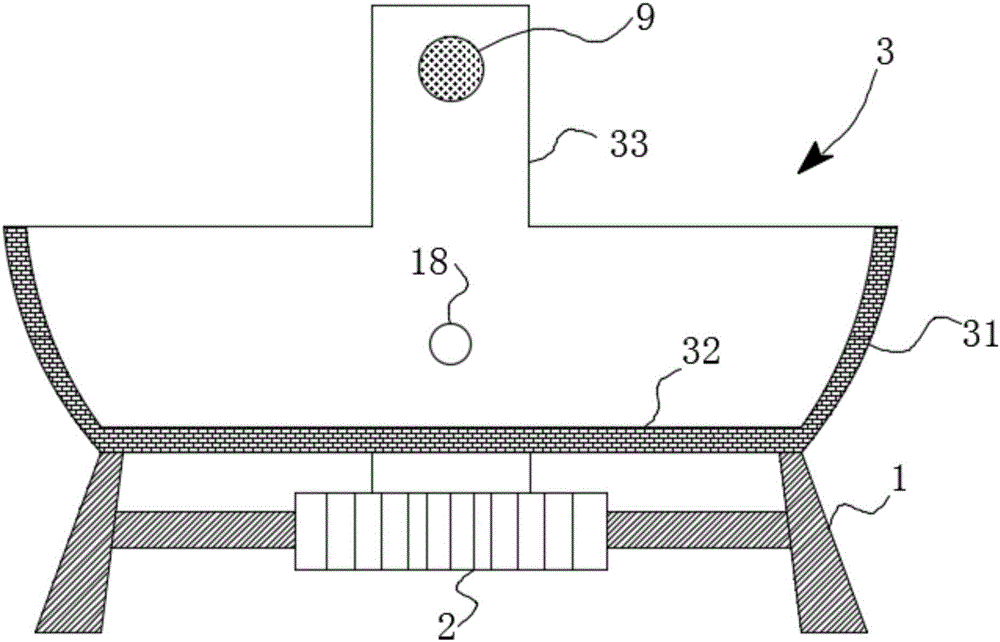

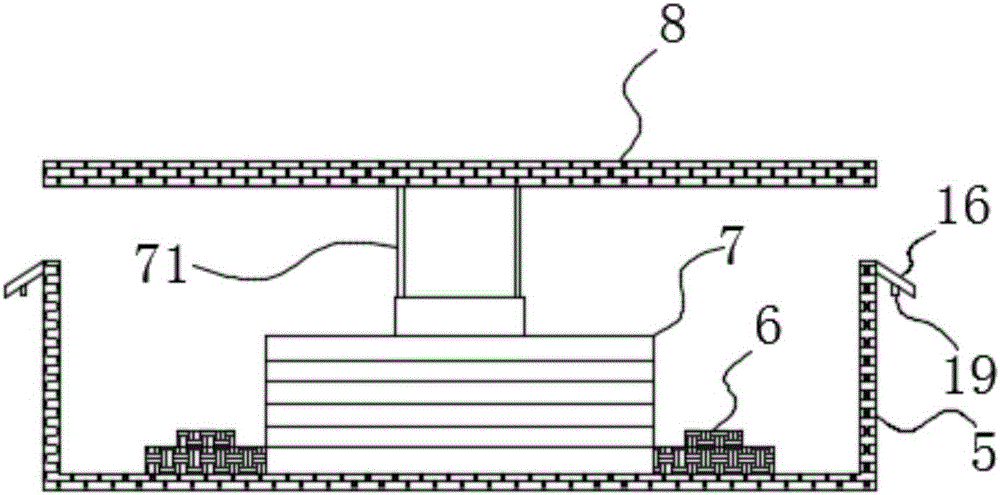

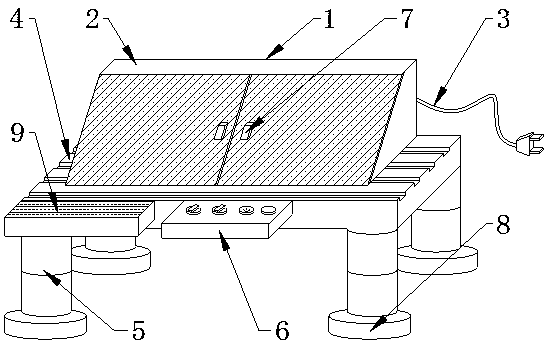

Stone machining platform with all-dimensional grinding function

InactiveCN106141910AAchieve height changeAchieve rotationGrinding carriagesGrinding drivesEngineeringSewage

The invention discloses a stone machining platform with an all-dimensional grinding function. The stone machining platform comprises a polishing platform support frame and a controller arranged on the side edge of the polishing platform support frame. According to the structure of the stone machining platform, a driving device and an extensible part mounting cavity are fixedly connected, and meanwhile a hydraulic lifting cylinder is fixedly mounted in the extensible part mounting cavity so that the height of a polishing platform can be changed through lifting adjustment of the hydraulic lifting cylinder. Meanwhile, the driving device and the hydraulic lifting cylinder are designed together, rotation and height change of the polishing platform can be realized, and thus stone on the polishing platform can be matched with the position of a polisher to be adjusted conveniently. Moreover, by the adoption of a mechanical arm and a sliding mechanism, the position of the polisher can be better adjusted, and hence the entire device can well meet the polishing requirement for different directions in the polishing process of the stone. Due to the arrangement of a water guide plate and a water collecting plate, water can be better guided away, and the phenomenon of sewage splashing can be avoided.

Owner:罗军

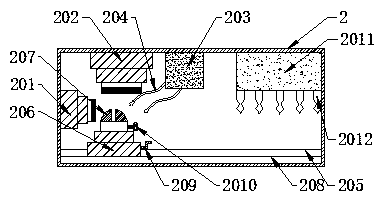

Electromechanical product rust removing device

InactiveCN109176273AEmbody inventivenessGood rust removal effectGrinding carriagesGrinding drivesEngineeringRust

The invention discloses an electromechanical product rust removing device which comprises a rust removing device body, a dust removing bin and a bearing plate, wherein the dust removing bin is fixedlyconnected with the top of the dust removing device body; the bearing plate is fixedly connected with the bottom of the dust removing device body; a first grinding knife is fixedly connected with themiddle part of one side of the interior of the dust removing bin; a second grinding knife is fixedly connected with the top of one side of the interior of the dust removing bin; spray heads are fixedly connected with the interior of the dust removing bin; and a clamping device is movably connected with the bottom of the interior of the dust removing bin. The grinding knives can be driven by the clamping device to clean up rust on the surface of a product more rapidly, so that the high efficiency of the rust removing device body can be reflected; through the strong control capability of an NS16032 control chip, the convenience and the rapidness of the dust removing device body can be reflected; through a plating liquid, the product of which the rust is removed can have the anti-rust function after being treated, and then the multifunctionality of the dust removing device body can be reflected; and the electromechanical product rust removing device is convenient to use, is high in safety, is applicable to the technical field of dust removing devices, and has broad development prospects in the future.

Owner:含山县人和铸造有限公司

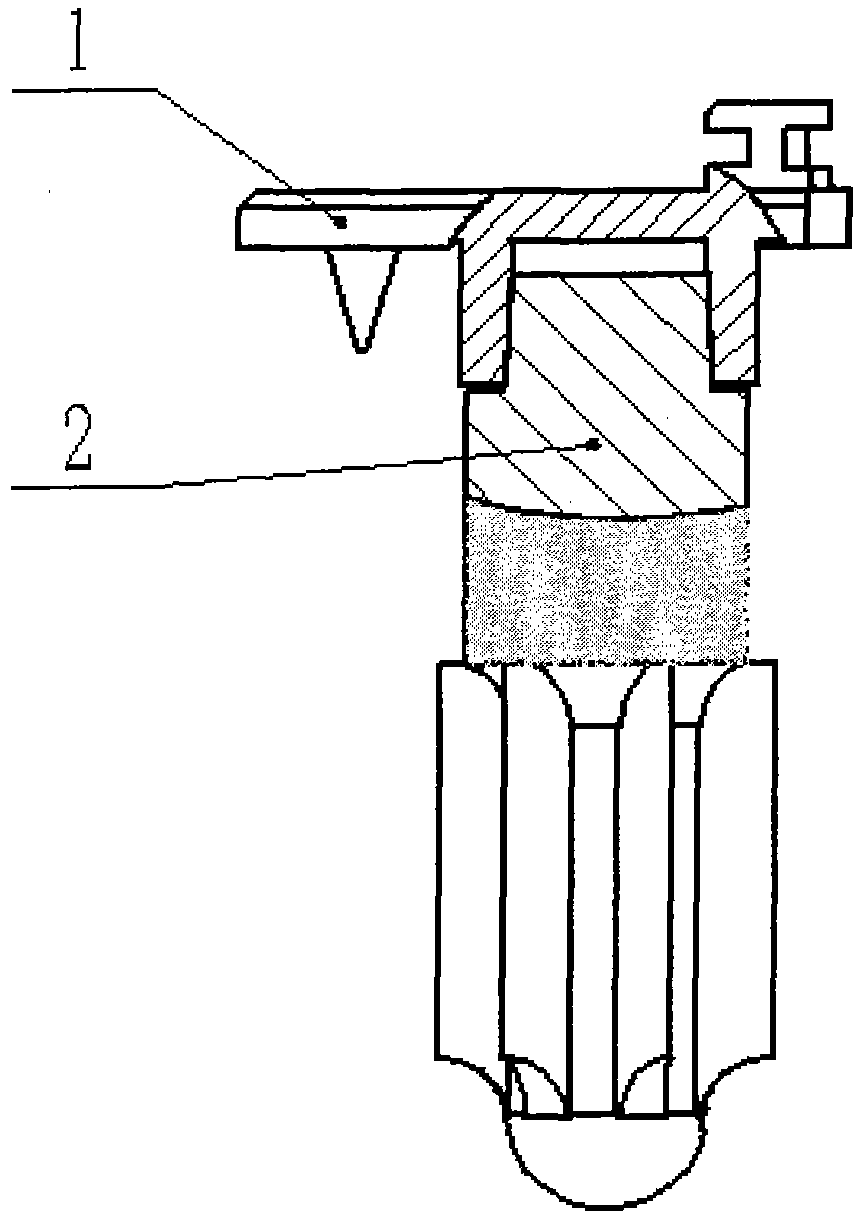

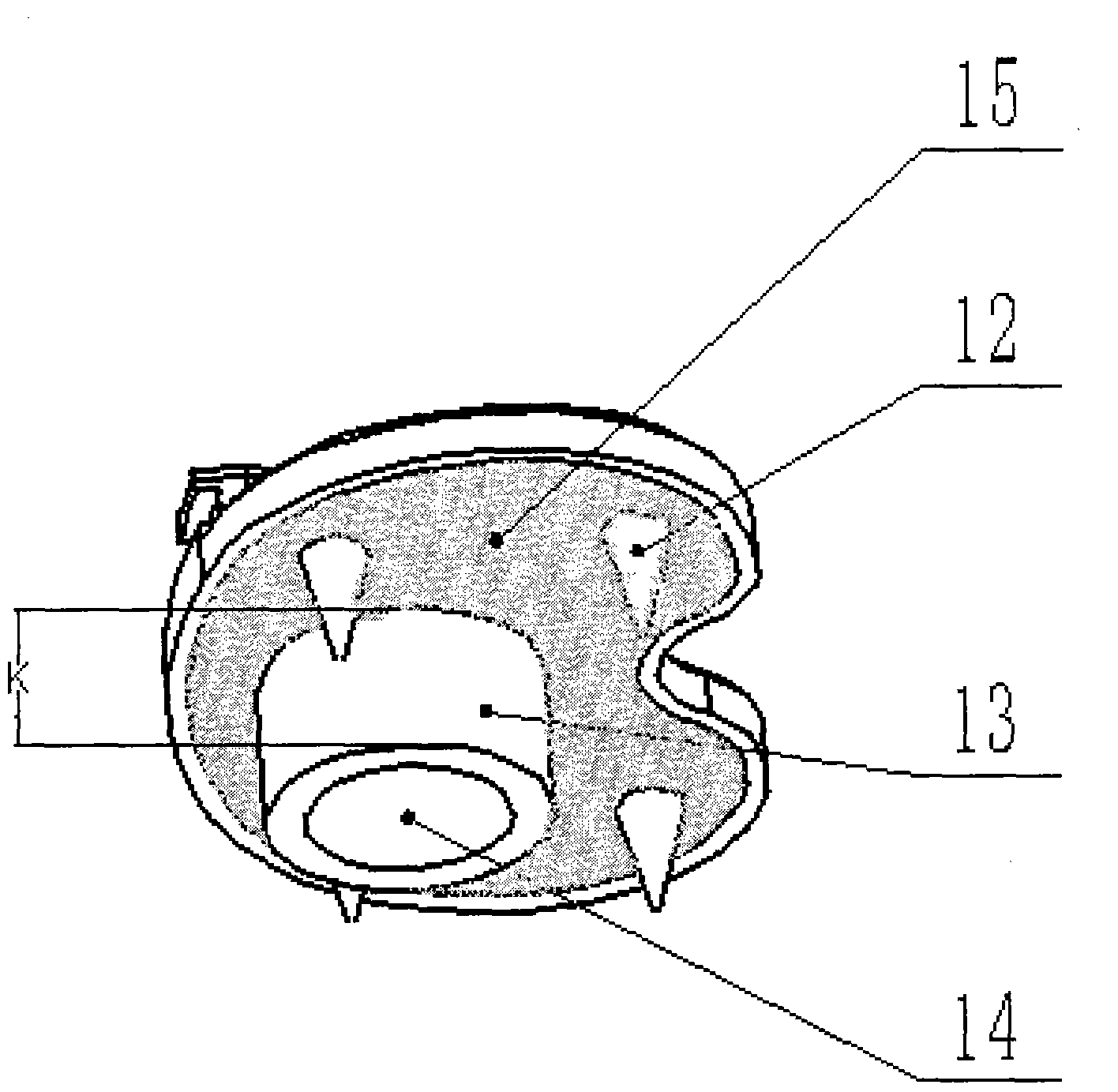

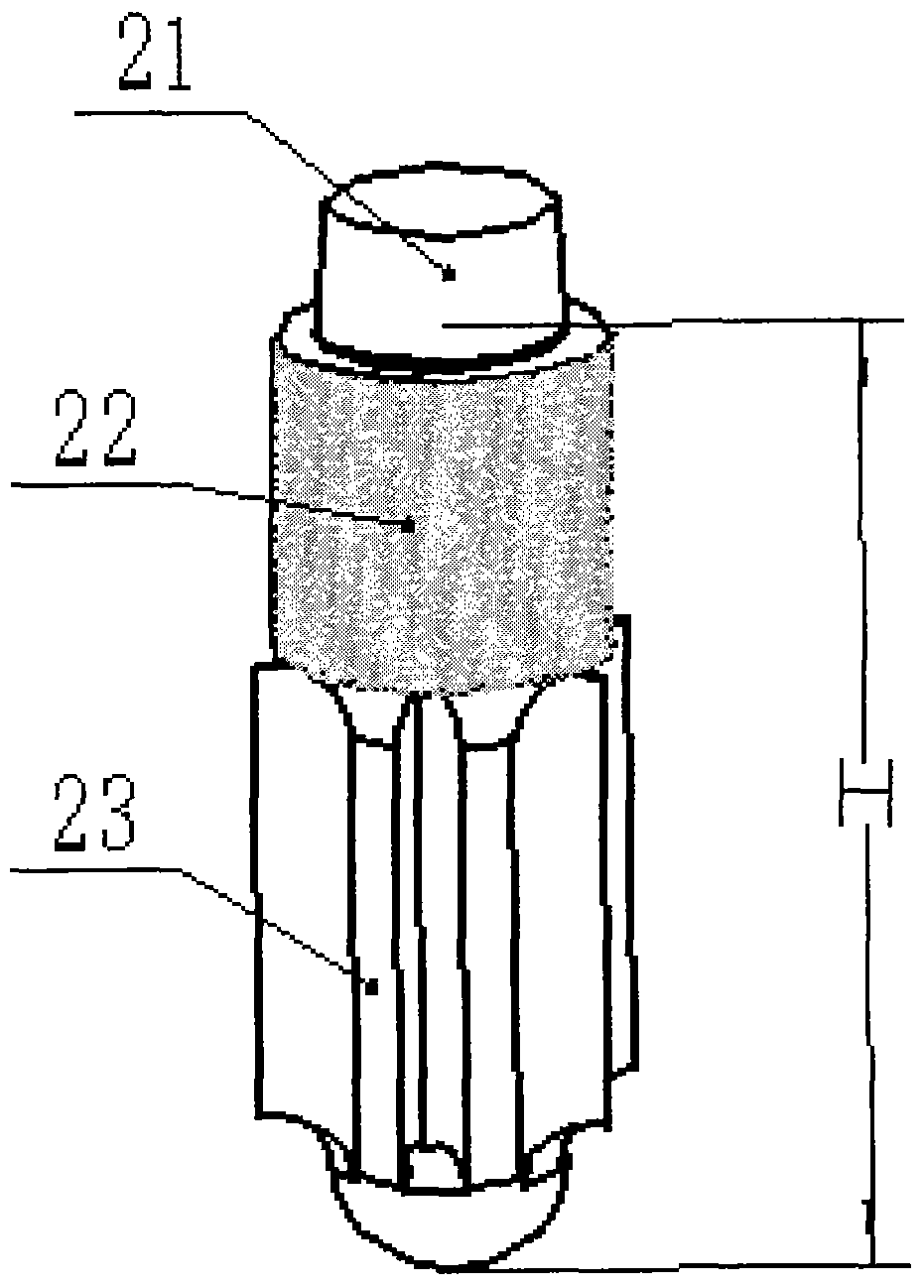

Biological fixation type tibia platform

InactiveCN103705319AGood for initial fixationStable anti-rotation abilityJoint implantsCoatingsTibiaIntramedullary rod

The invention discloses a biological fixation type tibia platform for surgery implants. The biological fixation type tibia platform is composed of a platform body and an intramedullary rod. A biological coating adheres to the lower surface of the platform body, and thorn-shaped protrusions are arranged on the platform body which facilitates initial fixation of the platform. The intramedullary rod is connected with the platform through a conical structure, the biological coating adheres to the upper portion of the intramedullary rod, and spine-shaped structures which are evenly distributed are arranged on the columnar face of the lower portion of the intramedullary rod. A prosthesis can be conveniently inserted into the bone, meanwhile, the anti-rotation function is provided, and the biological fixation type tibia platform can still be firmly fixed under the action of rotation force. The biological fixation type tibia platform can provide immediate fixation after an operation, the good anti-rotation function is achieved, and due to different combination modes, the biological fixation type tibia platform meets the requirements of different patients.

Owner:BEIJING AKEC MEDICAL

Household cleaning and carrying robot

PendingCN110013196AAchieve height changeExpand the scope of workCarpet cleanersFloor cleanersHome robotEngineering

The invention relates to a household cleaning and conveying robot, and belongs to the field of robots. The household cleaning and conveying robot comprises parts such as a motor, a steering gear, a belt pulley, a belt and a lifting platform. According to the household cleaning and conveying robot, navigate can be carried out through a camera mounted on a vehicle body, a control panel determines the orientation of an object according to photos taken by the camera, the object is found, caught and then sent to a designated place to be put down, and then an issued command is identified to continuesearching for other nearest objects or the control panel temporarily does not work. A cleaning device is further specially designed at the tail of a household robot body, and the unique working modeis more efficient than a common cleaning device.

Owner:KUNMING UNIV OF SCI & TECH

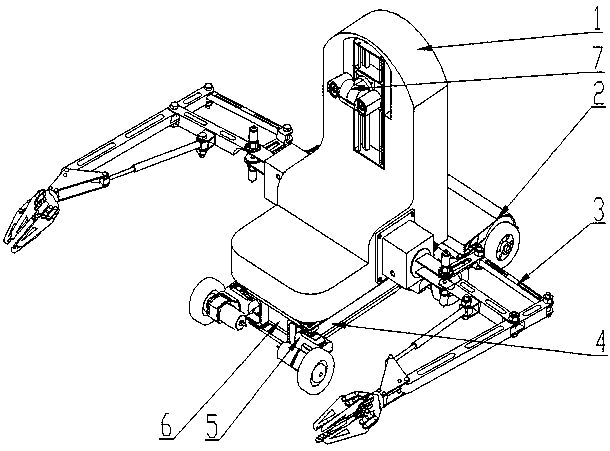

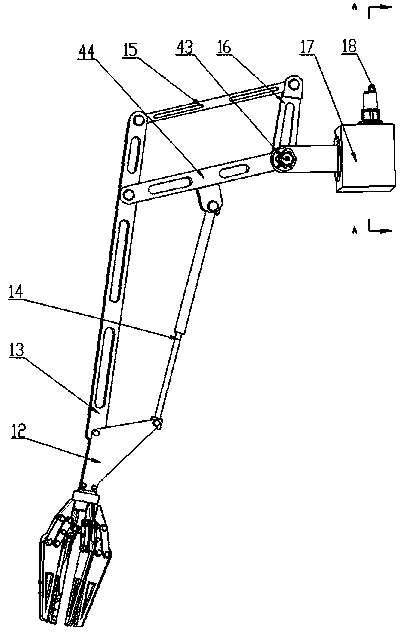

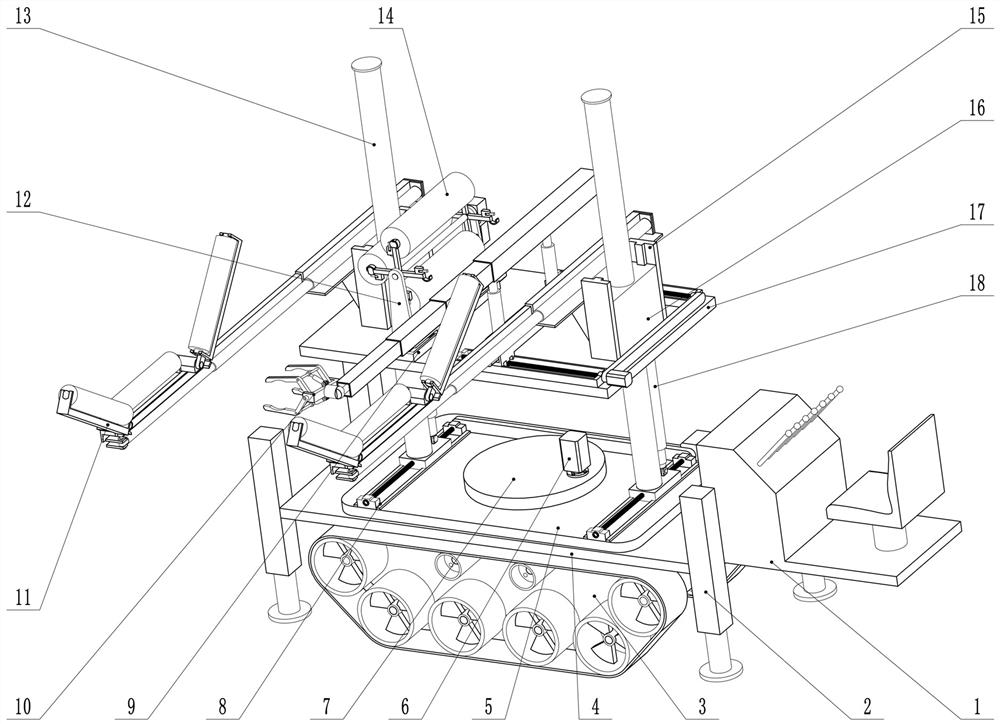

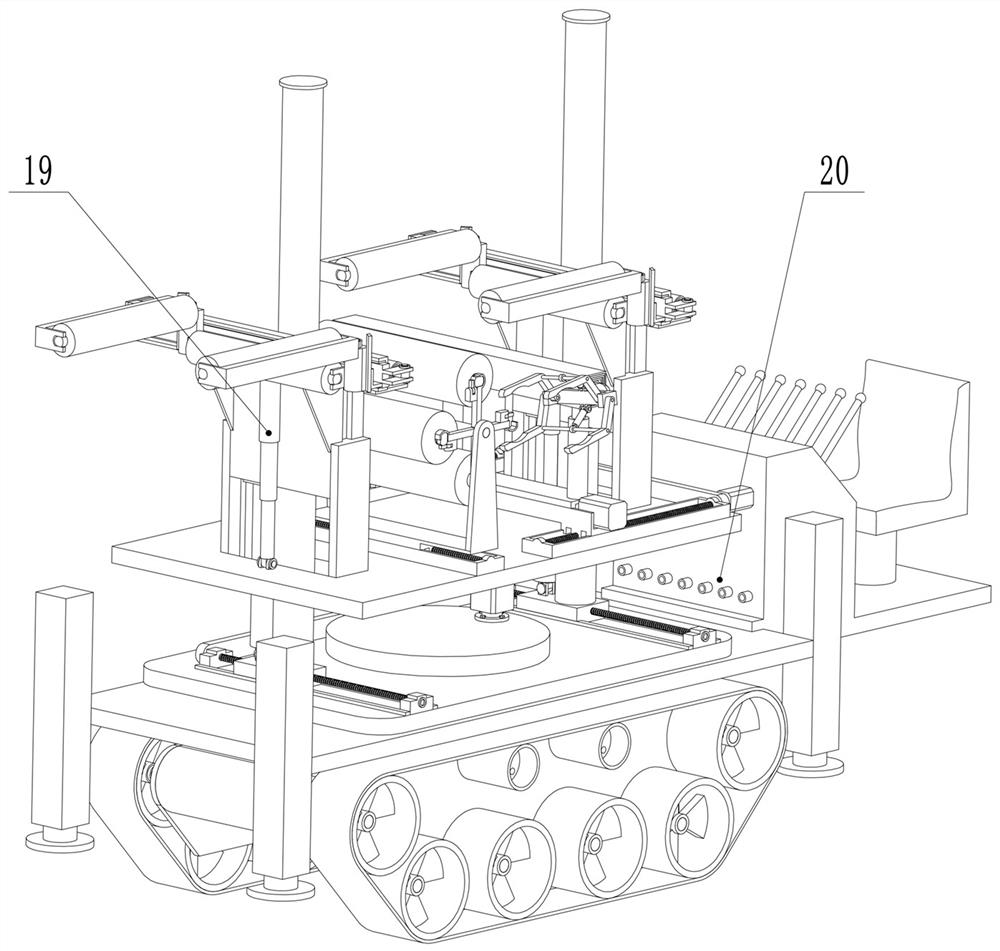

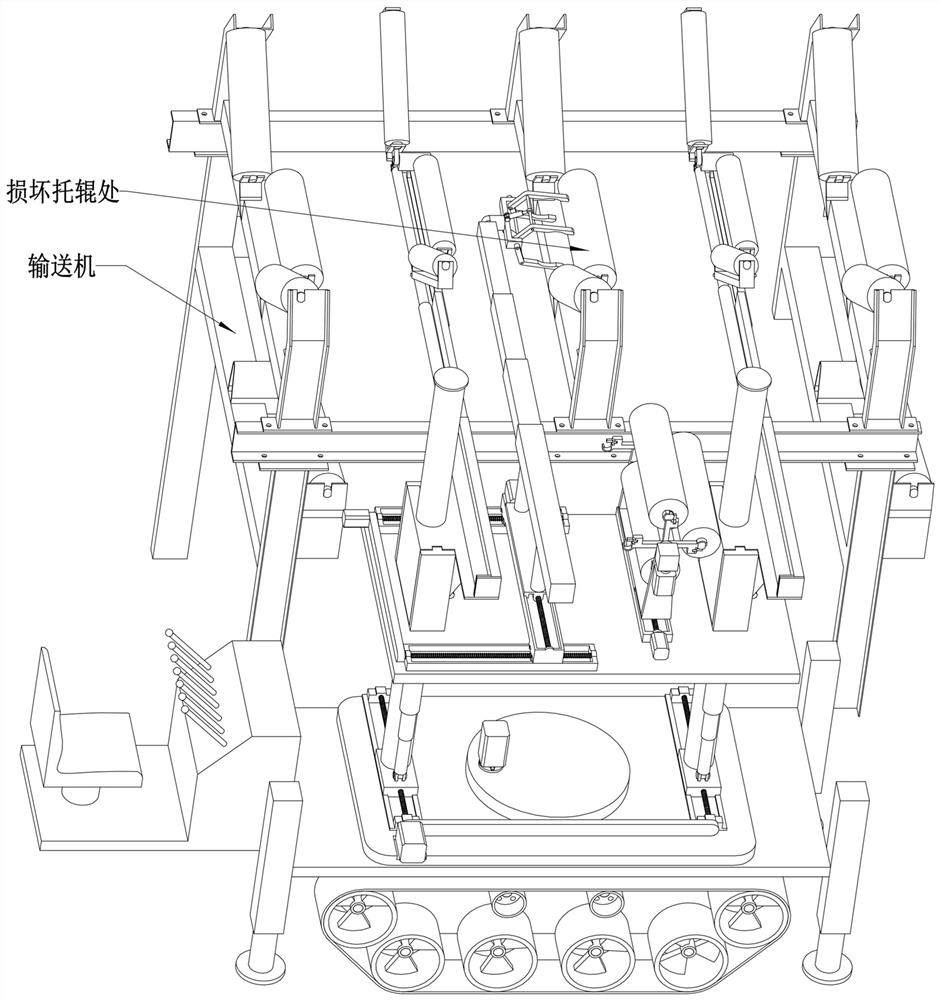

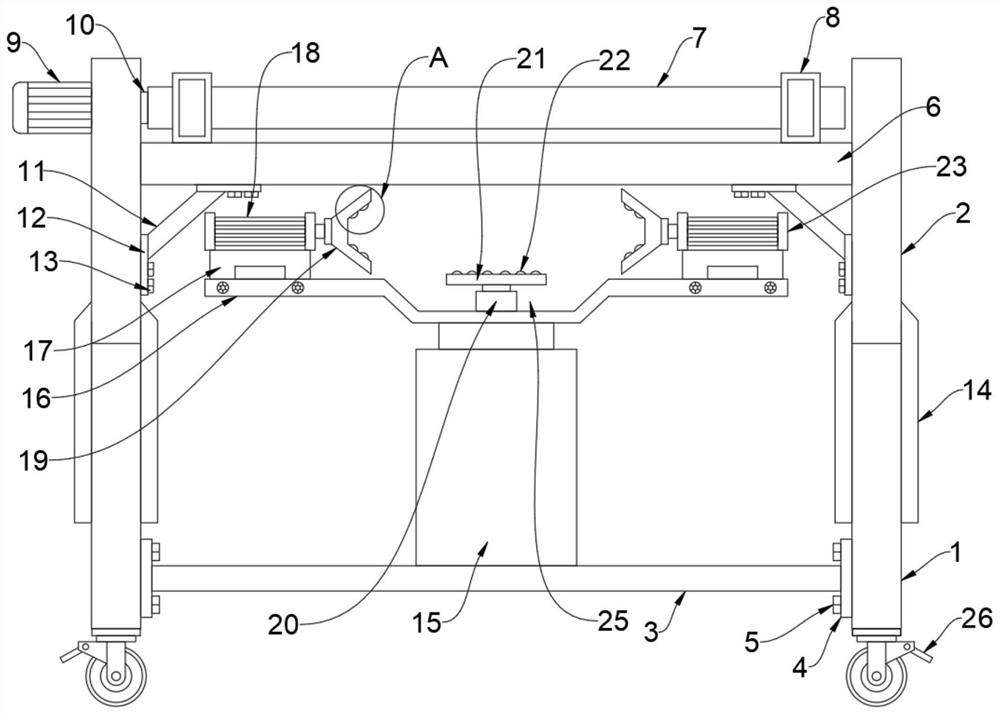

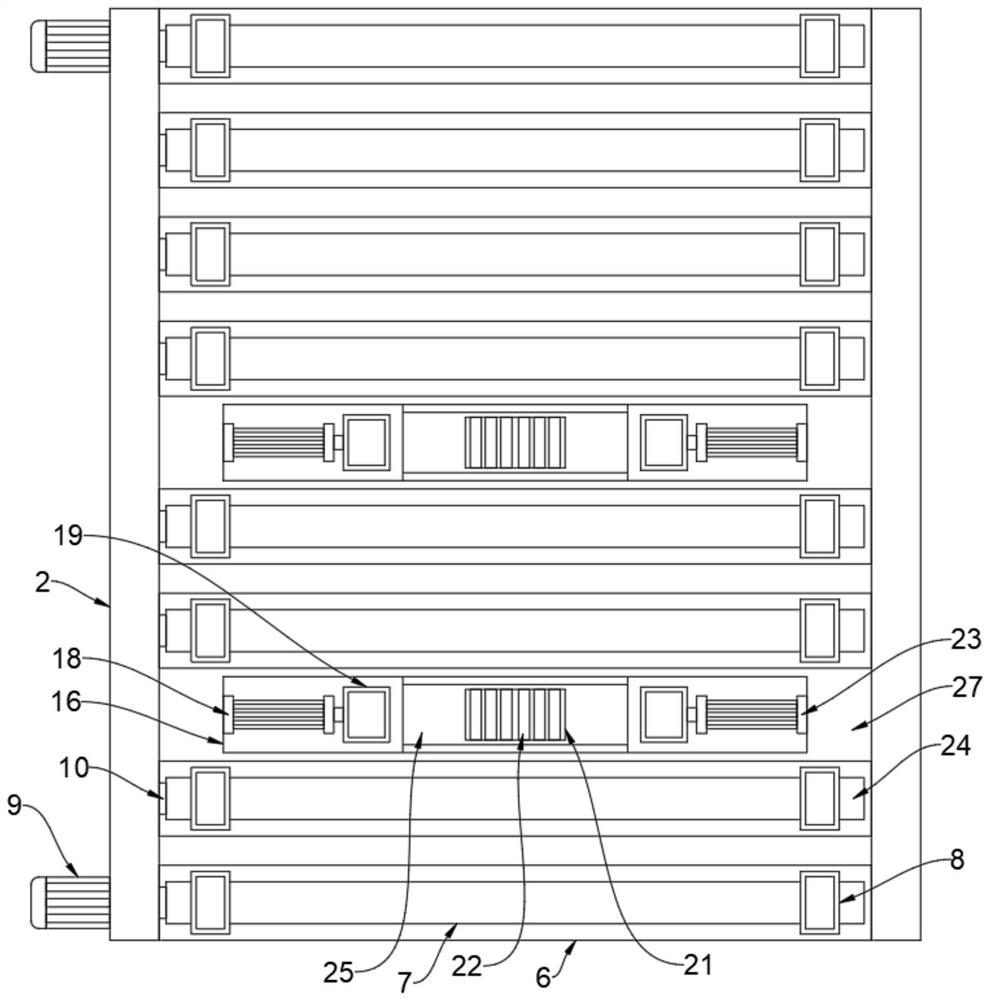

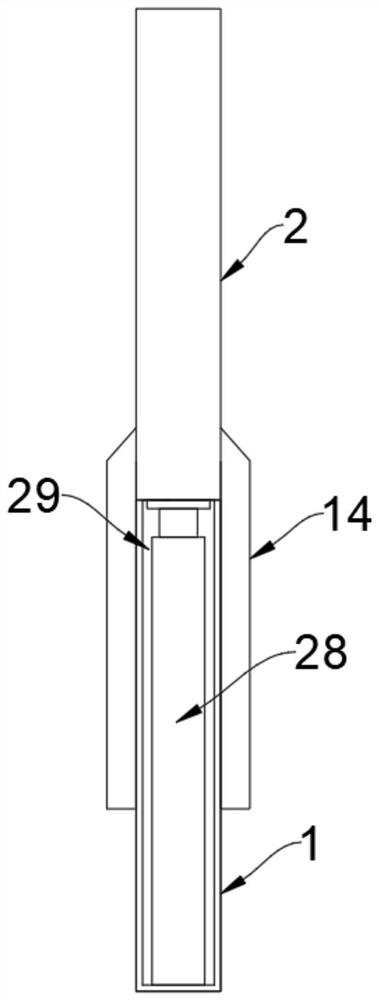

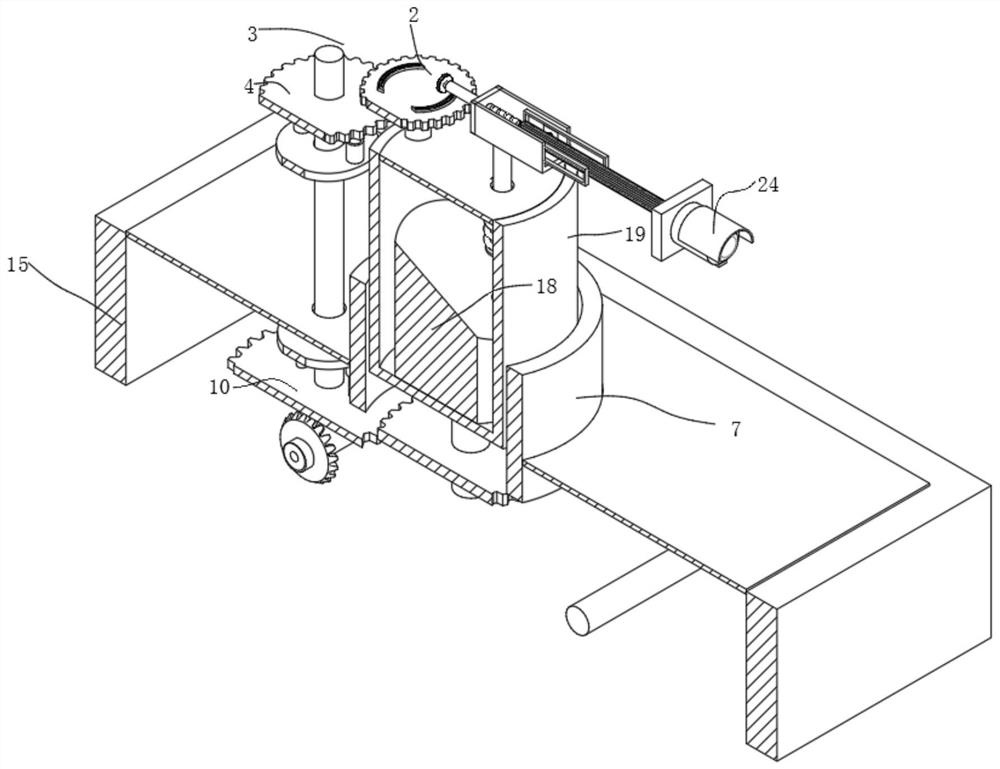

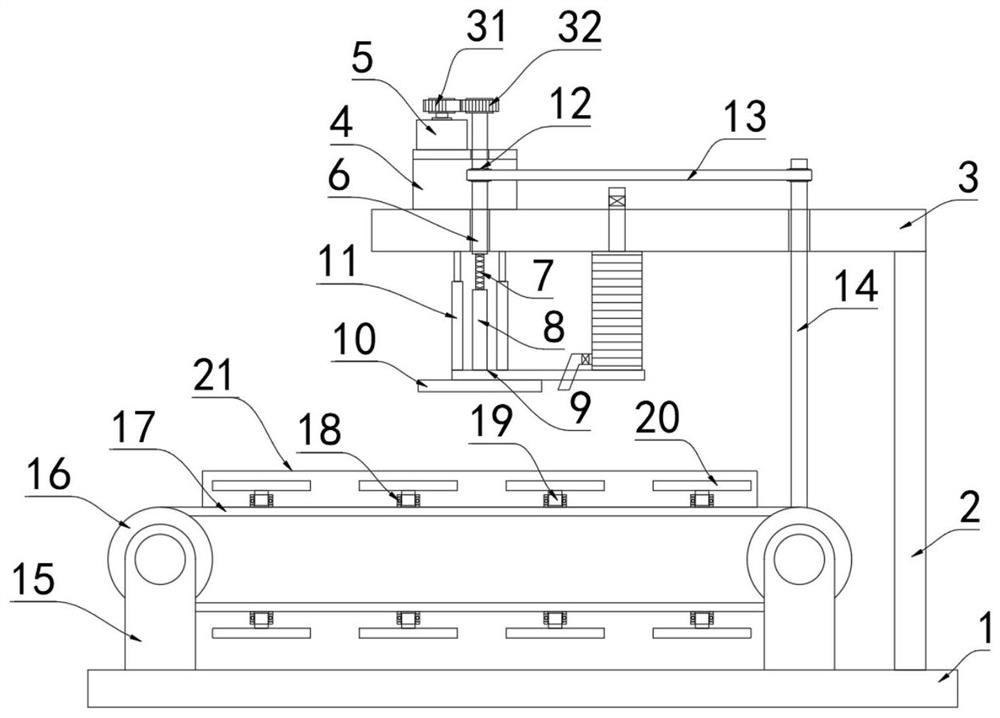

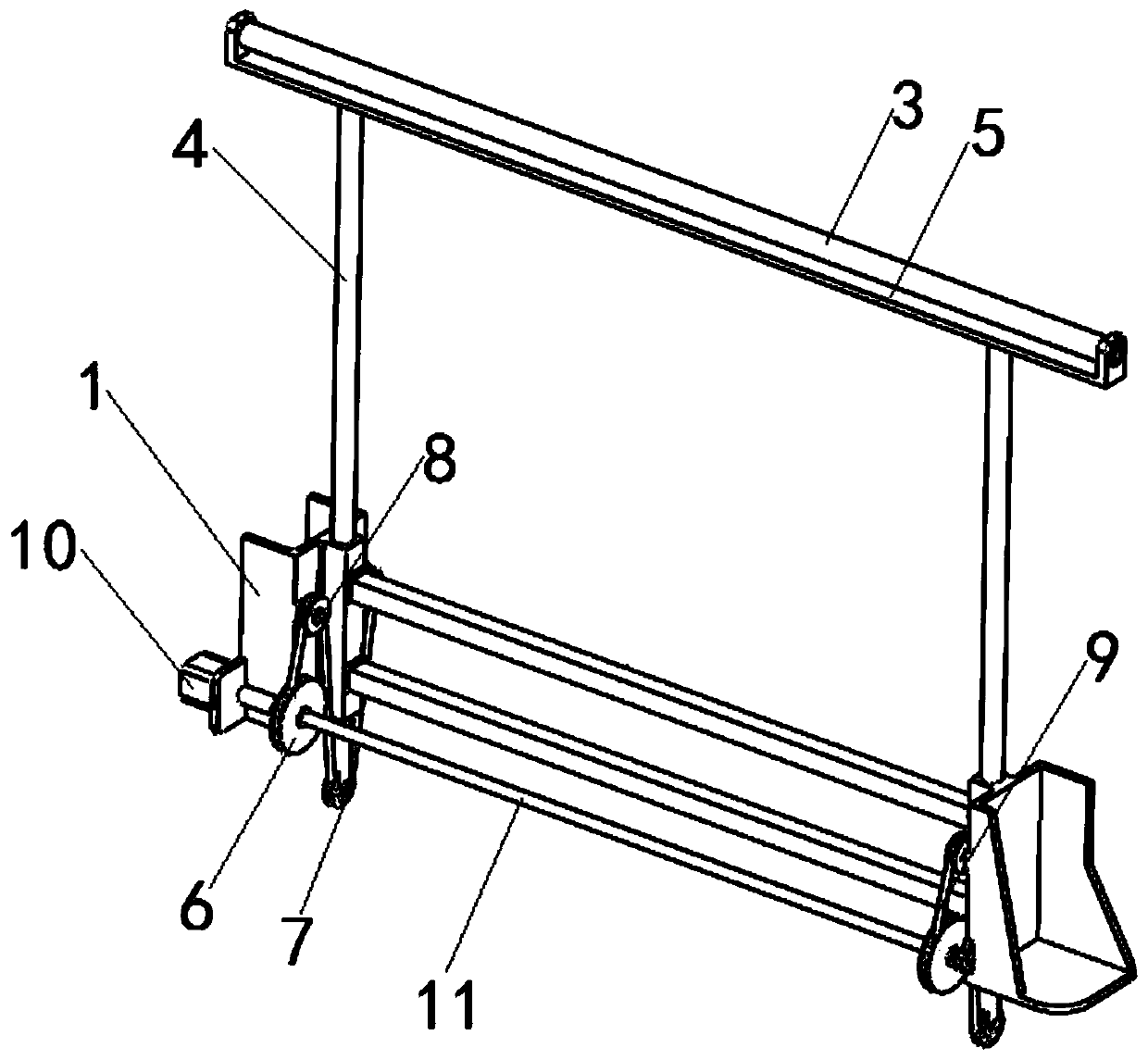

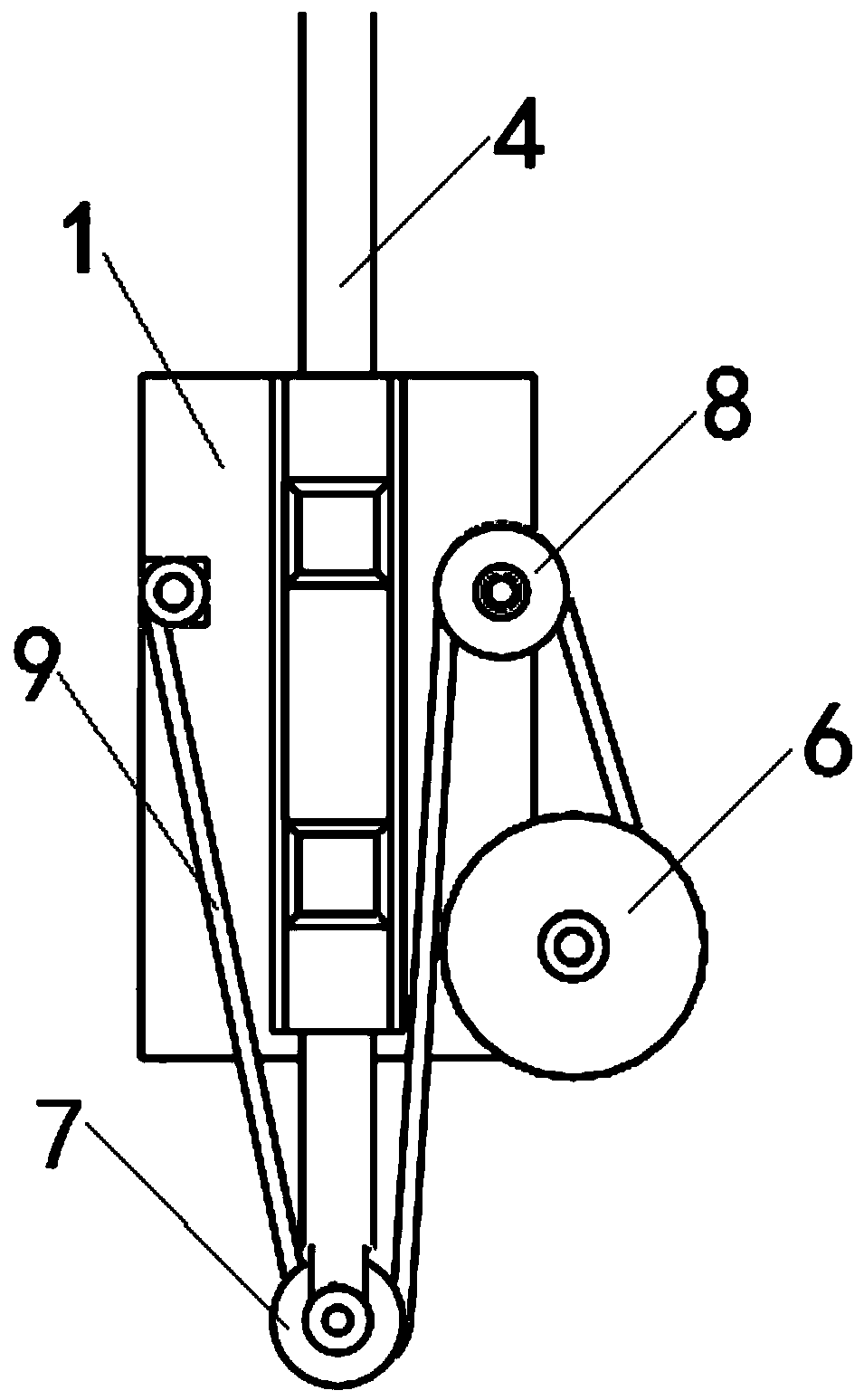

Carrier roller replacing vehicle under working state of belt conveyor

ActiveCN112975830ADoes not affect the normal feeding workImprove maintenance efficiencyMetal-working hand toolsEngineeringRolling chassis

The invention relates to a carrier roller replacing trolley under the working state of a belt conveyor. The carrier roller replacing vehicle comprises a chassis, a turntable, a supporting seat, guide columns, supporting arms, a manipulator, a standby carrier roller rotating disc and a standby carrier roller. The chassis comprises an operation table, a crawler walking device, a hydraulic system and the like. The supporting seat bears all replacement mechanisms. Each supporting arm comprises a carrier roller support, a carrier roller, a supporting sliding rail, a hydraulic motor and the like. The manipulator comprises a hydraulic cylinder, a clamping device, a hydraulic motor and the like. The standby carrier roller rotating disc comprises a rotating disc, a rotating disc support, a servo motor and the like. When the carrier roller replacing vehicle runs to the damaged carrier roller, the supporting arms extend into the two sides of the damaged carrier roller and support a conveying belt after rotating so that the damaged carrier roller can be separated from the conveying belt, and the manipulator extends into the damaged carrier roller to clamp out the damaged carrier roller, convey the damaged carrier roller to the standby carrier roller rotating disc, take down the standby carrier roller and return to the damaged position for replacement. According to the carrier roller replacing vehicle under the working state of the belt conveyor, the damaged carrier roller can be replaced in the working state of the belt conveyor, and energy losses caused by starting and stopping of a large conveyor are greatly reduced.

Owner:LIAONING TECHNICAL UNIVERSITY

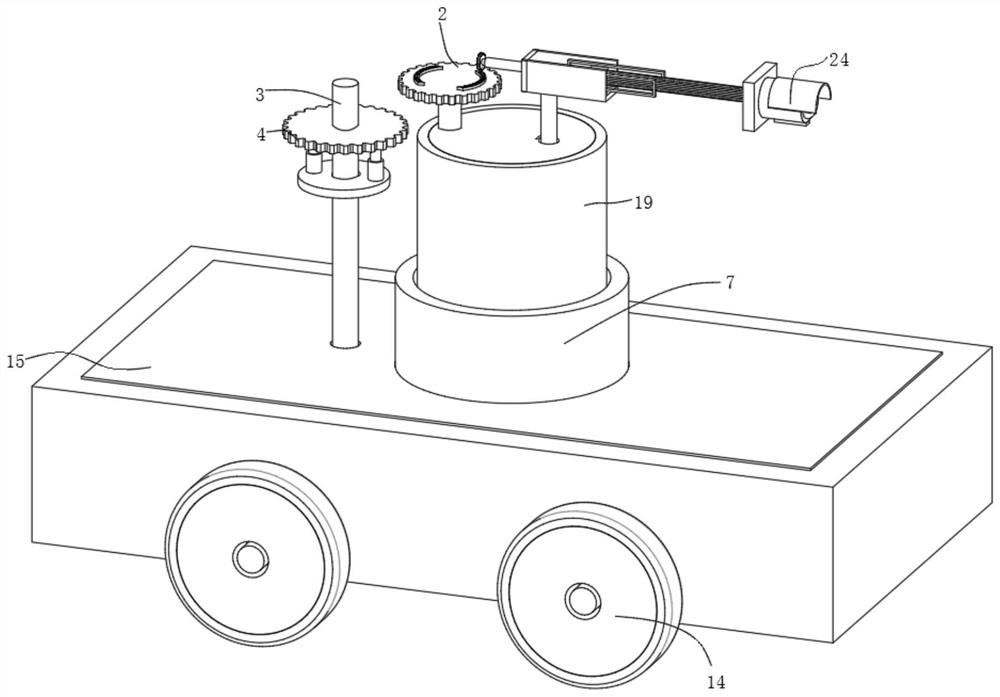

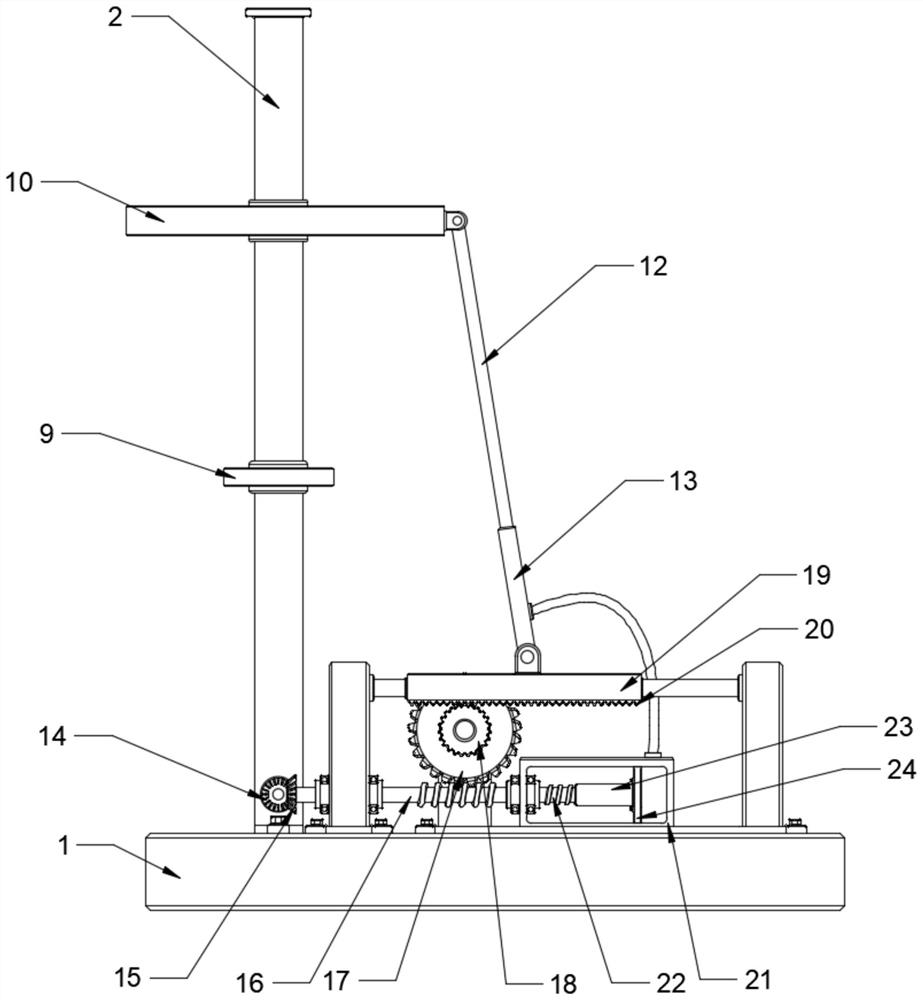

Movable tennis ball serving robot

PendingCN108837470AAchieve height changeImproved longitudinal crash performanceSport apparatusPistonEngineering

The invention relates to a movable tennis ball serving robot. Wheel motors are fixed at the four corners of a vehicle main body, and wheels are installed on the wheel motors; a lower supporting plateis fixedly arranged on the vehicle main body, a left-right moving motor is arranged on the vehicle main body, and an upper supporting plate is arranged on the lower supporting plate; a rotary slidingplate support is arranged between the lower supporting plate and the upper supporting plate, and a bullet bin support is fixedly arranged on the upper supporting plate; an up-down moving stepping motor is arranged on one side of the bullet bin support, and a shaft at one end of a launching tube support is connected with a rotating shaft of the up-down moving stepping motor; a shaft of the other end of the launching tube support penetrates through a shell of the corresponding bullet bin support, and a launching tube is arranged at the bottom of the launching tube support; a ball bin is arrangedon the launching tube support, and a piston is arranged in the rear end of the launching tube; the piston is connected with a four-bar mechanism motor through a piston moving rod, the two sides of the launching tube are each provided with a friction wheel, and the friction wheels are installed on friction wheel stepping motors. The robot can freely move on a table tennis table, so that the changeproperty and interestingness of ball serving are greatly improved.

Owner:江苏第二师范学院

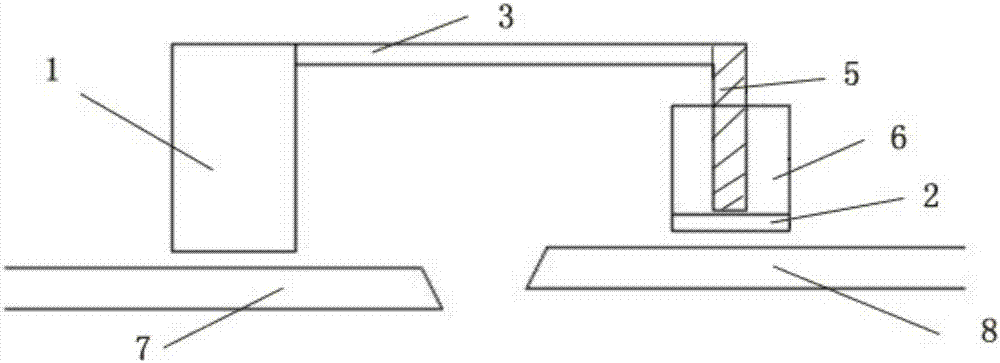

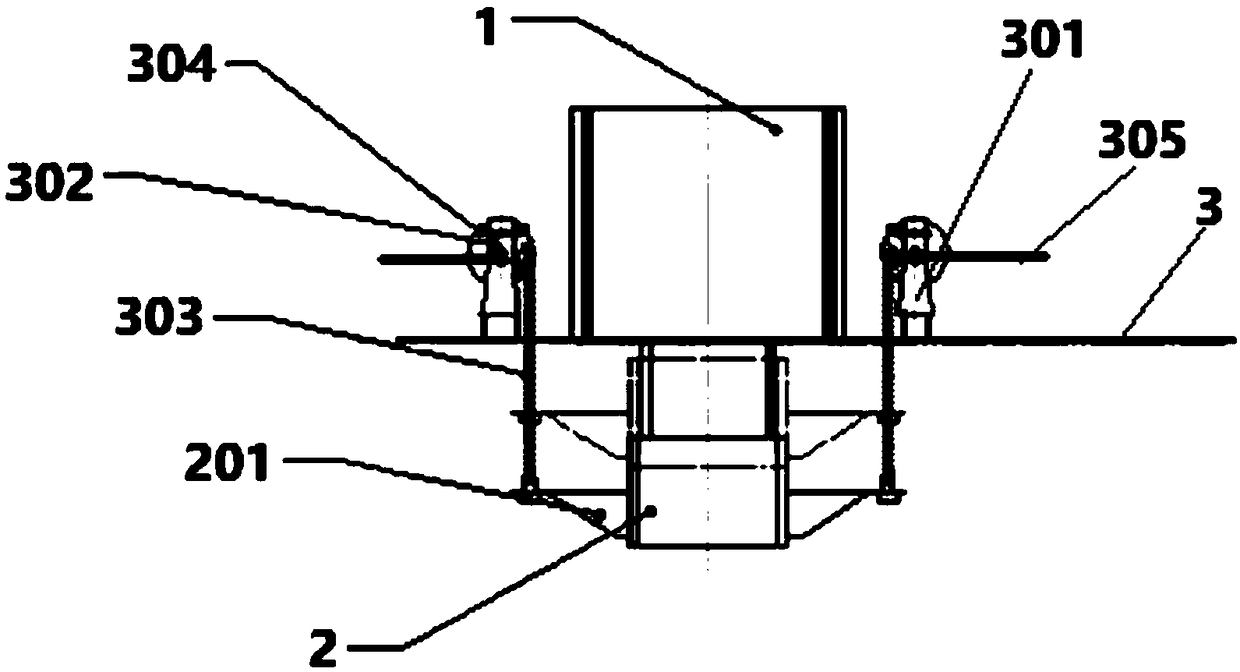

Steel plate position adjustment device using magnetism attraction method, and construction method thereof

PendingCN107570939AImprove weld gradeAchieve height changeWelding/cutting auxillary devicesAuxillary welding devicesHeight differenceMagnet

The invention relates to a steel plate position adjustment device using a magnetism attraction method, and a construction method thereof. The steel plate position adjustment device comprises a first magnet 1, a second magnet 2, a first steel plate 7 and a second steel plate 8, and is characterized by further comprising a movement device. The first steel plate 7 is attracted by the first magnet 1.The second magnet 2 is connected with the movement deice. The second steel plate 8 is attracted by the second magnet 2. The second steel plate 8 attracted by the second magnet 2 is driven by the movement device to move upwards or downwards so that the height difference between the second steel plate 8 and the first steel plate 7 can be adjusted. According to the steel plate position adjustment device using a magnetism attraction method, and the construction method thereof, the movement device can be adjusted to move upwards or downwards to drive the second steel plate to move upwards or downwards, height difference welding of the first steel plate and the second steel plate is realized, welding is finer, and the weld joints of steel plate welding are upgraded.

Owner:JSTI GRP CO LTD +1

Ballast bed precast slab production mold with ultrahigh adjustment support

InactiveCN107813410AMeet production needsReduce typesBallastwayMouldsAgricultural engineeringRail transit

The invention belongs to the field of rail transportation, and in particular relates to a mold for producing a ballast bed prefabricated slab with a super-height adjustment bracket. Including the mold body and the super-height adjustment bracket, the mold body is provided with an inner rail platform relief hole and an outer rail platform relief hole on the mold body corresponding to the position of the ballast prefabricated slab rail platform. There is an inner rail platform forming height adjustment groove in the hole, and an outer rail platform forming height adjustment groove is provided in the outer rail platform relief hole, and the inner rail platform forming height adjustment groove and the outer rail platform forming height adjustment groove are respectively Fixed on the super-height adjustment bracket, there are adjustments between the inner rail platform relief through hole and the inner rail platform forming height adjustment groove, and between the outer rail platform relief through hole and the outer rail platform forming height adjustment groove Clearance, the super-height adjustment bracket is hingedly connected with the mold body on the side corresponding to the forming height-adjusting groove of the inner rail platform, and the super-height adjustment bracket is provided with a height adjustment between the side corresponding to the forming height-adjusting groove of the outer rail platform and the mold body locking device.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH +2

Lifting type roller machine conveying device for automatic pipeline welding

ActiveCN112518084AAchieve height changeEasy to weldWelding accessoriesRoller-waysElectric machineryEngineering

The invention discloses a lifting type roller machine conveying device for automatic pipeline welding. The lifting type roller machine conveying device comprises lower supporting legs, upper supporting legs arranged at the upper ends of the lower supporting legs, a transverse frame which is arranged at one sides of the upper supporting legs and is fixedly connected with the upper supporting legs,a driving wheel which is arranged above the transverse frame, a first hydraulic mechanism which is arranged at one sides of the lower supporting legs, a lifting plate which is arranged at the upper end of the first hydraulic mechanism and is fixedly connected with the first hydraulic mechanism, a first air cylinder mechanism which is arranged above the lifting plate, a second air cylinder mechanism which is arranged at one side of the first air cylinder mechanism, and third hydraulic mechanisms which are arranged in the lower supporting legs, wherein a plurality of driven wheels are arranged at one side of the driving wheel, and a motor mechanism is arranged on one side of the driving wheel. By means of the lifting type roller machine conveying device, the height of a pipeline feeding roller machine can be adjusted, and therefore the problem that welding is inconvenient is effectively avoided.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG +1

Automatic following shot machine for outdoor special effect cinematography

InactiveCN113701021ARealize the dynamic shooting processAchieve circumferential rotationTelevision system detailsGearingControl theoryMechanical engineering

The invention discloses an automatic following shot machine for outdoor special effect cinematography. The automatic following shot machine comprises a vehicle body and a camera, wherein the bottom of the vehicle body is connected with a moving mechanism for moving the device, the middle portion of the vehicle body is provided with an adjusting mechanism for controlling multi-directional following shooting of the camera, and the moving mechanism is connected with a control mechanism for driving the adjusting mechanism to operate; and the adjusting mechanism comprises a fixing seat, the fixing seat is arranged in the middle portion of the vehicle body through a through groove, a mounting sleeve is rotationally arranged on the fixing seat, and a supporting column is slidably arranged on the top of the mounting sleeve. According to the automatic following shot machine for outdoor special effect cinematography, the movement of the camera in different directions is realized by utilizing the movement process of the device, and when the movement speed changes, the movement speed of the camera can be adaptively adjusted, so that the adverse effect caused by the fact that the movement speed of the camera cannot be adjusted in time is effectively avoided.

Owner:孙守祥

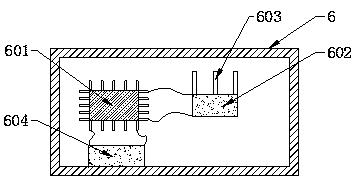

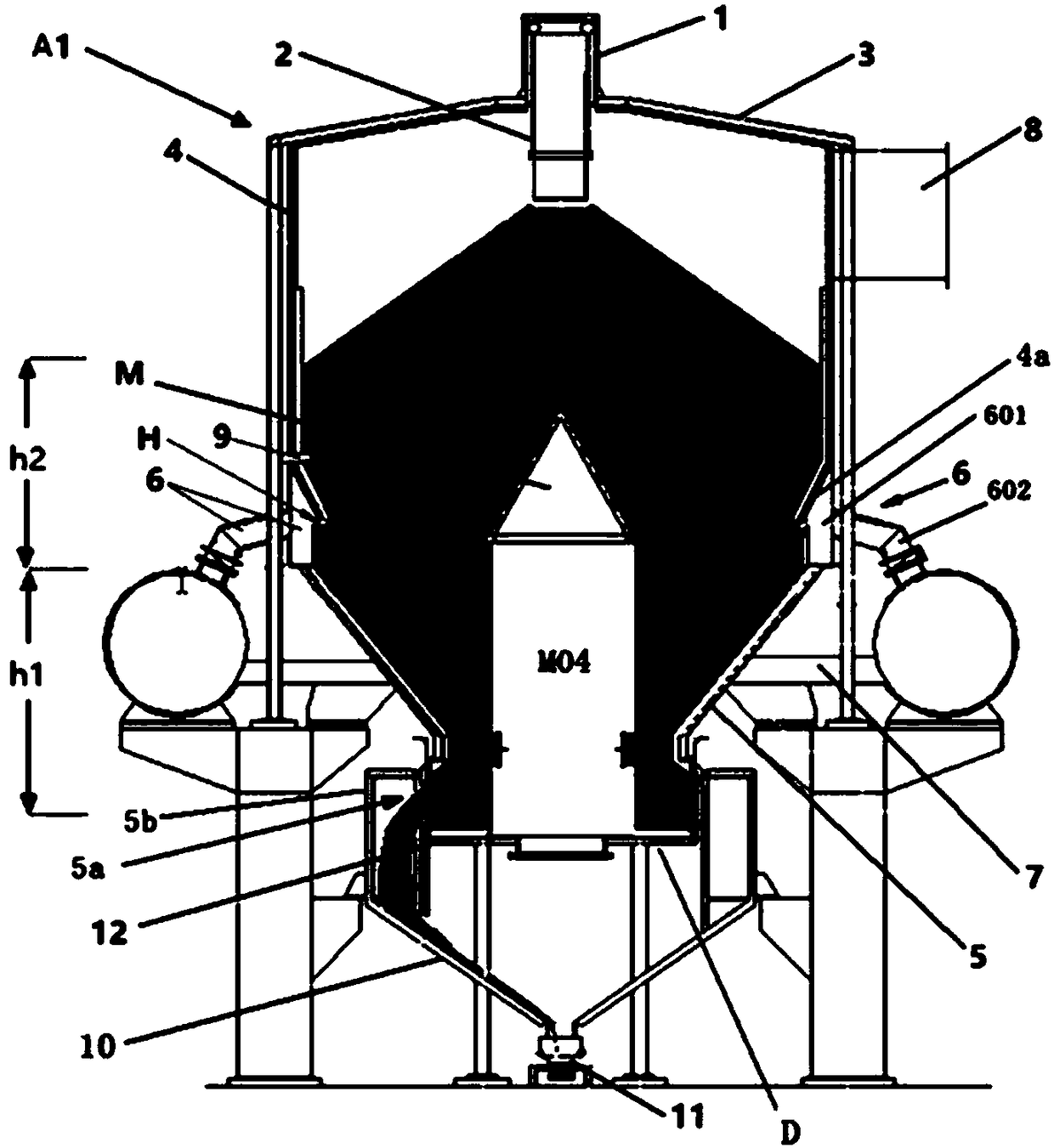

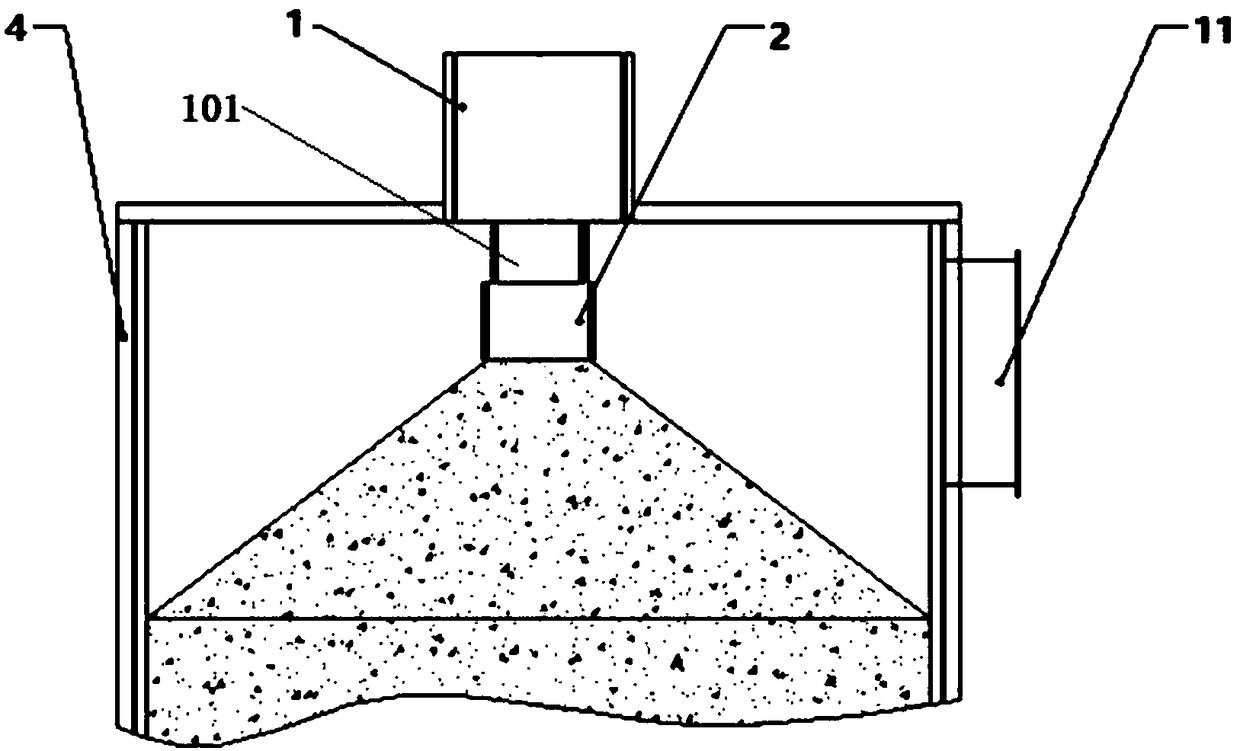

Flashboard unloading-type vertical cooler with material position adjusting device and sintering ore cooling method

PendingCN108692576AAchieve height changeEasy to operateHandling discharged materialTowerWaste management

A flashboard unloading-type vertical cooler comprises a bin (1), a material height adjusting device (2), a tower composed of a tower top cover (3), a tower wall (4), a tower cone barrel (5) and a tower base (D), a wind ring (H), a wind cap (M), a plurality of discharge outlets (5a) formed in the lower portion of the discharge cone bucket (5), and a hot air outlet (8) formed in the upper portion ofthe tower wall (4) or in the tower top cover (3), wherein the tower cone barrel (5) is located on the lower portion of the tower wall (4). A circle of fixed gap is formed between the lower portion ofthe tower wall (4) and the top of the discharge cone bucket (5) to serve as the wind ring (H). The center of the tower base is provided with the wind cap (M) which upwards extends into the inner space of the tower. Discharge gates or discharge flashboards (12) are arranged at the discharge outlets (5a) accordingly, and a discharge channel (10) is formed below the discharge gates (12).

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

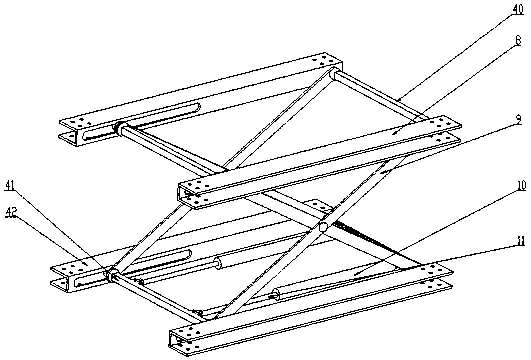

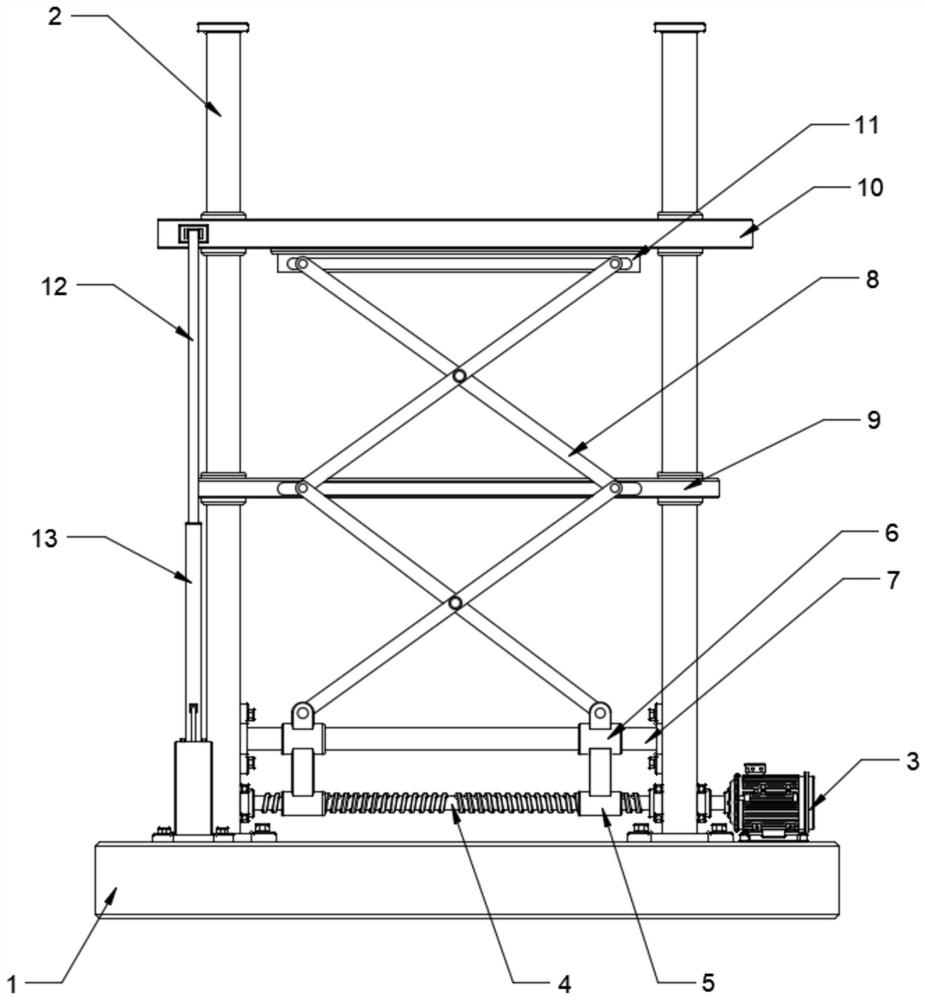

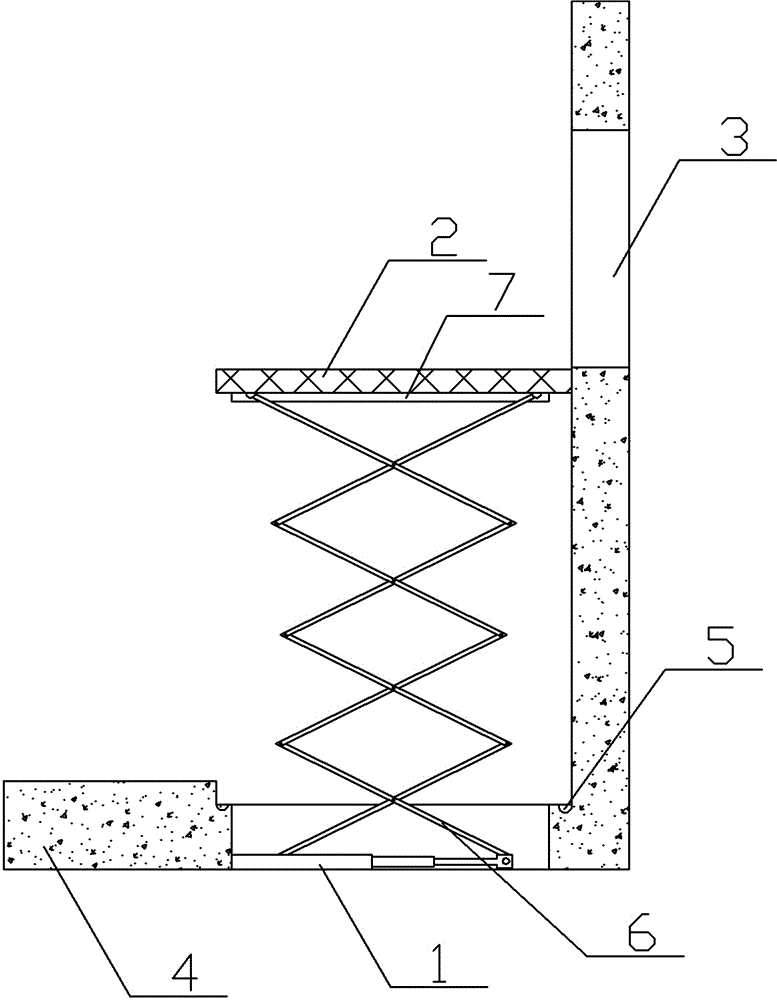

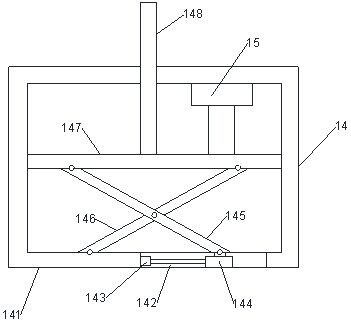

Telescopic assembly and book taking shelf for book arrangement

The invention relates to the field of book management, in particular to a telescopic assembly and a book taking shelf for book arrangement. The telescopic assembly comprises a workbench and two supporting rods fixed to the workbench, wherein a servo motor is further arranged on the workbench, the servo motor is connected with an adjusting assembly arranged between the supporting rods, the adjusting assembly is connected with a guide assembly arranged between the supporting rods through a connecting piece, the guide assembly is connected with a shear fork assembly arranged between the supporting rods, the shear fork assembly is connected with a lifting plate arranged on the supporting rods in a sliding mode, the adjusting assembly is connected with a supporting assembly arranged on the workbench through a transmission assembly arranged on the workbench, the supporting assembly is connected with the lifting plate, the adjusting assembly is further connected with a balance assembly arranged on the workbench through the transmission assembly, and the balance assembly is connected with the supporting assembly through a guide pipe, the design is novel, the structure is simple, and the practicability is high.

Owner:SHANGQIU MEDICAL COLLEGE

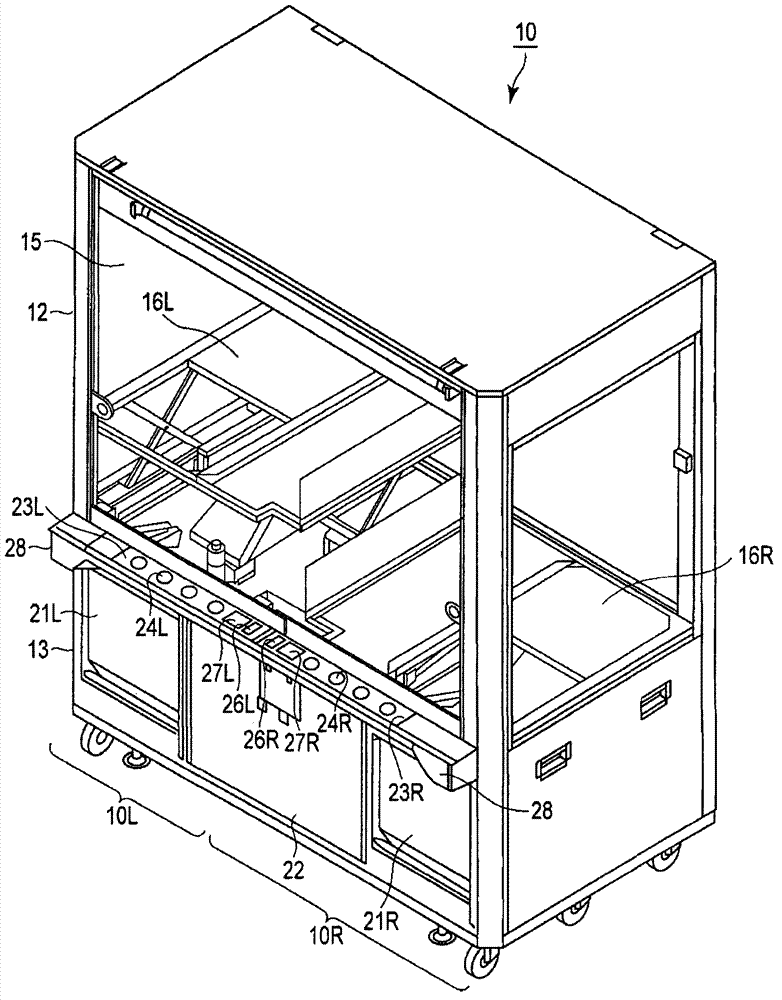

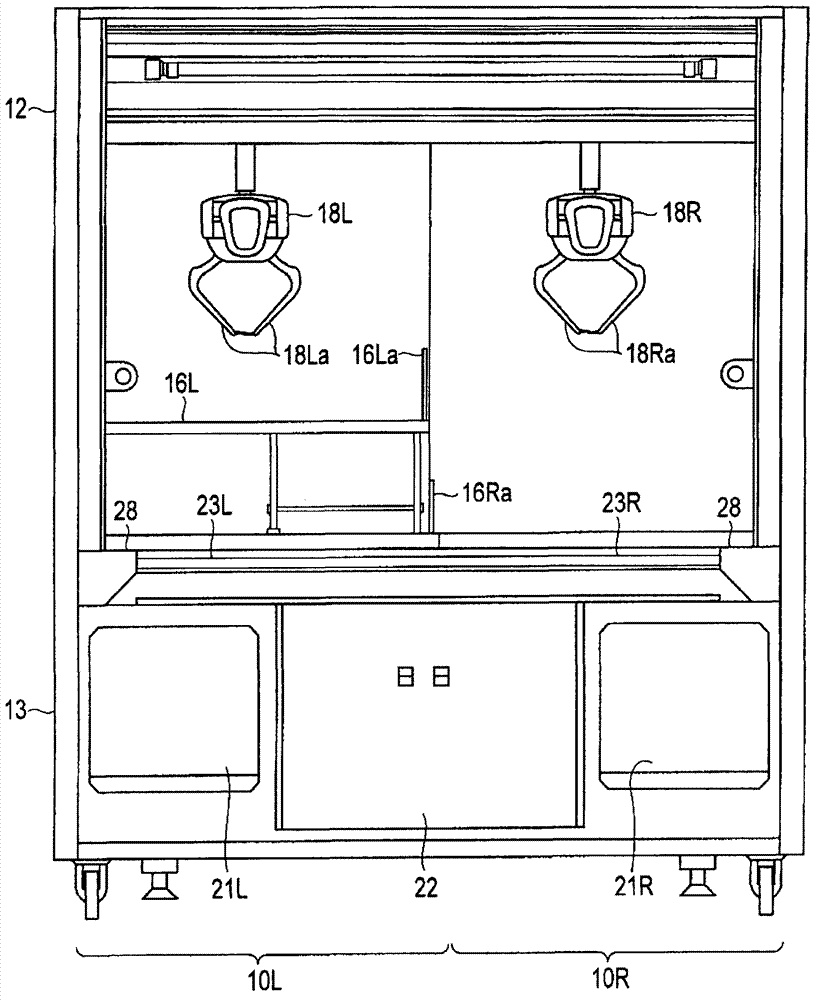

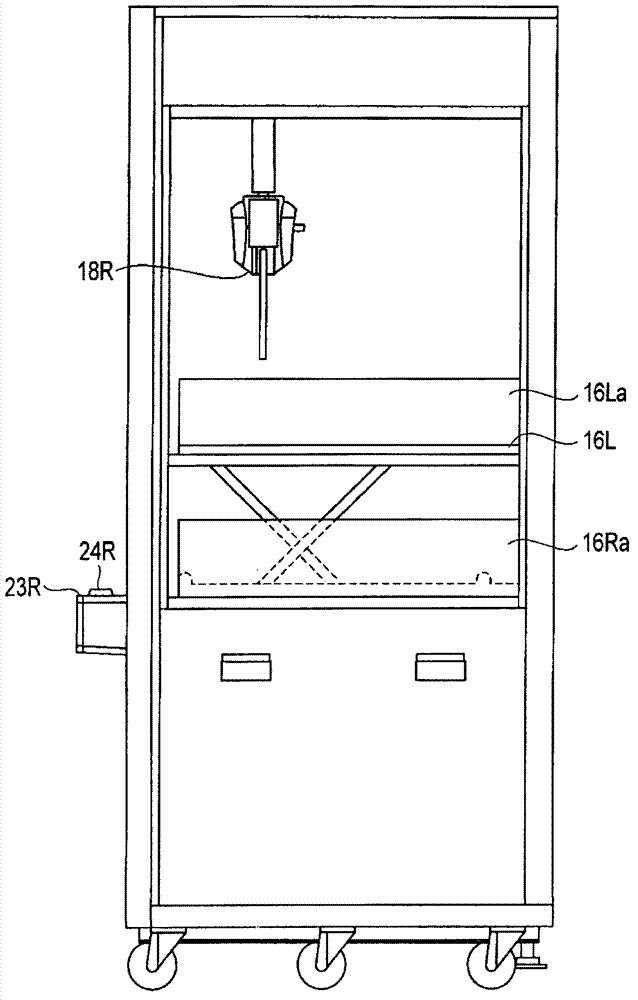

Game device

Owner:TAITO KABUSHIKI KAISHA

Storage lifting platform of service lift

Owner:CHONGQING WESTER ELEVATOR

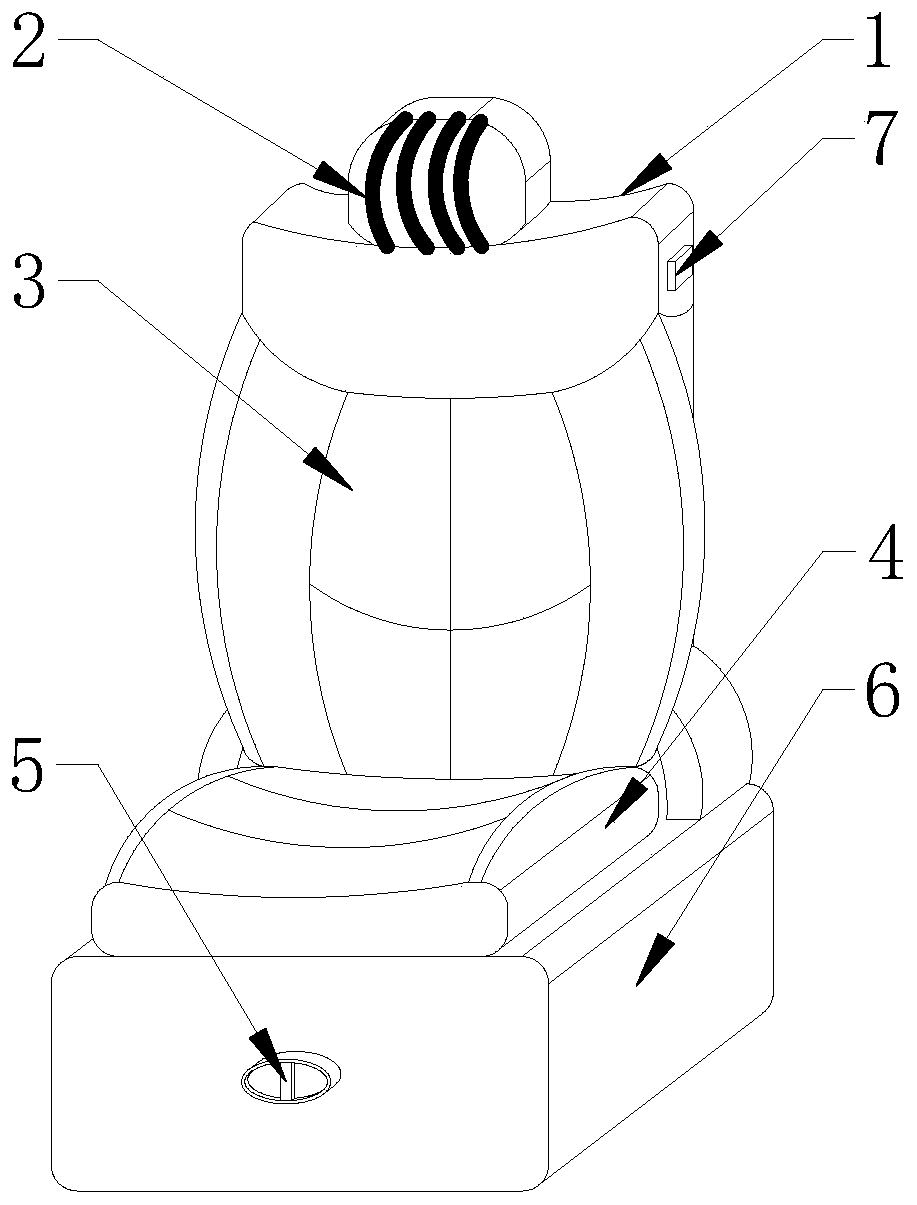

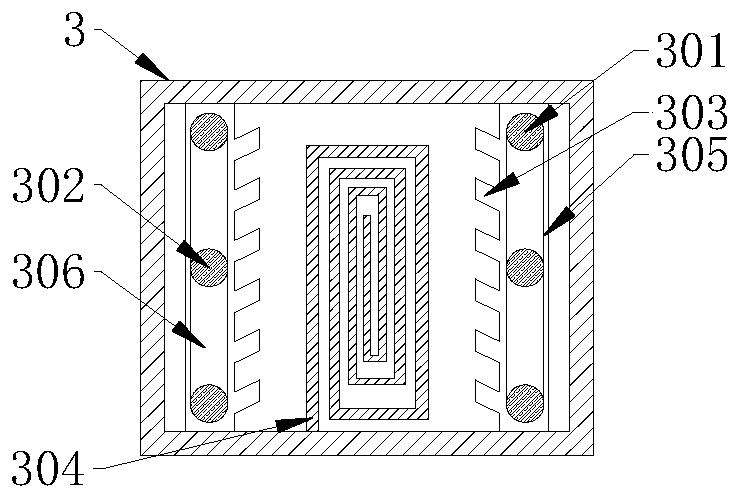

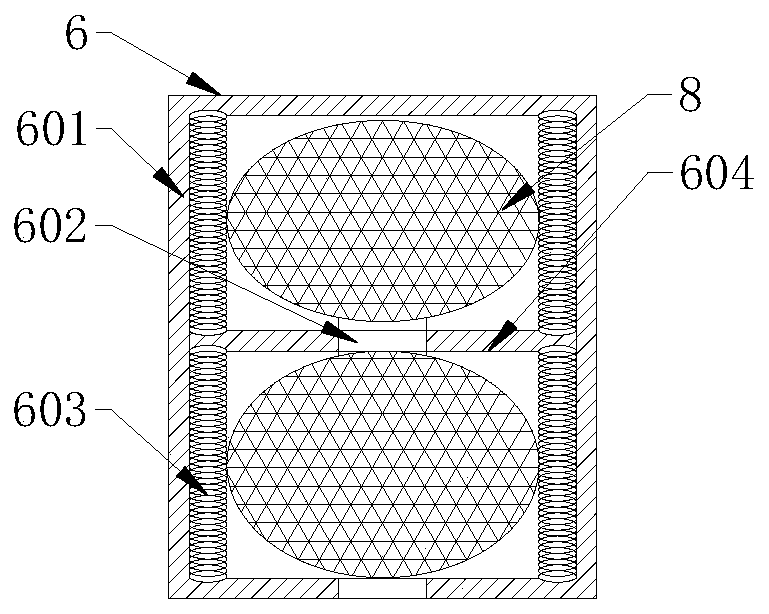

Adjustable safety seat

InactiveCN110370997ARest comfortablyImprove driving feelingSeat heating/ventillating devicesPedestrian/occupant safety arrangementBack restsEngineering

The invention discloses an adjustable safety seat which comprises a safety seat main body, a headrest and an adjustable backrest; the headrest is fixedly connected to the top of the safety seat main body; the adjustable backrest is fixedly connected to the bottom of the headrest; an adjusting rod is fixedly connected to one side of the interior of the adjustable backrest; fixing wheels are fixedlyconnected to the middle part of the adjusting rod; fixed teeth are fixedly connected to one side of the adjusting rod; connecting belts are movably connected to one side of the interior of the adjustable backrest; and a heating pipe is fixedly connected to the middle part of the interior of the adjustable backrest. The heating pipe can heat the seat for a user to improve the use feeling of the user in winter, an pneumatic pump can perform inflation and exhaust on an air bag to improve the safety of the seat, and the adjustable backrest enables the user to freely adjust a height and an angle of the seat to greatly satisfy the use feeling of the user, so that the adjustable safety seat is convenient to use, high in safety and suitable for the field of automobile accessories and has a wide development prospect in the future.

Owner:诸暨市领跑管理咨询事务所

Transmission belt type product radio detection position adjusting device

InactiveCN114217099AHeight adjustableEasy to moveMeasurement instrument housingEnvironmental/reliability testsHydraulic motorTransmission belt

The invention discloses a transmission belt type product radio detection position adjusting device which comprises a base, a vertical plate is fixedly connected to the base, a transverse plate is fixedly connected to the upper end of the vertical plate, two supporting frames are installed on the base, transmission rollers are installed on the two supporting frames, the two transmission rollers are connected through a conveying belt, and the conveying belt is fixedly connected with the transverse plate. A plurality of placing circular plates are rotatably mounted on the conveying belt, a vertical plate is fixedly connected to the base and abuts against the placing circular plates, an L-shaped plate is mounted on the transverse plate, and a rotating rod rotatably connected with the L-shaped plate is arranged on the L-shaped plate in an up-down penetrating mode. The hydraulic motor is used as execution power to change the relative position of a product and the wireless detector, interference of elements such as the motor on a detection result is reduced, meanwhile, the height change of the wireless detector and the angle change of the elements are achieved, and therefore multi-angle and height detection of the elements can be achieved, and dust removal treatment can also be conducted on the elements.

Owner:亳州道智盛智能科技有限公司

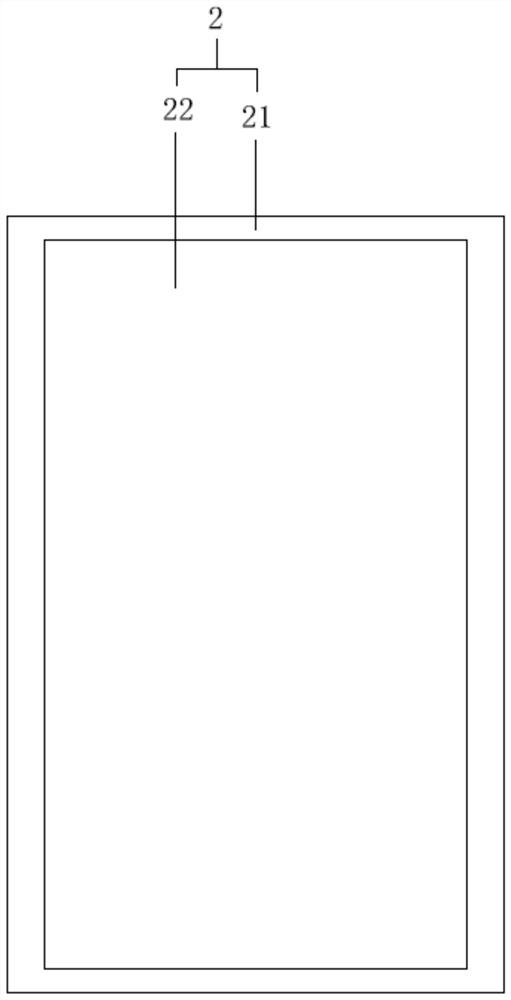

Position-adjustable assembly type dressing mirror device

PendingCN112237360AReduce distanceAvoid damagePicture framesDomestic mirrorsElectric machineryEngineering

The invention provides a position-adjustable assembly type dressing mirror device which comprises a lifting device and a mirror body, the lifting device comprises a base, a screw rod, a motor and a mounting seat, the base is embedded into a wall, the screw rod is rotatably mounted on the base, an output shaft of the motor is connected with the screw rod, the mounting seat sleeves the screw rod, and the back surface of the mirror body is fixedly mounted on the mounting seat. According to the invention, the height of the mirror body can be adjusted through the lifting device, meanwhile, the requirements of users with different heights are met, and the mirror body can be transversely arranged to be used by more people.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Traditional Chinese medicine processing equipment capable of changing drying angle and height

InactiveCN109297278ARealize up and down reciprocating motionAchieve height changeDrying solid materialsDrying machines with non-progressive movementsReciprocating motionHeat resistance

The invention discloses traditional Chinese medicine processing equipment capable of changing a drying angle and height. The traditional Chinese medicine processing equipment comprises a housing, wherein a heating layer is distributed on the bottom in the housing; heating resistance wires are distributed in the heating layer; two horizontal plates are symmetrically and fixedly connected on the inner side wall of the housing; the lower sides of the horizontal plates are fixedly connected with a lifting plate through height regulating devices; the upper side of the lifting plate is symmetricallyand fixedly connected with two supporting plates; a connecting frame is fixedly connected between the two supporting plates; and an angle regulating device is arranged on the connecting frame. The traditional Chinese medicine processing equipment has the beneficial effects that: a first rotary shaft drives a cam to rotate, the cam directly acts on a pressure plate, and the pressure plate drives avertical column to move downwards, so that the lifting plate moves downwards; the cam is separated from the pressure plate, the vertical column is downwards returned under action of a first spring, and the cam enables the pressure plate to move downwards again, so that up-down reciprocating motion of the lifting plate is realized, and therefore, height changes of a disturbance device are realized, and the drying effect is effectively improved.

Owner:伍超群

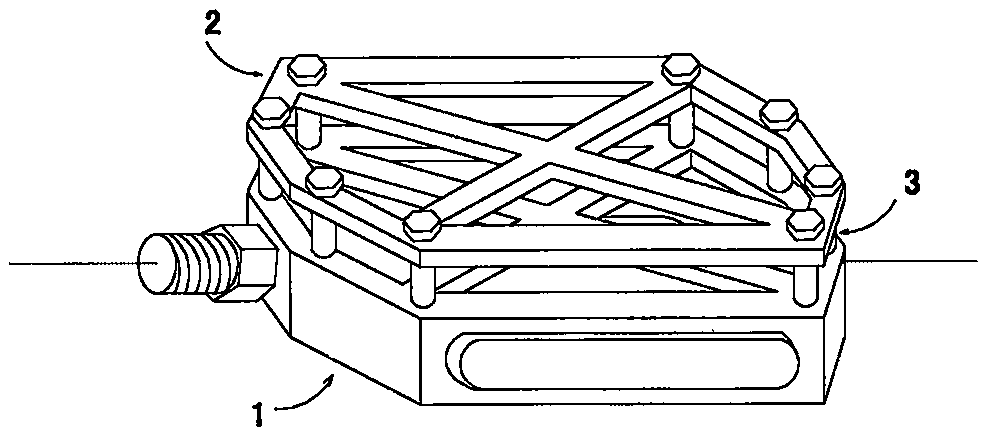

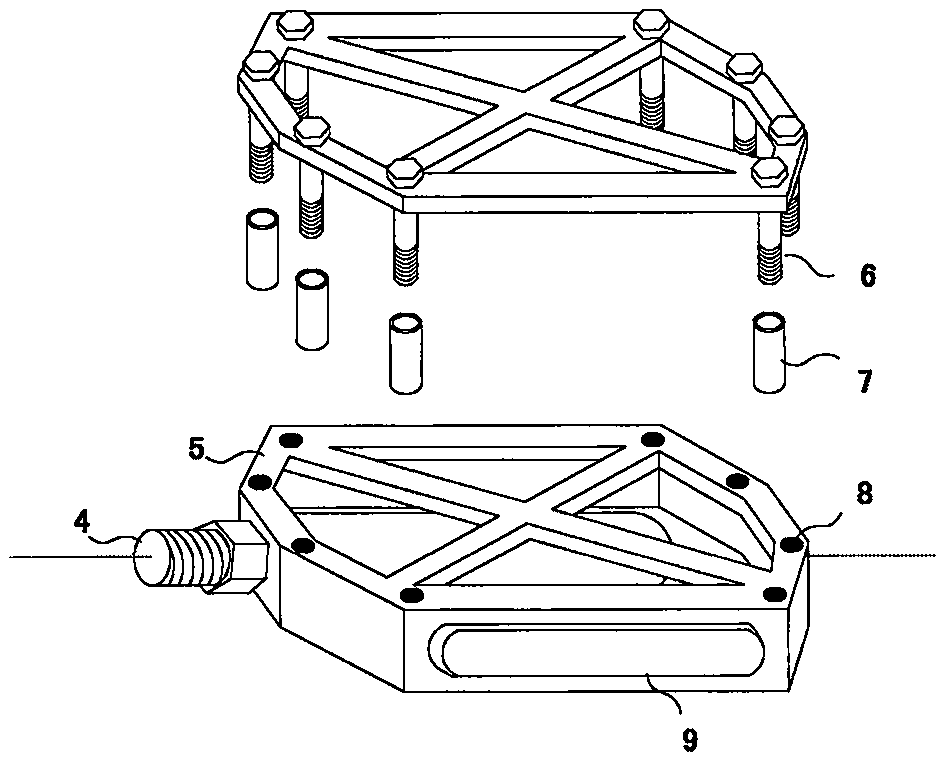

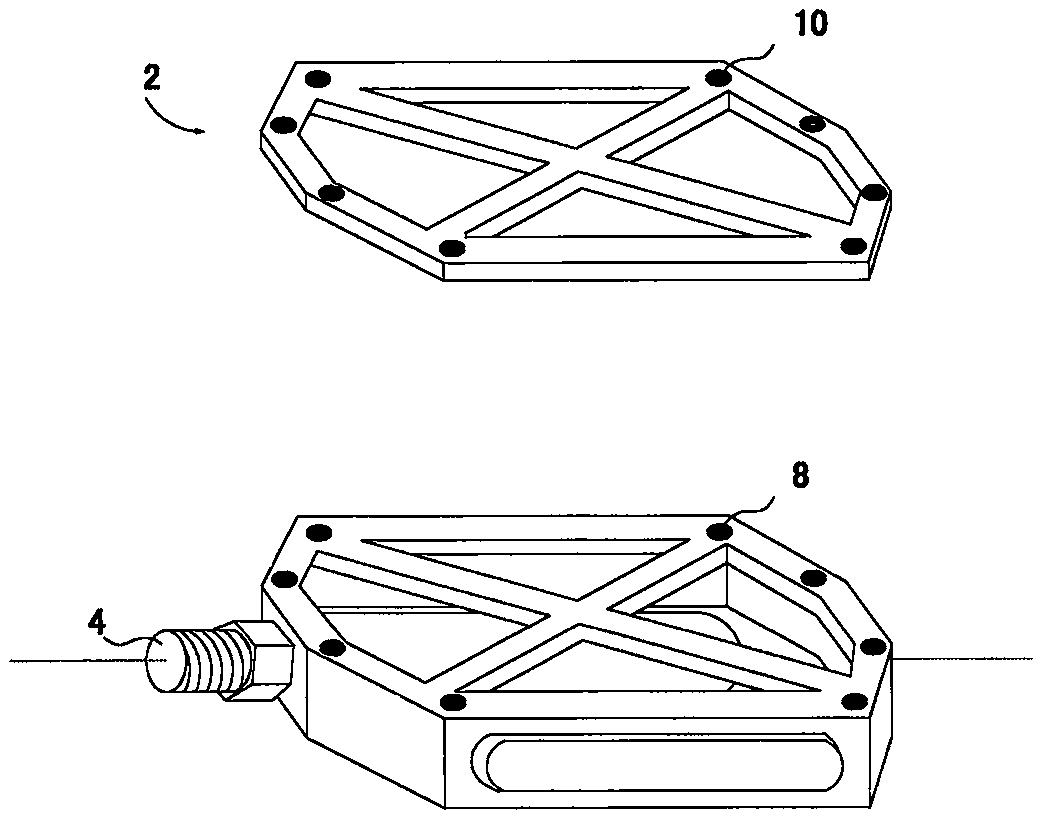

Manufacturing and using method of high-low-face eccentric pedal for travel, leisure and riding

PendingCN107628184ARegulates and relieves fatigueSuit one's needsVehicle cranksBicycle exerciserKnee Joint

The invention belongs to the field of cycling equipment and particularly relates to a manufacturing and using method of a high-low-face eccentric pedal for travel, leisure and riding. The high-low-face eccentric pedal is mainly composed of a pedal body, an auxiliary pedal and a limiting-fixing assembly. The auxiliary pedal is connected and fixed through a limiting sleeve and fastening screws to form the high-low-face eccentric pedal, so that when a user treads high and low pedal surfaces different in height to ride and treads the lowest points of the pedal with feet, the bending angles of kneejoints change, and regulating and lower limb fatigue relieving effects can be played. For the part limited by lower limb length, even when a saddle descends to the lowest position and the pedal is turned to the lowest point, the rider can complete pedaling actions by making the knee joints straight and upright completely. The knee joints can still keep certain bending and the rider does not needto make knee joints straight and upright for pedaling by using the pedal when the pedal is turned to the lowest point, the knee joints can be effectively protected, the fatigue of the knee joints andthe lower limbs can be relieved, and the rising comfort can be improved.

Owner:河北对外经贸职业学院

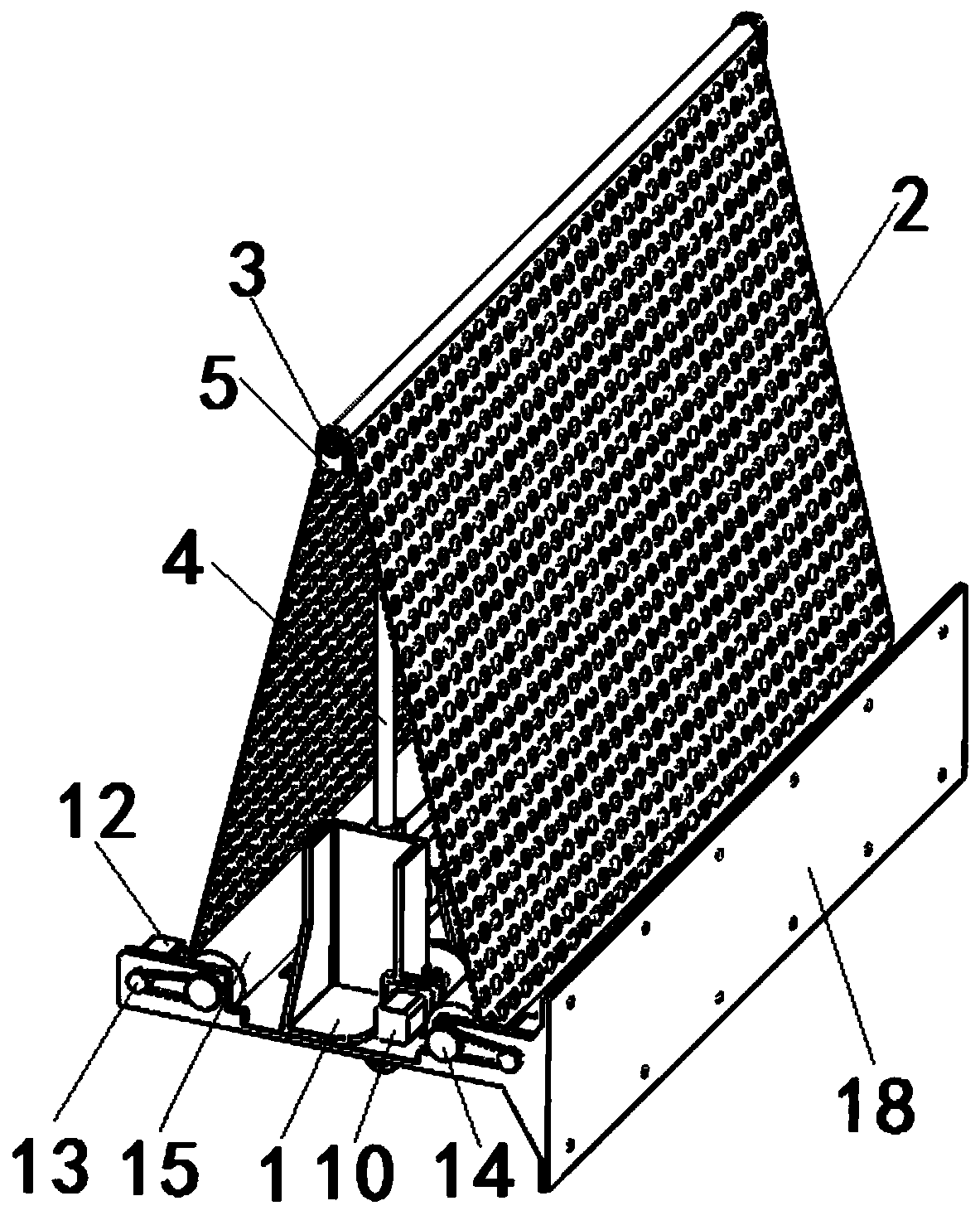

Bridge wind barrier device with adjustable height and porosity

PendingCN111236098AExpand the scope of useGood windproof effectProtective constructionWeather dataLeather belt

The invention discloses a bridge wind barrier device with adjustable height and porosity. The bridge wind barrier device comprises a rack, a wind shielding belt, an anemorumbometer, a weighing module,a high-definition snapshot module and a data processing and control module. A roller rotationally connected with the rack is arranged on the rack. The roller used for supporting the wind shielding belt, lifting devices are arranged on the two sides of the rack. The lifting device is used for achieving lifting of the roller, the wind shielding belt winding and unwinding devices are arranged on thetwo sides of the rack, through holes of different sizes are formed in the wind shielding belt, the size of the through holes of the wind shielding belt can be changed, and bidirectional adjustment ofthe size and the height of the through holes of the wind shielding belt can be achieved to adapt to different weathers. And the data processing and control module can receive data such as wind speedand load, send an instruction to the wind barrier module in combination with information of the weighing module, and adjust related parameters of the wind barrier module.

Owner:XIAMEN UNIV OF TECH

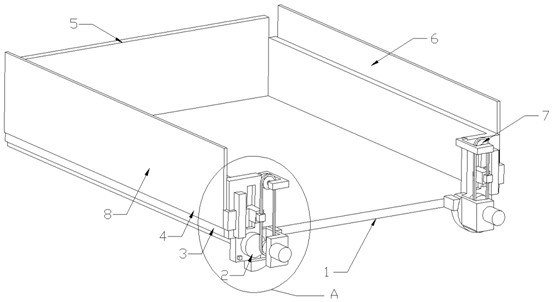

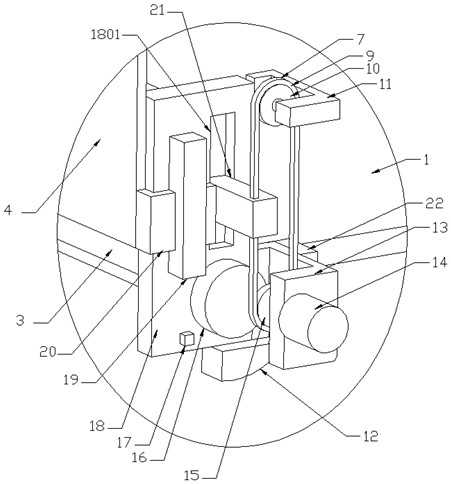

A trailer with adjustable movable board

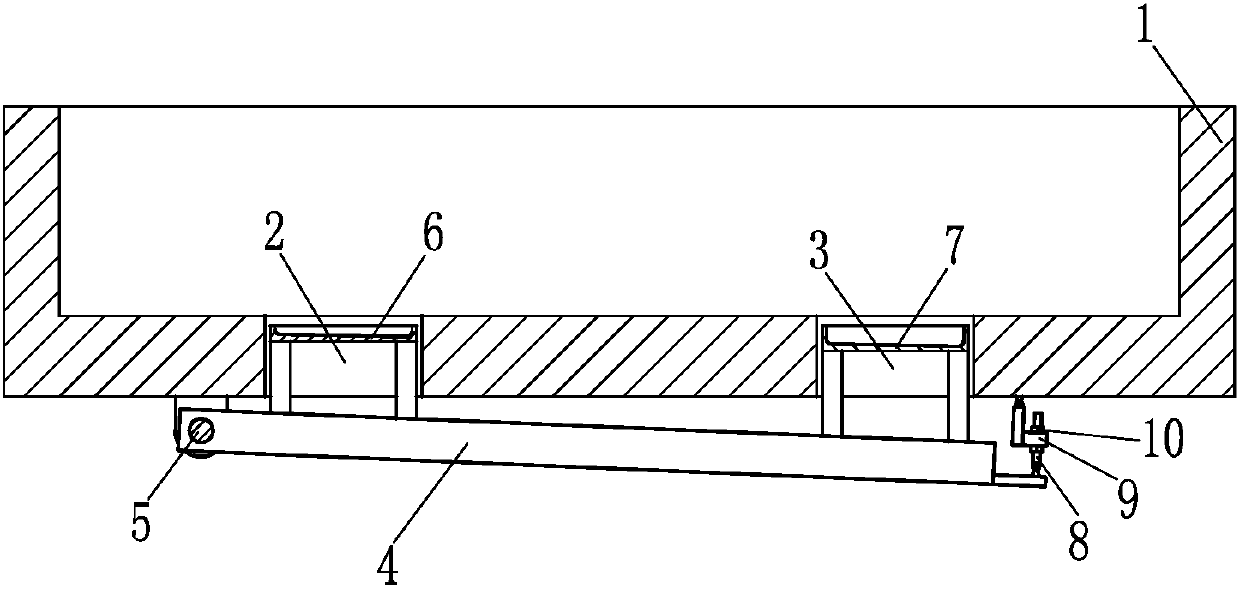

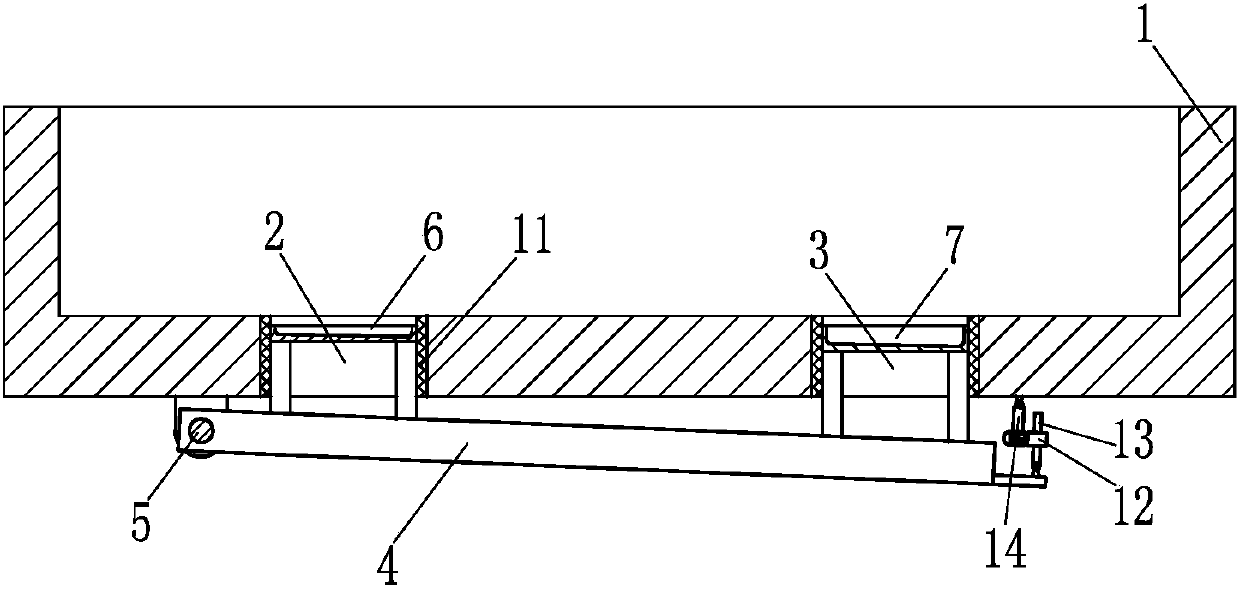

ActiveCN113335391BChange heightMeet the needs of protectionElectric/fluid circuitVehiclesStructural engineeringMechanical engineering

The invention relates to the technical field of trailer equipment, and specifically discloses a trailer with an adjustable movable plate, which includes a trailer body, the trailer body includes a compartment floor, and also includes two protective plate mechanisms and two sets of driving mechanisms; the two protective plate mechanisms can be It is rotatably arranged on both sides of the carriage floor; the protective plate mechanism includes a fixed plate and a moving plate; each set of driving mechanisms includes a driving mechanism I and a driving mechanism II; the two protective plate mechanisms can be driven by the corresponding driving mechanism I to rotate to the first state or the second state; when the protective plate mechanism is in the first state, the fixed plate and the movable plate are arranged vertically, and the movable plate can move vertically along the corresponding fixed plate under the drive of the corresponding drive mechanism II, thus changing the movement The height of the protective plate formed by the plate and the fixed plate; when the protective plate mechanism is in the second state, the fixed plate and the movable plate are arranged horizontally. The present invention can be adapted to goods of different heights, and is convenient for loading and unloading goods.

Owner:沛县迅驰专用车辆制造有限公司

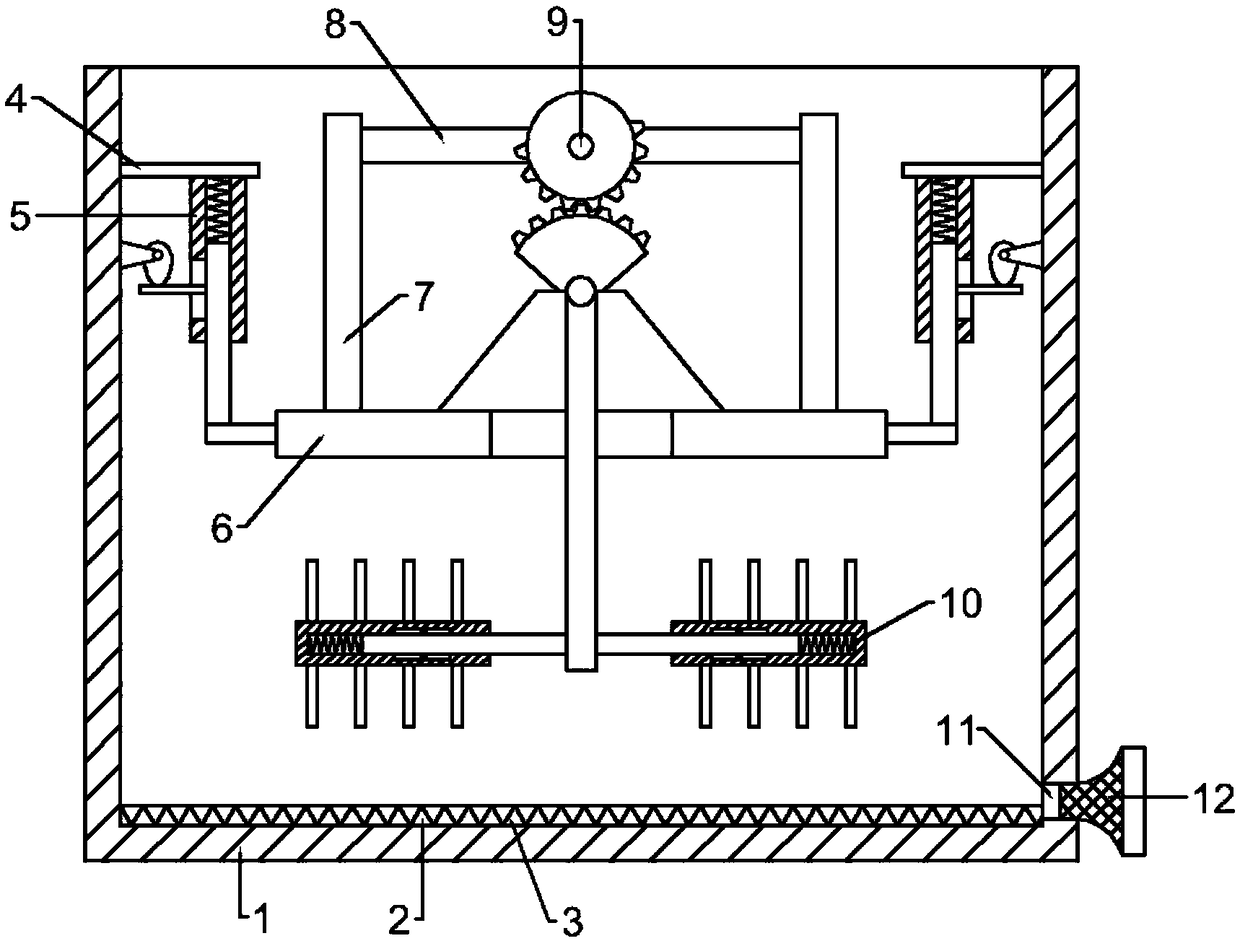

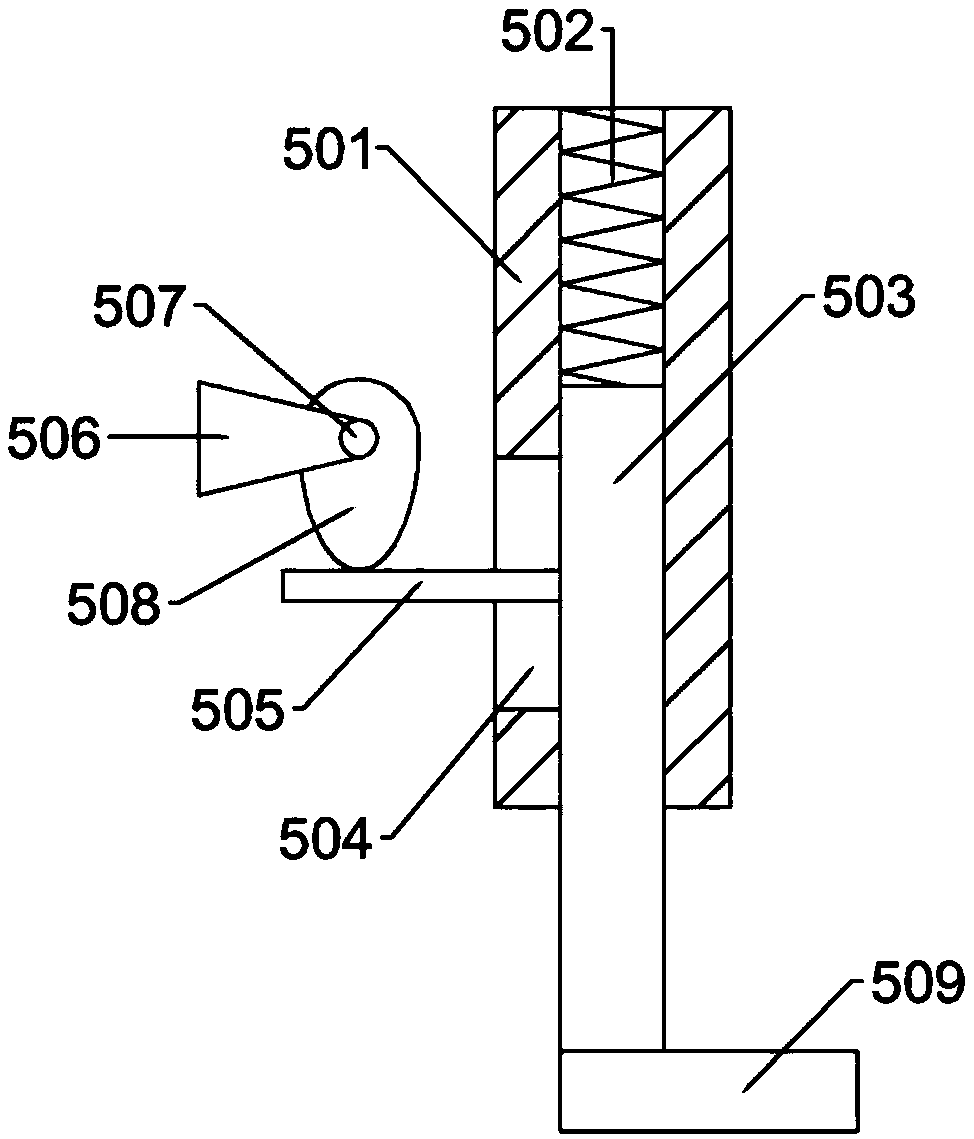

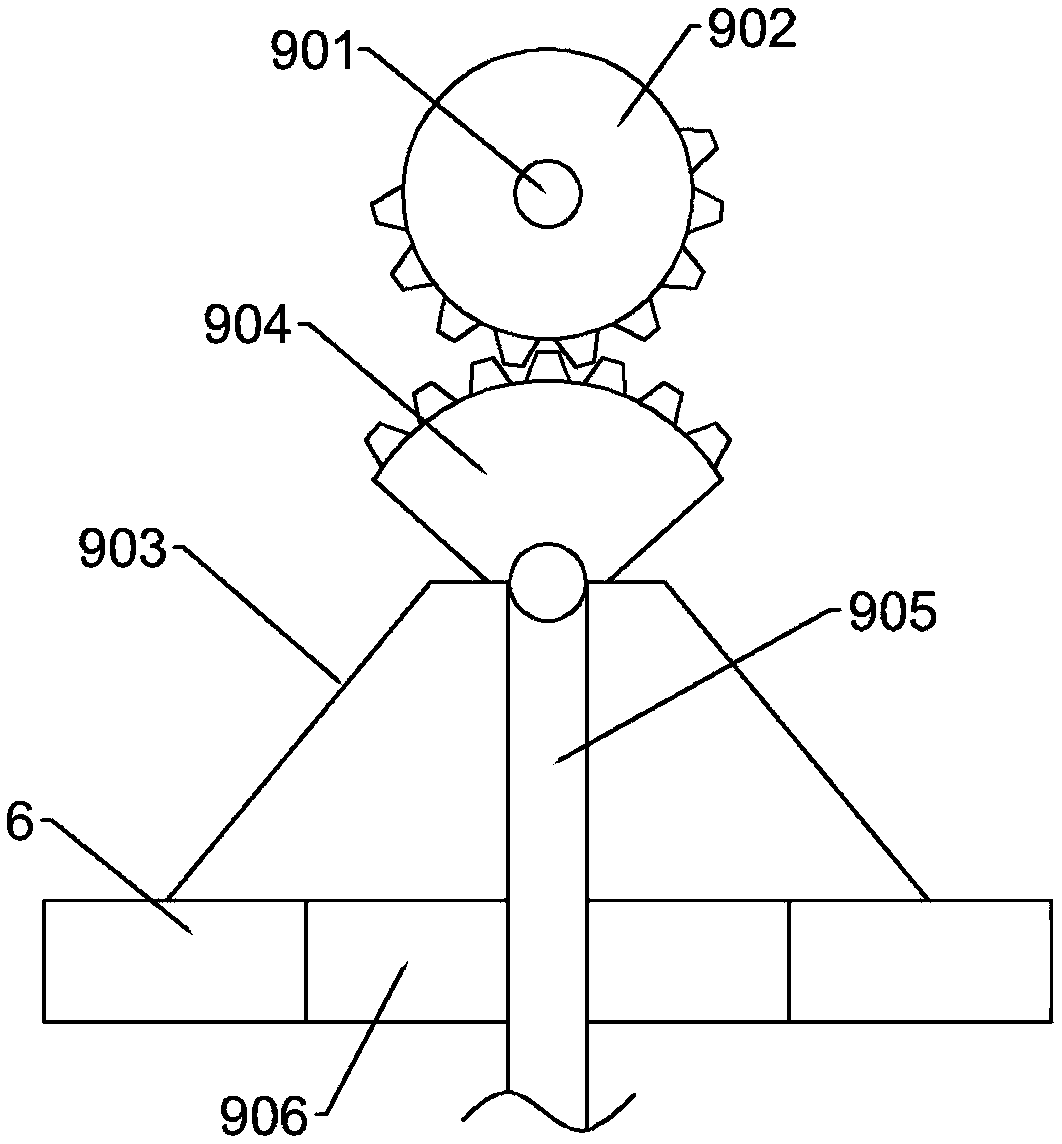

Cutting height adjustment based comb weeding device for stone-bearing ground

The invention relates to the technical field of agricultural machinery and discloses a cutting height adjustment based comb weeding device for stone-bearing ground. The comb device comprises a shell,a handle is movably connected to the left side of the upper end of the shell, a pull rod is movably connected to the right end of the handle, a pulling rope is movably connected to the outer side of the pull rod, and a connecting rod is movably connected to the front side of the bottom end of the shell. By the cooperation and use of a rotating shaft, a lifting cylinder, a sector gear, an adjustingblock and other structures, the effect of easy cutting height adjustment is achieved; through cooperation and use of the rotating shaft, a fixing frame, a combing block, slip nooses and other structure, the effect of weeding on the stone ground can be achieved; through the cooperative use of the connecting rod, a slider, a spring, guide wheels and other structure, the effect that the slip noosescan be located after use is achieved in the course of using the device.

Owner:湖南天爱农业科技有限公司

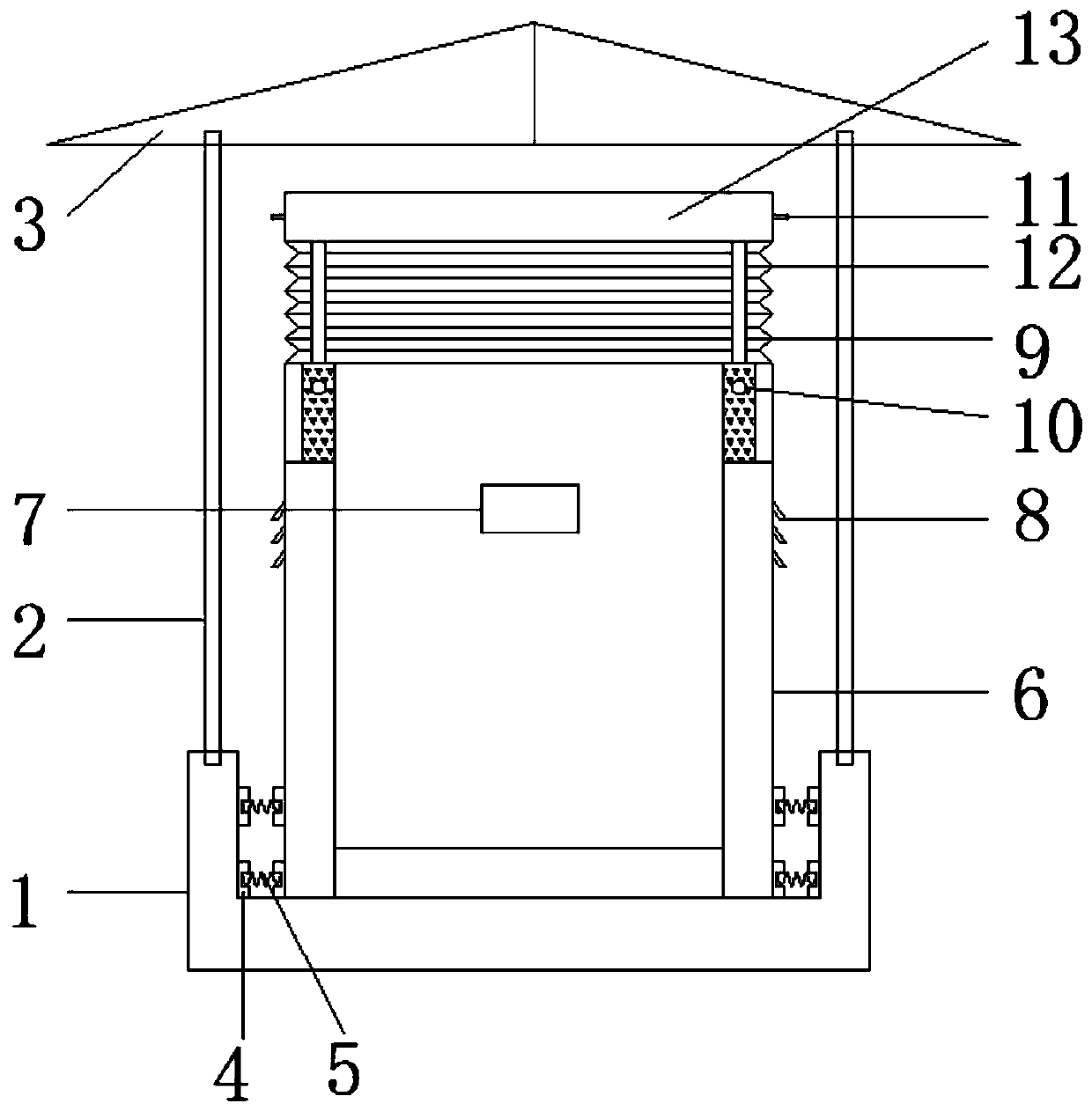

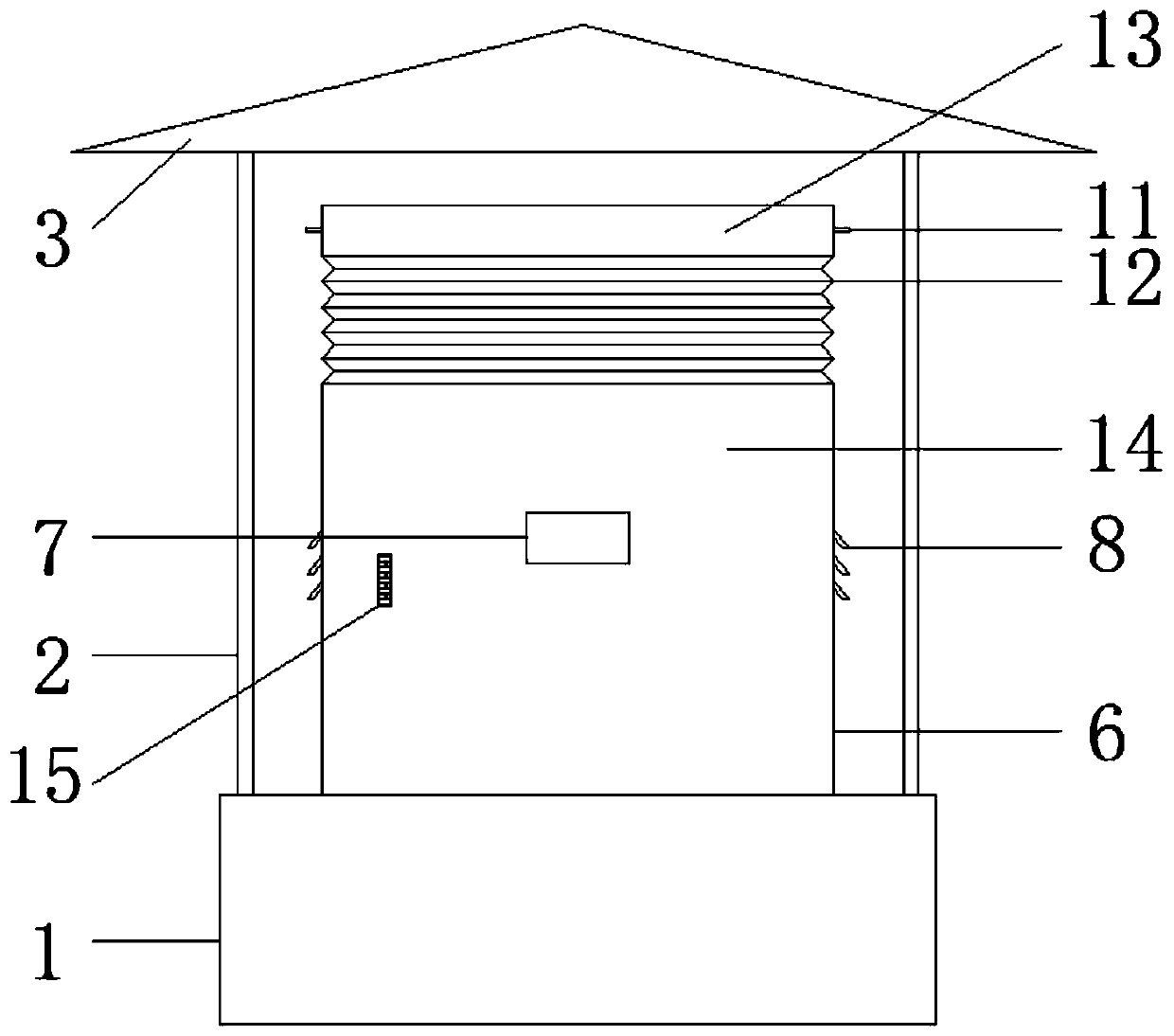

Electric power cabinet with changeable shape

InactiveCN111525416APrevent invasionImprove securitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsStructural engineeringShock resistance

The invention discloses an electric power cabinet with a changeable shape. The cabinet comprises a base, supporting columns, a rain shelter, connecting blocks, springs, a cabinet body, an observationwindow, ventilation openings, telescopic columns, connecting rods, a first handle, telescopic pipes, a top plate, a door body and a second handle. The bottom of the base is placed on the ground. A base and a rain shelter are arranged at the two ends of the supporting column respectively. The connecting blocks are placed on the inner side wall of the base and the outer side wall of the cabinet body. The spring is placed in the connecting block. The bottom of the cabinet body is placed in the base. The observation window is placed on the door body. The ventilation openings are formed in the leftand right side walls of the cabinet body. The telescopic column is connected with the cabinet body and the top plate, the telescopic pipe is arranged outside the telescopic column, the connecting rodis fixedly connected with the cabinet body and the telescopic column, the first handles are arranged on the left side and the right side of the top plate respectively, the door body is arranged on the front face of the cabinet body, and the second handle is arranged on the left side of the door body. The electric power cabinet has functions of adjustable height and water and shock resistance.

Owner:周哉明

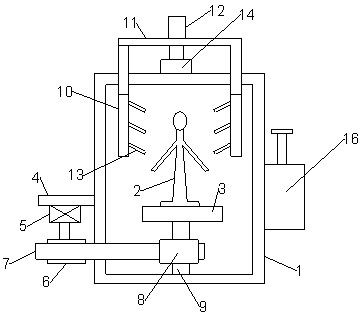

Dummy model equipment for testing waterproof and anti-pollution performance

PendingCN112326533AJudging the level of anti-seepageImprove comprehensivenessPermeability/surface area analysisHuman bodyDrive wheel

The invention discloses dummy model equipment for testing the waterproof and anti-pollution performance, which comprises a detection cabinet and a dummy body, wherein the dummy body comprises a simulated human body and simulated skin arranged on the surface layer of the simulated human body, the simulated skin is made of a silicone rubber material, heating skin is arranged at the physiological signal detection position of the simulated human body, a rotating seat is arranged in the detection cabinet, the dummy body is fixedly mounted on the rotating seat, a mounting seat is arranged on the outer side of the detection cabinet, a driving motor is arranged at the lower part of the mounting seat, and an output shaft of the driving motor is connected with a driving wheel. According to the invention, protective clothing can be placed in a waterproof detection cabinet to be used, the dummy model equipment is used for wearing disposable protective clothing, the dummy model can be tailored anddisposable and is similar to real human skin tissue, whether the protective clothing is waterproof or not is judged by observing whether the surface of the dummy model leaks water or not, and if the dummy model is kept dry after one-hour water spraying of the protective clothing, the anti-seepage grade of the protective clothing can be judged.

Owner:广东朗固实业有限公司

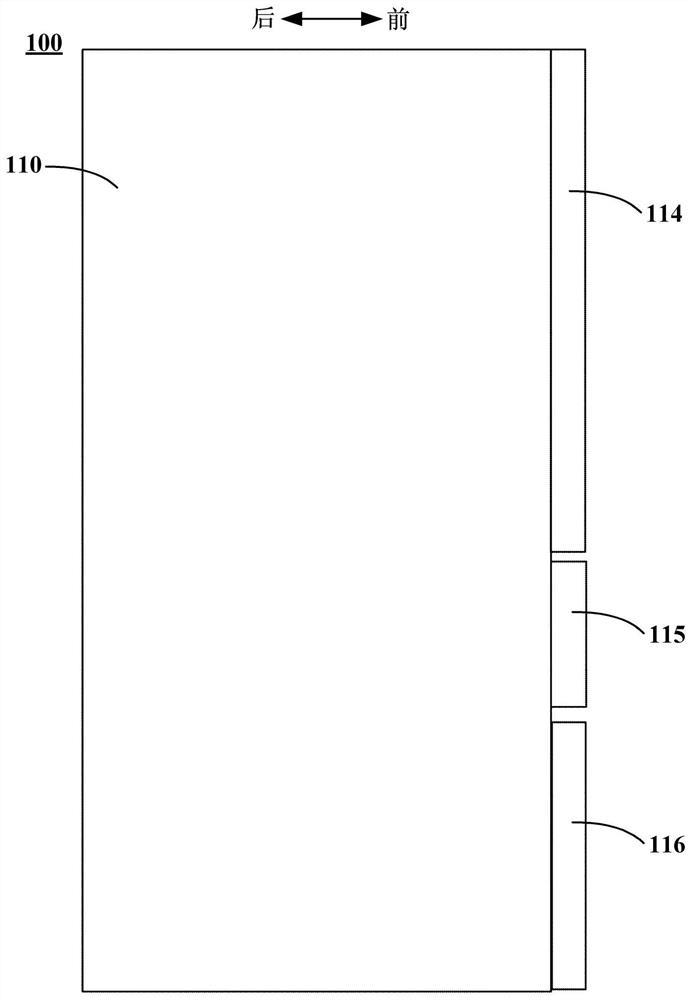

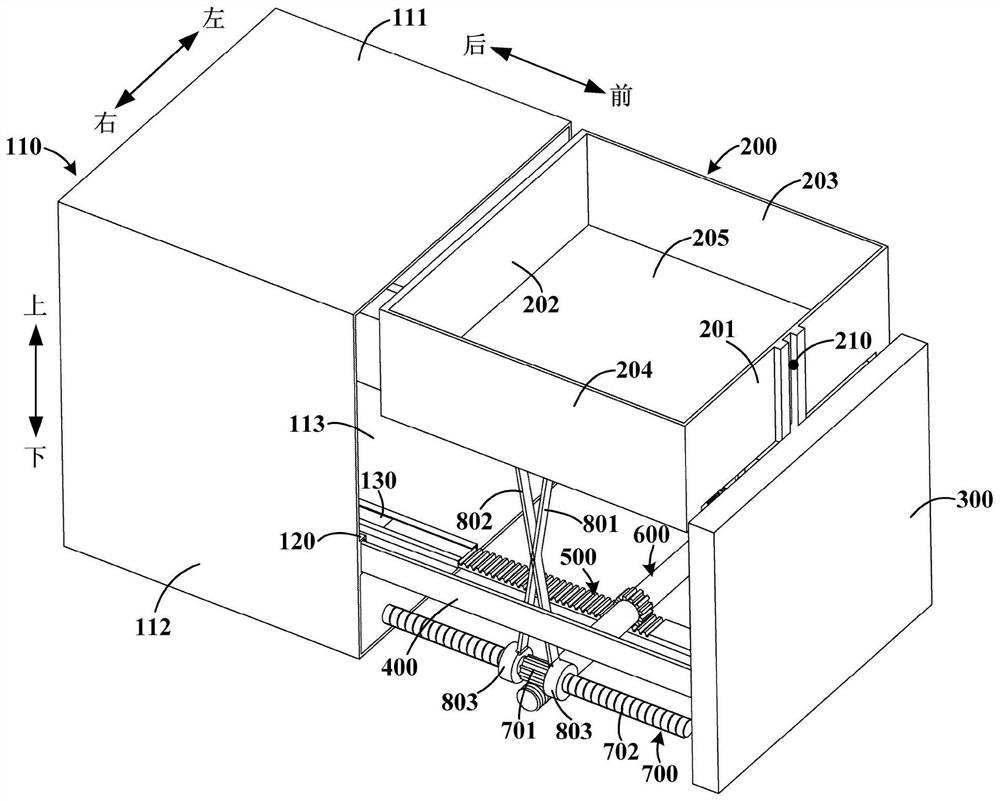

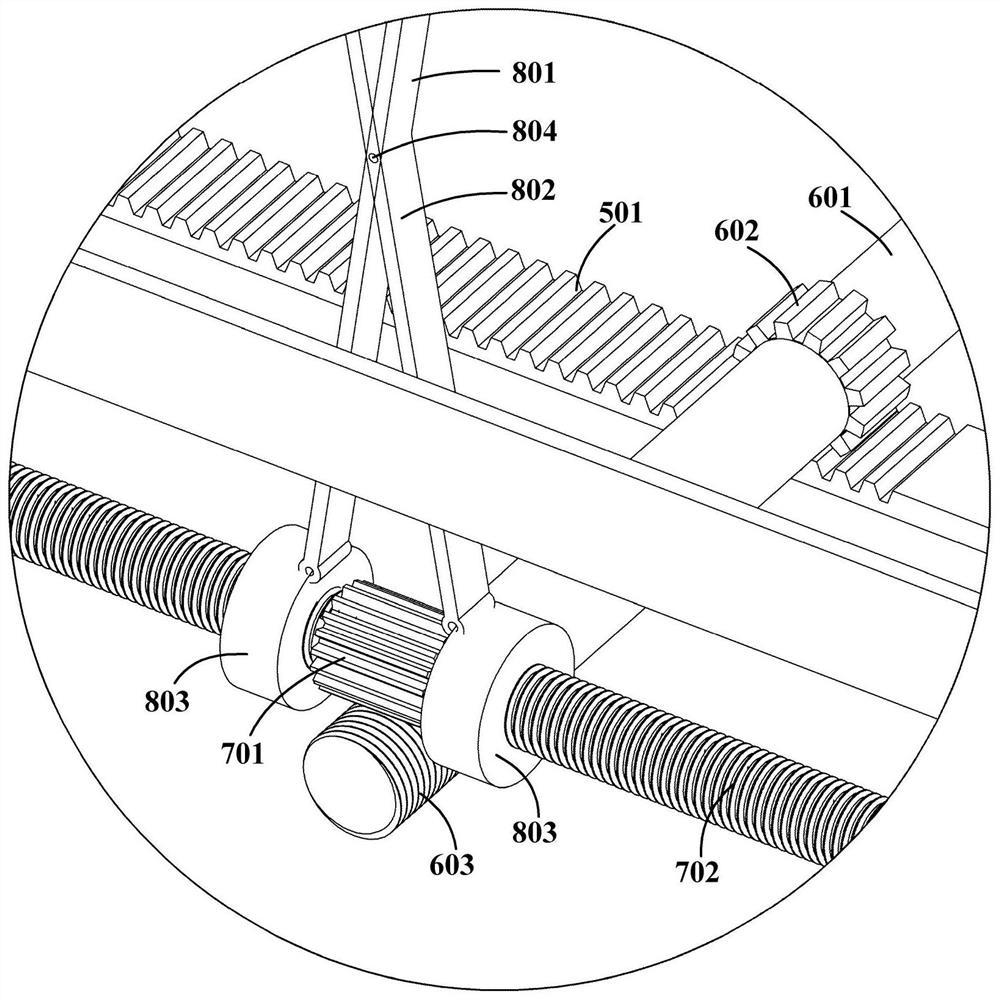

refrigerator

ActiveCN111765709BSimple structureEasy to assembleLighting and heating apparatusSupportIceboxEngineering

The present invention provides a refrigerator, comprising: a box body, which defines at least one storage compartment inside; a drawer body, accommodated in the storage compartment; a front panel, arranged on the front side of the drawer body, and The boxes are connected and configured to move forward / backward relative to the boxes; and a linkage assembly configured to form a linkage connection between the drawer body and the front panel so that the front panel moves toward the When moving forward, the drawer body moves forward out of the storage compartment and is lifted up by the linkage assembly, and when the front panel moves backward, the drawer body moves backward into the storage compartment and relies on Gravity falls back down. The refrigerator of the present invention does not require users to bend over when using it, and has a simple structure, easy assembly, and easy maintenance.

Owner:CHONGQING HAIER REFRIGERATION ELECTRIC APPLIANCE CO LTD +2

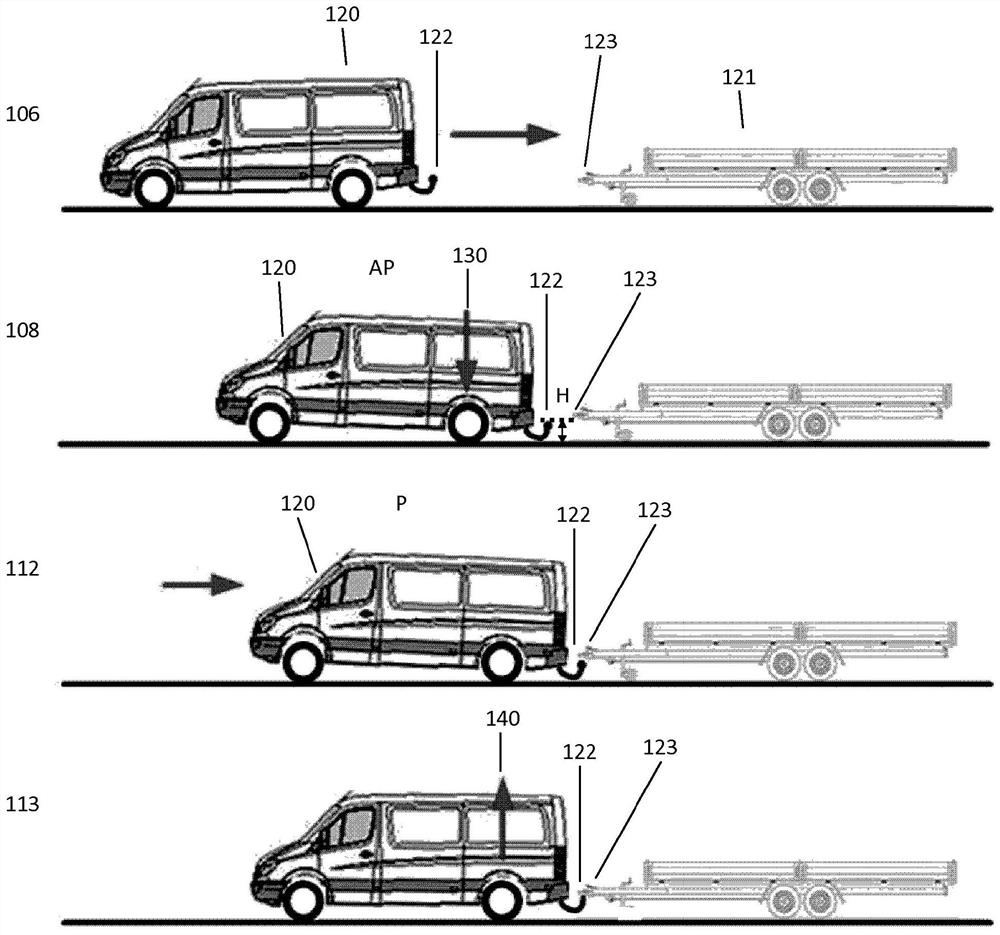

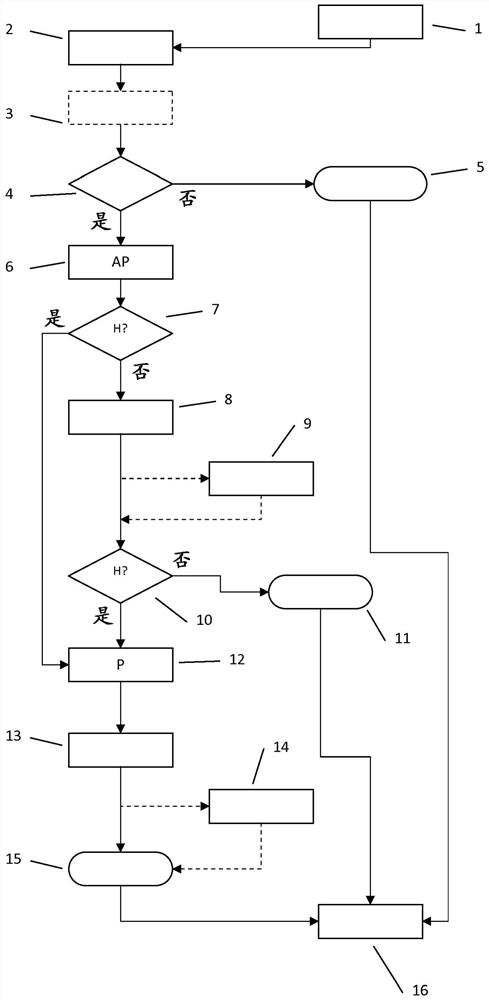

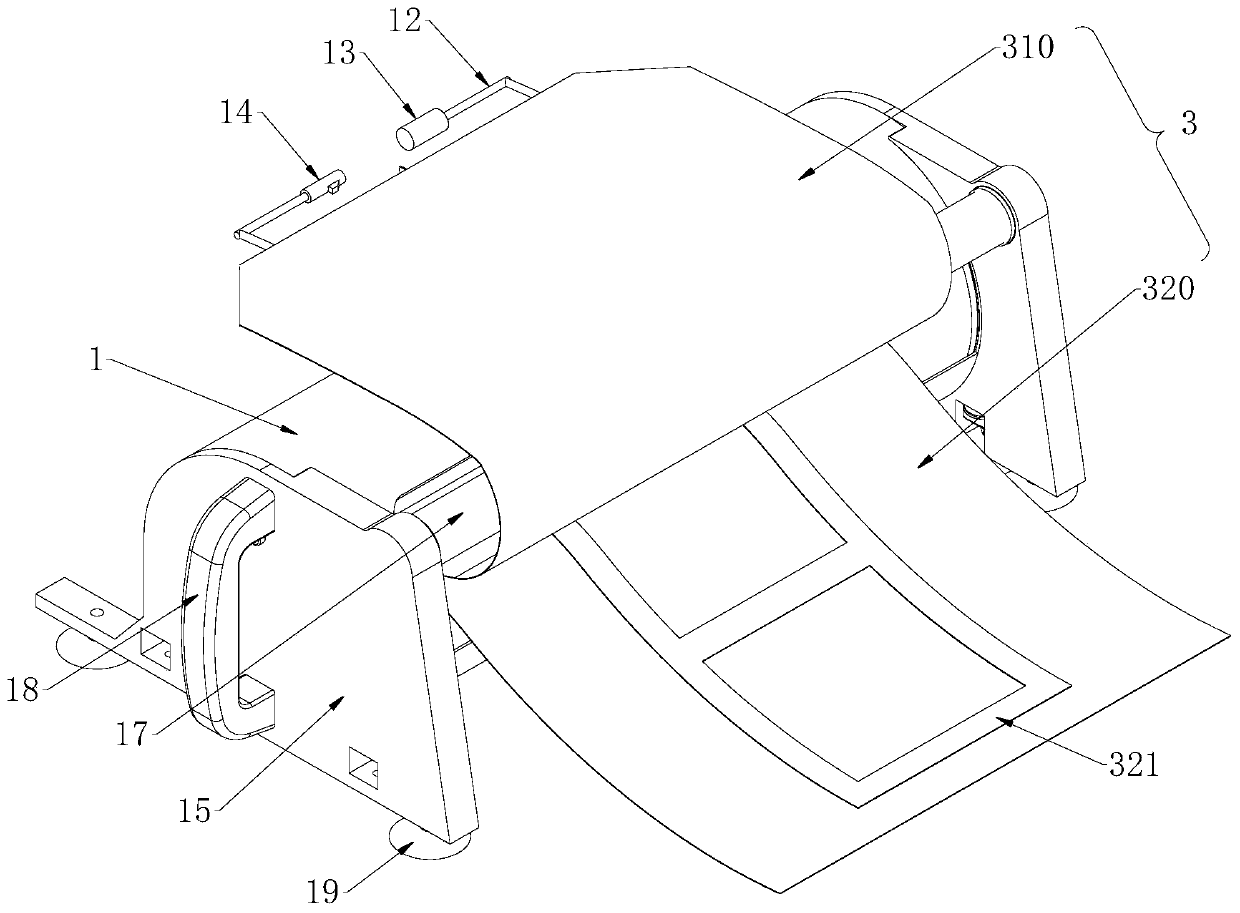

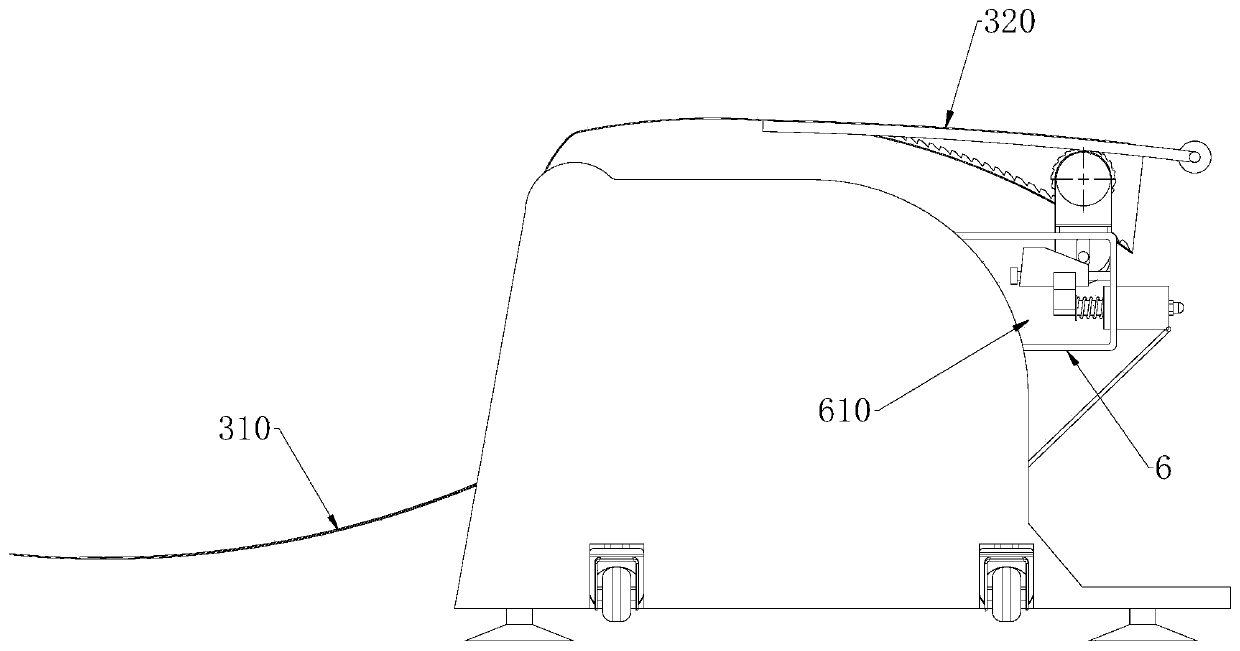

Method and device for coupling a motor vehicle to a trailer

ActiveCN107835753BFully automatedDrive control realizationPneumatic tyre reinforcementsSignalling/lighting devicesControl mannerControl theory

The invention relates to a method for coupling a motor vehicle with a trailer coupling device to a coupling element of a trailer, which method is at least semi-automatically based on data detected by means of an environmental sensor system, in particular of an environmental sensor system of the motor vehicle A motor vehicle is controlled in a controlled manner, wherein a controlled height change is carried out at at least one axle on the basis of detected data by means of an air suspension system of the motor vehicle. The invention also relates to a control device for carrying out the method.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Automotive full-automatic protection cover

PendingCN110861477AGuaranteed stabilityReduce failureRemovable external protective coveringsIndustrial engineeringAutomation

The invention discloses an automotive full-automatic protection cover, and relates to the technical field of automotive protection covers. The automation degree that automobile bodies are covered withautomobile covers is increased, and labor burdens of users are relieved. The automotive full-automatic protection cover comprises a collection barrel located at the upper end of an automobile body, acenter shaft is rotationally arranged in the collection barrel, an automobile cover body is connected to the center shaft, and an opening is formed in the side wall of the collection barrel. The automobile cover body is folded and wound on the center shaft, the automobile cover body stretches out from the opening to from a first automobile cover and a second automobile body which back on to eachother. A toothed belt is arranged below the first automobile cover. A gap is arranged between the toothed belt and the first automobile cover. The lower end of the first automobile cover is connectedwith connecting cloth. The toothed belt and the first automobile cover are connected through the connecting cloth. A fixed frame is arranged on the outer wall of the collection barrel, a drive unit cooperating with the toothed belt is arranged on the fixed frame, and a pressing wheel capable of achieving lifting motion is arranged at the lower end of the toothed belt.

Owner:王光军

A radio-driven active suspension device

ActiveCN107804130BReduce usageExtended service lifeResilient suspensionsWireless transmissionElectrical drive

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com