Novel waste heat utilization and emission reduction process for hot air systems of chain grate machine, rotary kiln and circular cooler

A technology of rotary kiln and ring cooler, which is applied in waste heat treatment, lighting and heating equipment, furnaces, etc. It can solve the problems of large exhaust gas emissions and high desulfurization costs, so as to save energy, reduce operating costs, heat and hot air The effect of small resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

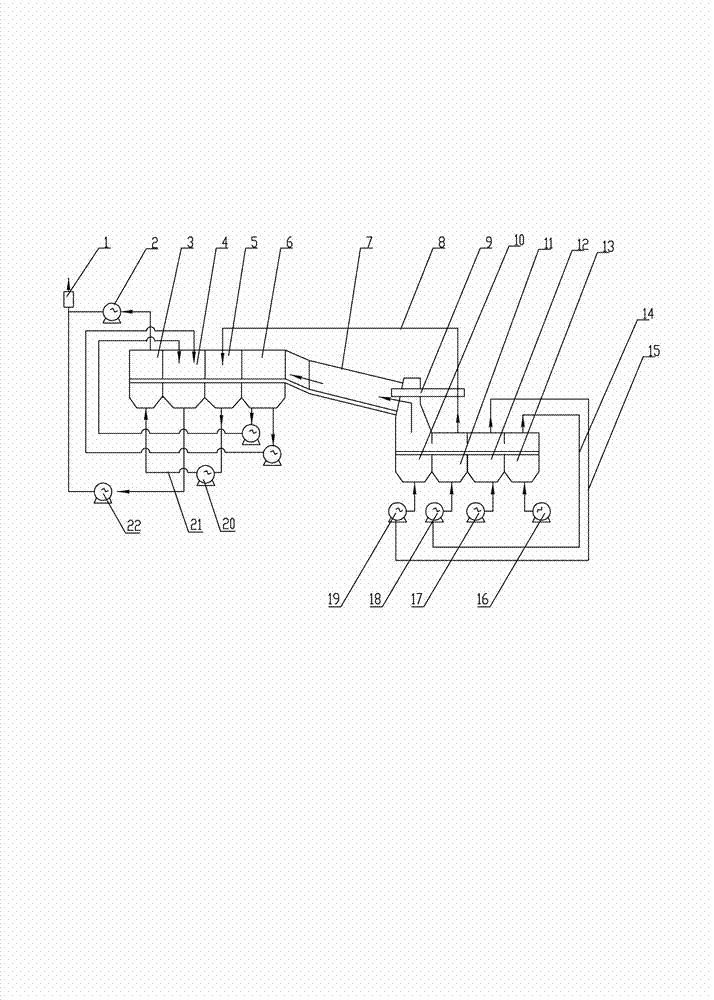

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0017] like figure 1 As shown, the waste heat utilization and emission reduction system of the chain grate machine-rotary kiln-circular cooler hot air system of the present invention includes a blast drying section 3, an exhaust drying section 4, a preheating section 5, and a preheating section 6. The chain grate machine consists of the first cooling section 10 and NO.1 cooling fan 19, the second cooling section 11 and NO.2 cooling fan 18, the third cooling section 12 and NO.3 cooling fan 17 and the fourth cooling section 13 and NO.4 The annular cooler composed of cooling fan 16 is connected to the rotary kiln 7 of the chain grate machine and the annular cooler, the burner 9 arranged on the rotary kiln 7, and the main exhaust fan 22 connected to the desulfurization device 1 are set The blast drying furnace cover fan 2 between the desulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com