Method for smelting ultra-low sulfur, silicon and titanium grey nodular cast iron by pig iron

A smelting method and ultra-low sulfur technology, applied in the field of iron and steel metallurgy, can solve the problems of large investment in equipment, difficulty in ensuring product quality stability, and unsuitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

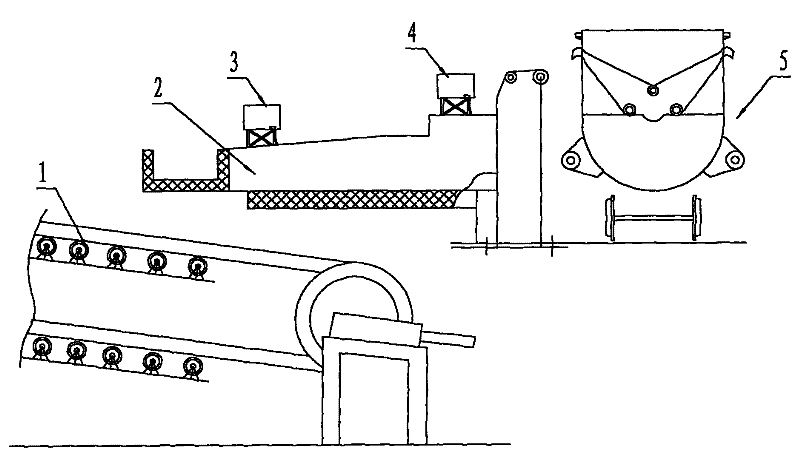

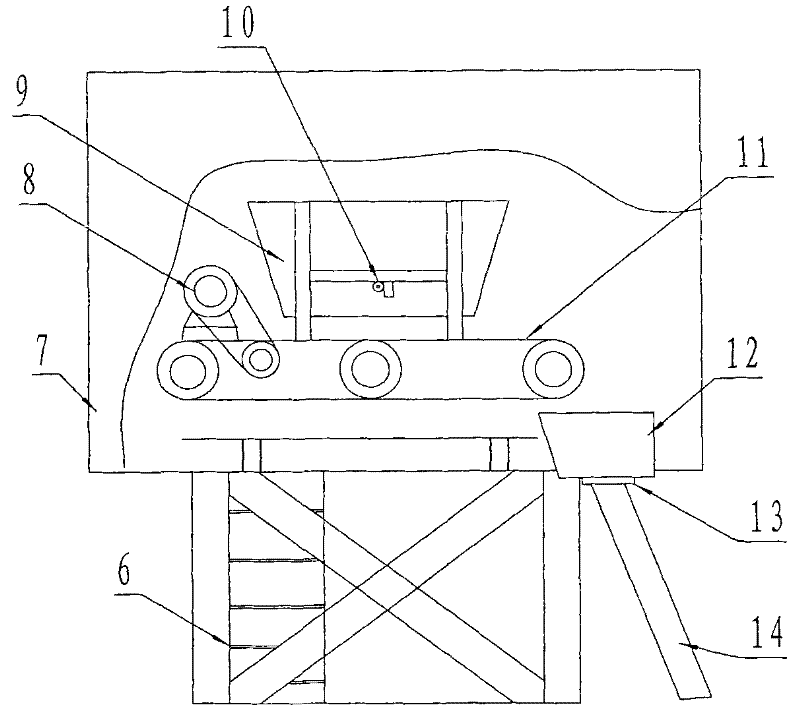

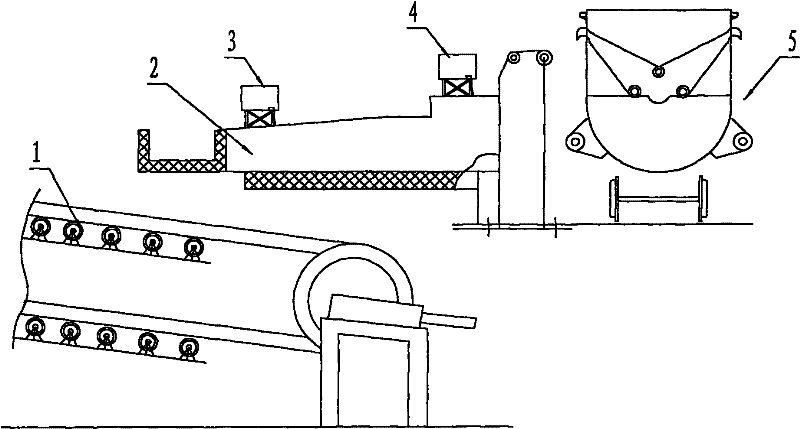

[0040] Example 1: At 600m 3 For the pig iron used in smelting ductile iron for high-grade blast furnaces, the raw materials for blast furnaces shall be selected according to the standards in Attached Table 1, including 66.61% of high-alkali sintered nodular pig iron pellets and 33.39% of nodular pig iron pellets, and the alkalinity of high-alkali sintered nodular pig iron is controlled at 1.98; Si] control 0.15-0.35%, R 2 Control 1.15-1.20, control [Ti] ≤ 0.032%; molten iron detection [Si] is 0.15%, [S] is 0.014%; weigh 270kg of ferrosilicon powder according to the standard of attached table 2, and add ferrosilicon powder evenly when tapping to the molten iron flow; subsequent processing of industrial alkali Na 2 CO 3 200kg, spray nitrogen into the molten iron in the molten iron tank through the spray gun after tapping, the pressure of the nitrogen flow is controlled at 600Kpa, and the injection time is 40 seconds; use the inoculant adding device 4 of the cast iron machine t...

Embodiment 2

[0041] Example 2: at 600m 3 For pig iron used in smelting ductile iron for high-grade blast furnaces, raw materials for blast furnaces shall be selected according to the standards in Attached Table 1, including 70% of high-alkali sintered nodular pig iron and 30% of nodular pig iron pellets, and the alkalinity of high-alkali sintered nodular pig iron shall be controlled at 1.95; Si] control 0.15-0.35%, R 2 Control 1.15-1.20, control [Ti] ≤ 0.032%; molten iron detection [Si] is 0.35%, [S] is 0.011%; weigh 110kg of ferrosilicon powder according to the standard of attached table 2, and add the ferrosilicon powder evenly when tapping the iron to the molten iron flow; subsequent processing of industrial alkali Na 2 CO 3 80kg, spray nitrogen into the molten iron in the molten iron tank through the spray gun after tapping, the nitrogen flow pressure is controlled at 700Kpa, and the injection time is 30 seconds; the inoculant silicon-barium alloy is added according to 0.9kg / t molten...

Embodiment 3

[0042] Example 3: At 600m 3 For pig iron used in smelting ductile iron for high-grade blast furnaces, raw materials for blast furnaces shall be selected according to the standards in Attached Table 1, including 65% of high-alkali sintered nodular pig iron pellets and 35% of nodular pig iron pellets, and the alkalinity of high-alkali sintered nodular pig iron is controlled at 2.00; Si] control 0.15-0.35%, R 2 Control 1.15-1.20, control [Ti] ≤ 0.032%; molten iron detection [Si] is 0.30%, [S] is 0.015%; weigh 230kg of ferrosilicon powder according to the standard of attached table 2, and add the ferrosilicon powder evenly when tapping the iron to the molten iron flow; subsequent processing of industrial alkali Na 2 CO 3 _120kg, spray nitrogen into the molten iron in the molten iron tank through the spray gun after tapping the iron, the pressure of the nitrogen flow is controlled at 500Kpa, and the injection time is 60 seconds; use the inoculant adding device 4 of the cast iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com