High-temperature air source heat pump air heater with evaporator with adjustable heat exchange capability

A technology of air source heat pump and heat exchange capacity, which is applied in the direction of evaporator/condenser, heat pump, refrigerator, etc., which can solve the inconvenience of production, the inability to increase the heat exchange area, increase the heat collection capacity of the evaporator, and the load of the compressor problems such as increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

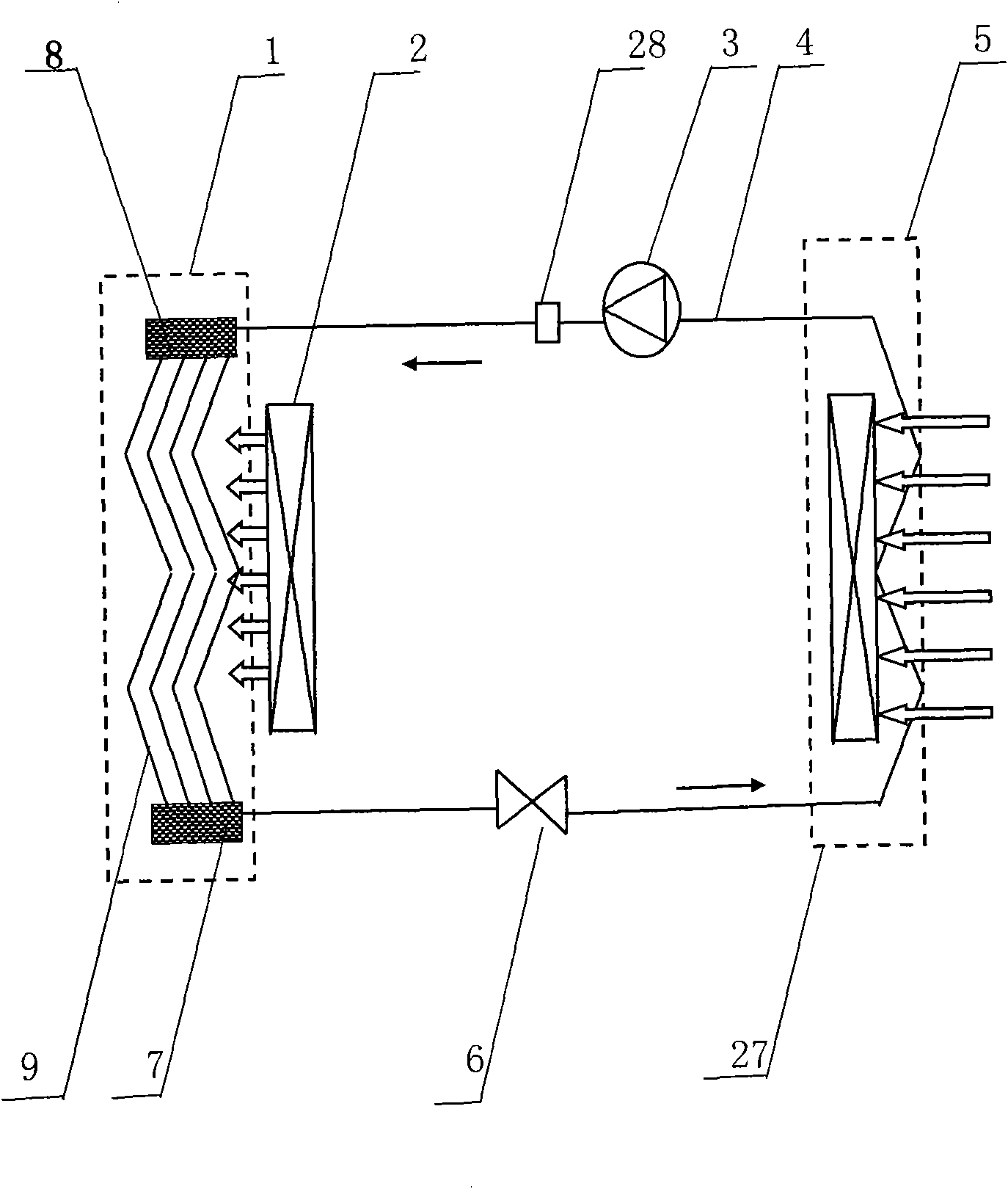

[0019] see figure 1 , reflecting a specific structure of the present invention, including an air source heat pump and a condenser fan 2 mainly composed of an evaporator 5, a compressor 3, a condenser 1, and a throttling device 6 connected with a working fluid circulation pipeline 4 in sequence. The working medium in the evaporator 5 absorbs heat from the environment through the speed-regulating fan 27 , and releases heat in the condenser 1 through the compressor 3 . The speed-regulating fan 27 is driven by a motor, and the temperature measuring probe 28 is installed at the output end of the compressor 3. The temperature parameters measured by the temperature measuring probe 28 are fed back to the speed-regulating fan 27 to automatically adjust and control the motor speed.

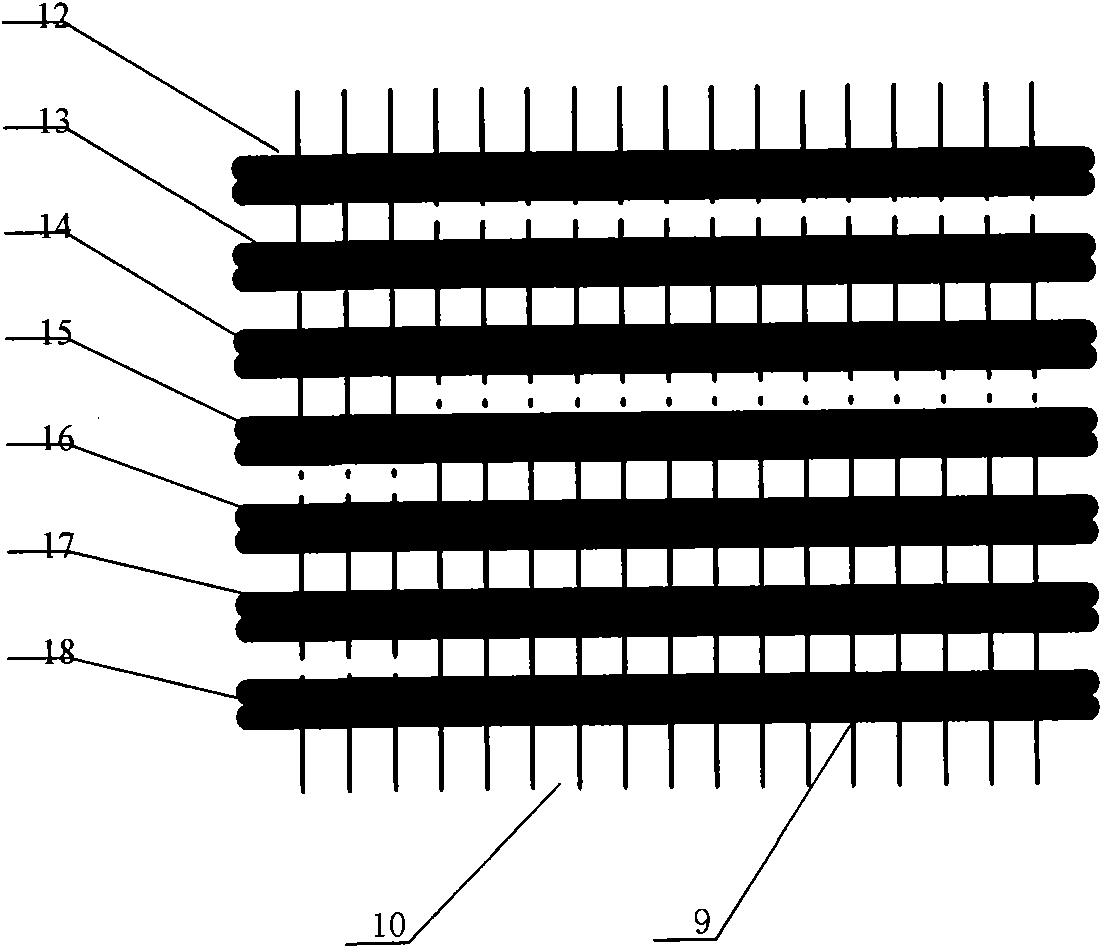

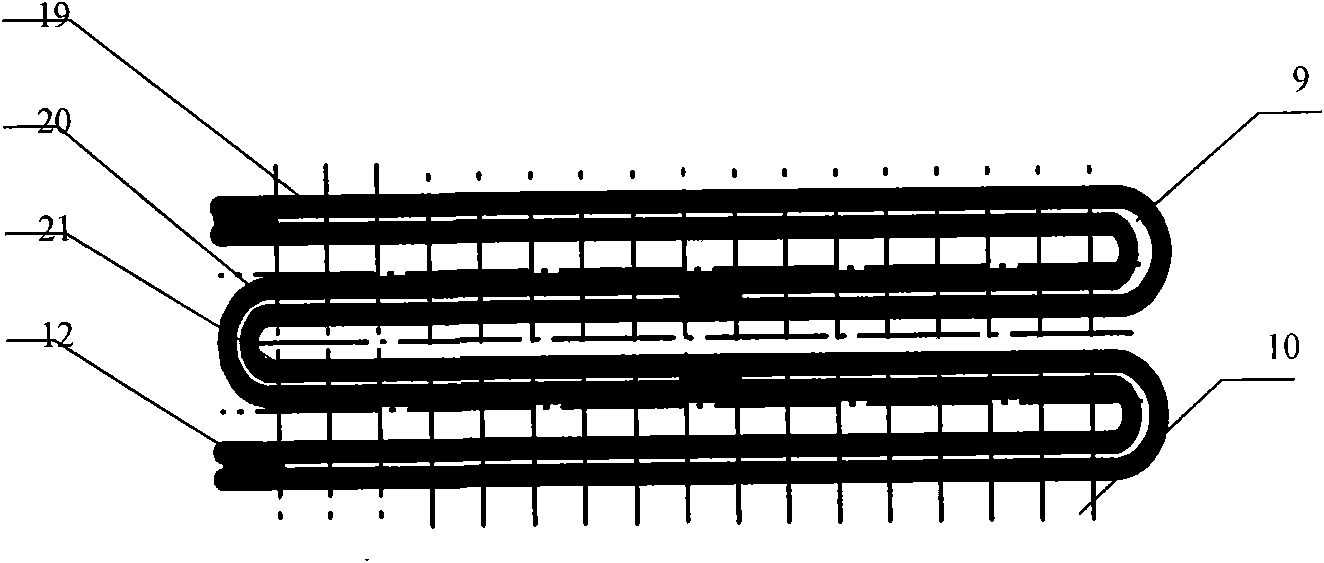

[0020] Condenser 1 includes the air inlet and outlet on the shell and the shell and the working fluid circulation pipe 4 in the shell, and also includes a working fluid splitter 8, a working fluid shunt pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com