Waste heat internal and external circulation comprehensive recycling method and hot air flow system of pellet production equipment

A technology of internal and external circulation and internal circulation, applied in the field of energy saving in the metallurgical industry, can solve the problems of large thermal energy loss, low thermal energy utilization efficiency, and thermal energy not being recycled, so as to improve the temperature and thermal energy of hot air, and to strengthen and improve the advantages of energy saving and emission reduction. The effect of waste heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

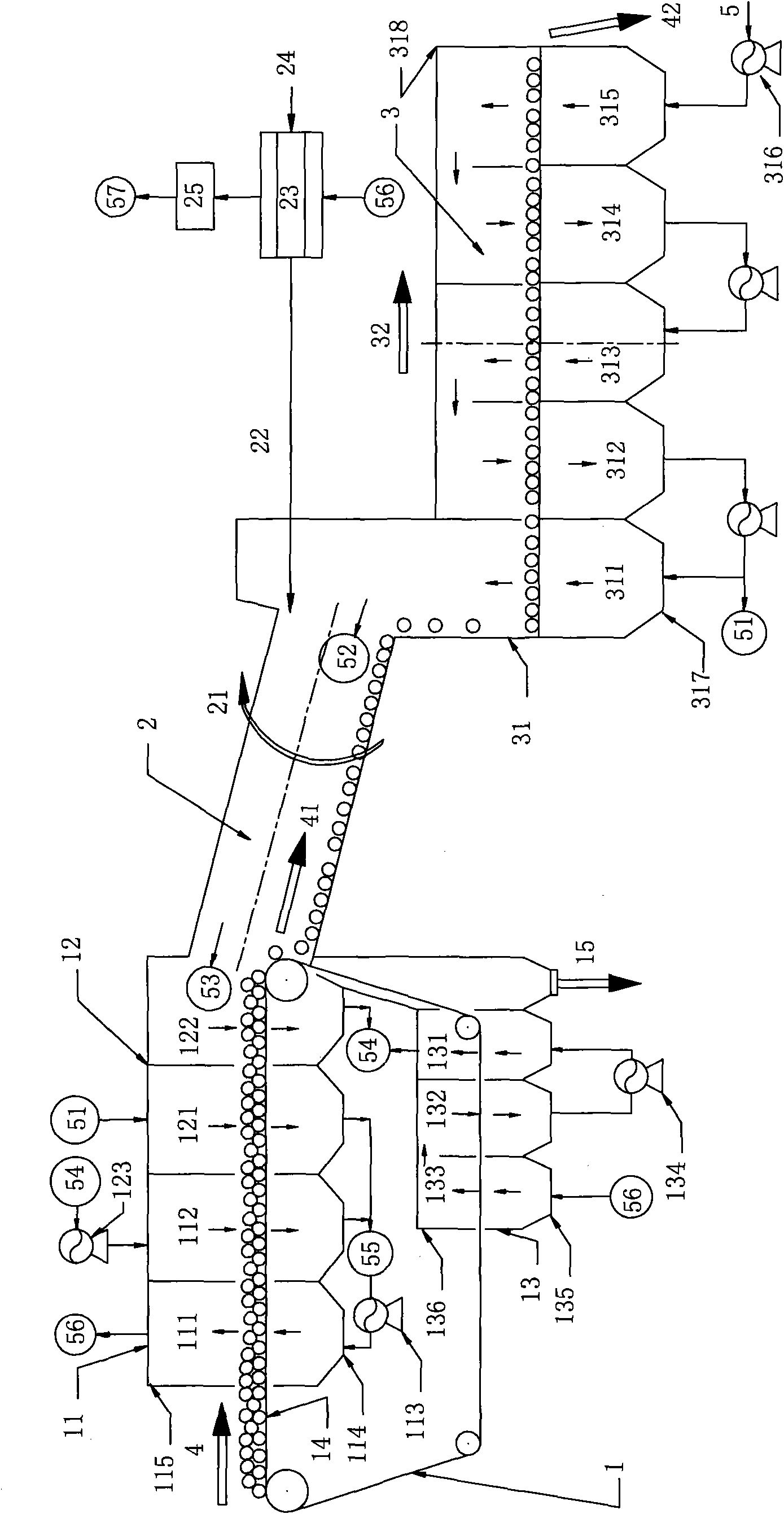

[0017] The specific implementation of the present invention will be described for the specific situation of 2.4 million tons of grate machine (B4.5×60m).

[0018] Such as figure 1 As shown, the hot air flow system realized by the comprehensive recovery and utilization method of waste heat internal circulation and external circulation of the pellet production equipment of the present invention, the grate machine 1 part includes: grate bed drying section 11, grate bed preheating section 12, grate bed waste heat recovery Section 13, grate bed 14, dust recovery 15. The grate bed drying section 11 includes: a grate bed blast drying section 111 and a hot air exhaust drying section 112 . The grate bed preheating section 12 includes: the first grate bed preheating section 121 and the grate bed preheating second section 122. Below the grate bed is a drying and preheating section wind box 114, and above the grate bed is a drying and preheating section air cover 115. The grate bed was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com