Ballast bed precast slab production mold with ultrahigh adjustment support

A technology for adjusting brackets and prefabricated panels, which is applied in the field of rail transit, can solve problems such as difficulty in ensuring accuracy and high cost, and achieve the effects of good applicability, reduced mold costs, and reduced types and quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

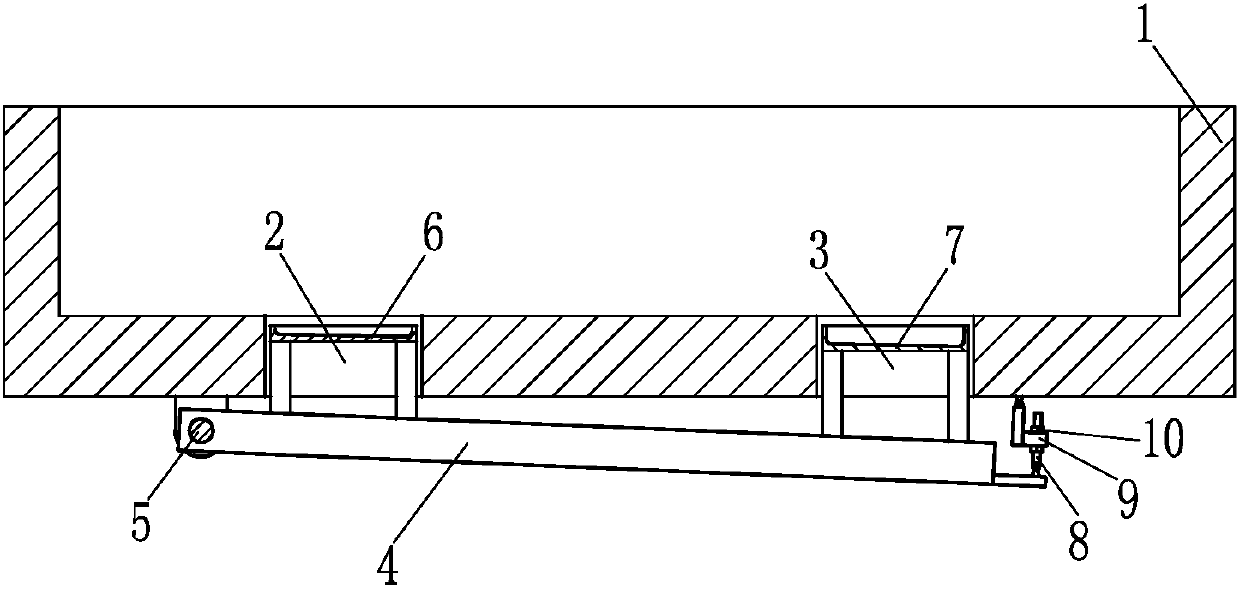

[0013] Such as figure 1 The mold for the production of ballast prefabricated slabs with super-height adjustment brackets shown in the present invention includes a mold body 1 and super-height adjustment brackets 4. The position of the mold body 1 corresponding to the position of the ballast prefabricated slab rail bearing platform is set to give way The through hole 2 and the outer rail platform give way through hole 3, the inner side rail platform is provided with the inner rail platform forming height adjustment groove 6 in the said inner side rail platform step-off through hole 2, and the outer side bearing platform is provided with the outer side bearing through hole 3. The height-adjusting groove 7 of the rail platform, the height-adjusting groove 6 of the inner rail-supporting platform and the height-adjusting groove 7 of the outer rail-supporting platform are respectively fixed on the super-height adjustment bracket 4, and the inner rail-supporting platform gives way to ...

Embodiment 2

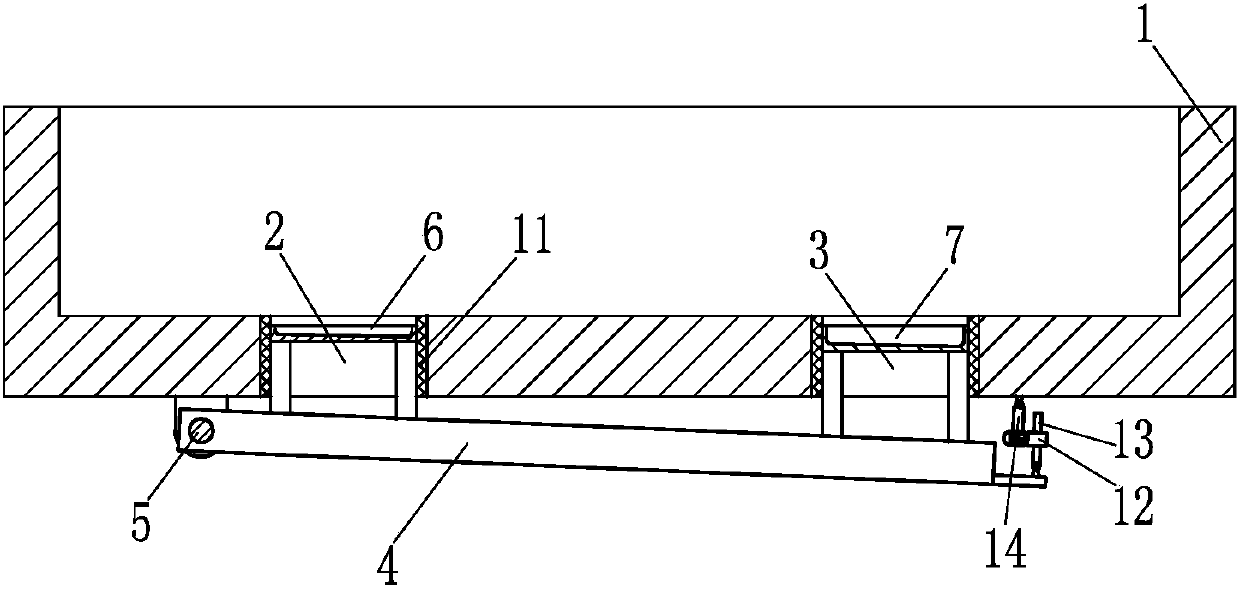

[0018] Such as figure 2 The difference between the production mold of the ballast bed prefabricated slab with the super-height adjustment bracket of the present invention and the first embodiment is that the height adjustment locking device is a push rod, specifically the electric push rod 12, and the worm rod 13 in the electric push rod One end is hinged with the super-height adjustment bracket 4, and the bracket 14 in the push rod is hinged with the mold body 1; in addition, a sealing strip 11 is provided in the adjustment gap, and the sealing strip 11 is made of elastic polyurethane material; in addition, the super-height adjustment bracket 4 The center of rotation of the pin shaft 5 hingedly connected with the mold body 1 coincides with the center of the top surface of the rail which is set under the working state of the inner rail bearing platform of the produced ballast bed prefabricated slab.

[0019] Because the center of rotation of the pin shaft 5 hingedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com